Underwater concrete and preparation method thereof

An underwater concrete and cement technology, applied in the field of concrete, can solve the problems of waste of raw materials and labor costs, long construction time, etc., and achieve the effects of low loss rate, short setting time and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

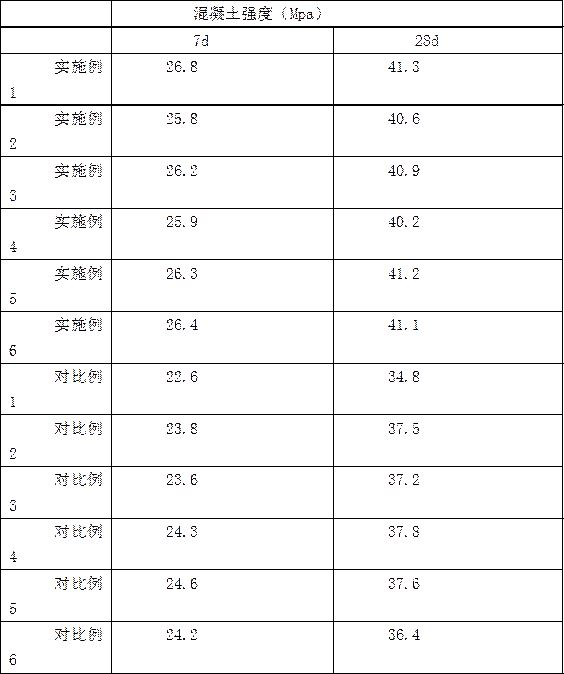

Examples

Embodiment 1

[0044] Weigh the raw materials with the following weights:

[0045] Gravel 40kg

[0046] Fly ash 1kg

[0047] Silica fume 3kg

[0049] Machine-made sand 22kg

[0050] Ferro-aluminate cement 7kg

[0051] Portland cement 7kg

[0052] Polycarboxylate superplasticizer 0.4kg

[0053] Sodium fluorosilicate 0.01kg

[0054] Aluminum fluoride 0.03kg

[0055] Diethanolamine 0.07kg

[0056] Xanthan gum 0.07kg;

[0057] Weigh each raw material by weight, take gravel, fine aggregate, machine-made sand, cement, polycarboxylate superplasticizer and pour into a mixer to stir to obtain mixed aggregate; then take sodium fluorosilicate, aluminum fluoride, diethanolamine, Add 10 times the amount of water to dissolve xanthan gum, then add 7kg of water, mix well, pour into the mixed aggregate under stirring, and stir evenly.

Embodiment 2

[0059] Weigh the raw materials with the following weights:

[0060] Gravel 35kg

[0061] Fly ash 1kg

[0062] Silica fume 1kg

[0064] Machine-made sand 20kg

[0065] Ferro-aluminate cement 3kg

[0066] Portland cement 3kg

[0067] Polycarboxylate superplasticizer 0.1kg

[0068] Sodium fluorosilicate 0.05kg

[0069] Aluminum fluoride 0.01kg

[0070] Diethanolamine 0.03kg

[0071] Xanthan gum 0.05kg;

[0072] Weigh each raw material by weight, take gravel, fine aggregate, machine-made sand, cement, polycarboxylate superplasticizer and pour into a mixer to stir to obtain mixed aggregate; then take sodium fluorosilicate, aluminum fluoride, diethanolamine, Add 10 times the amount of water to dissolve xanthan gum, then add 4kg of water, mix well, pour into the mixed aggregate under stirring, and stir evenly.

Embodiment 3

[0074] Weigh the raw materials with the following weights:

[0075] Gravel 45kg

[0076] Fly ash 2kg

[0077] Silica fume 4kg

[0079] Machine-made sand 25kg

[0080] Ferro-aluminate cement 10kg

[0081] Portland cement 10kg

[0082] Polycarboxylate superplasticizer 0.6kg

[0083] Sodium fluorosilicate 0.2kg

[0084] Aluminum fluoride 0.05kg

[0085] Diethanolamine 0.1kg

[0086] Xanthan gum 0.1kg;

[0087] Weigh each raw material by weight, take gravel, fine aggregate, machine-made sand, cement, polycarboxylate superplasticizer and pour into a mixer to stir to obtain mixed aggregate; then take sodium fluorosilicate, aluminum fluoride, diethanolamine, Add 10 times the amount of water to dissolve xanthan gum, then add 10kg of water, mix well, pour into the mixed aggregate under stirring, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com