Marine sulphoaluminate cement for rapid construction and preparation method thereof

A technology of marine sulphoaluminate and sulphoaluminate cement, which is applied in the field of marine sulphoaluminate cement for rapid construction and its preparation, and can solve the problem that the concrete construction conditions and construction time cannot be guaranteed, and cannot meet the rapid construction of the project , affect the normal construction of concrete and other issues, to achieve the effect of high resistance to chloride ion diffusion, good compactness, and high resistance to sulfate erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

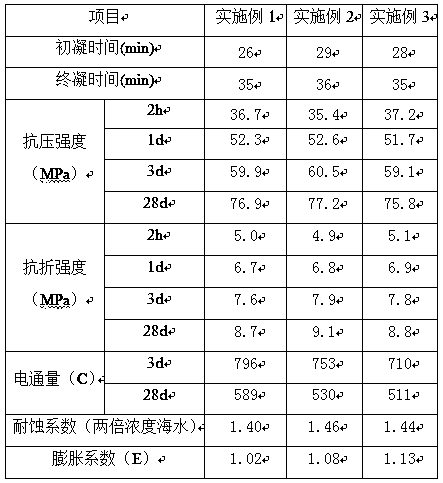

Embodiment 1

[0027]A marine sulphoaluminate cement for rapid construction, made of the following raw materials in parts by weight: 40 parts of sulphoaluminate cement clinker, 5 parts of modified nano-calcium carbonate, 0.05 parts of high-efficiency water reducer, and accelerator 4 parts, 6 parts of anti-cracking and waterproof expansion agent, 3 parts of redispersible latex powder, 10 parts of clinker sea sand, 2 parts of silica fume, 6 parts of granulated blast furnace slag powder, and 0.01 part of modified graphene.

[0028] The modified nano-calcium carbonate is prepared by mixing dry nano-calcium carbonate and SP-1800 polyester hyperdispersant in a weight ratio of 10:1, and stirring at a constant temperature of 110° C. for 30 minutes.

[0029] The high-efficiency water reducer includes modified melamine and polycarboxylate water reducer, the weight ratio of which is 1:2, and the fineness of modified melamine is below 100 mesh.

[0030] The accelerator is composed of potassium metaalumi...

Embodiment 2

[0040] A marine sulphoaluminate cement for rapid construction, made of the following raw materials in parts by weight: 50 parts of sulphoaluminate cement clinker, 8 parts of modified nano-calcium carbonate, 0.1 part of high-efficiency water reducer, and accelerator 2 parts, 7 parts of anti-cracking and waterproof expansion agent, 4 parts of redispersible latex powder, 12 parts of clinker sea sand, 4 parts of silica fume, 8 parts of granulated blast furnace slag powder, and 0.05 part of modified graphene.

[0041] The modified nano-calcium carbonate is prepared by mixing dry nano-calcium carbonate and SP-1800 polyester hyperdispersant in a weight ratio of 10:1, and stirring at a constant temperature of 110° C. for 30 minutes.

[0042] The high-efficiency water reducer includes modified melamine and polycarboxylate water reducer, the weight ratio of which is 1:2, and the fineness of modified melamine is below 100 mesh.

[0043] The accelerator is composed of potassium metaalumin...

Embodiment 3

[0053] A marine sulphoaluminate cement for rapid construction, made of the following raw materials in parts by weight: 60 parts of sulphoaluminate cement clinker, 10 parts of modified nano-calcium carbonate, 0.2 parts of high-efficiency water reducer, anti-cracking and waterproof 8 parts of expansion agent, 5 parts of redispersible latex powder, 15 parts of clinker sea sand, 5 parts of silica fume, 10 parts of granulated blast furnace slag powder, and 0.1 part of modified graphene.

[0054] The modified nano-calcium carbonate is prepared by mixing dry nano-calcium carbonate and SP-1800 polyester hyperdispersant in a weight ratio of 10:1, and stirring at a constant temperature of 110° C. for 30 minutes.

[0055] The high-efficiency water reducer includes modified melamine and polycarboxylate water reducer, the weight ratio of which is 1:2, and the fineness of modified melamine is below 100 mesh.

[0056] The anti-crack and waterproof expansion agent is a GNA high-efficiency ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com