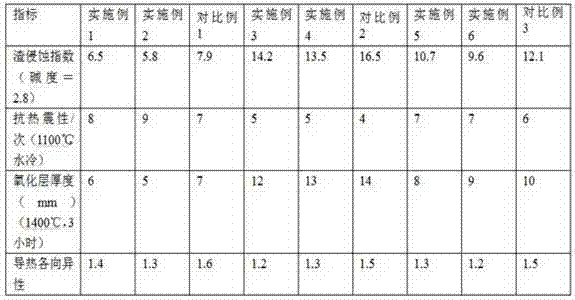

Patents

Literature

80results about How to "Solve heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

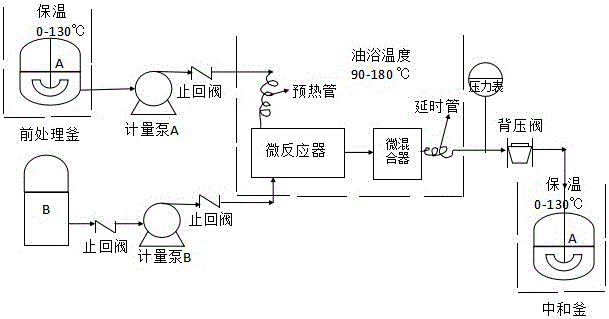

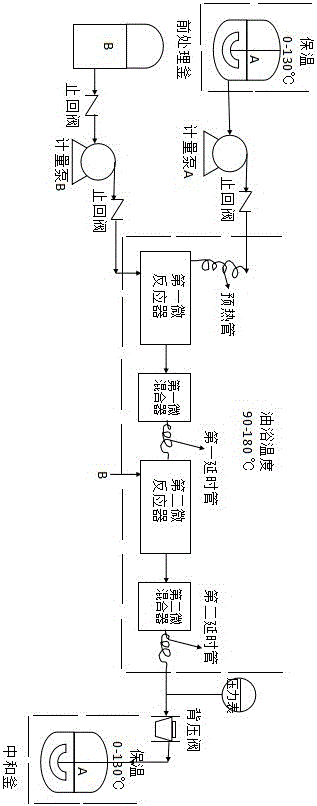

Method for producing alkoxylate through microchannel reactor

The invention relates to a method for producing alkoxylate through a microchannel reactor, and discloses a method for continuously performing alkoxylation reaction in a microreactor. According to the invention, initiator potassium alcoholate in which low molecules (the low molecules herein are mainly water and methanol) are removed and epoxide enter a microreactor, a delay line and a mixer in a liquid-phase form to perform liquid-liquid reaction, the purpose of sufficient mass transfer and heat transfer is achieved, and the liquid-liquid reaction is realized by increasing the pressure of the reaction system and adding a counterbalance valve. Compared with the alkoxylation reaction in the prior art, the method can effectively solve the heat transfer problem of such reaction, realizes fast and uniform mixing and constant reaction temperature, avoids the temperature runaway phenomenon and reduces the side reaction; the process is continuous flow reaction, and the reaction time is shortened to a few minutes, thus obviously improving the reaction efficiency and production efficiency; and the microreactor hardly has scale-up effect and is high in safety performance, thus being suitable for industrial production.

Owner:YANGZHOU SPED CHEM

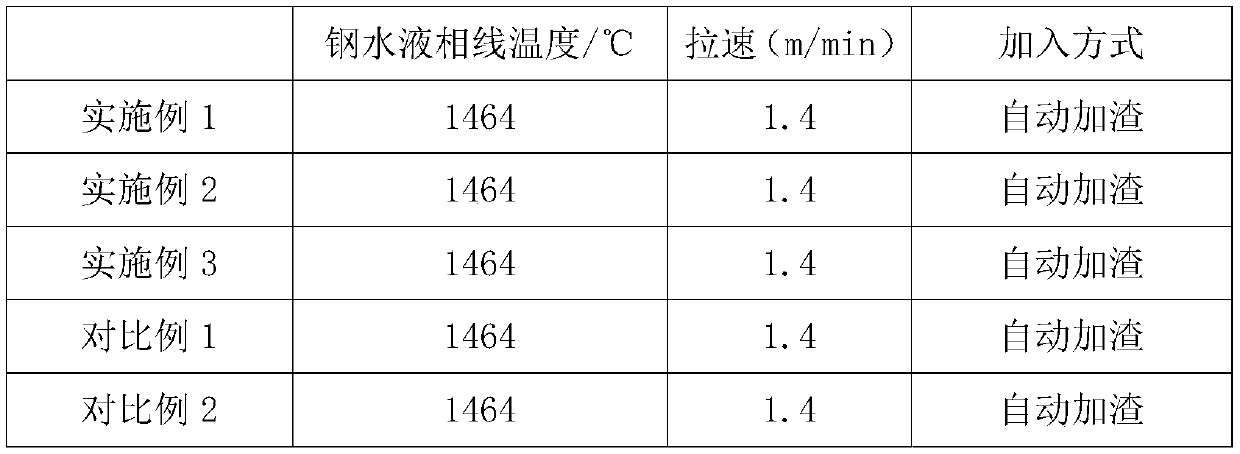

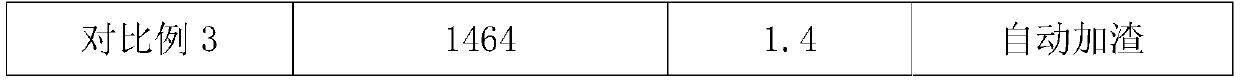

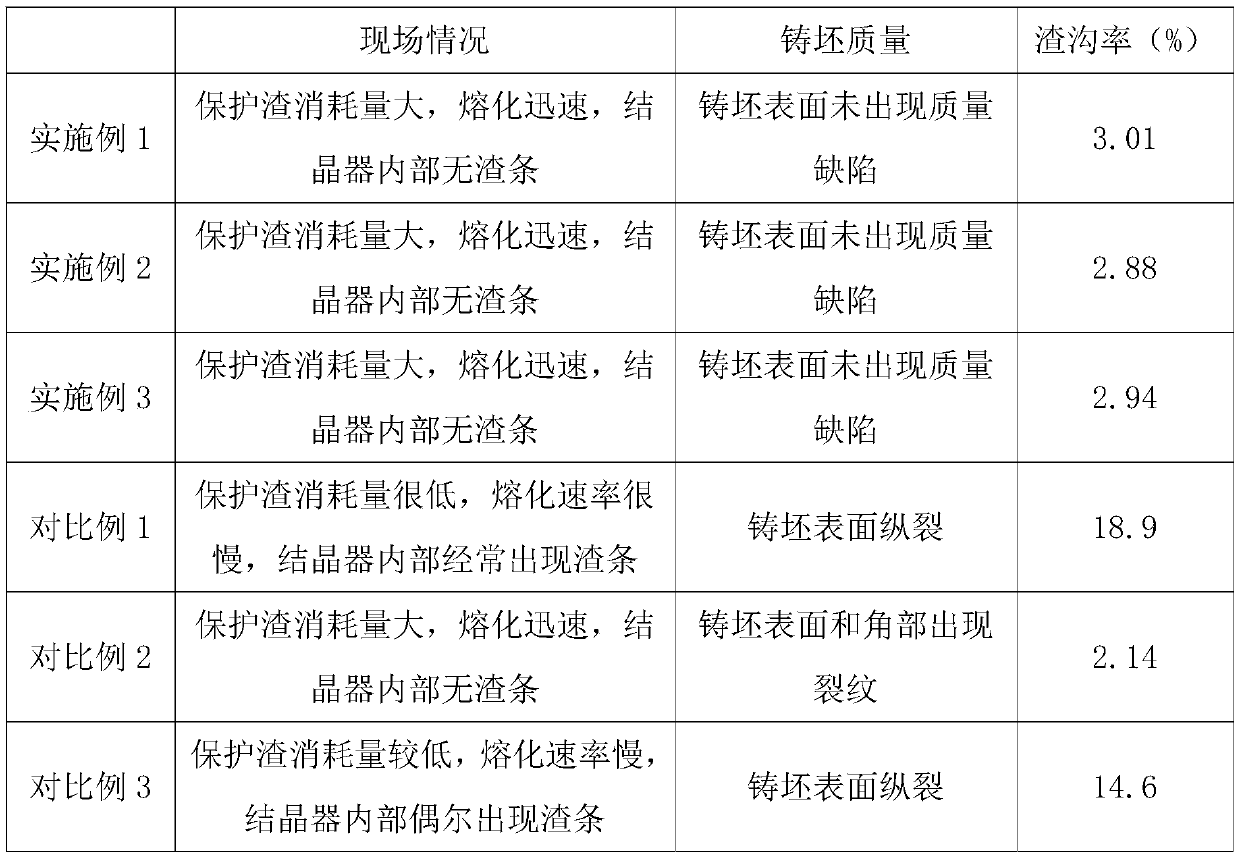

Continuous casting crystallizer casting powder special for bar plate stainless steel containing titanium and manufacturing technique thereof

The invention relates to an auxiliary product for metallurgy used for continuous casting of titanium-containing stainless steel in the metallurgy field, which is mainly applied in the mould powder technique of pre-melted crystallization mould of continuous casting for high titanium containing stainless steel. The materials of the invention comprise: specific used pre-melted base materials containing boron, flux materials, carbonaceous materials and additives; wherein, the flux materials comprise Li2CO3, Na2CO3, NaF, etc. The invention is characterized by good performance of accommodating and adsorbing titanium inclusion under the condition of meeting requirements for adding no carbon and reducing regrinding of traditional stainless steel; besides, after absorption of inclusion, the viscosity properties and solidification properties of the mould powder can be kept relatively stable, and compared with the import slag, the invention has the advantages of lower caking bleeding rate, casting billet with less surface defect, high anterograde of processing. Besides, the production of the invention has little slag strip; reaction in the crystallization mould is active; spreading property is good.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

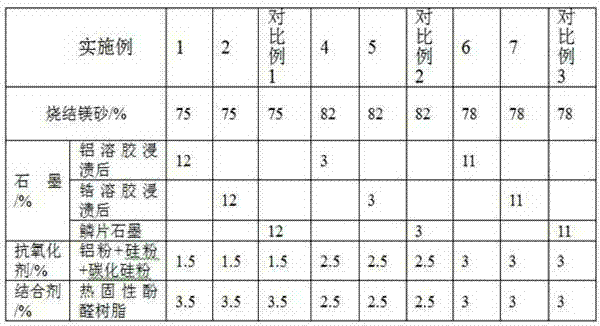

High-performance magnesia-carbon brick and production method thereof

The invention discloses a magnesia-carbon brick for a steelmaking converter and a steel ladle and a production method of the magnesia-carbon brick. The magnesia-carbon brick is prepared from the raw materials in percentage by weight: 72-83 percent of sintered magnesia, 3-15 percent of graphite grain, 1-15 percent of antioxidant and 2-5 percent of binder. The preparation method comprises the steps: (1) carrying out mechanical crushing on massive magnesia, then sending the crushed massive magnesia into a ball mill, and carrying out fine grinding on the crushed massive magnesia to prepare the magnesia in five specifications; and (2) carrying out burdening according to the required weight percentage, sending the burdened materials into a mixer to carry out mulling, adding coarse-grained magnesia, a thermosetting phenol-formaldehyde resin binder, the graphite grains and a mixed powder of fine-grained magnesia and the antioxidant into the mixer sequentially, carrying out material mixing for more than 25 minutes, and carrying out processing forming finally. According to the magnesia-carbon brick and the production method disclosed by the invention, as the graphite grains are adopted to replace crystalline flake graphite, the material yield is increased, and the spalling resistance and the structure spalling resistance of the materials are improved.

Owner:浙江金磊耐火材料有限公司

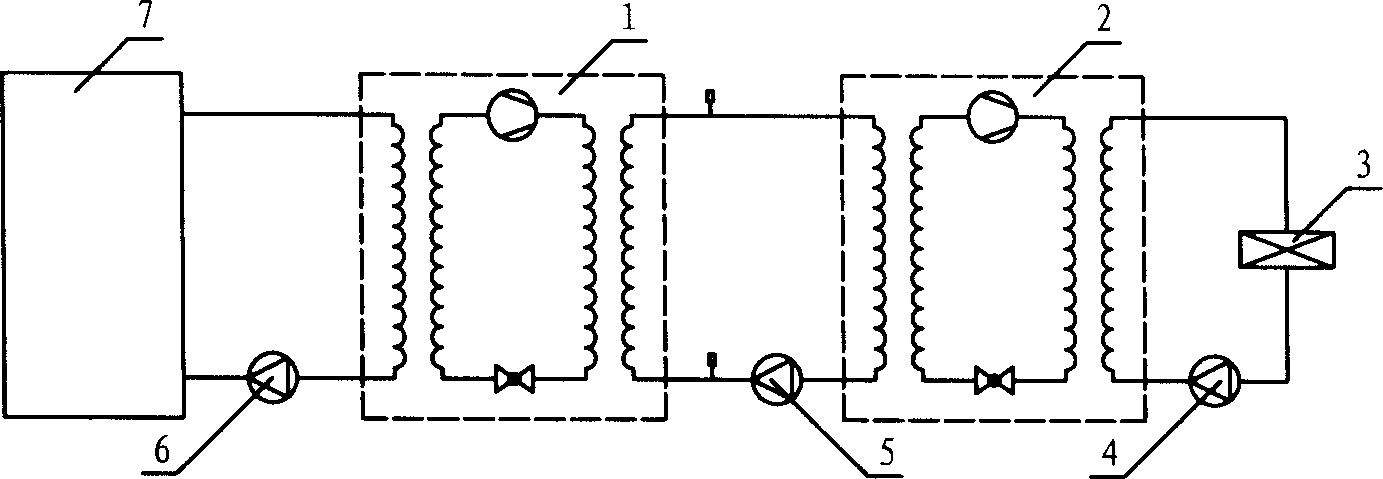

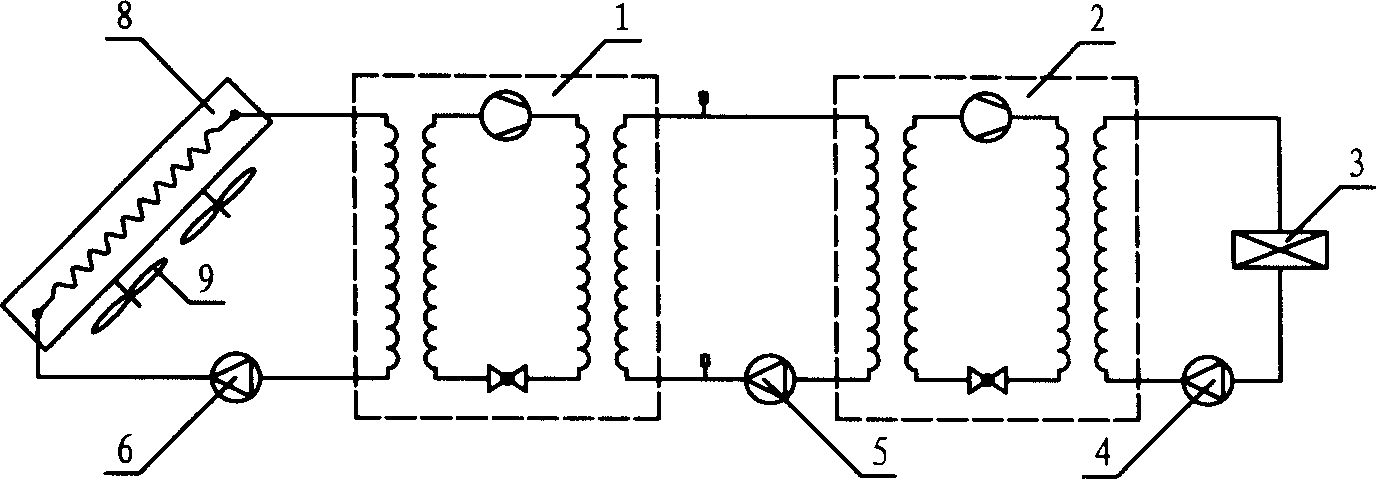

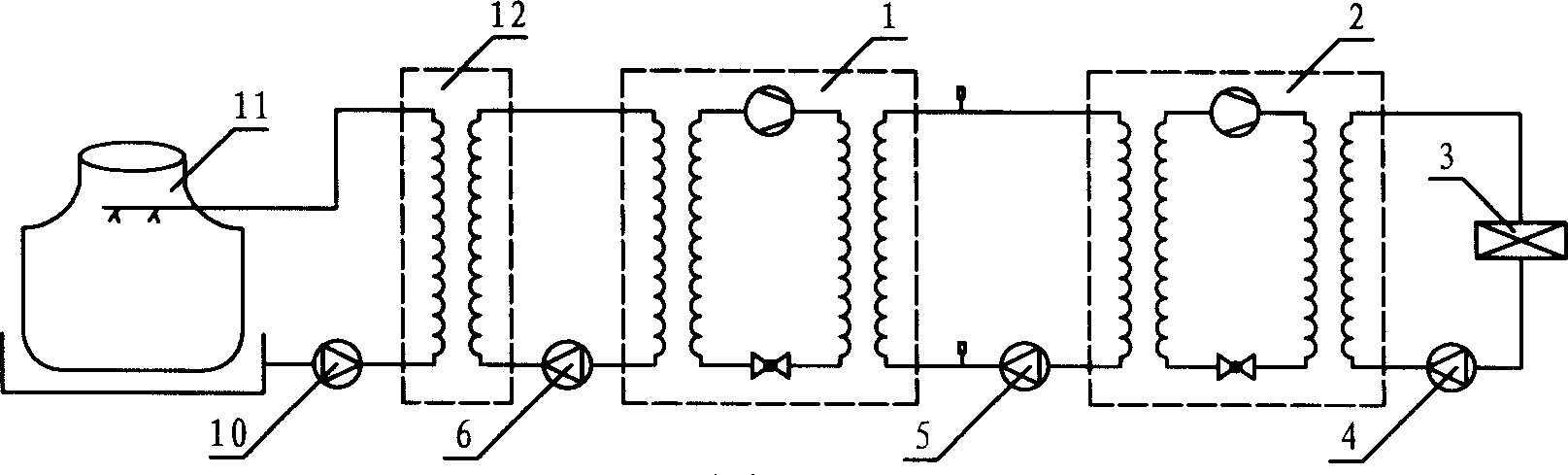

Heat pump air conditioner of air source, solar, water source

InactiveCN1869555ASolve heat transferSolve many problems caused by drilling groundwater wellsHeat pumpsWater source heat pumpWater source

The invention is an air-source solar water-source heat pump air- conditioning system, comprising two water-source heat pumps, where the two water-source heat pump are interconnected through the pipeline equipped with circulating pump to compose a first-stage air source heat pump and a second-stage artificial water source heat pump, the output end of the second-stage artificial water source heat pump is connected through the above pipeline with the air-conditioning terminal equipment, and the first-stage air source heat pump is connected through the above pipeline with the air source heat exchanger. And it connects two water-source heat pumps in series, configures an air-source heat exchanger for the fore-stage heat pump to obtain low-temperature heat energy in the air, and makes them compose a heat pump air-conditioning system with a first-stage air-source heat pump and a second-stage artificial water-source heat pump, thus effectively solving many problems caused by the current water source heat pump air-conditioner of needing to bury soil heat exchanger and drill a water well and making the heat pump air-conditioner suitable to safely, reliably and in high efficiency supply heat in the environment of outdoor air temperature below -7 deg.C.

