Square workpiece grinding machine

A grinding machine and grinding mechanism technology, applied in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of low grinding efficiency, diffuse dust in machine workshops, and inability to grind square workpieces at the same time, so as to achieve fast grinding speed , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

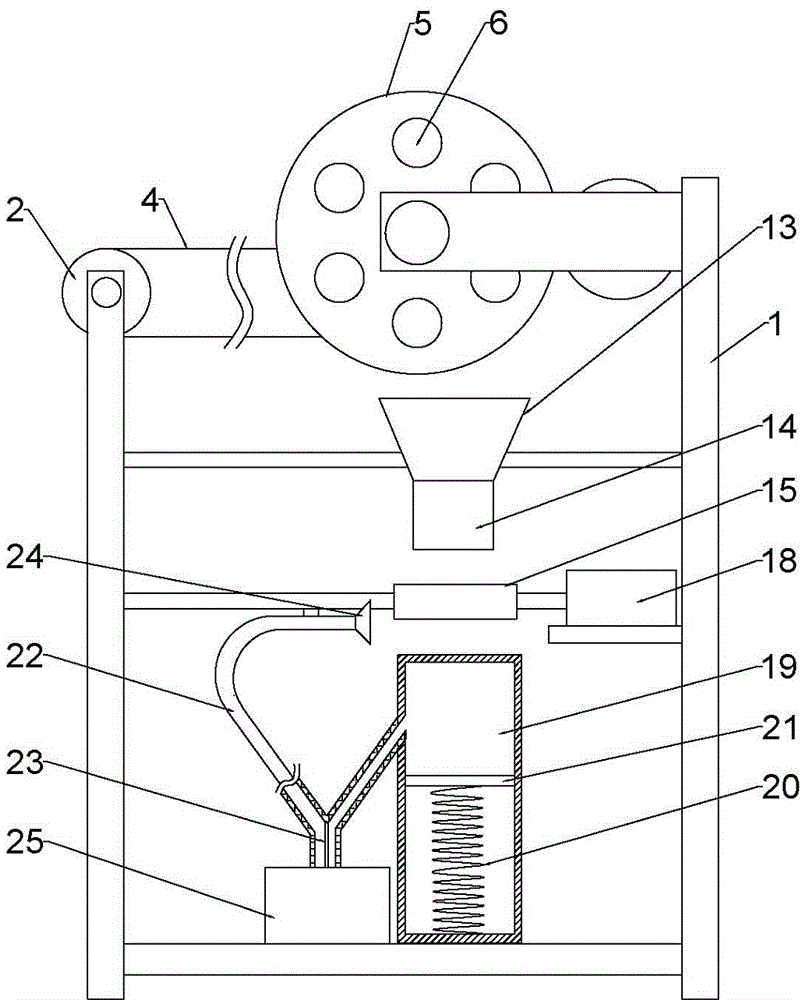

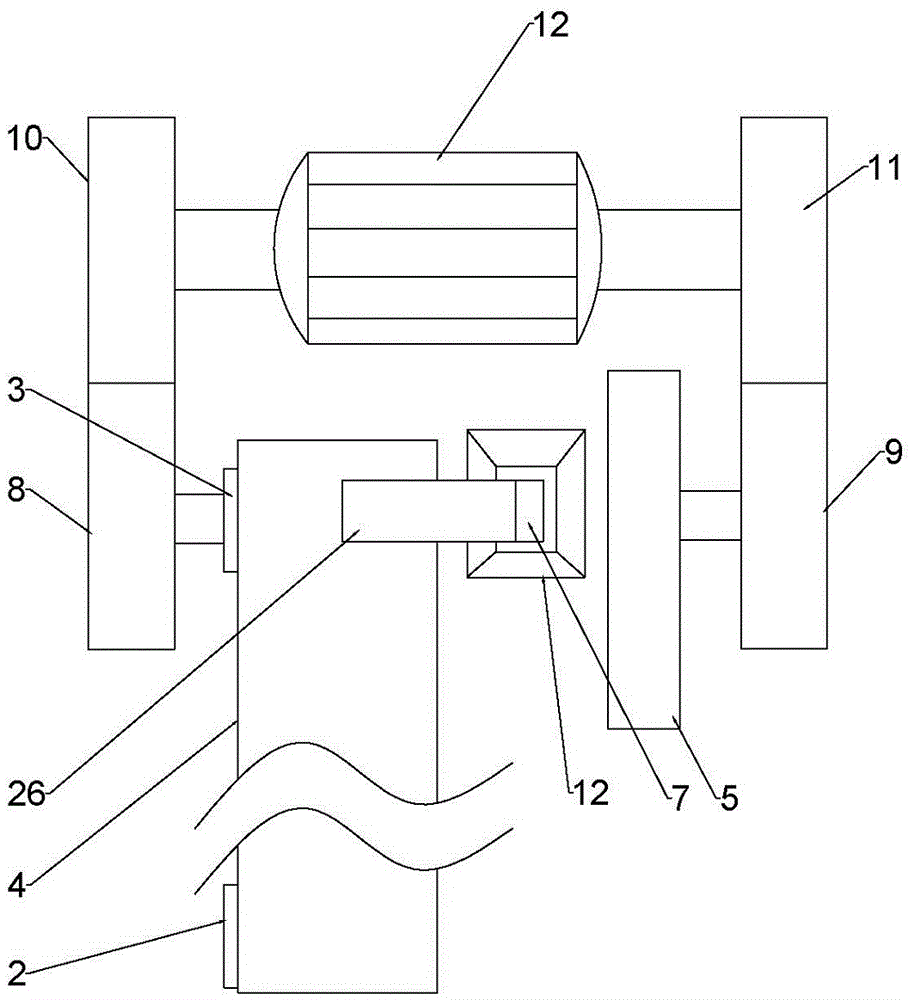

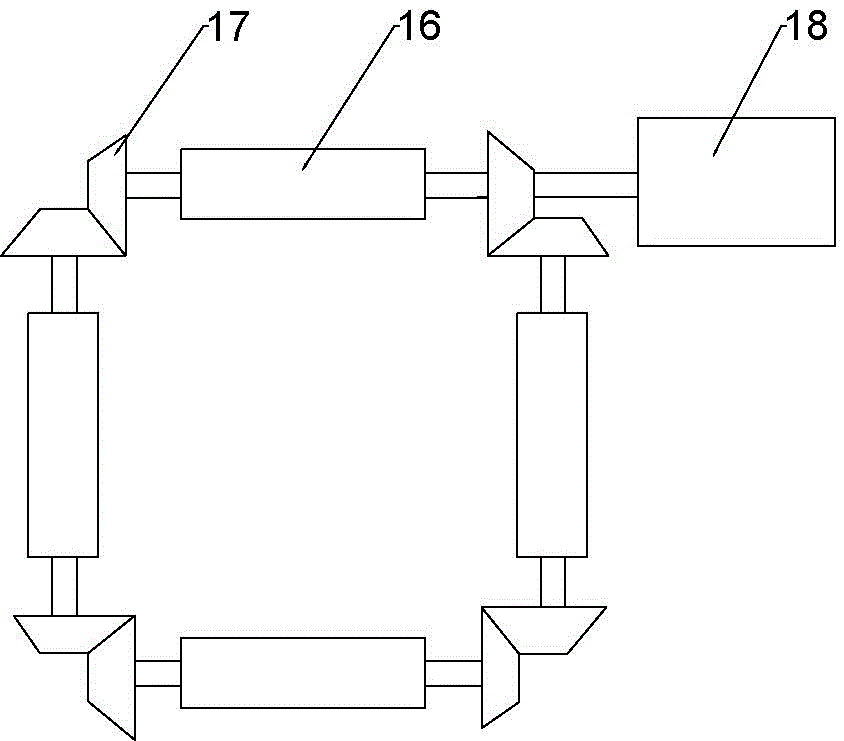

[0018] The reference signs in the drawings of the description include: frame 1, first roller 2, second roller 3, conveyor belt 4, turntable 5, through hole 6, first magnet 7, first gear 8, second gear 9. Third gear 10, fourth gear 11, second motor 12, tapered bucket 13, guide cylinder 14, grinding mechanism 15, grinding roller 16, bevel gear 17, first motor 18, piston cylinder 19, compression spring 20 , the second magnet 21, Y-shaped pipe 22, filter screen 23, conical cover 24, recovery box 25, square workpiece 26.

[0019] Example basic reference figure 1 , figure 2 and image 3 Shown: a square workpiece grinding machine, including a frame 1, a first motor 18, the first motor 18 is connected to the frame 1 by bolts, a conveying mechanism is installed on the frame 1, and the conveying mechanism includes a conveyor belt 4, a first roller Roller 2 and the second rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com