Technology method of reinforced grouting in high-pressure water-rich solution cavity of tunnel

A process method and grouting technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of poor media bonding ability, poor deformation resistance, formation instability, etc., and achieve control of excavation deformation and structural deformation. The effect of reducing and suppressing the deformation of the vault

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described with reference to the accompanying drawings and embodiments, and the given embodiments do not constitute any limitation to the present invention.

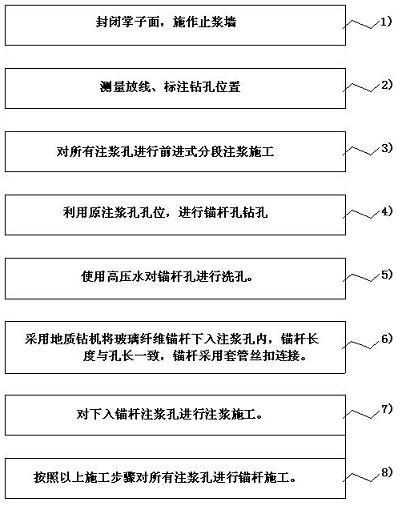

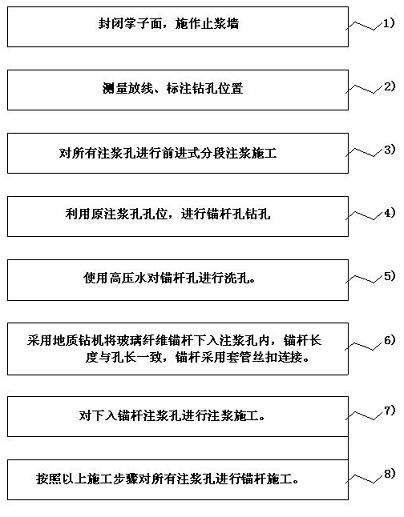

[0031] Such as figure 1 As shown, a tunnel high-pressure water-rich solution cavity reinforced grouting process, the specific process is:

[0032] For the area to be reinforced in front of the tunnel excavation face, advance segmental grouting is adopted to carry out drilling and grouting reinforcement;

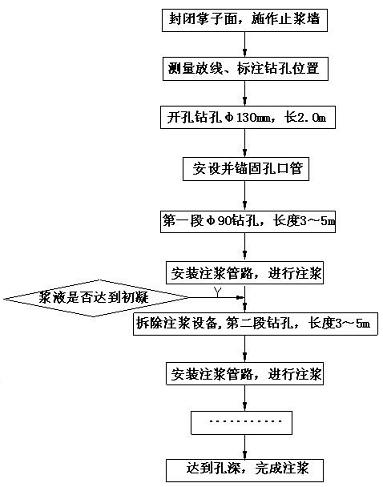

[0033] Progressive segmental grouting belongs to the advanced full-section grouting reinforcement technology. The advanced full-section grouting reinforcement process is currently a commonly used grouting reinforcement method for tunnel and underground engineering construction. Before, the whole section of the pre-excavated soil was reinforced and improved by grouting construction.

[0034] In advanced full-section grouting and grouting reinforcement, progressive segmental grouting is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com