Owner:王全龄

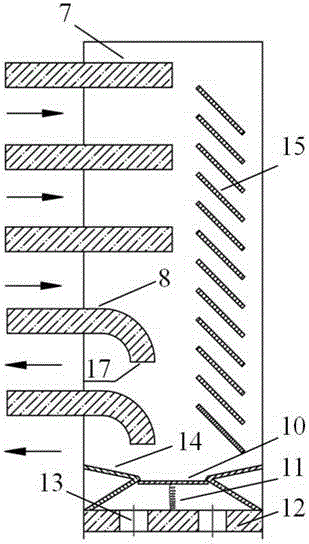

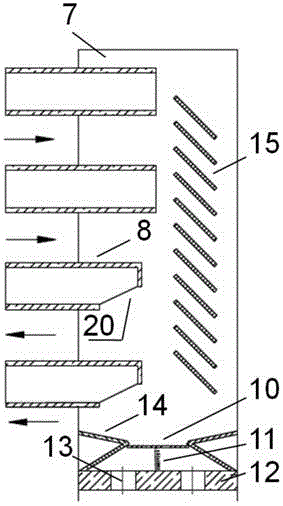

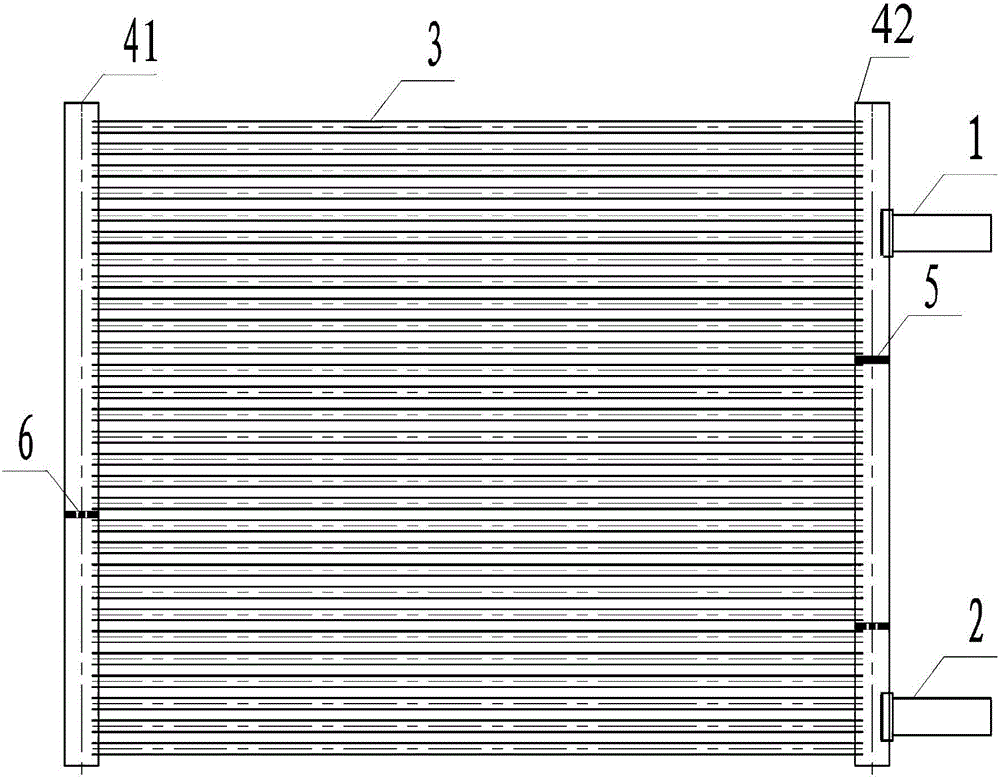

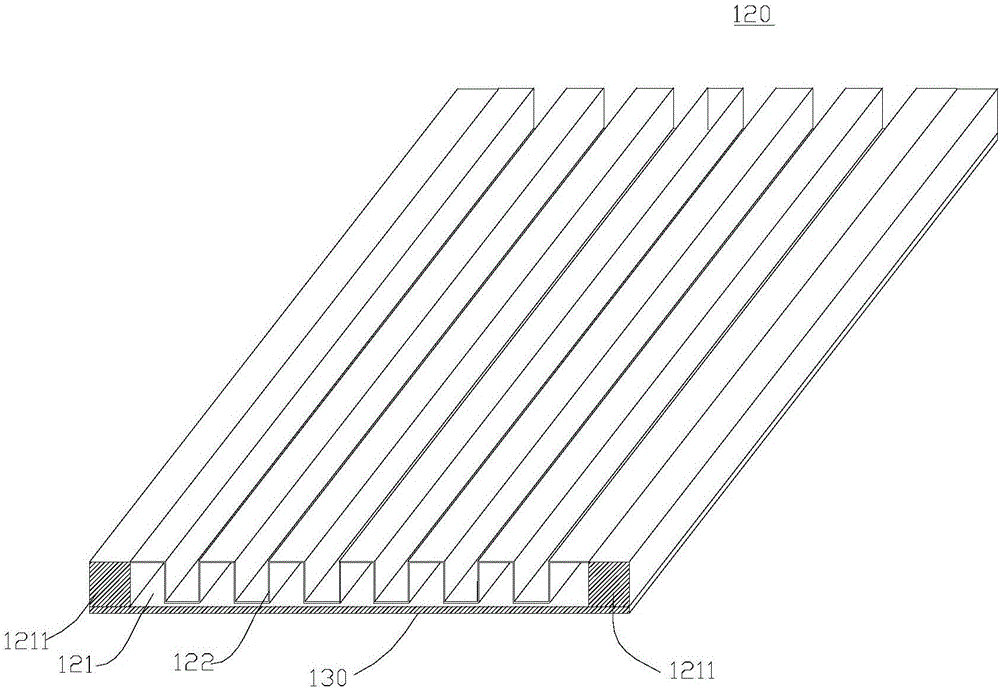

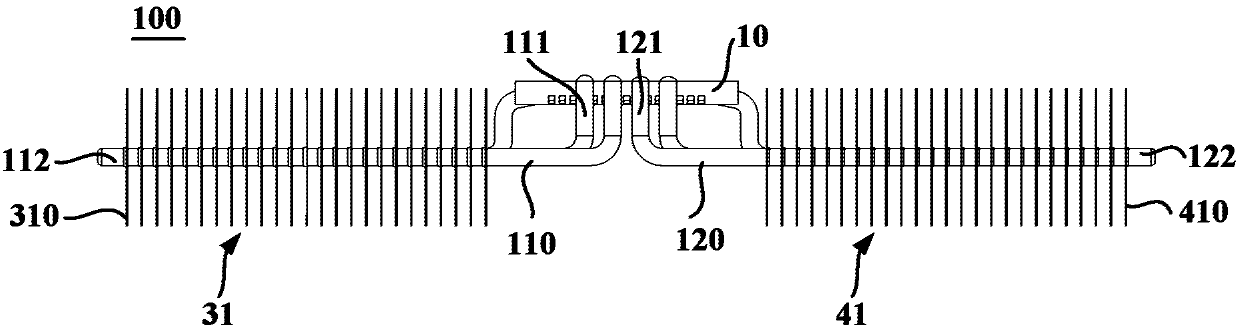

Multi-tube-row integrated header automatic adjusting dispensing condenser

ActiveCN105157441ASolve liquidity problemsSolve heat transferSteam/vapor condensersHeat exchanger casingsAuto regulationVapor–liquid separator

The invention discloses a multi-tube-row integrated header automatic adjusting dispensing condenser, comprising a first header, a second header, and heat exchange tubes. The header which is provided with an inlet pipe is provided with septums. The first header and the second header are internally provided with gas-liquid separators. The outlet tube segments of the heat exchange tubes extend into the cavity of the header, and the ends of the outlet tube segments bend downward. Or the outlet tube segments of the heat exchange tubes extend into the cavity of the header, and the outlet tube segments of the heat exchange tubes beveling downward from the diameter of the outlet tube segment and form bevel connections. Beneficial technical effects of the condenser are that heat transfer flowing performance of the condenser is improved, uniformity of working medium distribution is effectively improved, flow resistance is greatly reduced and high-efficiency heat exchange is maintained, a condensate liquid is prevented from being brought out of the headers, so as to greatly improve dispending effect of the headers on two ends, high-efficiency heat exchange flow state in tubes can be maintained on the tail of the condenser and under condition of lower area flow, and effect of enhancing heat transfer based on a dispensing condensing principle is improved.

Owner:广西高而美节能科技有限公司

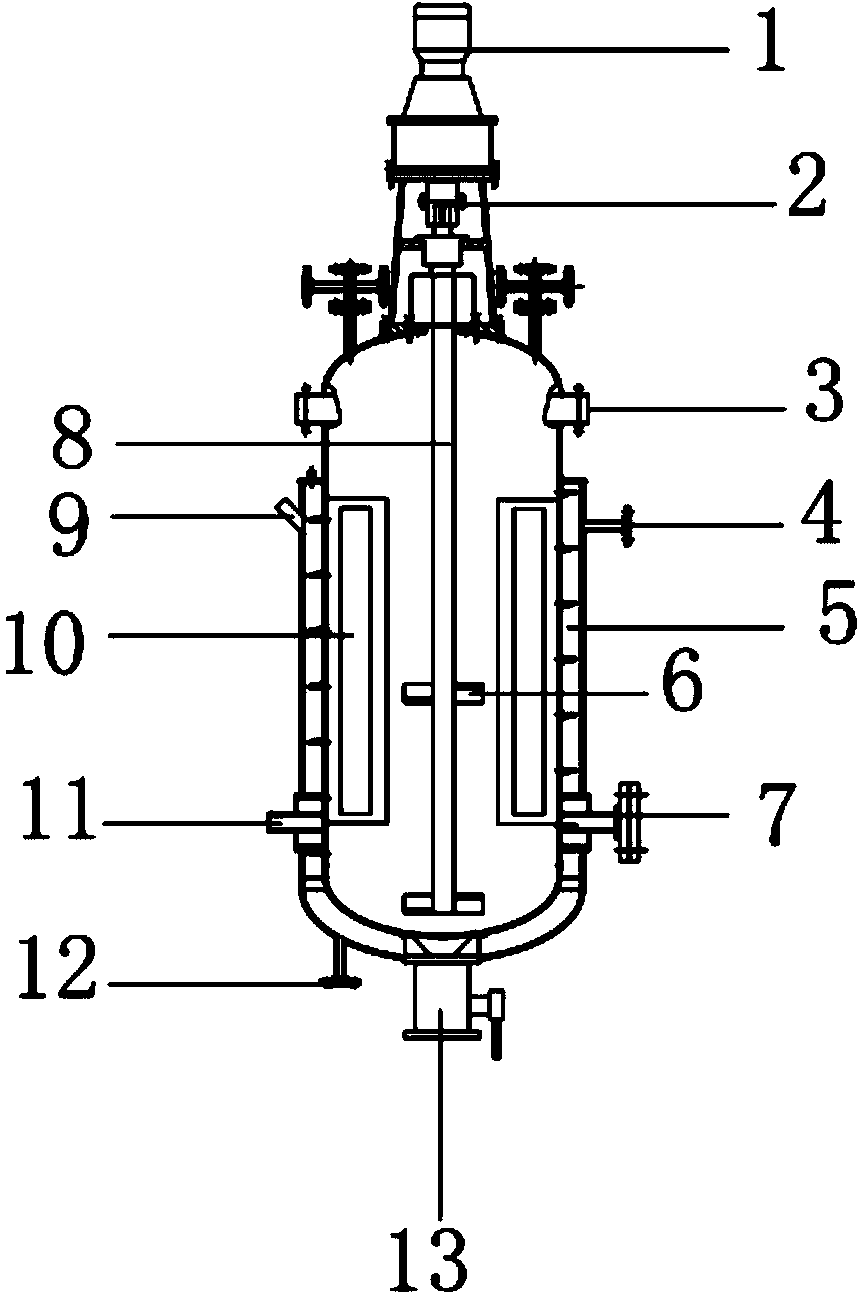

High-shear reaction kettle and application of kettle to production of suspension polymerization polyethylene

ActiveCN103894137APrevent the occurrenceSolve mass transferChemical/physical/physico-chemical stationary reactorsMotor driveParticle-size distribution

The invention relates to a high-shear reaction kettle which comprises a motor driving device, a stirring device, a kettle body, a clamping sleeve and a baffle plate, wherein the motor driving device is connected with the stirring device and is positioned on the top of the kettle body, and the stirring device is arranged in the kettle body; the clamping sleeve is arranged outside the kettle body, and the baffle plate is arranged in the kettle body; a material inlet, a material outlet and a kettle-inside temperature sensor inserting hole are formed in the kettle body, and a condensing medium inlet, a condensing medium outlet and a clamping sleeve temperature sensor inserting hole are formed in the clamping sleeve. The high-shear reaction kettle is applied to the production of the suspension polymerization polyethylene. Compared with the prior art, the reaction kettle can provide great radial shearing force, so that the generation of a dead angle in the reaction kettle is avoided. The polymerization reaction kettle is adopted to produce a polymerization product, namely the polyethylene, the molecular weight distribution and the particle size distribution of the polyethylene are narrow, the particle size of the polyethylene is uniform, the quality of finished products of the polymerization product is significantly improved and the rate of finished products of the polymerization product is significantly increased.

