Concrete prefabricated kerb demoulding auxiliary support frame

A technology for auxiliary supports and curb stones, which is applied in the direction of manufacturing tools, unloading devices, etc., to achieve the effects of improving appearance quality, saving time, and ensuring qualified rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

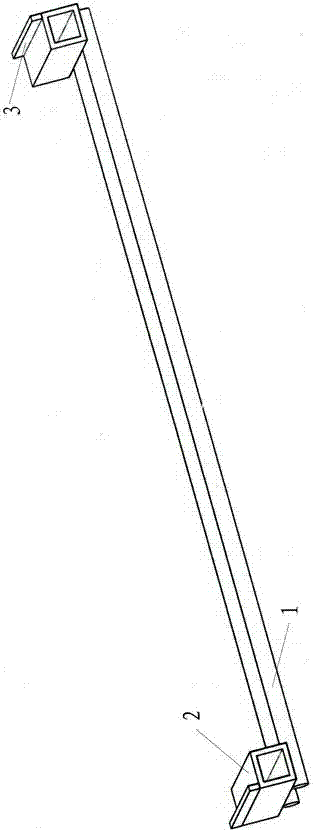

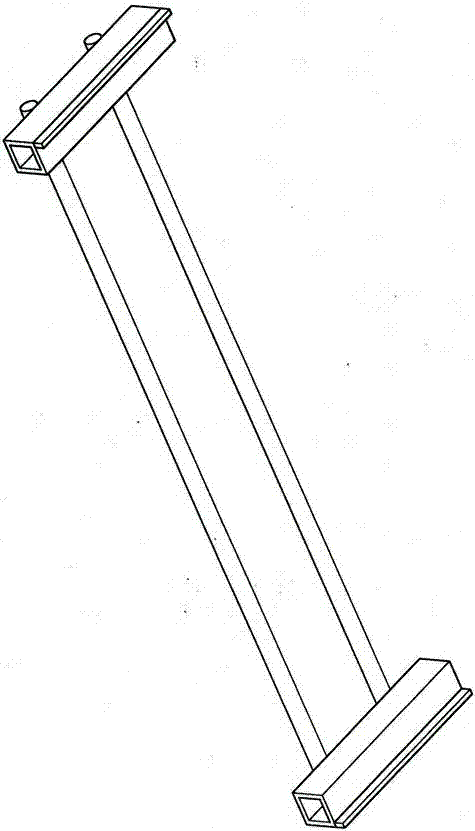

[0018] Such as figure 1 with figure 2 As shown, a concrete prefabricated curb demoulding auxiliary support includes a horizontal connecting beam and two mold supporting parts whose cross section is roughly "Ь" and extends longitudinally. The two mold supporting parts are respectively seated and fixed At both ends of the connecting beam, the two mold supporting parts are arranged opposite to each other and are located on the same side of the connecting beam. In the longitudinal view, the demoulding auxiliary bracket of the precast concrete curb is in the shape of " b d "shape.

[0019] Based on the consideration of the manufacturing process, the mold supporting part is composed of a square tube 2 and a long steel plate 3 seated on the lateral outer side of the square tube and fixed by welding.

[0020] Based on the consideration of the manufacturing process, the connecting beam is two rebars 1 arranged longitudinally at intervals.

[0021] Specifically, the rebar is 75cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com