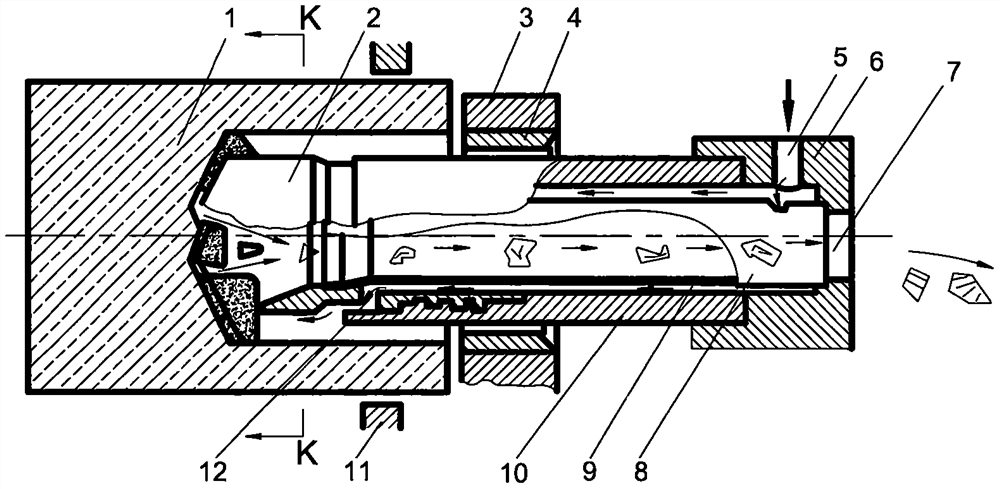

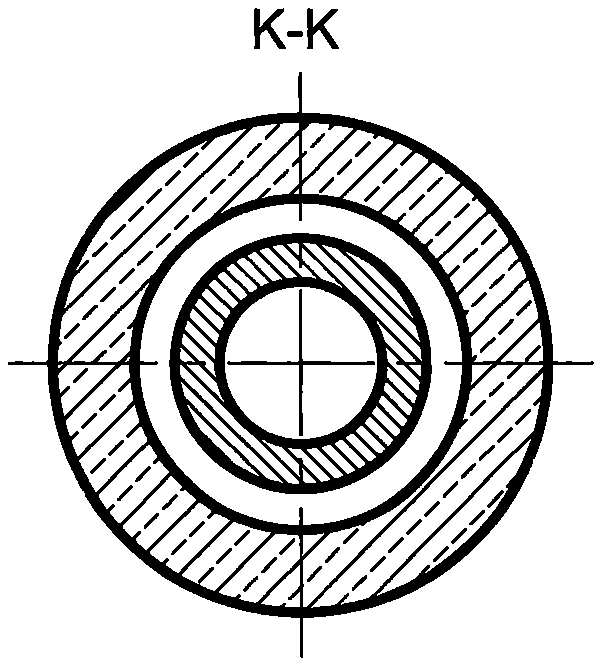

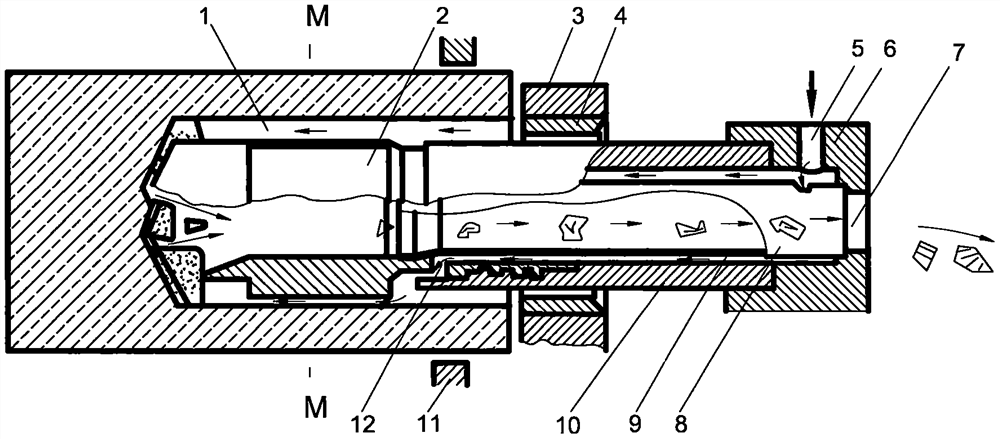

Spray-suction type hole machining method

A hole processing method and hole processing technology are applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve problems such as difficulty in chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The embodiments of the present invention will be further described below, and the specific embodiments are not limited to the present invention.

[0046]1. The wedge projection is a connection structure or an integral structure.

[0047]2. The liquid force is adjusted by mechanical, or electricity, or magnetic.

[0048]3. The wedge profile of the wedge-shaped convex portion is a circle, or a combination of the Aquiimed spiral surface, a line, other curves, or the above line.

[0049]4, the blade is a symmetrical arrangement or asymmetric arrangement; the cutting liquid is oil or other liquid, filtered through the mesh, or filtration, or magnetic method.

[0050]5, wedge-shaped projections or adjustment pads are in contact with the positioning parts.

[0051]6, the material and heat treatment requirements of the wedge-shaped projection require the same or different materials from the wedge-shaped projection body; the top of the wedge-shaped projection has a coating or a cemented carbide or no co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com