Owner:SHANGHAI RES INST OF CHEM IND +2

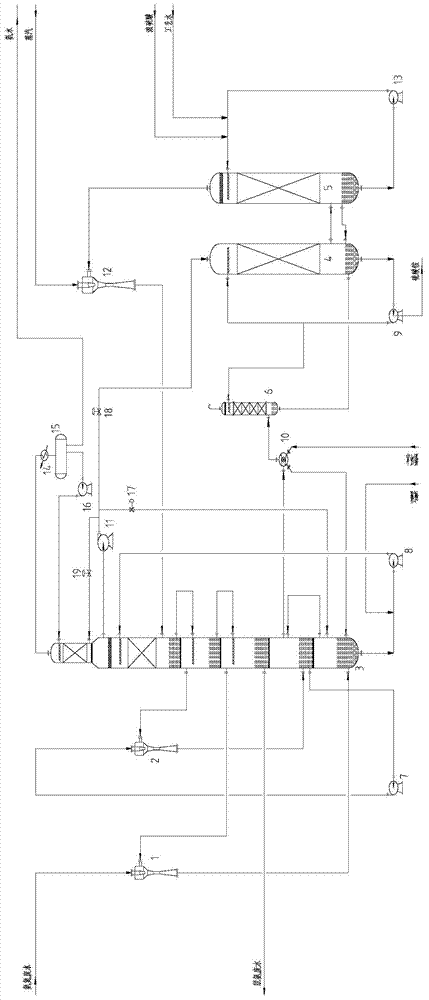

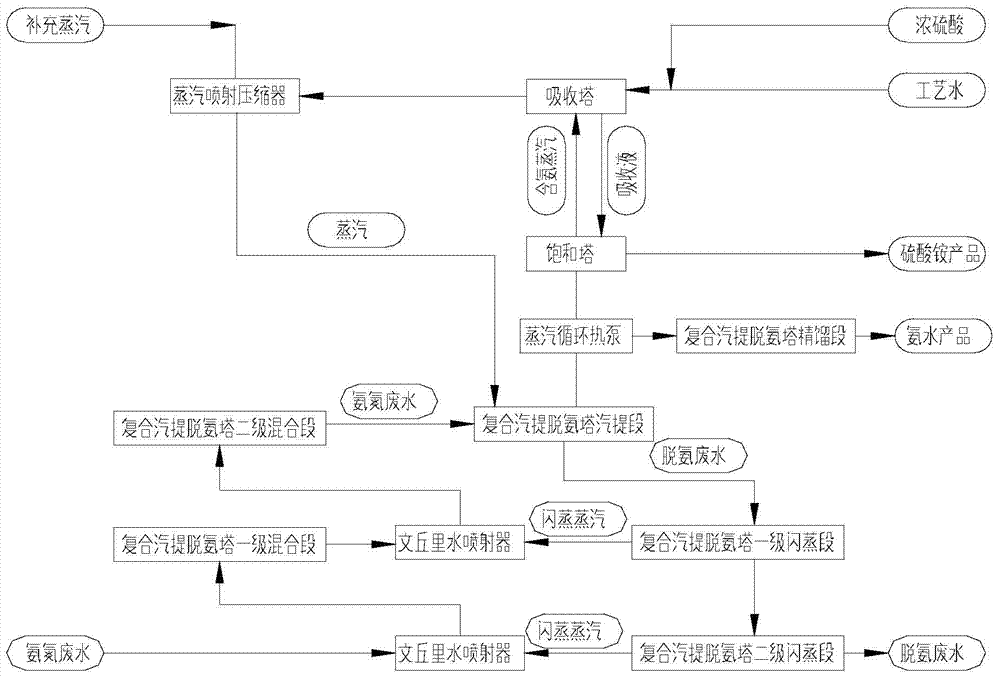

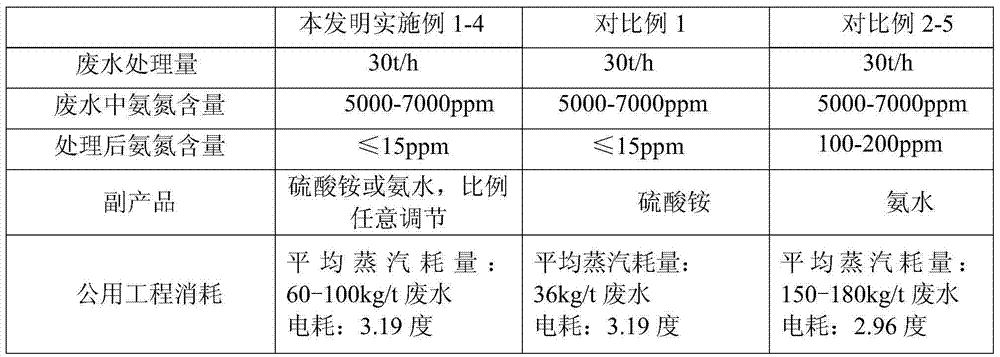

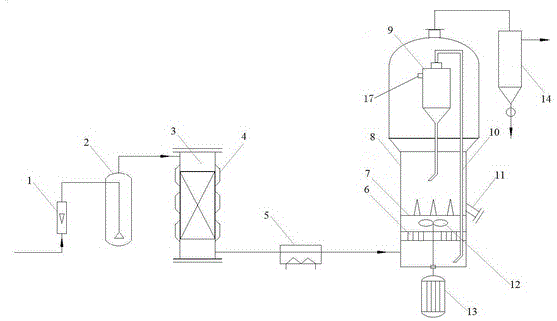

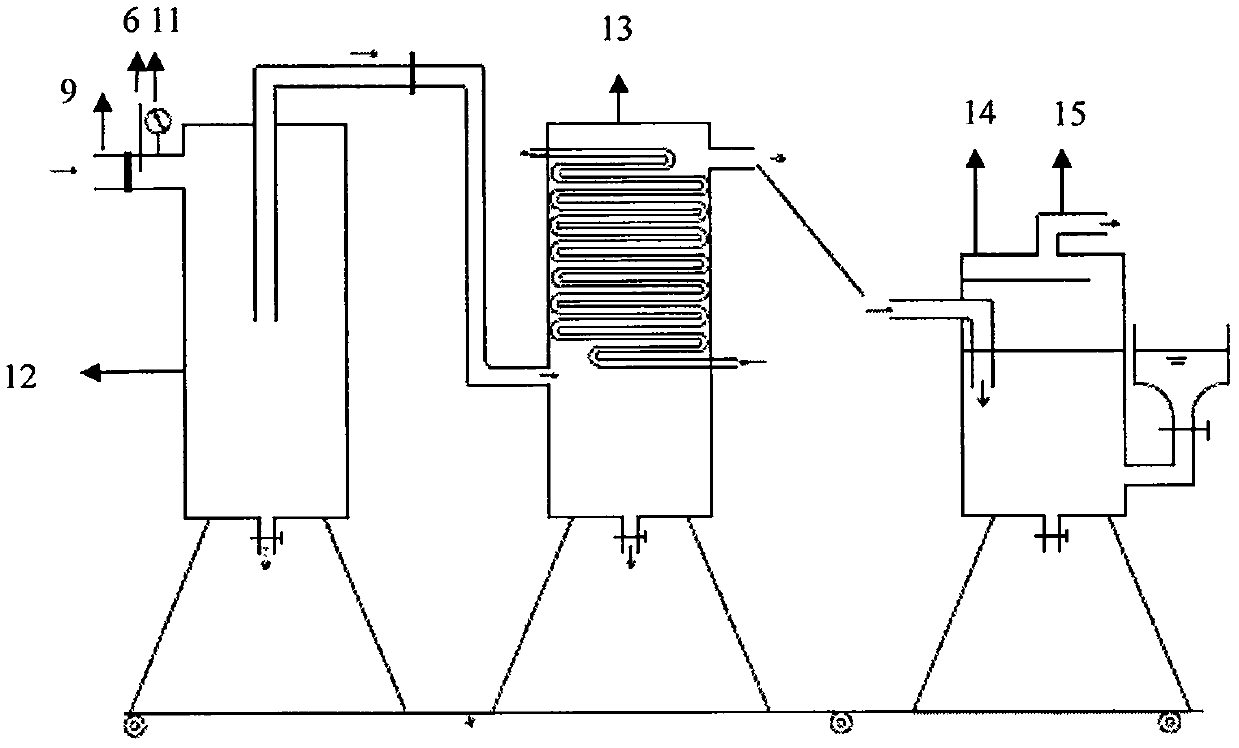

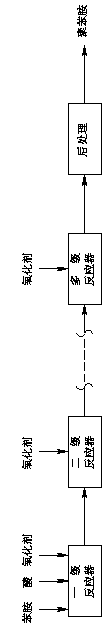

Method for combined production of ammonium sulfate and ammonia water through heat pump flash evaporation, stripping and deamination

ActiveCN104843816AReduce consumptionSolve the problem of easy fouling and blockage of equipmentWater contaminantsEnergy inputTowerAmmonia

The invention discloses a method for combined production of ammonium sulfate and ammonia through water heat pump flash evaporation, stripping and deamination. The method comprises the following steps: ammonia nitrogen steam discharged from the top of the stripping section of a composite stripping and deaminating tower (3) is pressurized through a steam circulating heat pump (11), and the pressurized ammonia nitrogen steam is divided into three parts; the first part of the ammonia nitrogen steam enters the two stage mixing section of the composite stripping and deaminating tower (3) to heat ammonia nitrogen wastewater; the second part of the ammonia nitrogen steam enters a saturation tower (4) and undergoes ammonia nitrogen preliminary absorption, and the absorbed ammonia nitrogen steam enters an absorption tower (5) and undergoes ammonia nitrogen purifying recovery; and the third part of the ammonia nitrogen stem enters the tower top rectifying section of the composite stripping and deaminating tower (3) to produce the ammonia water product. The method allows ammonium sulfate and ammonia water to be simultaneously produced, and a ratio of ammonium sulfate to ammonia water can be adjusted according to reuse requirements of a production device, so ammonia nitrogen recovered from the wastewater can be completely reused in the production device in order to realize good energy saving, consumption reduction and deamination effects.

Owner:CHINA PETROLEUM & CHEM CORP +3

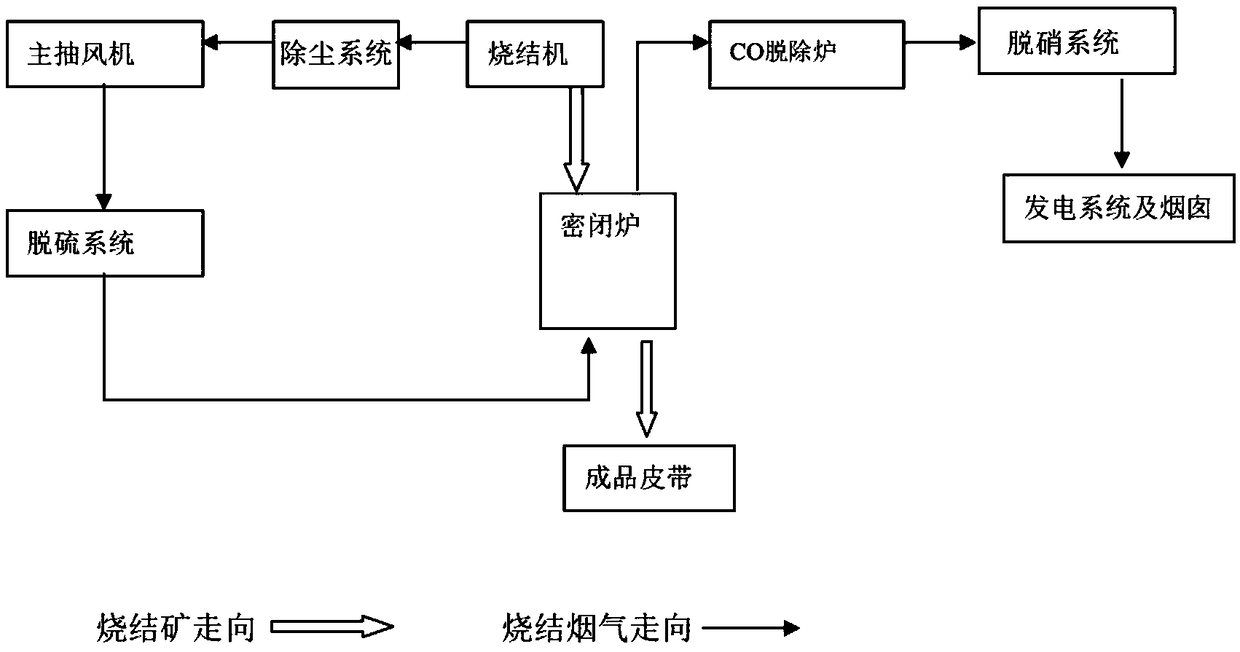

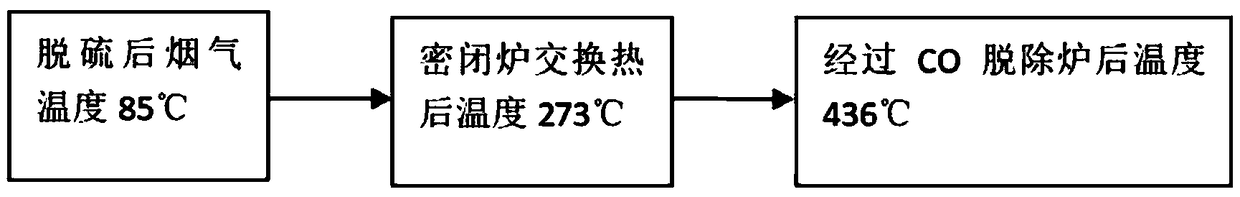

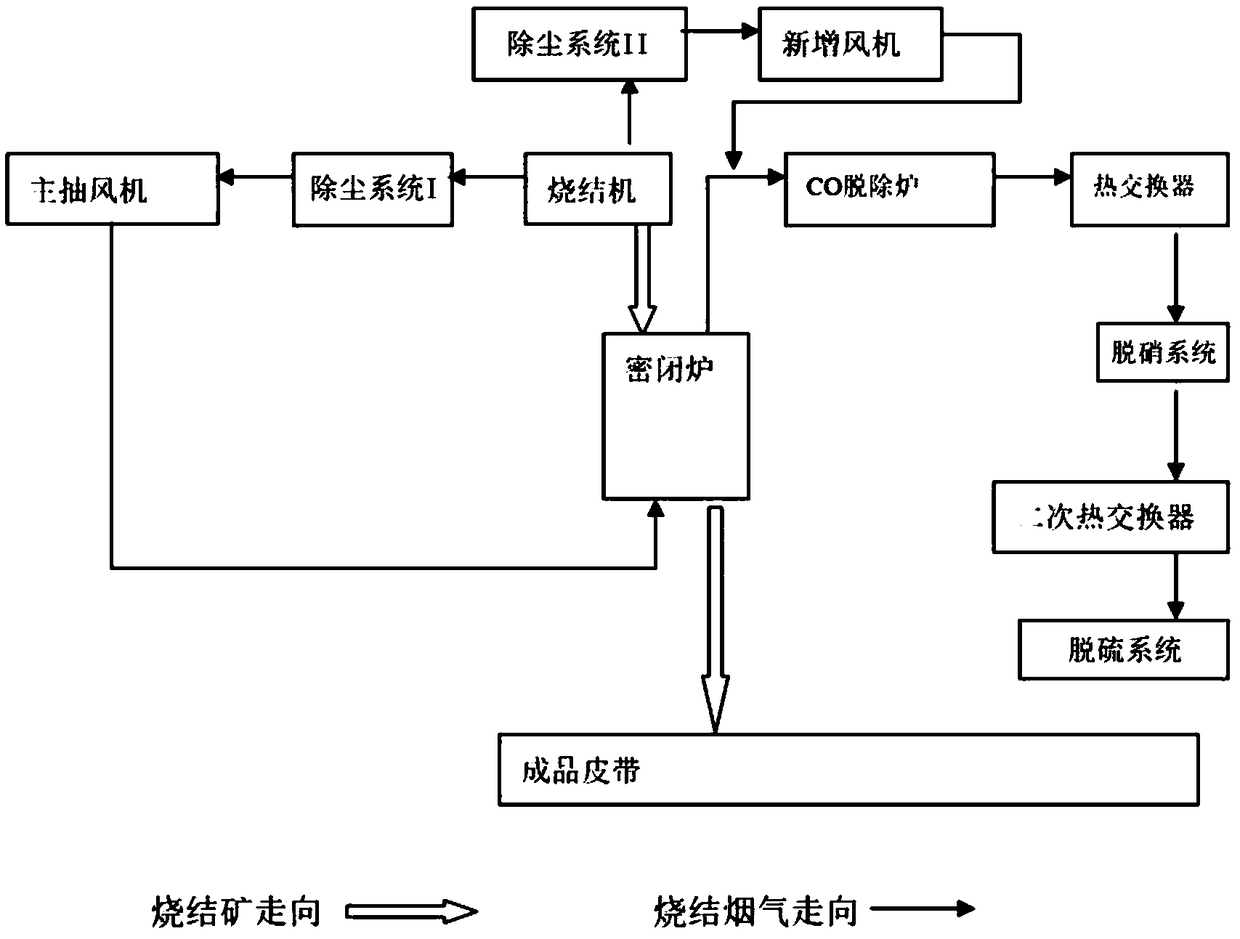

Sinter waste heat and sintering flue gas pollutant cooperative treatment process

InactiveCN108692579AHigh recovery rateSolve the problem that the temperature is low and cannot be recycledWaste heat treatmentParticulatesFlue gas

The invention relates to a sinter waste heat and sintering flue gas pollutant cooperative treatment process. The treatment process comprises the steps that sintering flue gas generated by metallurgy sintering is subjected to dedusting treatment to remove particulate matters to be then subjected to heat exchange treatment with sinter generated by metallurgy sintering, and at least part of CO in thesintering flue gas is oxidized and removed during heat exchange treatment; and the sintering flue gas is subjected to CO desorption treatment, and at least part of CO in the sintering flue gas is oxidized and removed during CO desorption treatment. According to the arrangement conditions of a sintering machine and a gas desulfurization system at present, the sintering flue gas can adopt the technology that SO2 is firstly or lastly desorbed. The cooperative treatment process solves the problems about CO desorption and utilization, and cooperative treatment of sinter waste heat and sintering flue gas pollutant is achieved.

