Mining mobile type power-supply-free water cutter

A water cutting machine, mobile technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

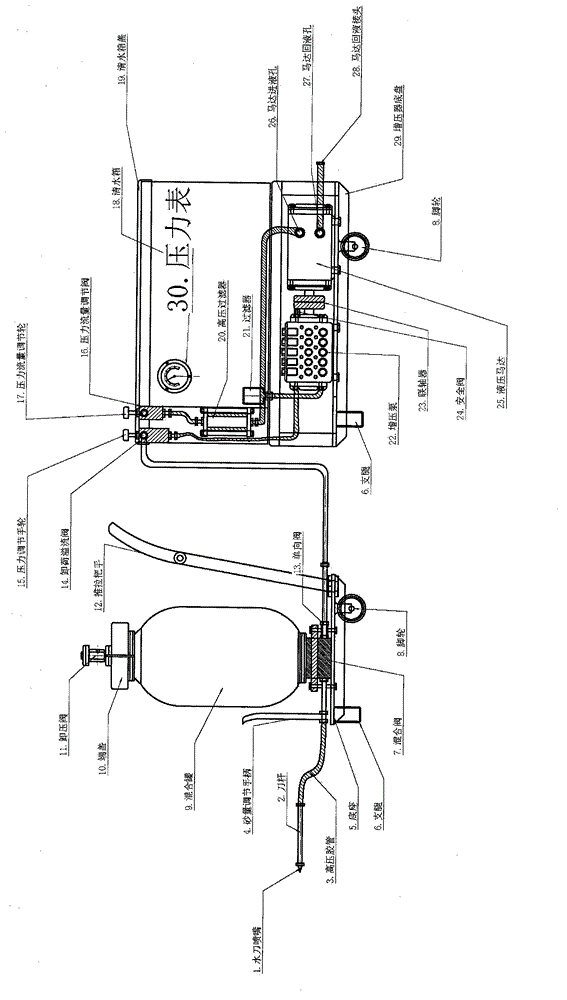

[0016] Such as figure 1 As shown, the (1) water jet nozzle described in the embodiment of the present invention, (2) cutter bar, (3) high-pressure rubber hose, (4) sand amount adjustment handle, (5) base, (6) supporting leg, (7) ) mixing valve, (8) casters, (9) mixing tank, (10) end cap, (11) pressure relief valve, (12) push-pull handle, (13) one-way valve, (14) unloading overflow valve, (15) pressure regulating handwheel, (16) pressure flow regulating valve, (17) pressure flow regulating handwheel, (18) clean water tank, (19) clean water tank cover, (20) high pressure filter, (21) filter , (22) Booster pump, (23) Coupling, (24) Safety valve, (25) Hydraulic motor, (26) Motor inlet, (27) Motor return hole, (28) Motor return connector , (29) supercharger chassis, (30) pressure gauge; It is characterized in that, described unloading relief valve (14), pressure adjustment hand wheel (15), pressure flow adjustment valve (16), pressure flow adjustment hand Wheel (17), pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com