Metal faucet tube and processing method thereof

A processing method and faucet technology, applied in the field of faucets, can solve problems affecting health and other problems, and achieve the effect of simple structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

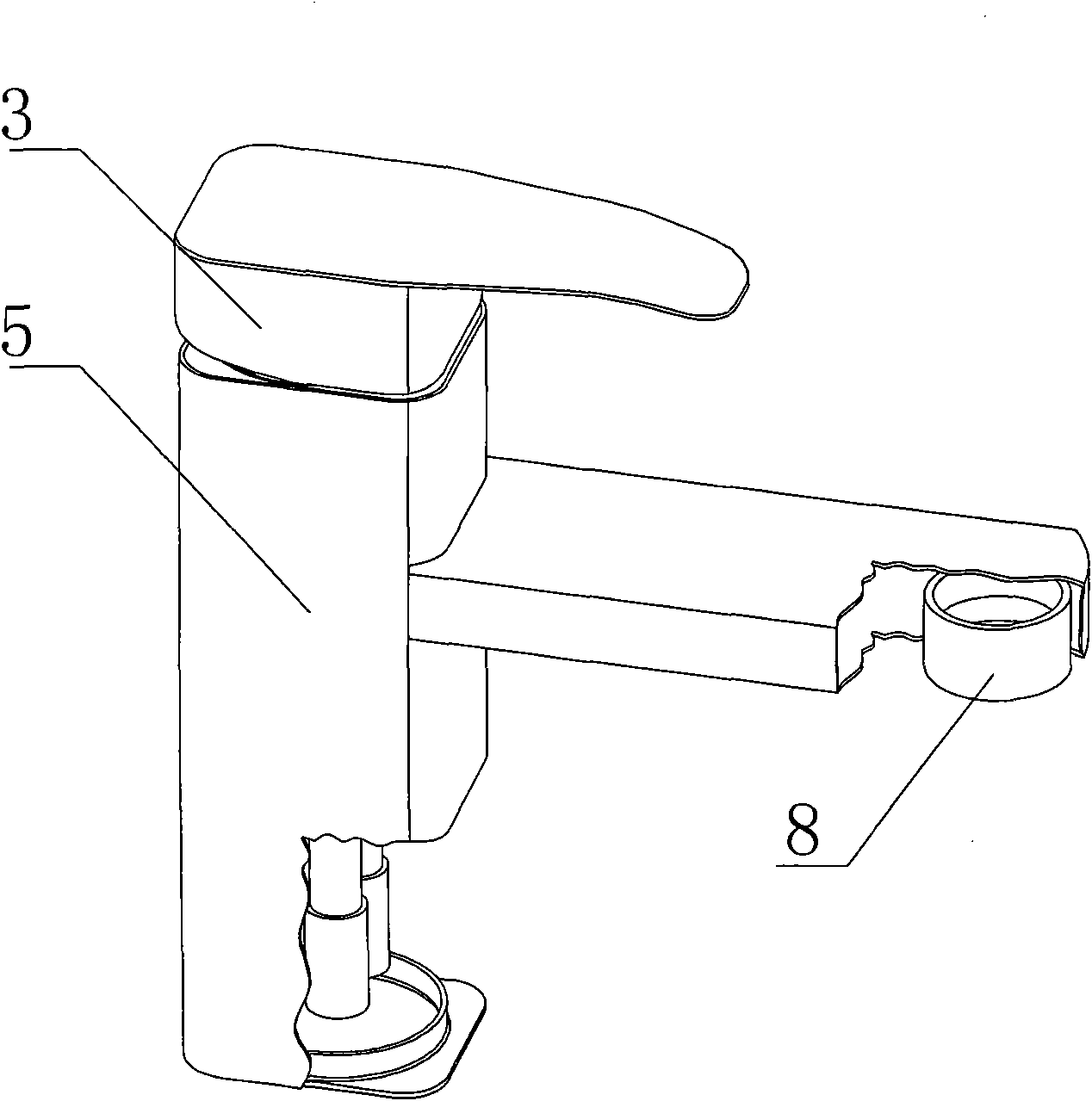

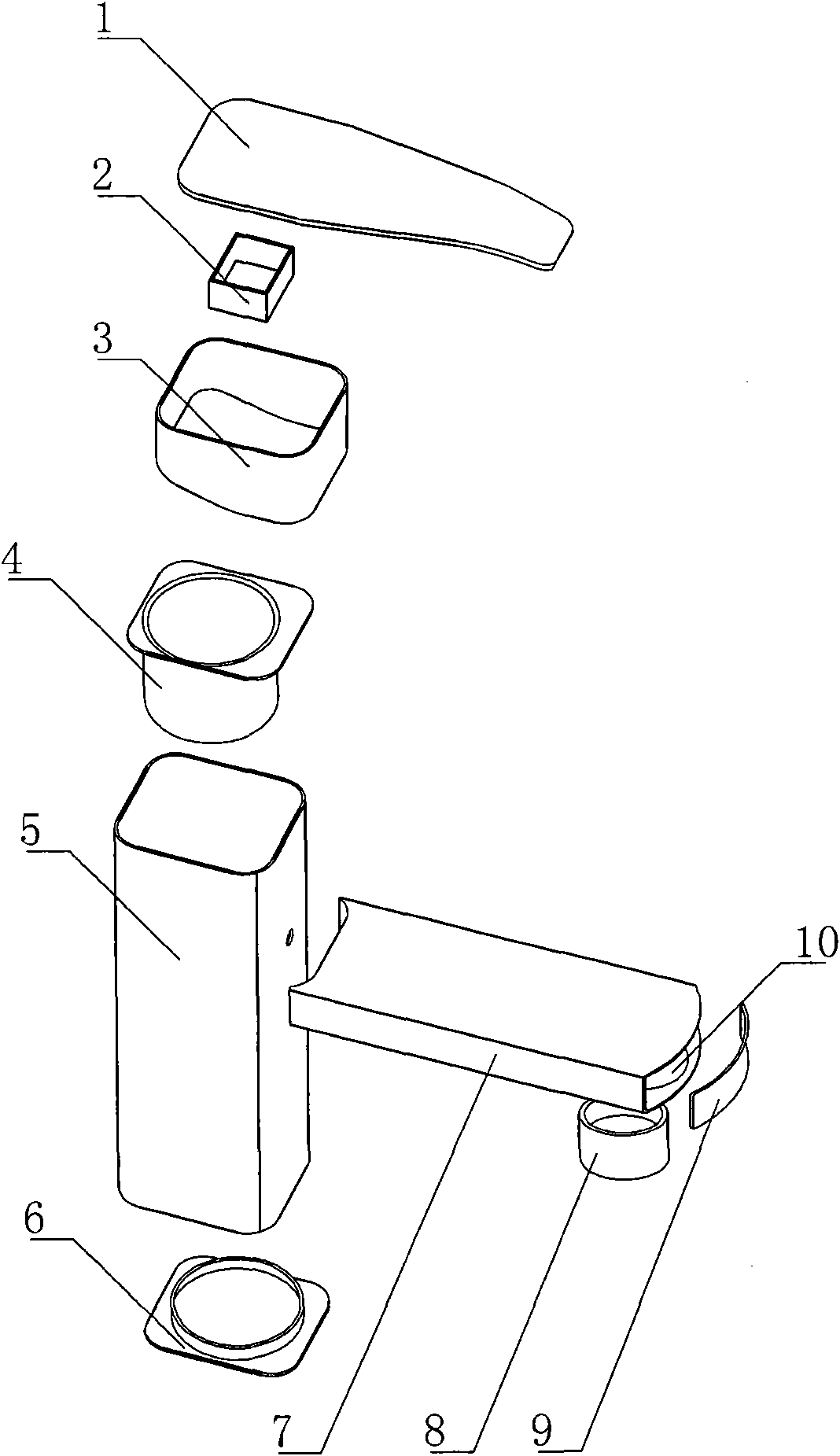

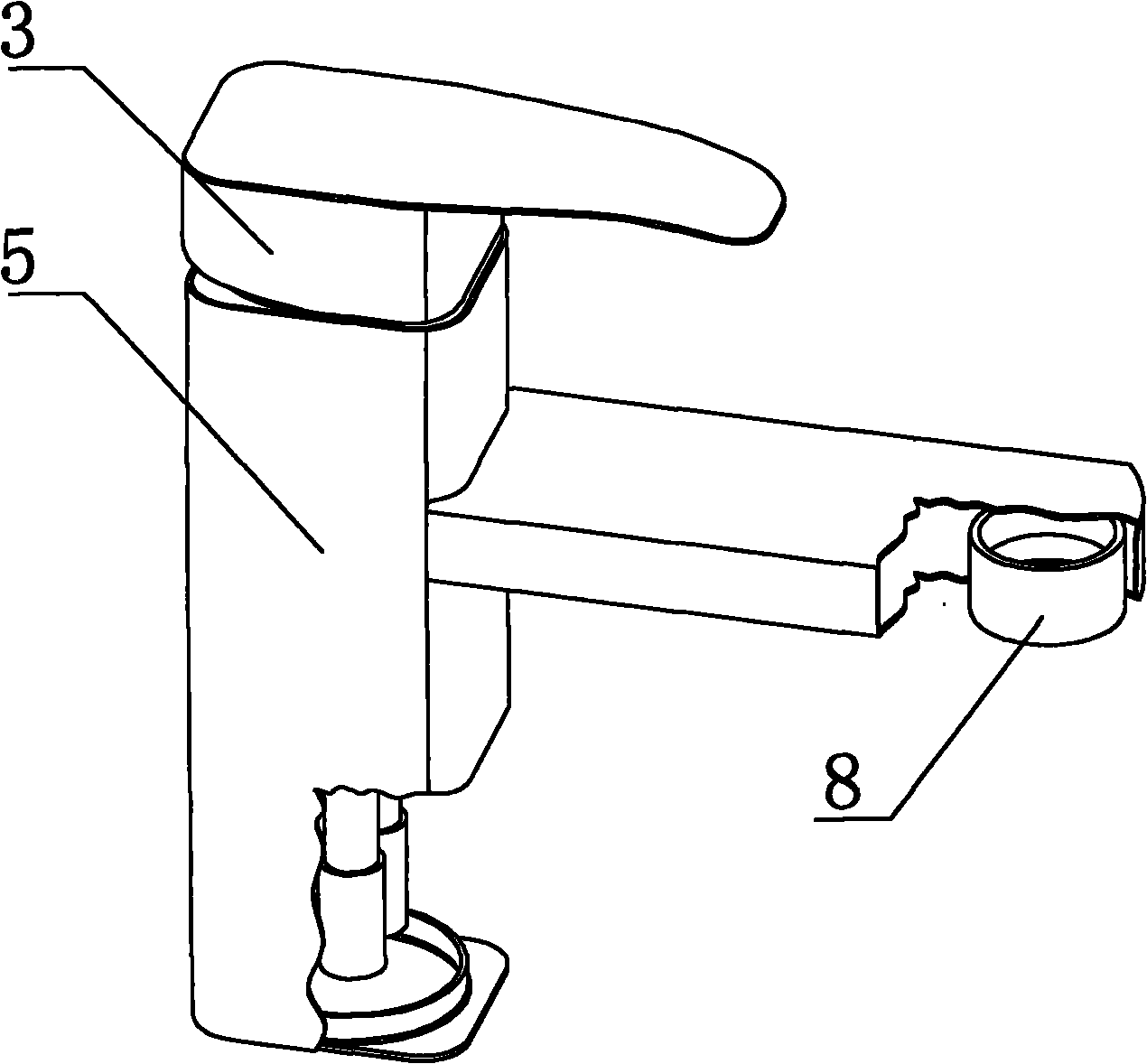

[0014] Attached below figure 1 And attached figure 2 To further illustrate the present invention, a preferred embodiment of the present invention is: the processing method of the metal faucet shell described in this embodiment, first, cut off the stainless steel type tube or pure copper type tube or aluminum type tube of the required length of the faucet, The shaped pipe is formed by extruding or stretching through a shaping die with an extrusion machine or a stretching machine. Then put the intercepted tube into the metal stamping die, stamp it with a stamping machine, and process it to form the size and shape of the required parts of the tube shell. After the stamping is completed, it is butt-welded with other processed metal tubes or stamped pieces. The processed stamped piece described in this embodiment is to put the plate or strip material of the same material as the metal tube into the metal stamping die Finally, the stamping machine is used for stamping and forming,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com