Owner:杨清海

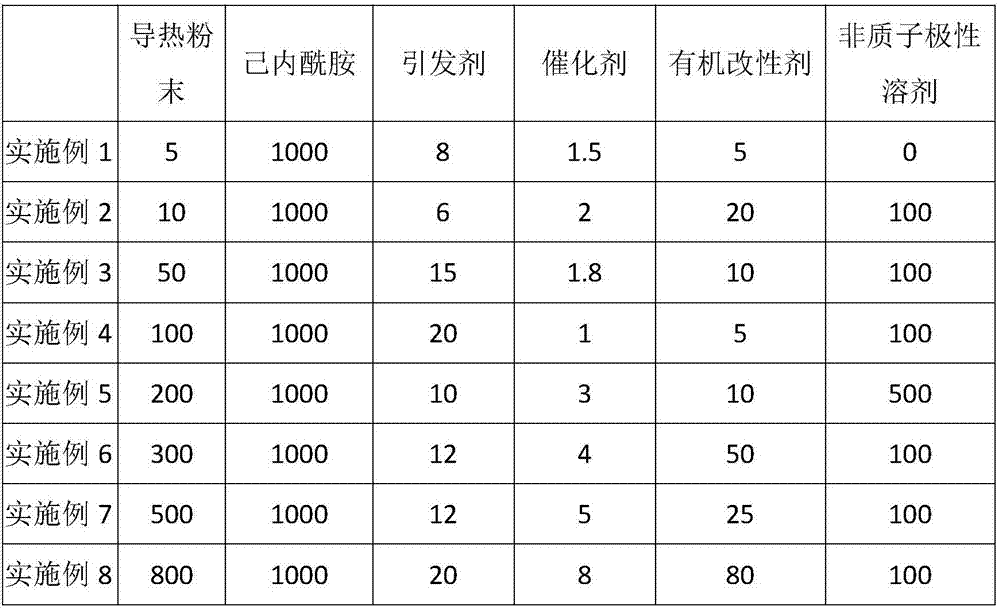

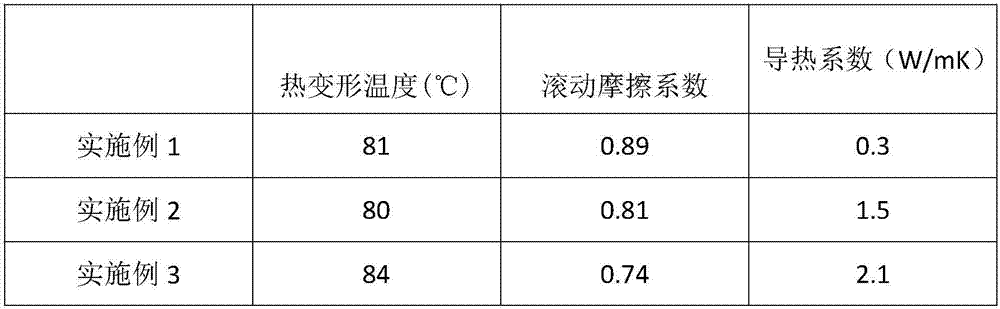

Heat conduction powder/monomer cast nylon nanometer composite material, method for preparing same and application of heat conduction powder/monomer cast nylon nanometer composite material

InactiveCN107011509AImprove mechanical propertiesFast heat conductionHeat-exchange elementsMetallurgyHeat stability

The invention discloses a heat conduction powder / monomer cast nylon nanometer composite material and a method for preparing the same. The method includes adding heat conduction powder, aprotic polar solvents and organic modifiers into a kettle A filled with caprolactam monomers, carrying out until the temperature reaches 70-85 DEG C, stirring the heat conduction powder, the aprotic polar solvents, the organic modifiers and the caprolactam monomers for 0.5-2 h to obtain mixtures, vacuumizing the kettle A for 15-60 min, heating the mixtures until the temperatures of the mixtures reach 130-140 DEG C, adding initiators into the mixtures and carrying out vacuumizing reaction for 15-30 min; heating a kettle B filled with caprolactam monomers until the caprolactam monomers are dissolved, vacuumizing the kettle B, adding catalysts into the completely dissolved monomers to obtain mixtures, heating the mixtures until the temperatures of the mixtures reach 130-140 DEG C and vacuumizing the kettle B for 10-15 min; mixing materials in the kettle A and materials in the kettle B with one another to obtain mixtures, pouring the mixtures into molds at the temperatures of 150-170 DEG C, carrying out polymerization molding, preserving heat for 10-60 min and then releasing the molds. The heat conduction powder / monomer cast nylon nanometer composite material and the method have the advantages that nylon matrixes and the heat conduction powder can be organically combined with one another by the aid of the heat conduction capacity of the heat conduction powder, and accordingly the problems in the aspect of heat conduction of cast nylon can be solved; the heat conduction powder / monomer cast nylon nanometer composite material prepared by the aid of the method is good in heat stability, high in abrasion resistance and excellent in comprehensive performance.

Owner:HUNAN UNIV OF TECH

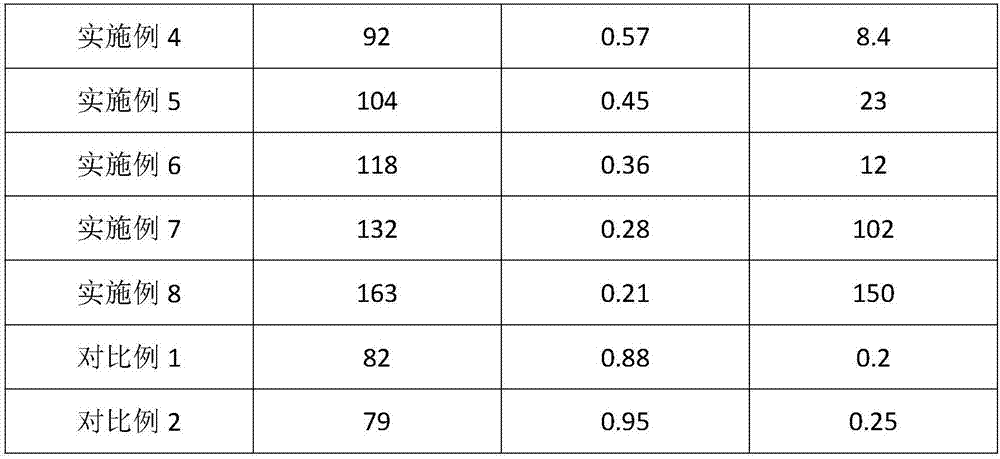

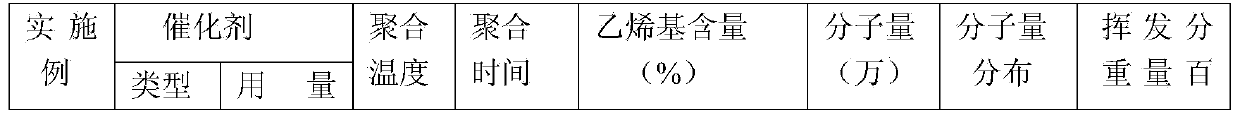

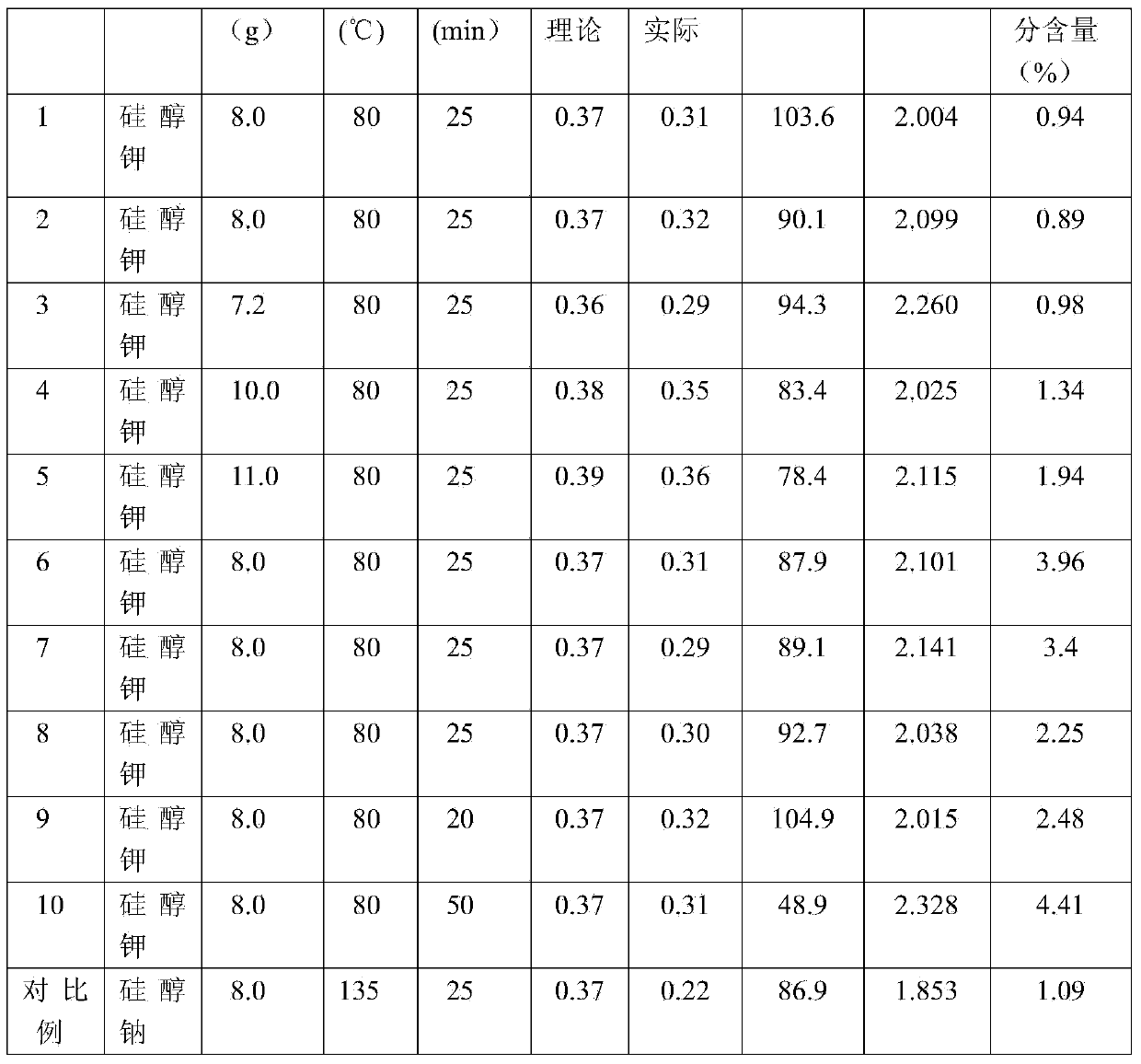

Preparation method of heat curing fluorosilicone raw rubber

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

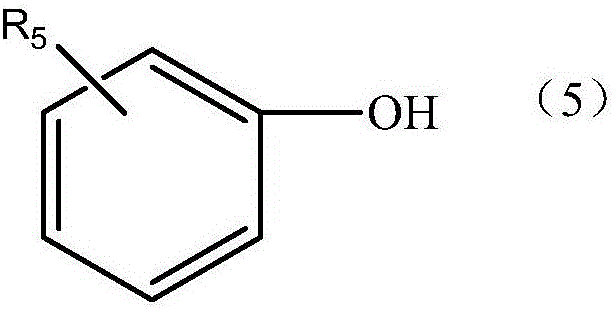

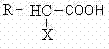

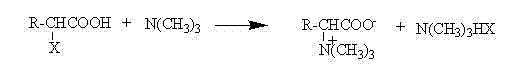

Method for preparing high-content alpha-lauryl betaine by solvent-free quaternization

InactiveCN102126964ASolve concentrationSolve heat transferOrganic compound preparationAmino compound preparationOrganic synthesisActive agent

The invention discloses a method for preparing high-content alpha-lauryl betaine by solvent-free quaternization, which belongs to the technical filed of organic synthesis. Particularly, a hot-press condition is implemented for quaternization of trimethylamine and alpha-halogenated carboxylic acid, and the trimethylamine which is one of reaction materials is liquefied under the hot-press condition and is simultaneously used as a reaction medium, so that the problem of difficulty in enhancing the reaction material concentration, mass and heat transfer and the like is solved skillfully; and an additional solvent is avoided being used, so that quaternization is undergone under the solvent-free condition to synthesize alpha-lauryl betaine, particularly alpha-long-chain lauryl betaine, serving as an amphoteric surfactant. The technology disclosed by the invention can be implemented under the solvent-free condition, so that the hydrolytic side reaction of alpha-halogenated carboxylic acid in an aqueous solution is avoided, the yield of alpha-lauryl betaine is effectively increased, or the product pollution and the environmental pollution caused by the use of an organic solvent are avoided, and the product purity is remarkably increased; and the method has a simple process, excessive raw material, namely trimethylamine, is recycled after being evaporated and recovered, an end product, namely alpha-lauryl betaine is a high-content solid-state product, and a preparation process is emission-free.

Owner:JIANGNAN UNIV

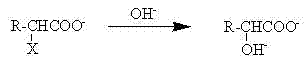

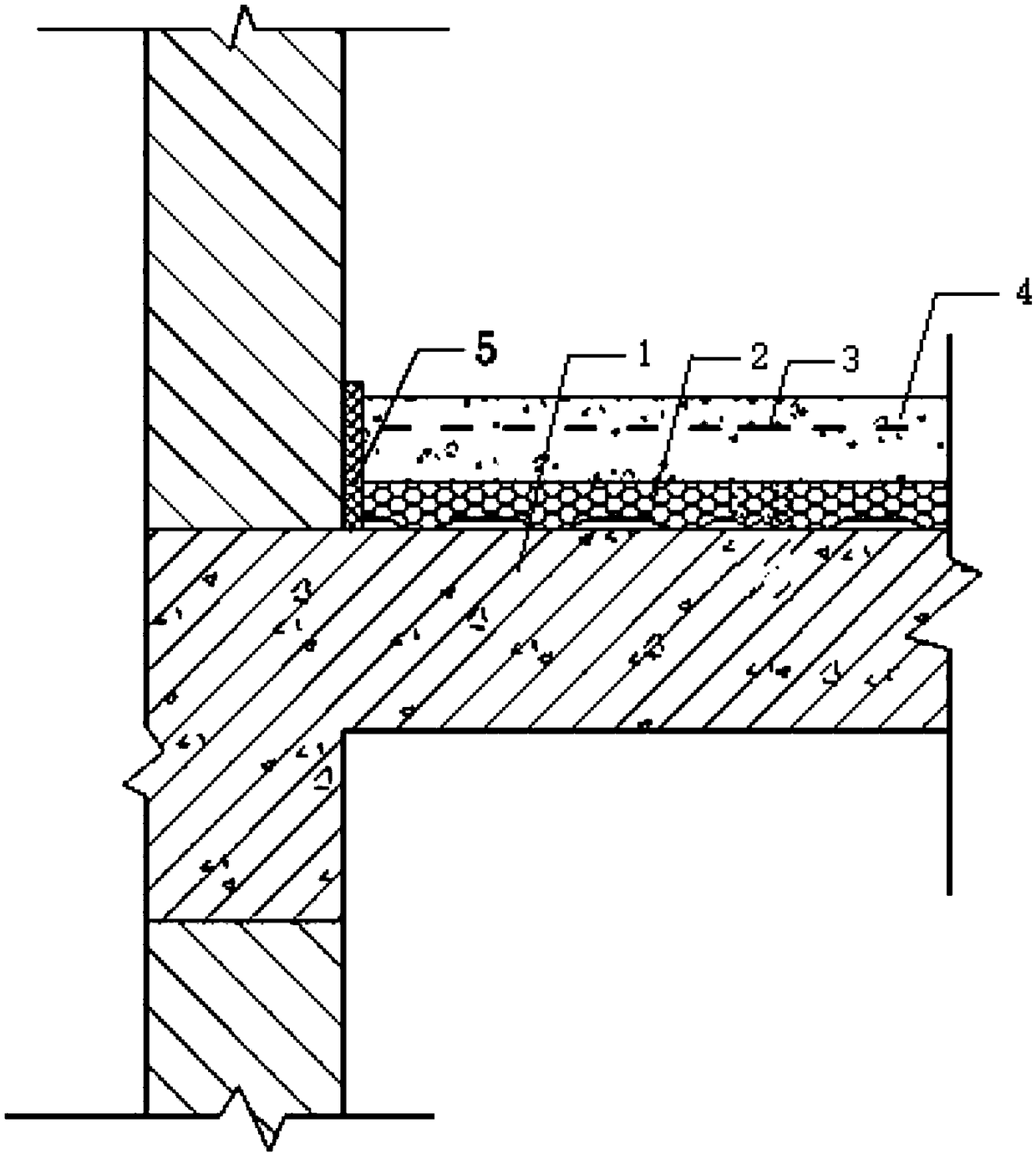

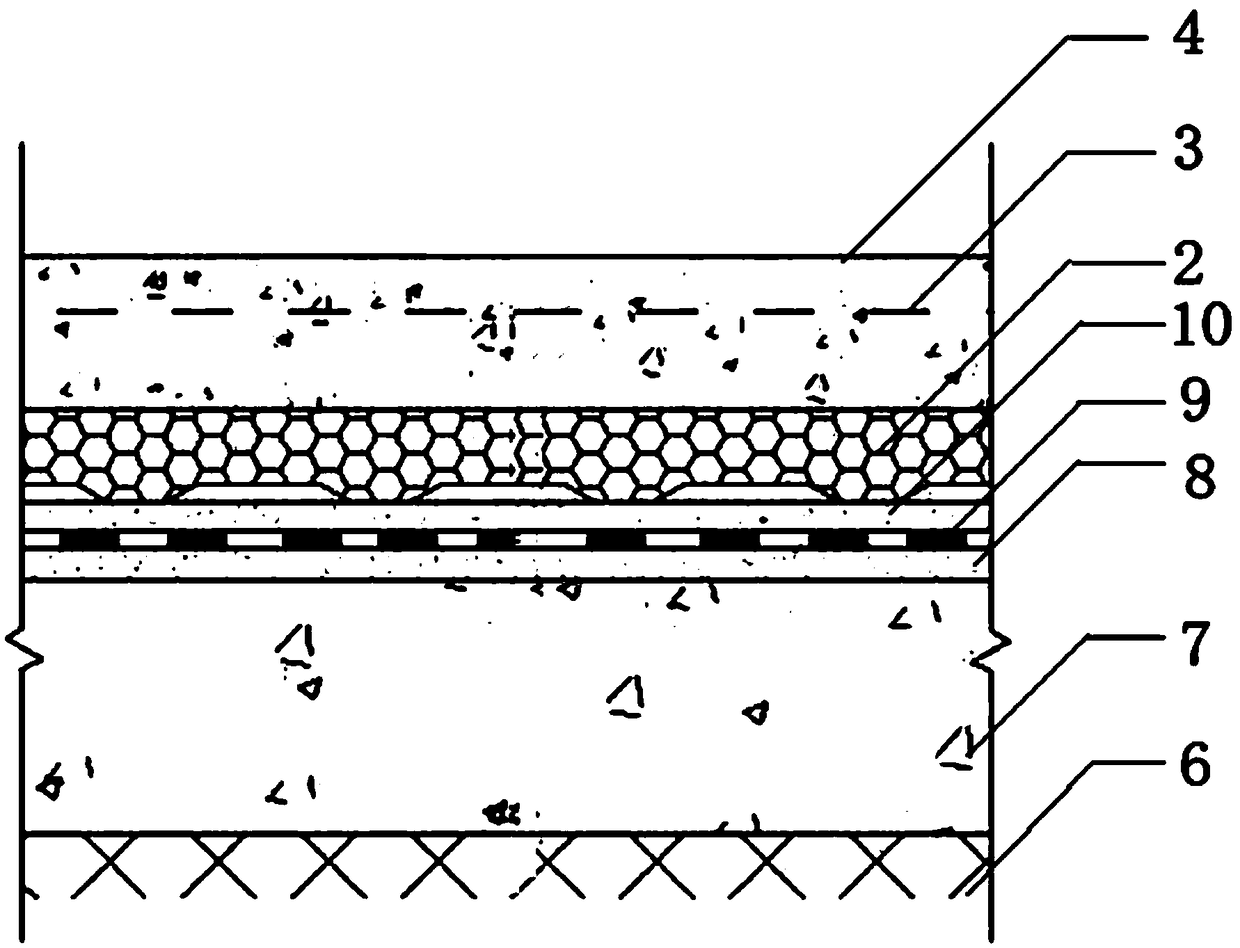

Floating floor slab thermal insulation sound insulation system and laying method thereof

