Robot polishing and grinding force control end effector

A technology of end effector and robot, which is applied in the direction of grinding head, grinding drive device, grinding machine tool parts, etc., can solve problems such as difficult to realize industrial production, poor algorithm stability, slow response speed, etc., and achieve simplified design and guaranteed The effect of grinding quality and small eccentric torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

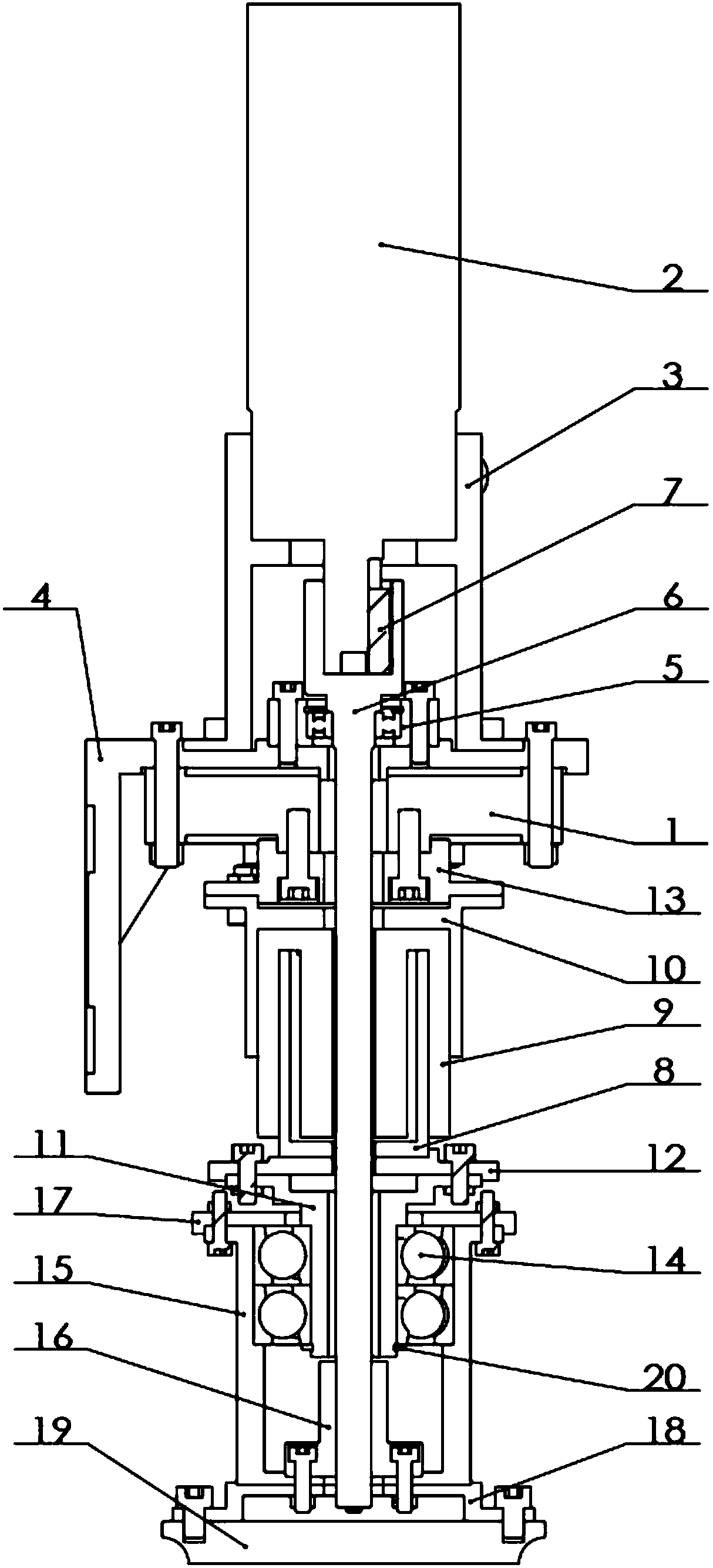

[0030] Such as figure 1 As shown, this embodiment discloses a robot polishing force control end effector, the end effector mainly includes a grinding head for grinding workpieces, a rotating part that drives the grinding head to rotate, and drives the grinding head to perform Give the linear motion department. The rotating part is connected with the mechanical arm, and its output end passes through the linear moving part and is connected with the grinding head in transmission.

[0031] Specifically, the rotating part includes an air motor 2 , a motor bracket 3 , an L-shaped connector 4 , a main shaft 6 , a key 7 , and a bearing assembly 5 . One side of the L-shaped connecting piece 4 is fixedly connected with the grinding mechanical arm, and the air motor 2 is fixedly installed on the other side of the L-shaped connecting piece 4 through the motor bracket 3 . One end of the main shaft 6 is connected to the output end of the air motor 2 through the key 7, and the other end is...

Embodiment 2

[0041] According to the polishing process, a novel robot end polishing actuator is invented. In the present invention, the cutting speed is provided by the air motor 2 of the polishing actuator, avoiding the use of a motor, and greatly reducing the mass of the responding part of the actuator. The polishing actuator can realize the force control of the polishing tool, avoid adjusting the parameters in the polishing operation through the robot controller, and improve the responsiveness of the polishing system. At the same time, the force is also used as a signal to realize the position control of the robot and the feed speed control during the polishing operation. The polishing force and rotary cutting speed can be changed according to the workpieces of different materials and the cutting volume of workpieces.

[0042] The fixed part of the front end of the air motor 2 is clamped by the motor bracket 3 with screws, and the motor bracket 3 and the L-shaped connector 4 are connec...

Embodiment 3

[0049] The polishing force control end effector can be installed on the end joint of the robot through the L-shaped connecting plate 4, and the actuator and the robot together constitute a macro-micro robot polishing system. The robot provides the feed movement during the polishing process, and the actuator provides the polishing speed and polishing tool force.

[0050] Turn on the switch of the air pump to provide the air source to the air motor 2, and the shaft of the air motor 2 rotates. The main shaft 6 and the air motor 2 are connected through the key 7. The speed and torque of the air motor 2 are transmitted to the main shaft 6. The main shaft 6 is used in conjunction with the ball spline 16. The grinding head provides the cutting speed of polishing by the rotation of abrasive material 19.

[0051] The lower surface of the L-shaped connecting plate 4 is equipped with a tension-torsion composite sensor 1 through bolts, which can detect the polishing force during the poli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com