Application grinding method of abrasive wheel muller in valve

A grinding method and technology of grinding machines, which are applied in grinding machines, seat surface grinding machines, grinding/polishing equipment, etc., can solve the problems that the self-adhesive abrasive cloth rubber surface is easy to soften, fall off, easily cause explosion and fire, and the high cost of diamond grinding heads , to achieve the effect of eliminating defects, fast grinding speed and high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

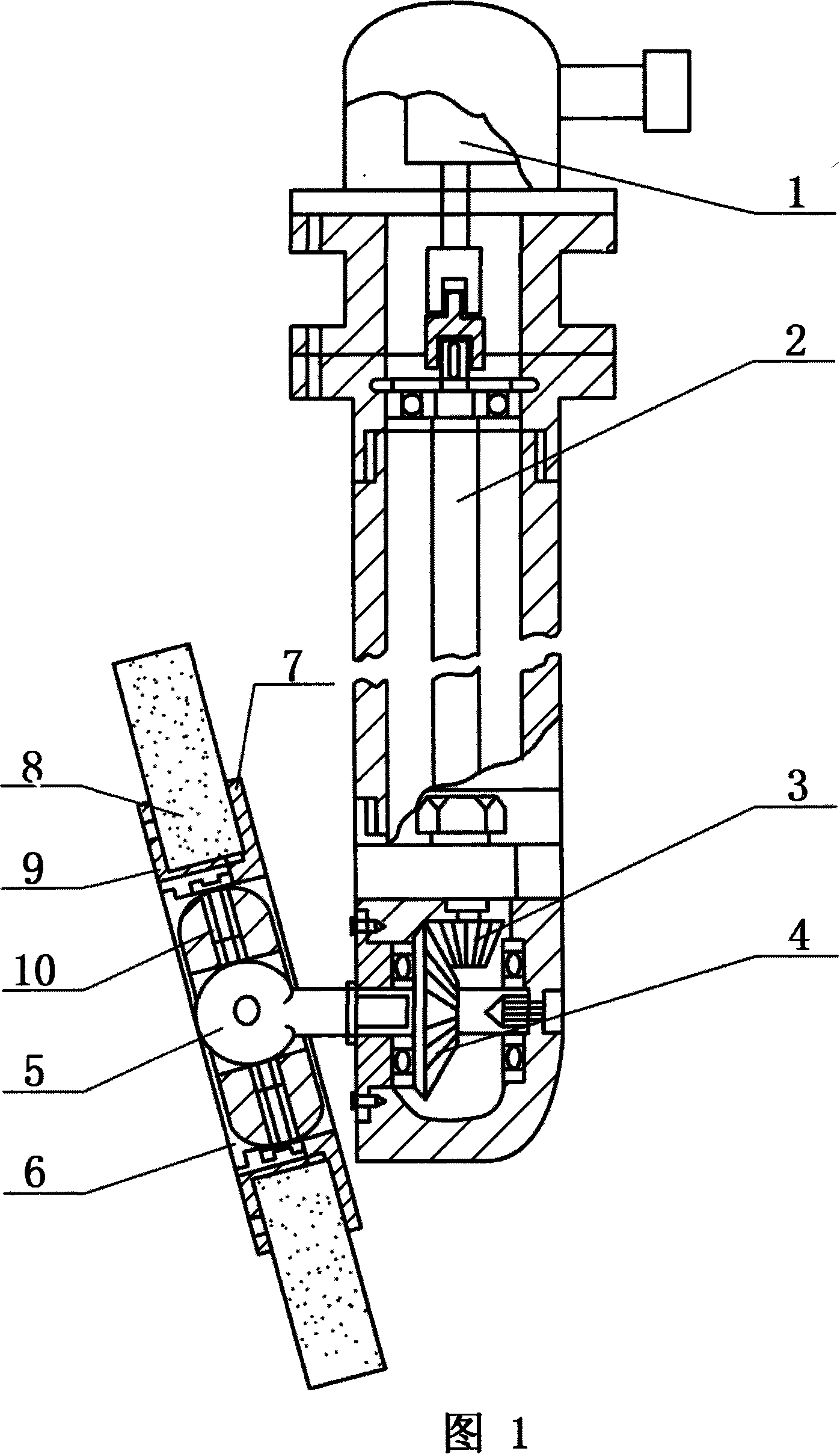

[0014] As shown in Figure 1, a grinding method for the application of a grinding wheel grinder on a valve. The grinding wheel grinder includes a pneumatic motor, a transmission rod, a grinding wheel, and a grinding wheel head. The grinding wheel grinder uses compressed air to directly drive the air motor (1). The air motor (1) does not produce electric sparks and leakage when starting the operation. The air motor (1) idling load is 3000 rpm, which is driven by the wind The motor (1) is connected to the transmission rod (2) through the connecting shaft, and drives the transmission rod (2) to rotate at a high speed; at the lower end of the transmission rod (2), a driving bevel gear (3) and a driven bevel gear (4) are installed. The meshing constitutes a transmission device, and the grinding wheel (6) is connected to the grinding wheel (6) through a universal joint (5) and an adjusting ball (10) outside the body of the grinding wheel grinder, and grooves (6) are provided at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com