InactiveCN109083292AAvoid crackingSolve noise interferenceHeat proofingSound proofingSurface layerFloor slab

The embodiment of the invention discloses a floating floor slab thermal insulation sound insulation system and a laying method thereof. The system comprises a thermal insulation sound insulation boardand a fine aggregate concrete protective surface layer which are successively laid on the upper surface of the basic layer of a concrete floor board from bottom to top, and steel wire screen pieces capable of preventing the fine aggregate concrete protective surface layer from cracking are arranged in the fine aggregate concrete protective surface layer. The system adopts the mode that the thermal insulation sound insulation board and the fine aggregate concrete protective surface layer are successively laid on the upper surface of the basic layer of the concrete floor board from bottom to top, the problem of upstairs and downstairs noise interference and heat conduction can be effectively solved, the steel wire screen pieces are utilized for avoiding the problem that the fine aggregate concrete protective surface layer cracks, and the technology is advanced, safe, reliable, economic and reasonable, ensures the project quality, and achieves significant economic, social and environmental benefits.

Owner:徐州海奥新材料科技有限公司

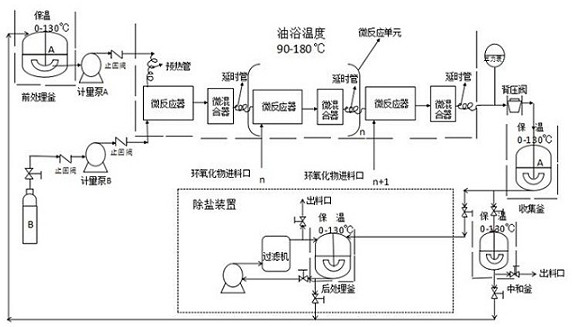

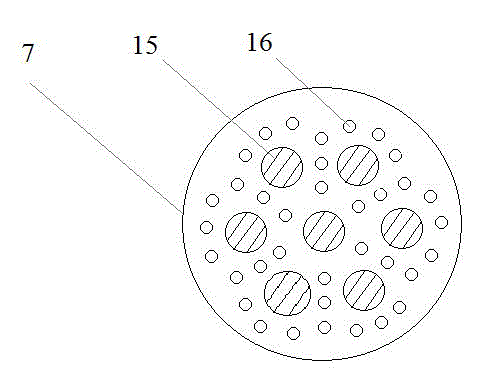

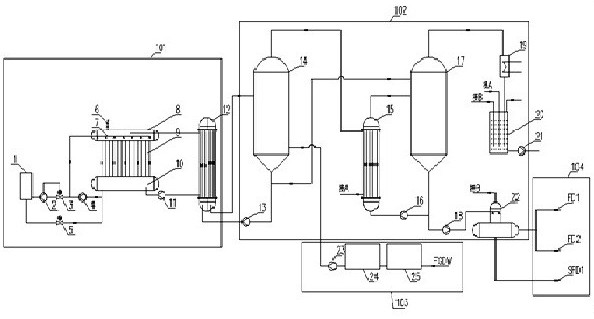

Method for continuously producing high-molecular-weight polyether by adopting micro-channel reactor

InactiveCN111925514AImprove securitySolve heat transferChemical/physical/physico-chemical microreactorsMicroreactorReactor system

The invention relates to a method for producing high-molecular-weight polyether by adopting a micro-channel reactor. The method adopts a micro-reactor, a micro-mixer, a pretreatment kettle, a preheating pipe, a delay pipe, a metering pump A, a metering pump B, an epoxy compound storage tank B, a collection kettle, a neutralization kettle, a desalting device, a post-treatment kettle, a back pressure valve and a pressure gauge. The micro-reactor is provided with a plurality of micro-channels, two micro-reactor feed ports and a micro-reactor discharge port; the micro-reactor, the micro-mixer andthe delay pipe form a micro-reaction unit; the desalting device comprises a post-treatment kettle and a filtering machine; and the pressure gauge is arranged between the micro-mixer and the back pressure valve. The method is advanced and scientific, the micro-reactor system adopted in the method is rapid and uniform in mixing, the over-temperature phenomenon is avoided, side reactions are reduced,low-unsaturation-degree and high-molecular-weight polyether can be continuously produced, direct large-scale production can be achieved, and the method has high safety performance and is suitable forindustrial production.

Owner:XIHUA UNIV

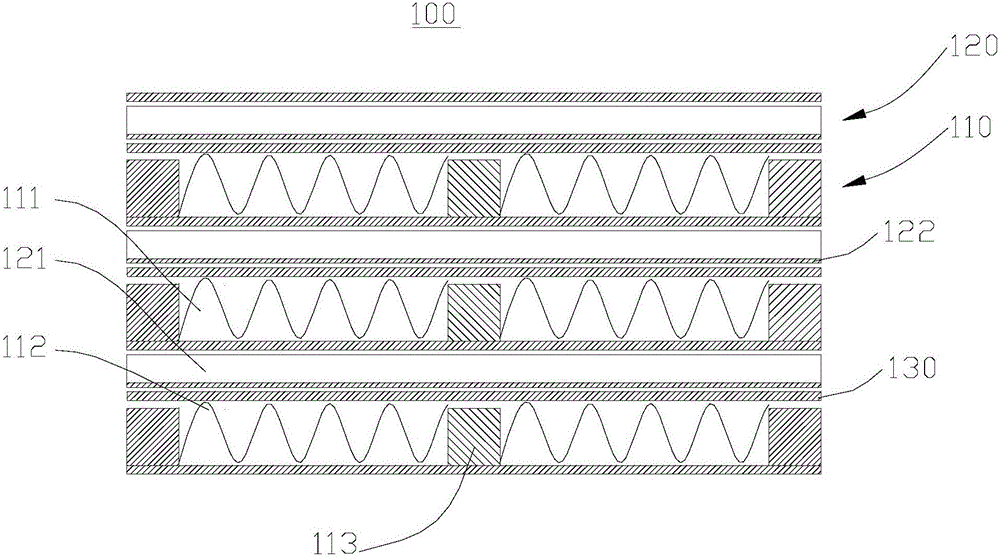

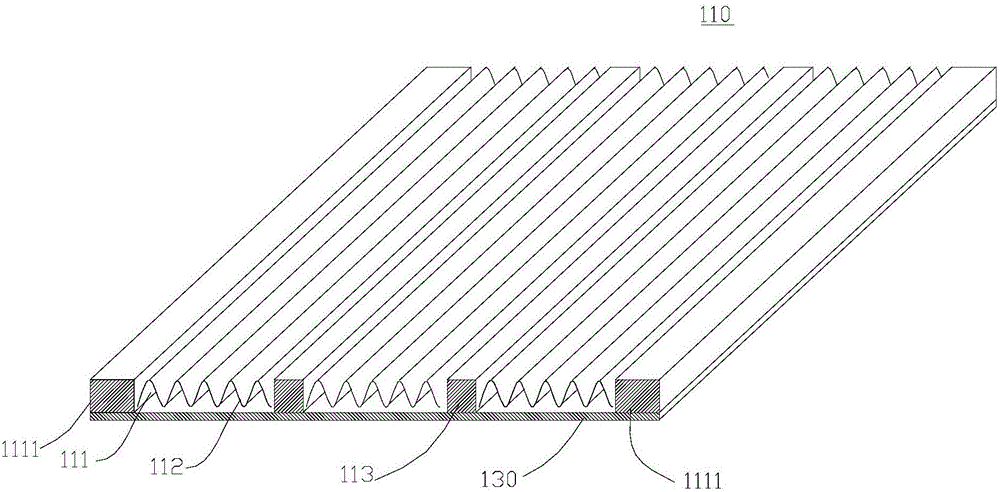

Reaction device and reaction equipment

InactiveCN106237939AIncrease production capacityMeet the requirements of industrial applicationsChemical/physical processesEngineering

Owner:CHENGDU SEPMEM SCI & TECH

Aluminum trichloride-immobilized catalyst boiling bed production apparatus and preparation technology thereof

InactiveCN104888816ALow costLow maintenancePhysical/chemical process catalystsAtmospheric airReaction temperature

The invention relates to an aluminum trichloride-immobilized catalyst production apparatus and a preparation technology thereof. especially relates to an aluminum trichloride-immobilized catalyst boiling bed production apparatus and a preparation technology thereof. A technical scheme of the present invention is characterized in that N2 gas is introduced in a CCl4 storage tank through a N2 flowmeter, N2 is taken as a carrying gas for carrying the CCl4 saturated vapor into an AlCl3 generator, AlCl3 gas is generated by reacting with Al2O3, AlCl3 gas is introduced in to a boiling bed reactor through a cooler, and is immobilized with a suspension carrier in the boiling bed; a gas internal circulation method is employed in the boiling bed reactor, so that AlCl3 is cycled in the boiling bed, and is fully contacted with carrier particles for reacting, N2 gas containing a few of AlCl3 passes through an AlCl3 collector, and is washed to remove the residual AlCl3 and then is discharged into atmosphere; and aluminum trichloride-immobilized catalyst is recovered for storage. The apparatus is easy for industrial production, equipment corrosion, environmental pollution and difficult separating with products can be effectively solved, and the method has the advantages of low reaction temperature, high immobilization rate and uniform supporting.

Owner:DALIAN JIAOTONG UNIVERSITY

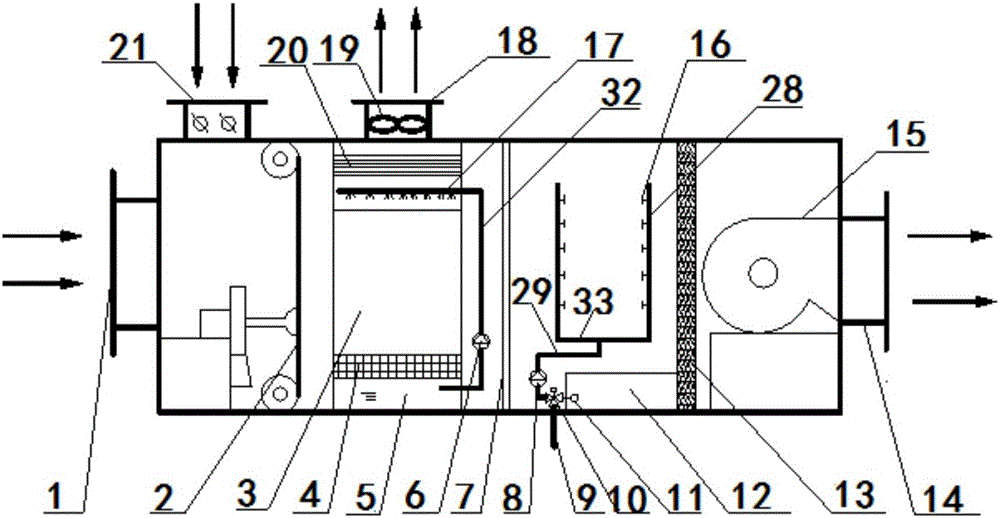

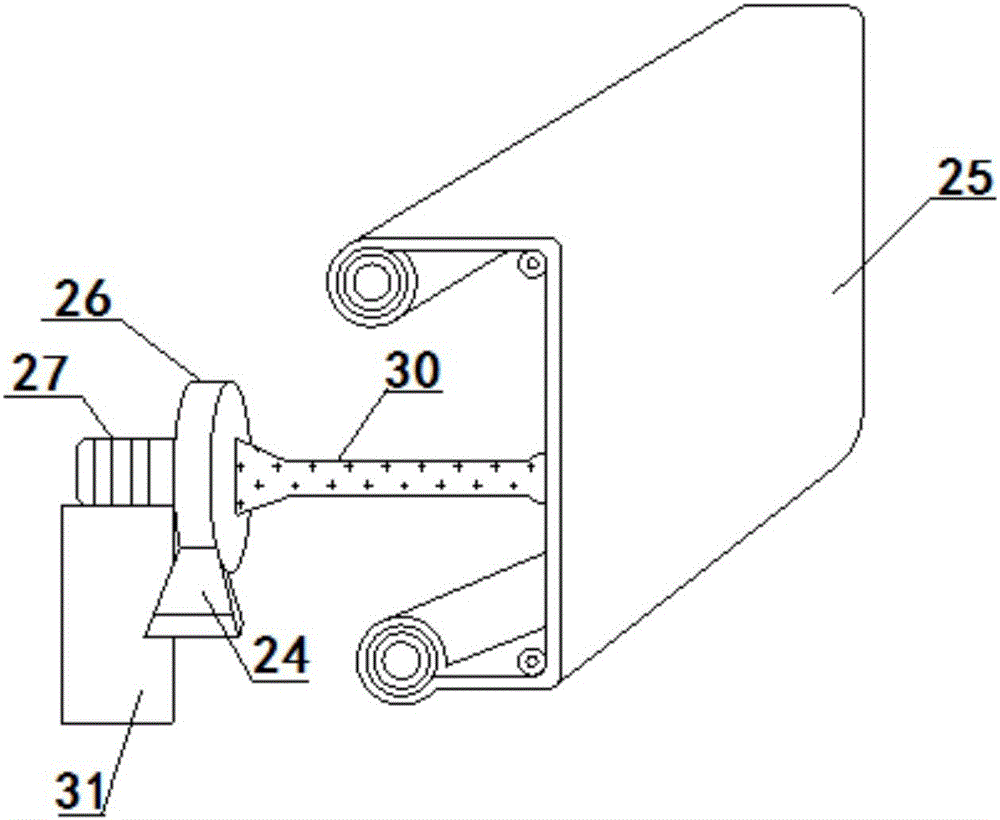

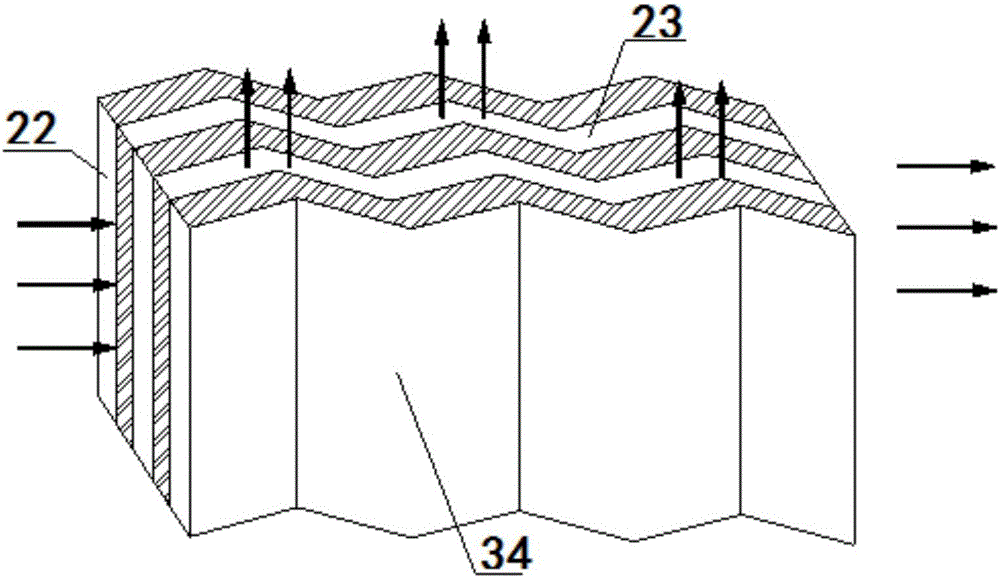

Corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit

InactiveCN105042735AImprove the cooling effectReduce running timeMechanical apparatusLighting and heating apparatusFiberTextile mill

The invention discloses a corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit. The air conditioning unit comprises a unit shell. An air inlet and an air outlet are formed in the two opposite side walls of the unit shell respectively. A fresh-air-and-returning-air mixing-filtering chamber, a corrugated-plate indirect evaporative cooler, a flow equalizing plate, a hydrodynamic force water spraying device, a water stop plate a and an air feeder are sequentially arranged in the unit shell in the flowing direction of entering air. An air returning opening is formed in the portion, corresponding to the fresh-air-and-returning-air mixing-filtering chamber, of the top wall of the unit shell. A secondary air exhausting opening is formed in the portion, corresponding to the portion above the corrugated-plate indirect evaporative cooler, of the top wall of the unit shell. According to the corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit, a self-cleaning winding type filter is adopted, dust and cotton fibers in returning air can be effectively filtered out accordingly, and therefore the returning air can be effectively used; and indirect evaporative cooling and hydrodynamic-force water spraying cooling are combined, and therefore the temperature in workshops of a textile mill can be effectively reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Continuous casting crystallizer protecting slag for medium-high carbon steel

The invention provides continuous casting crystallizer protecting slag for medium-high carbon steel. The continuous casting crystallizer protecting slag comprises, by mass percentage, 20.2-26.2% of CaO, 25.3-31.3% of SiO2, 1.1-2.7% of Al2O3, 5.5-8.3% of MgO, 7.4-12.2% of F, 9.5-14.1% of Na2O and 13.5-16.5% of C. Compared with the prior art, by designing the formula of the protecting slag, the problem that during practical use, lubrication of the protecting slag contradicts with heat transfer is solved, and thus the problem that currently, surface defects such as slag troughs and cracks frequently occur in medium-high carbon steel is solved. In the meanwhile, the yield of rolled products is increased, and the benefit of enterprise brands is increased.

