Structure and enclosure combined modular equipment room

A kind of equipment room and modularization technology, which is applied in the direction of building components, building structure, construction, etc., can solve the problems that cannot meet the speed-up requirements of business expansion, the lifting requirements cannot be met, and large buildings cannot be transported, so as to achieve saving On-site construction period, light structure, and the effect of ensuring installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

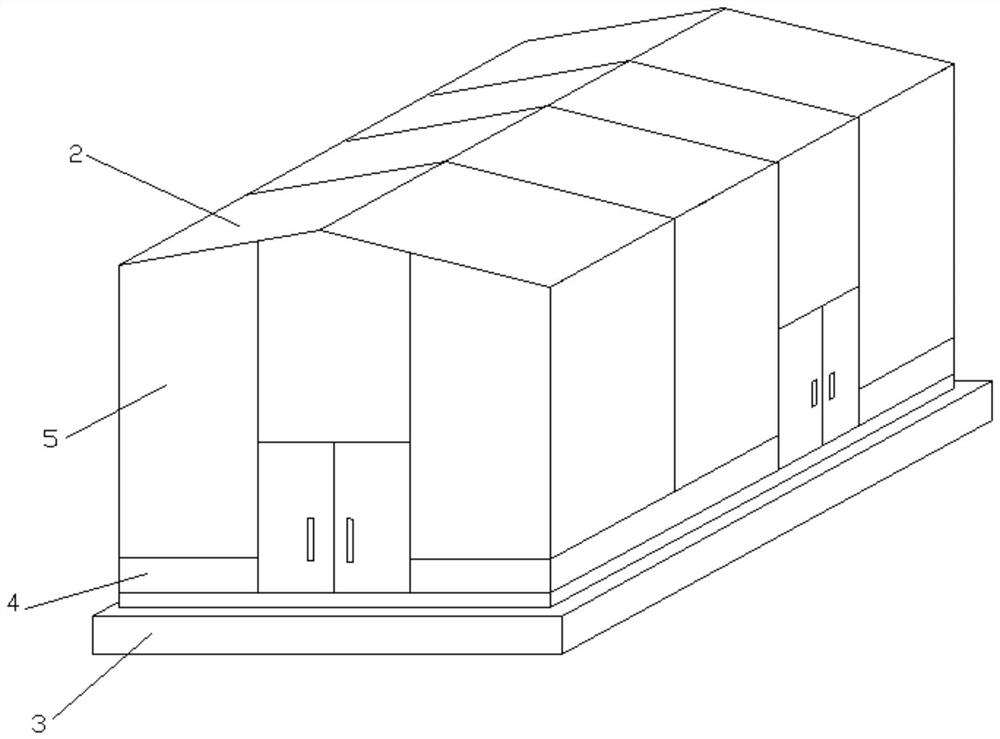

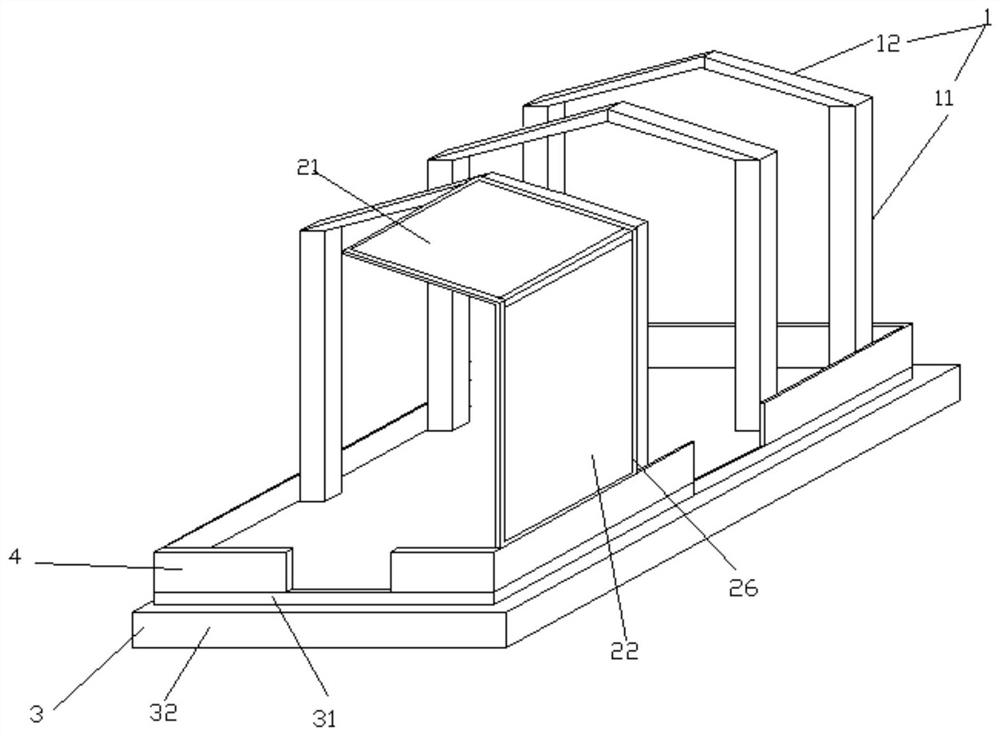

[0033] Embodiment: A modular equipment room with structure and enclosure combination, such as Figure 1-5 As shown, the equipment room as a whole is composed of folding roof and wall composite panels, bottom frame or frame