Automatic explosion suppressing device applicable to dust explosion in pipeline

A dust explosion, automatic technology, applied in blasting and other directions, can solve the problems of casualties, threats to industrial production safety, economic losses of enterprises, etc., and achieve the effect of avoiding explosion accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

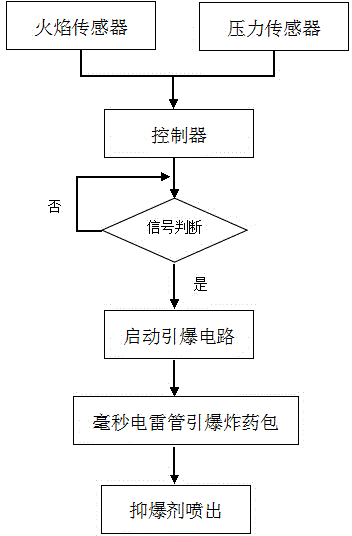

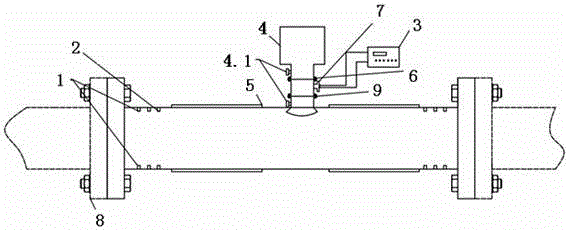

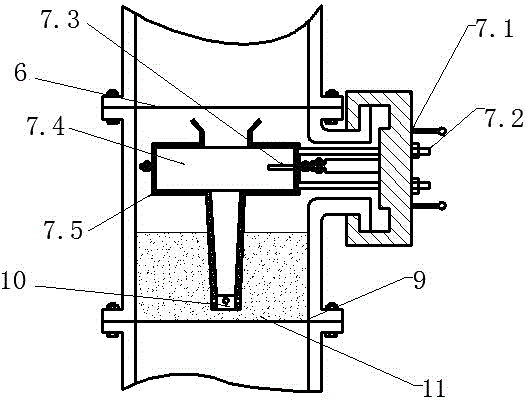

[0020] Such as Figure 2 to Figure 4 As shown, an automatic explosion suppression device for dust explosion in pipelines mainly includes flame sensor 1, pressure sensor 2, controller 3, high-pressure explosion suppression agent container 4, manual container pipeline cutoff control valve 4.1, explosion decompression layer 5 (Polymer fireproof buffer material), bursting disc 6, small detonating device 7.

[0021] A carbonate powder detonation suppressant is placed in the small detonation device 7, and the high-pressure detonation suppressant container 4 is filled with high-pressure N 2 Gas detonation agent, a burst disc 6 is arranged between the high-pressure detonation agent container 4 and the small detonator 7, which is used to separate the high-pressure N 2 A rupture disk diaphragm 9 is provided between the gas, small detonating device 7 and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com