Owner:WUHU XINXING DUCTILE IRON PIPES

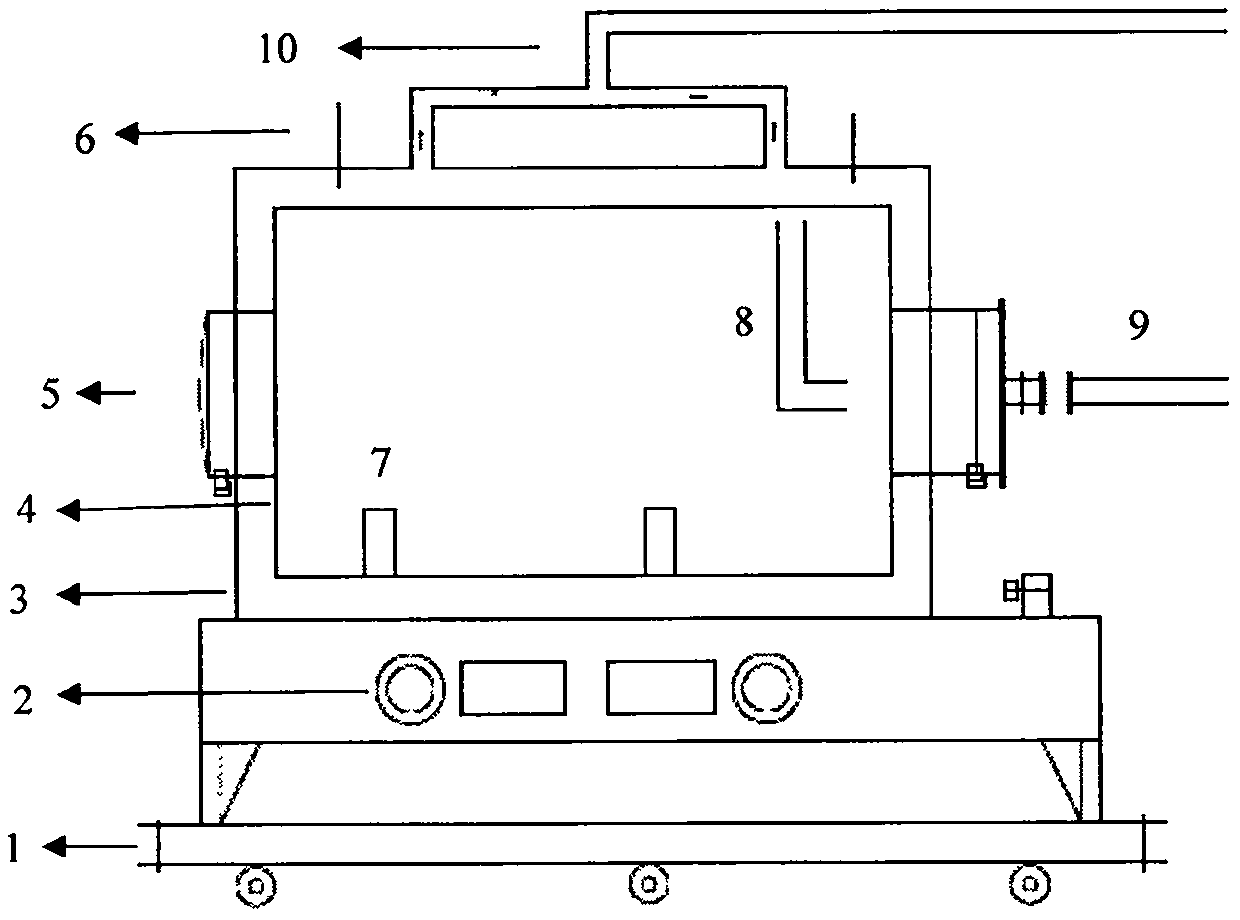

Fuel gas rotary furnace bio-organic matter heat treatment device

PendingCN107726336AImprove the heating effectSolving Heat Transfer ProblemsIncinerator apparatusProcess engineeringChiller

The invention relates to a fuel gas rotary furnace bio-organic matter heat treatment device. The fuel gas rotary furnace bio-organic matter heat treatment device comprises a burning furnace, a reactor, a pyrolysis gas re-burning device and a base. The burning furnace and the reactor are placed on the base provided whit universal wheels, so that moving of the heating furnace is convenient. The fuelgas rotary furnace bio-organic matter heat treatment device is provided with an air cooler, pyrolysis gas generated by the reactor is subjected to air cooling, water cooling and water sealing in sequence and then returns to the bottom of the burning furnace to burn under burning supporting of burning-supporting agents, and the condensing load is effectively reduced through the air cooler. The burning furnace conducts heating in a fuel gas burning mode. A cooking range is arranged, a pyrolysis gas returning pipe is arranged in the middle of the cooking range, and thus the pyrolysis gas and burning-supporting gas burn jointly.

Owner:华清绿景(北京)生态环境损害评估鉴定技术研究中心

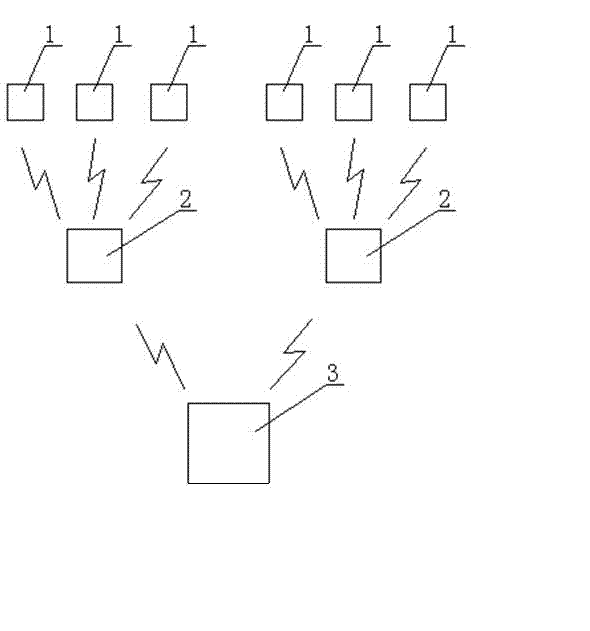

Heat metering apportioning device adopting temperature area method and without heat gauge and apportioning method

InactiveCN102928125ASolve heat transferSolve the problem of unfair heating feesTariff metering apparatusCalorimeterComputing centerThermodynamics

The invention provides a heat metering apportioning device adopting the temperature area method and without a heat gauge. The device is characterized by comprising indoor temperature collectors, building supervisors and a data computation center computer, wherein each indoor temperature collector is mounted inside a house of a user or each room of the house of the user; the indoor temperature collectors for users of the same house type in one building are equal in height, and are in signal connection with the building supervisor in a wireless or wired manner; each building supervisor is installed in each building on the middle floor door at the middle floor; and the building supervisors are in signal connection with the data computation center computer through a mobile communication network. The building heat gauge is not needed to be installed, the construction is simple, and the operation is reliable. The apportioning method is that the heating area of users and indoor temperature are adopt as metering references, the conventional heat supply systems of users are not involved, and the method is scientific, fair, reasonable and strong in operability.

Owner:JILIN HONGSHEN TECH +1

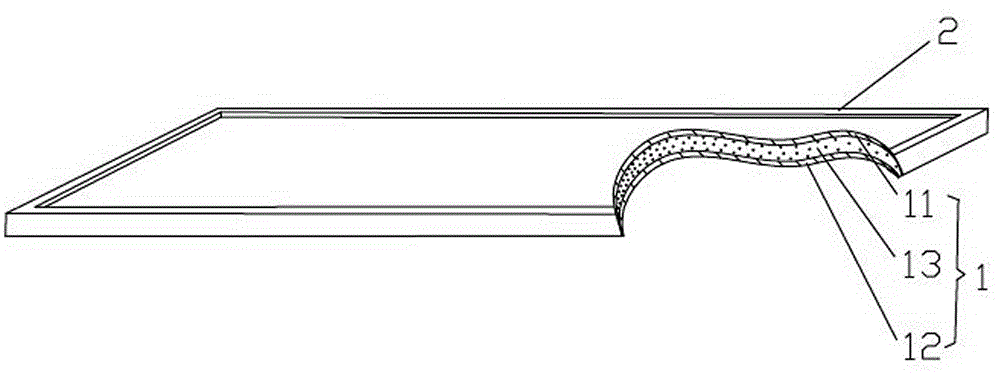

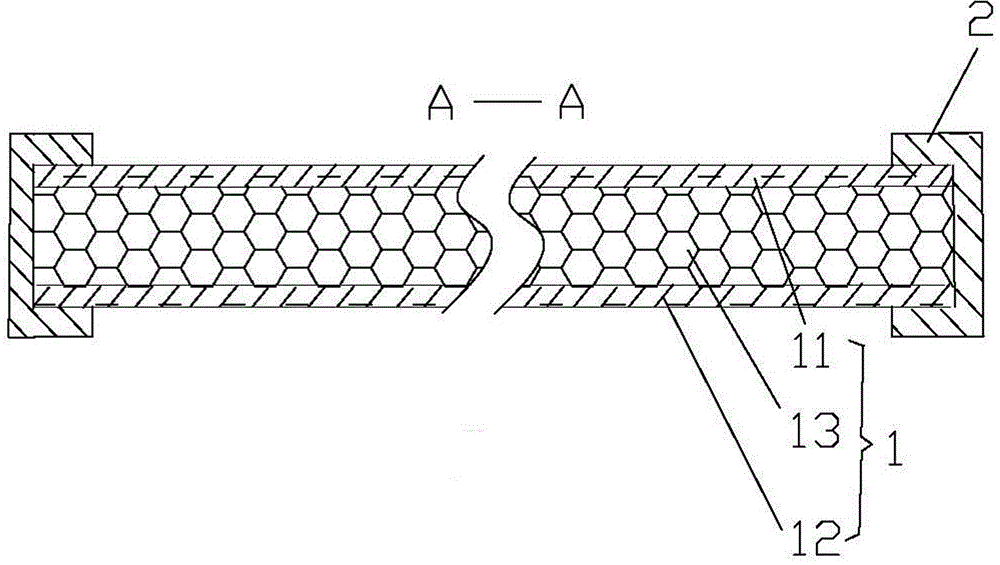

Heat-insulating color steel plate

InactiveCN103821238AGood heat insulationImprove insulation performanceRoof covering using slabs/sheetsHeat proofingSheet steelPolyvinyl chloride

The invention discloses a heat-insulating color steel plate, and relates to building and decoration plates. The heat-insulating color steel plate comprises a color steel plate body. A groove-shaped edge covering strip made of an athermic material, namely polyvinyl chloride (PVC), covers the edge of the color steel plate body. A mounting groove is formed in the groove-shaped edge covering strip. The side edge of the color steel plate body is embedded in the mounting groove of the groove-shaped edge covering strip. The color steel plate body comprises color coated steel plates arranged on two sides and a middle sandwich layer. The middle sandwich layer is made of a heat-insulating material. The groove-shaped edge covering strip made of the PVC which is good in heat insulation performance is adopted to cover the edge of the color steel plate body, so that the problem that aluminum alloy edge covering strips conduct heat to two sides of color steel plates in the prior art is solved, conventional concepts that people only pay attention to the heat-insulating material of the middle sandwich layer but neglect that the heat can be also conducted between two sides of the color steel plate through a lateral aluminum-alloy edge covering strip or mounting frame during production of the heat-insulating color steel plate are overcome, and heat insulation performance of the color steel plate is greatly improved.

Owner:广东澳星科技有限公司

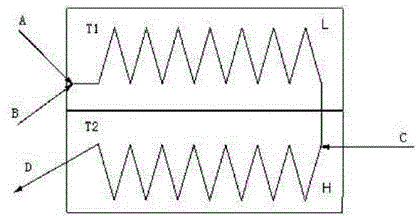

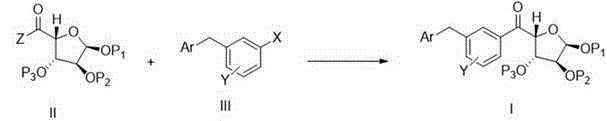

Method for preparing sodium-glucose co-transport enzyme inhibitor intermediate through utilization of micro-reactor

InactiveCN106279194AImprove securityReduce lossesSugar derivativesBulk chemical productionOrganic solventGlucose polymers

The invention discloses a method for preparing a sodium-glucose co-transport enzyme inhibitor intermediate through utilization of a micro-reactor. The method comprises: mixing a solution formed from a compound III and an organic solvent with a metal organic reagent in a micro-reactor unit (L) through material pipes, and allowing the mixed solution to flow to a micro-reactor unit (H) through (L); mixing a solution formed from a compound II and an organic solvent with the solution obtained in the first step in the micro-reactor unit (H) at a pre-set temperature (T2) through a material pipe, allowing the mixed solution to pass through the micro-reactor unit (H) and to flow out from an outlet after a reaction is over; post-treating the reaction liquid flowing out of the outlet to obtain a target product, which is sodium-glucose co-transport enzyme inhibitor intermediate I. The intermediate I is prepared through the micro-reactor, and the problem in heat release of such reaction is solved. The safety of the reaction is improved, the reaction yield is increased, the reaction time is shortened, and the reaction efficiency is improved. An amplification effect hardly exists in a micro-reactor, and therefore, compared with conventional batch-type technology, the method is more suitable for industrial production.