chassis, lightweight concrete strips and door and window composite panels. According to the requirements of transportation size, they can divide the equipment room into several independent modules. The equipment room can be built with different groups of folding roof and wall composite panels according to the size, so as to make the structure universal and facilitate unified production.

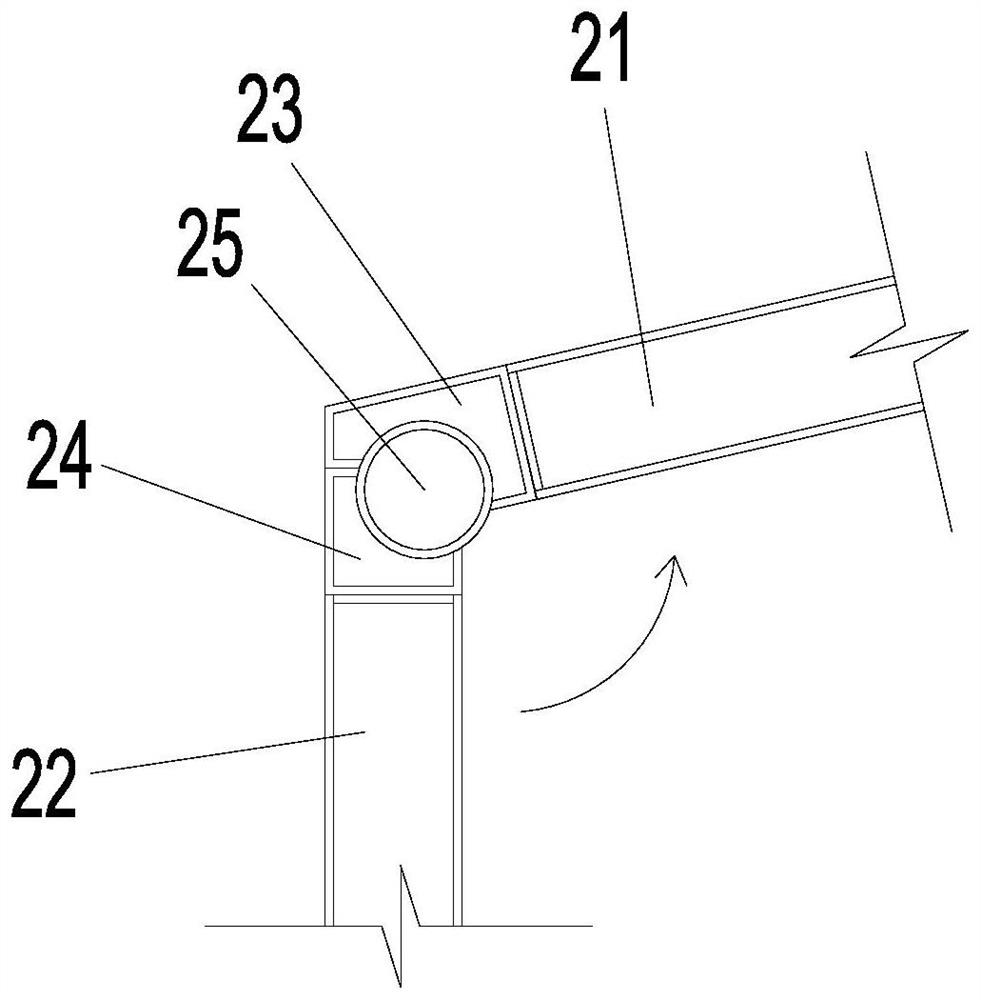

[0034]When the portal steel frame structure is added, the structure includes steel columns and steel beams, which are connected by full bolts. The structure is reliable, the installation is convenient, and it meets the requirements of large bays in the equipment room.

[0035] Frame chassis, including the chassis as the ground foundation and the bottom frame that defines th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com