Edge working platform for building and construction method thereof

A working platform and construction technology, applied in the direction of construction, building structure, house structure support, etc., can solve the problems of heavy suspension frames, heavy climbing frames, and many rooting points of attached supports, so as to improve the ability to bear loads , Convenience in construction and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application will be described in further detail below in conjunction with the accompanying drawings.

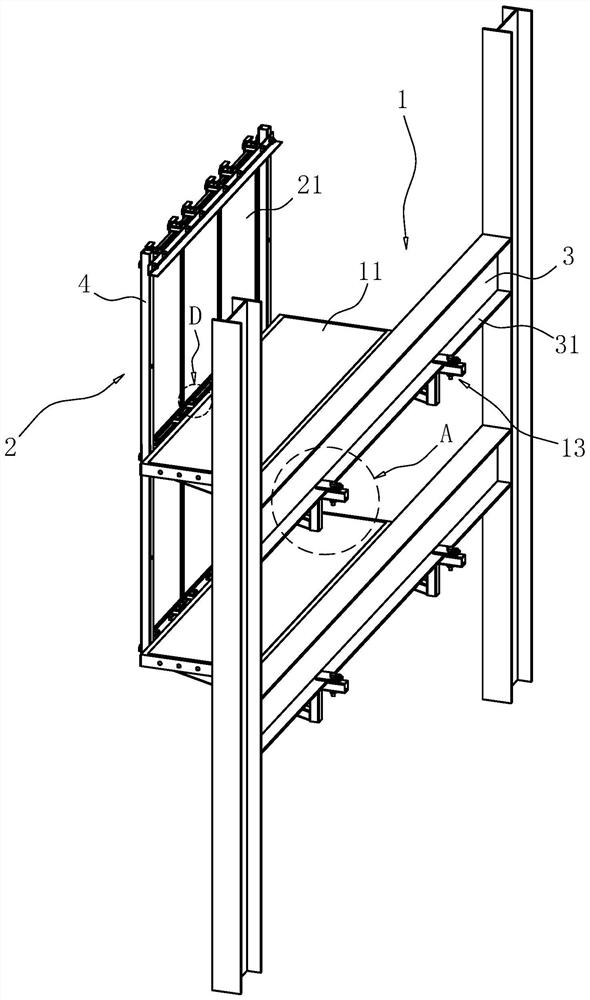

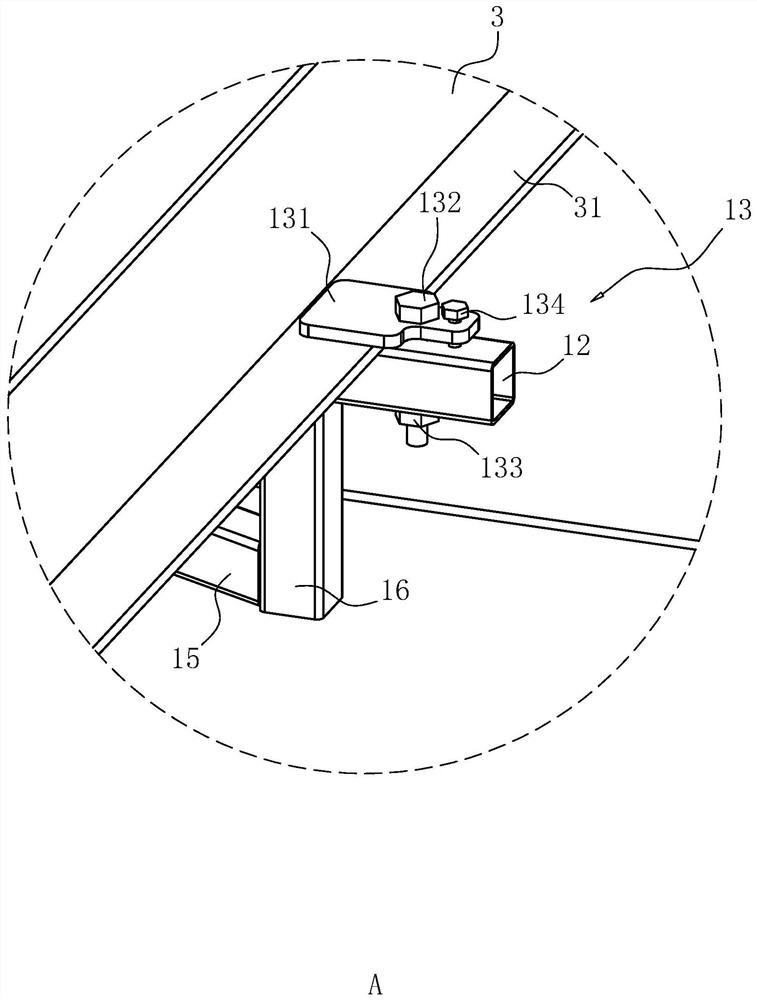

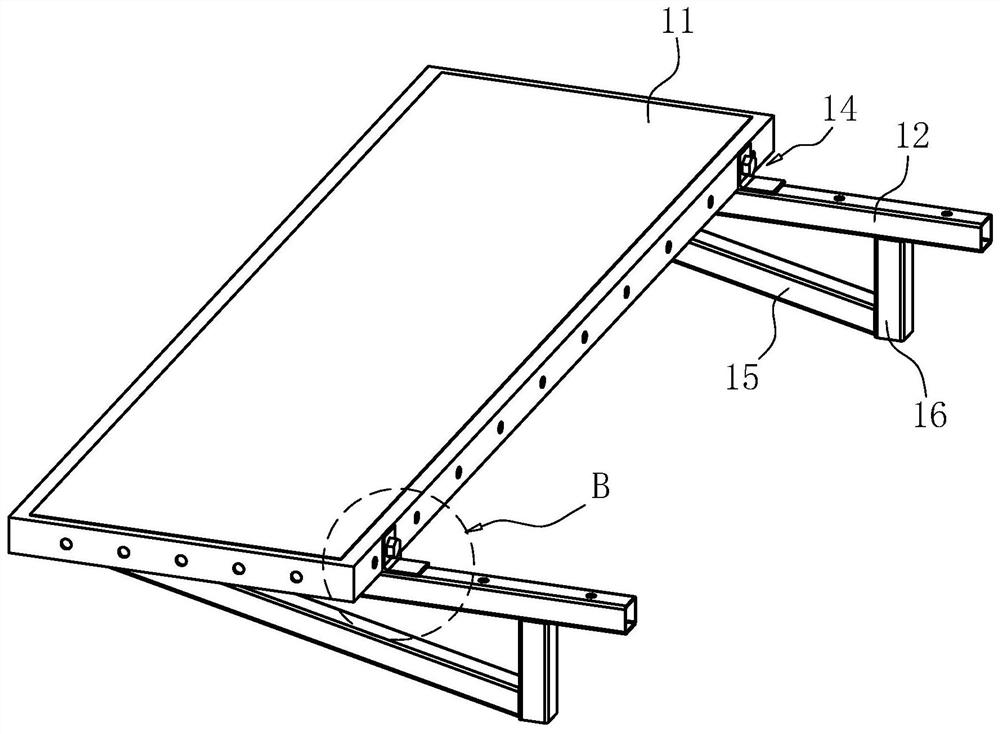

[0042] refer to figure 1 , the application provides a construction edge working platform, which is arranged on a plurality of horizontally arranged H-shaped steel 3 distributed at equal intervals up and down, the plurality of H-shaped steel 3 are vertically coplanar, and the wing plates 31 of the H-shaped steel 3 are arranged horizontally The edge working platform includes a walkway device 1 for construction personnel to walk or construct on one side of the H-shaped steel 3 and a protective device 2 to prevent construction personnel from accidentally falling from the walkway device 1; the quantity of the walkway device 1 is the same as that of the H-shaped steel 3 The number is the same and each walkway device 1 is fixed on the corresponding H-shaped steel 3, and the number of protective devices 2 is the same as the number of walkway devices 1 and is fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com