Owner:CHANGZHOU FANGNAN MEDICINE TECH CO LTD

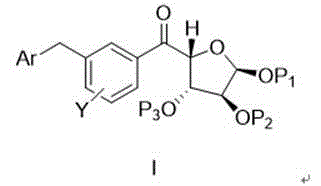

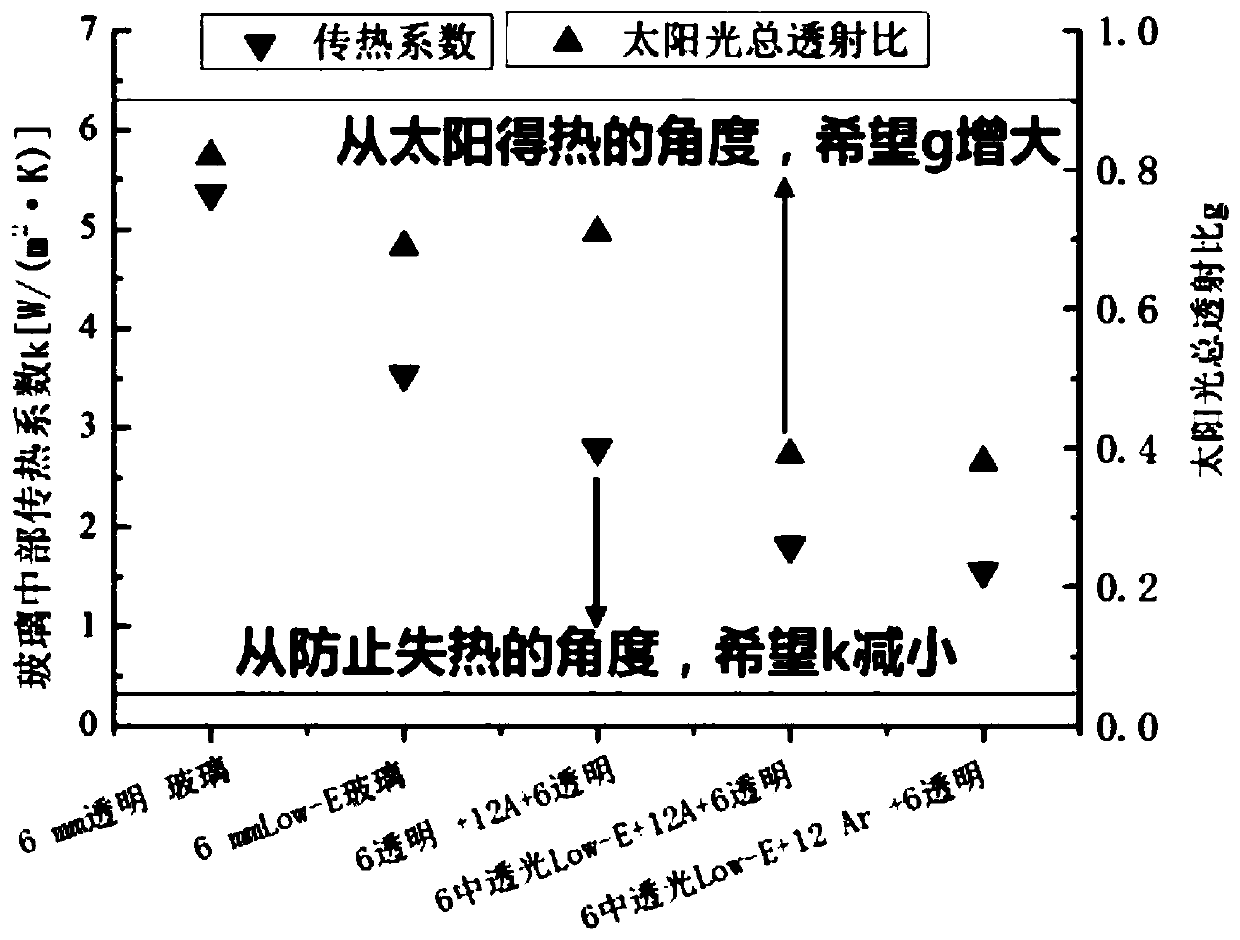

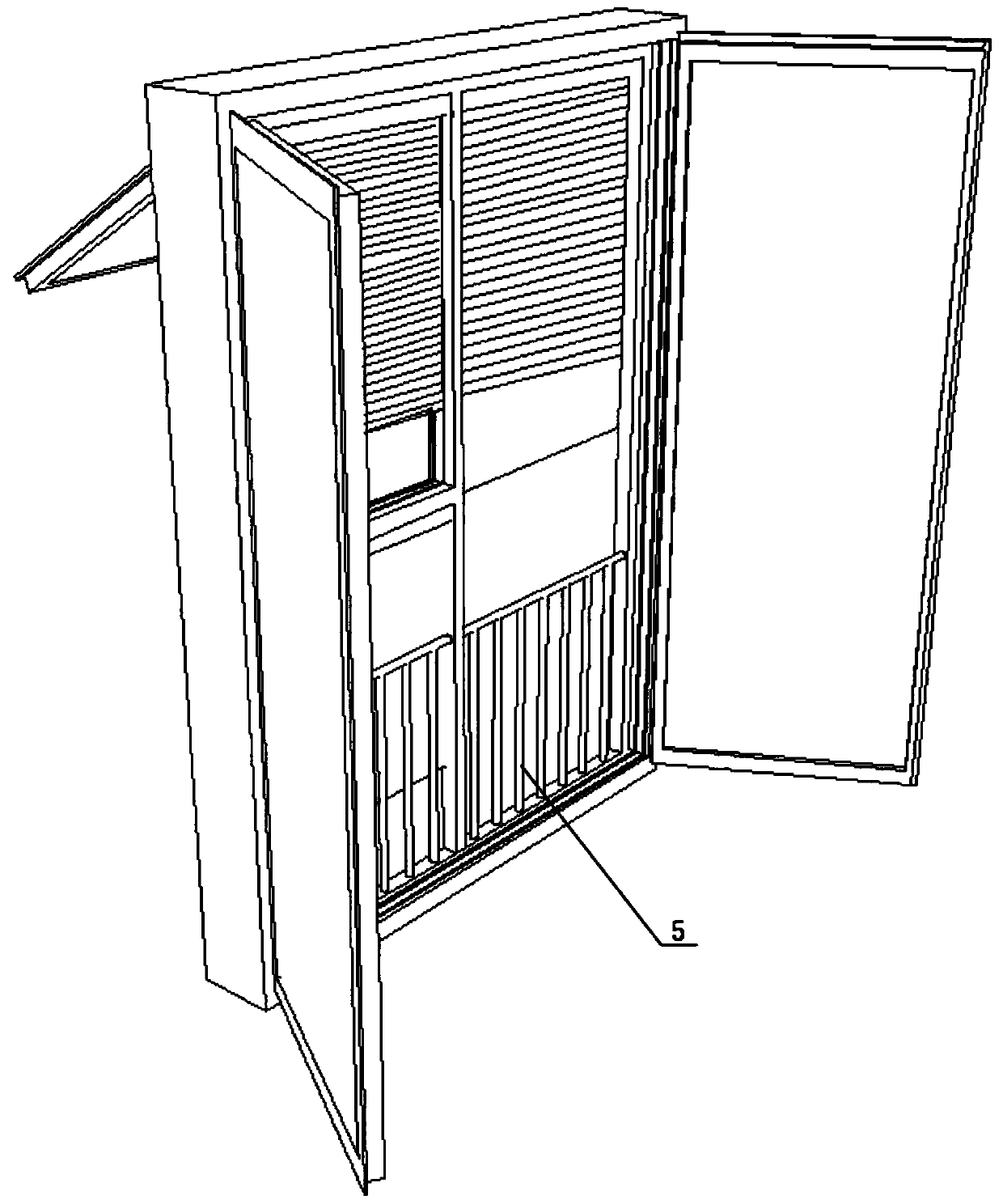

Dynamically adjustable high-performance window and operation control method thereof

PendingCN110761695ASolve the problem that the total solar transmittance is large during the daySolve heat transferFireproof doorsNoise insulation doors/windowsStructural engineeringMechanical engineering

The invention discloses a dynamically adjustable high-performance window and a control method thereof. The window includes a window frame. An inner layer window body and an outer layer window body areintegrated on one window frame. When the inner layer window body and the outer layer window body are fully opened or partially opened, when the inner layer window body and the outer layer window bodyare in a closed state, the inner layer window body and the outer layer window layer are sealed to form an air layer with a certain distance, and a movable sunshade curtain is arranged between the inner layer window body and the outer layer window body. The dynamically adjustable high-performance window adopts the structural design of an inner window body and an outer window body on the window frame, the movable sunshade curtain is arranged between the inner window body and the outer window body, the contradiction problem that an existing window has a large total solar transmittance during theday and a small heat transfer coefficient at night is effectively solved, moreover, while noise controllability is achieved, windows are installed conveniently, the cost is reduced, and an effectivesunshade effect can be achieved especially in summer.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD +1

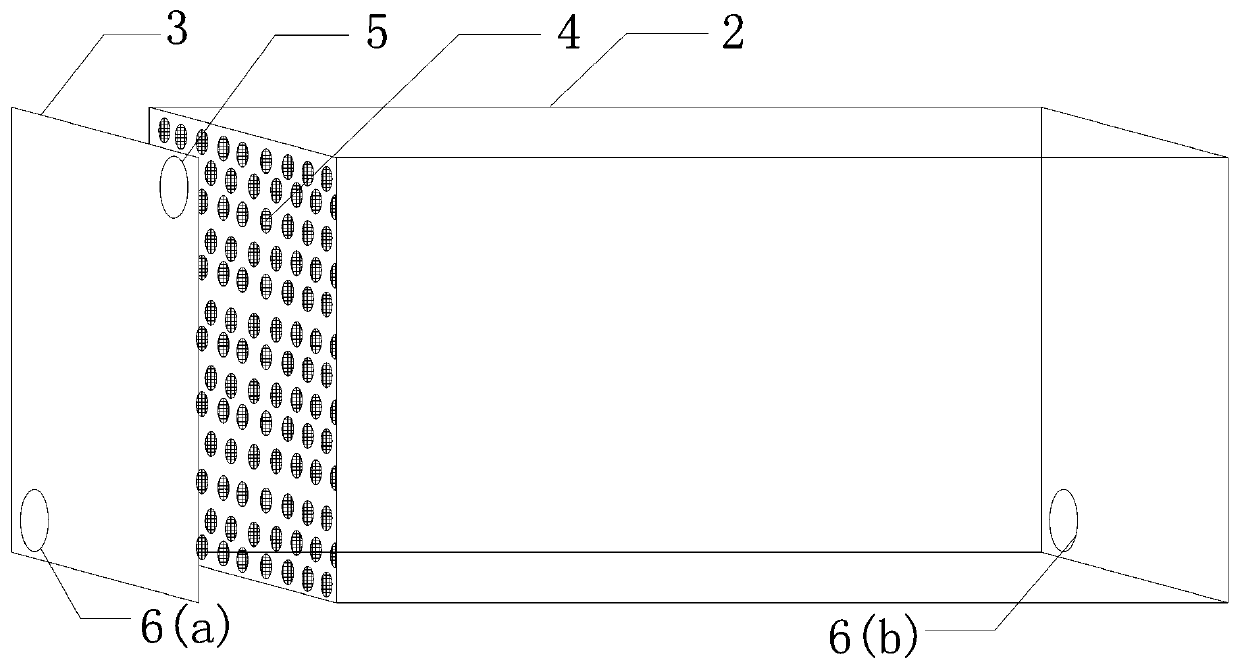

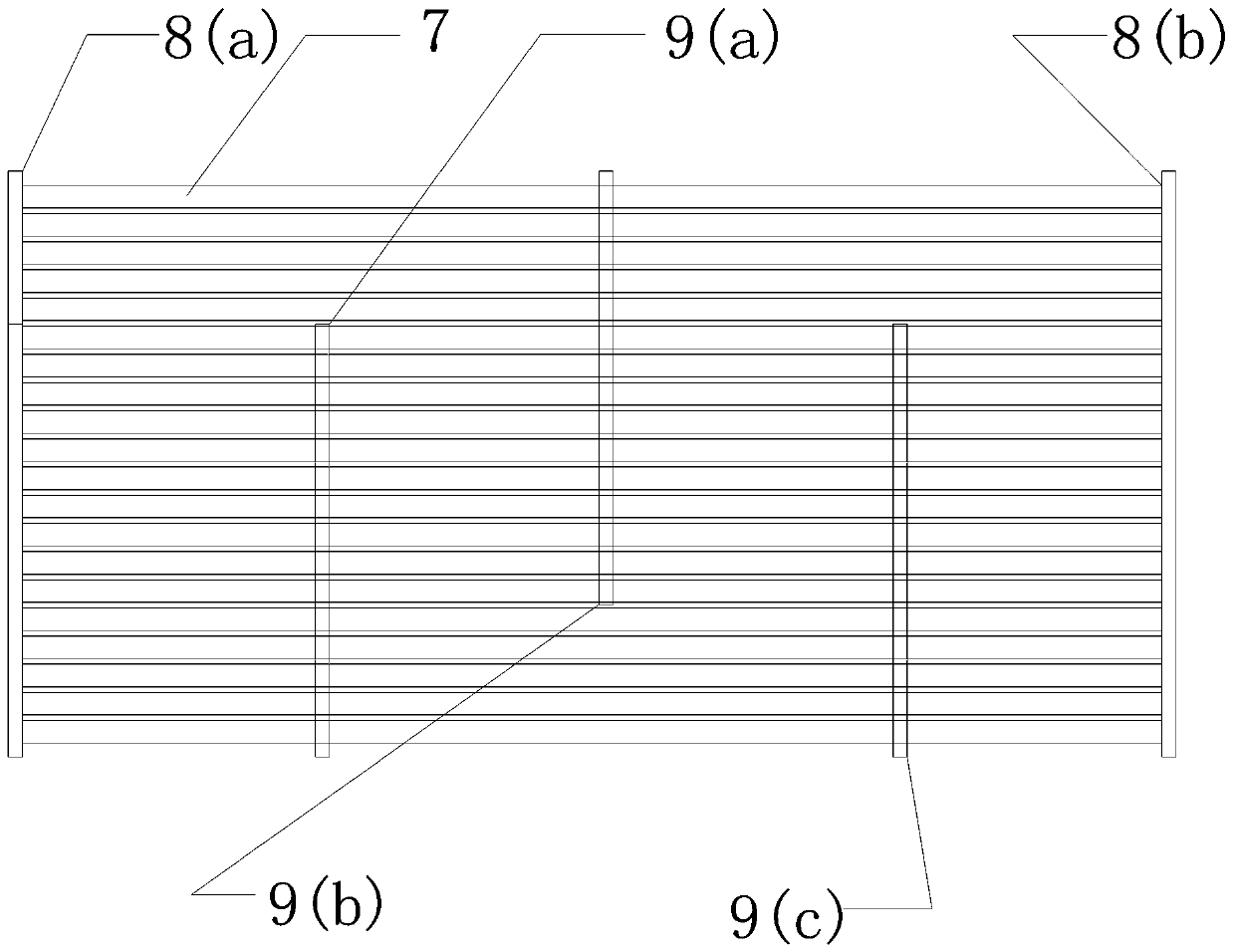

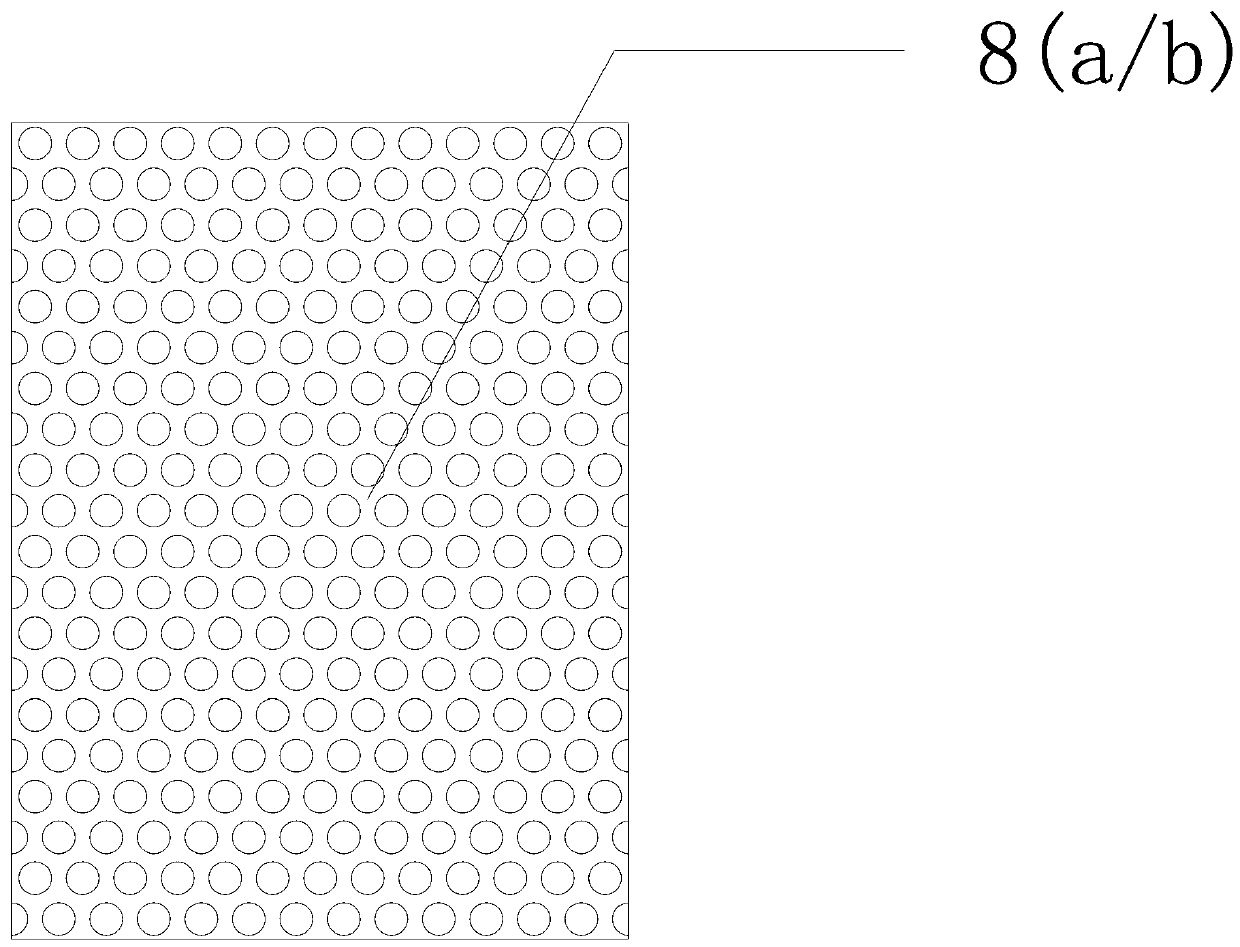

Magnetic refrigeration heat exchanger and refrigeration heating system and method

PendingCN110657603AImprove reliabilityImprove versatilityEvaporators/condensersMachines using electric/magnetic effectsCapillary TubingMagnetic refrigeration

The invention discloses a magnetic refrigeration heat exchanger and a refrigeration heating system and method. The magnetic refrigeration heat exchanger comprises a rectangular heat exchanger, whereinthe rectangular heat exchanger comprises a heat exchanger shell, a capillary matrix filled with a magnetic working medium is mounted in the heat exchanger shell, and cover plates are mounted at the two ends of the heat exchanger shell and encapsulates the capillary matrix inside the heat exchanger shell; the upper edges of the two side cover plates or the upper heat exchanger shell are processedwith a first through hole for air inlet and exhaust according to different processes in the heat exchanger; the lower edge of the two side cover plates or the upper heat exchanger shell is provided with a second through hole and a third through hole for circulating heat carrying and cooling fluid. The magnetic refrigeration heat exchanger aims at improving the reliability and universality of the heat exchanger and enhancing the heat exchange efficiency.

Owner:CHINA THREE GORGES CORPORATION

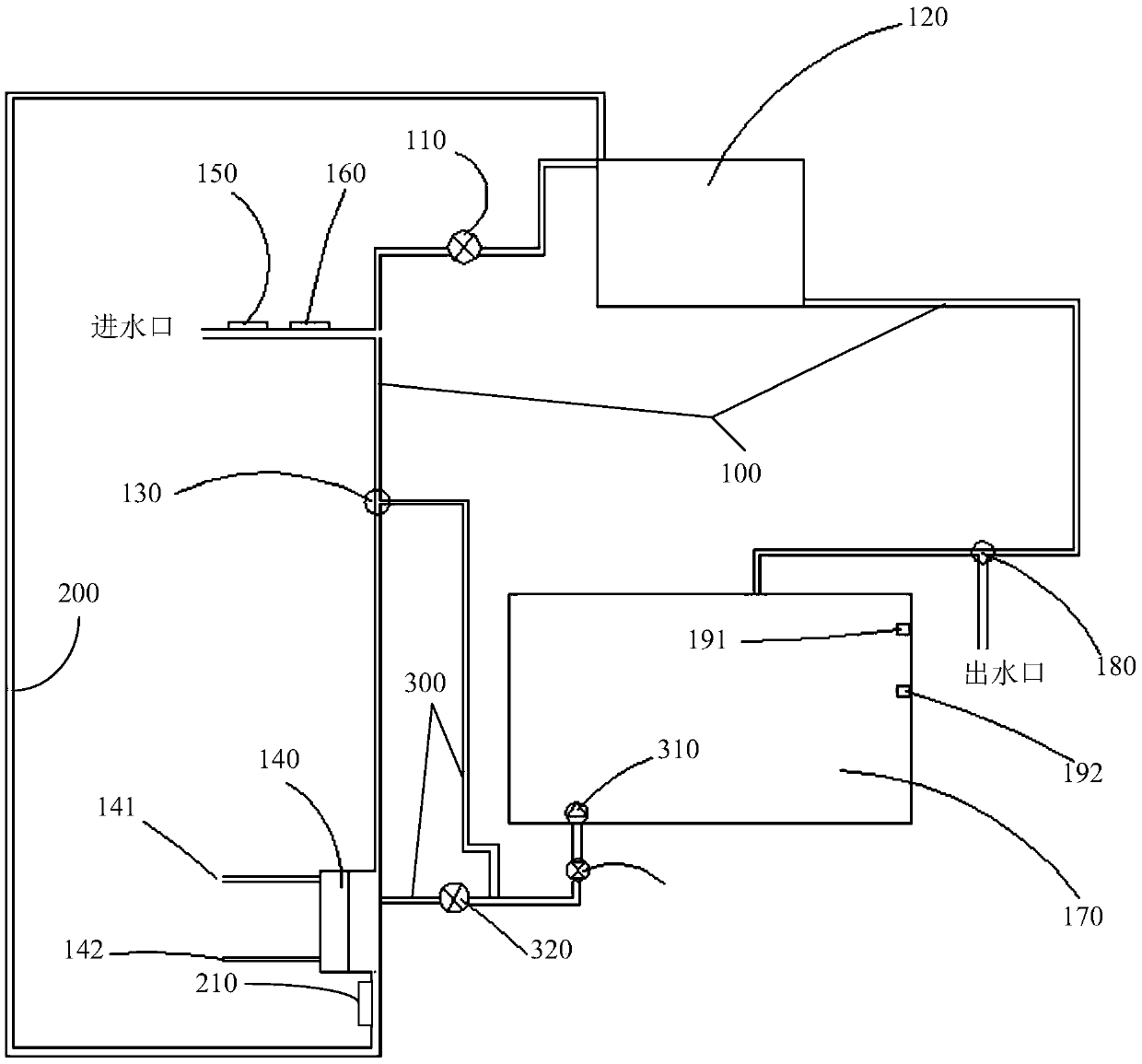

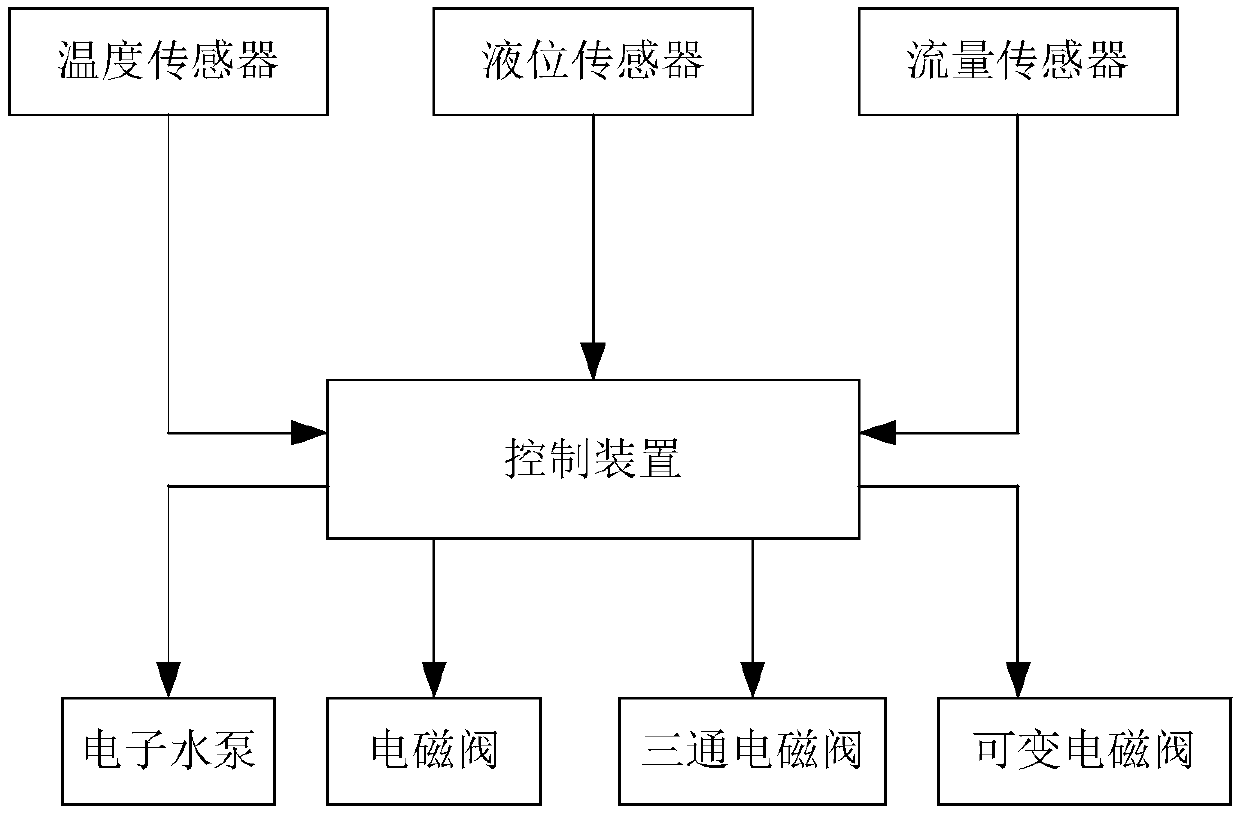

Vehicle air conditioning system and condensate water recycling system thereof

ActiveCN110920347AMonitor temperature in real timeReduce the temperatureAir-treating devicesVehicle heating/cooling devicesWater flowEngineering

The invention relates to the technical field of vehicles and provides a vehicle air conditioning system and a condensate water recycling system thereof. The invention comprises a condensate water conveying pipeline. Condensate water flowing into the condensate water conveying pipeline flows to a first heat exchange device through a first electromagnetic valve to be subjected to heat exchange so asto reduce the temperature in a vehicle or flows to a second heat exchange device through a first outlet of a first three-way electromagnetic valve to be subjected to heat exchange so as to reduce thetemperature of condensate water; the condensate water feedback pipeline is communicated with the second heat exchange device and the first heat exchange device; the temperature detection device is used for detecting the temperature of condensate water; control device. Moreover, a control device is configured as follows: when the temperature of the condensate water is smaller than or equal to a set temperature threshold value, the first three-way electromagnetic valve and the first electromagnetic valve are controlled, so that the condensate water enters the first heat exchange device to be subjected to heat exchange and cooling, and otherwise, the condensate water enters the second heat exchange device to be subjected to heat exchange and then flows to the first heat exchange device through the condensate water feedback pipeline. The problem that heat exchange cannot be conducted due to insufficient temperature of condensate water is solved.

Owner:GREAT WALL MOTOR CO LTD

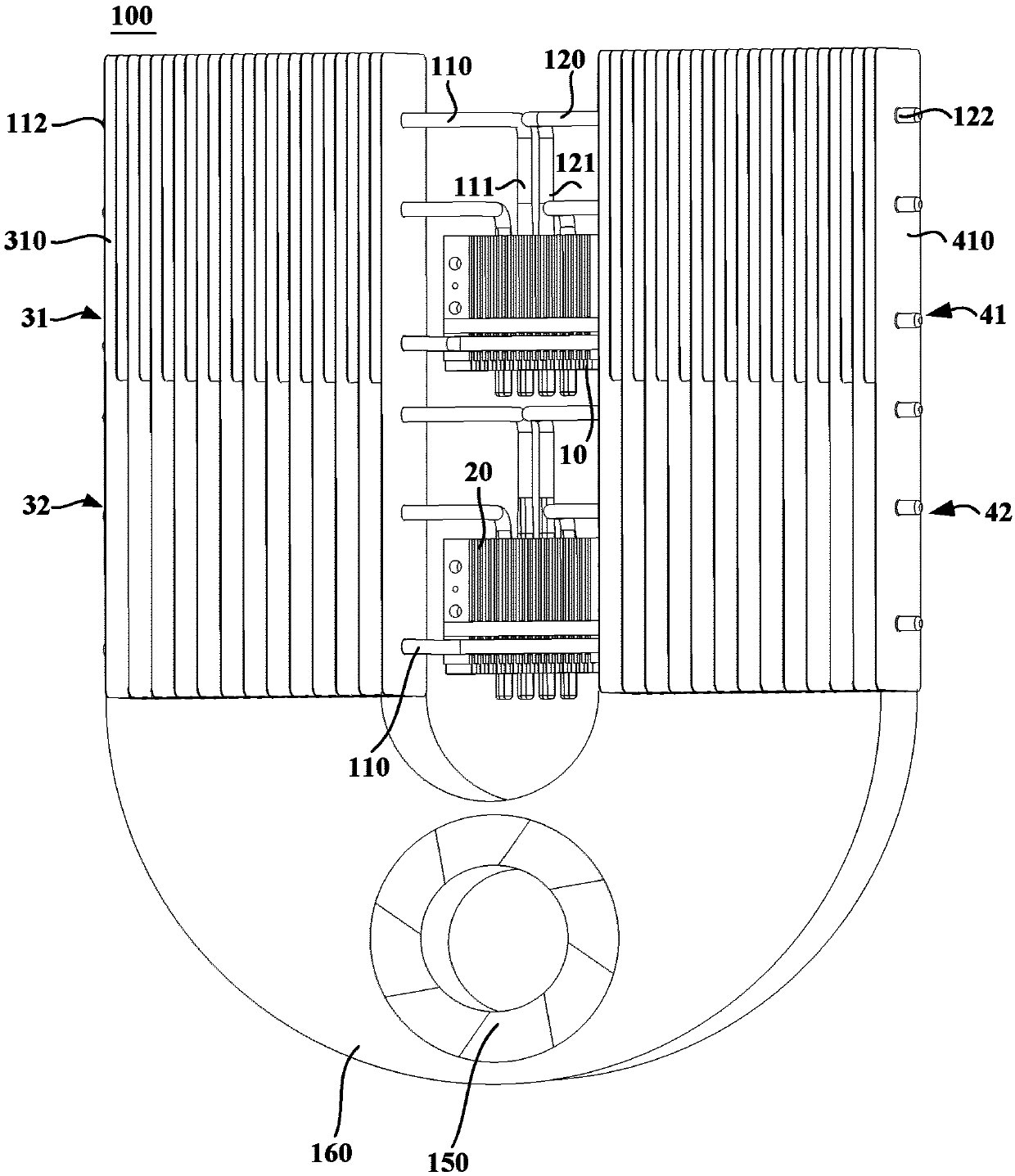

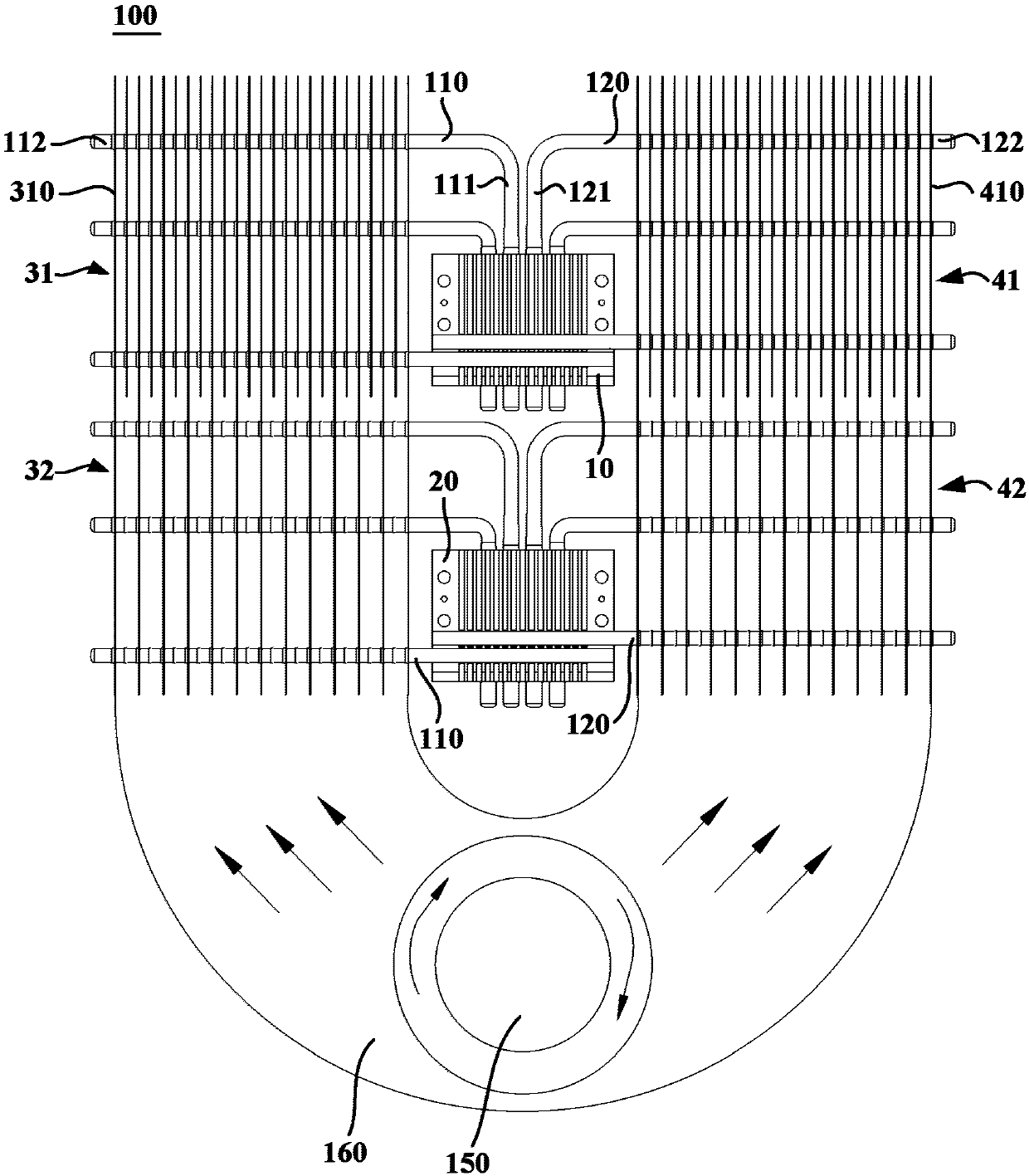

Heat exchange device and semiconductor refrigeration equipment with same

InactiveCN107764113AImprove heat transfer efficiencyReduce thicknessIndirect heat exchangersMachines using electric/magnetic effectsEngineeringRefrigeration

The invention provides a heat exchange device and semiconductor refrigeration equipment with the heat exchange device. The heat exchange device comprises at least one heat transfer substrate, at leastone first heat pipe, a first cooling fin set and a fan. Each heat transfer substrate is provided with a heat exchange face in hot connection with heat sources to receive heat from the corresponding heat sources. Each first heat pipe is provided with a connecting section connected with one heat transfer substrate and a heat radiation section extending from one end of the connecting section to thetransverse side of the heat transfer substrate. The first cooling fin set comprises a plurality of first cooling fins which vertically extend and are arranged in the transverse direction at intervals,and the first cooling fin set is arranged on the heat radiation sections of the first heat pipes to dissipate heat transmitted from the connecting sections to the heat radiation sections. The fan isarranged above or below at least one heat transfer substrate and / or the first cooling fin set and configured to drive air flow to vertically flow in a clearance between any two adjacent first coolingfins. The thickness of the heat exchange device can be reduced, and the heat radiation efficiency of the heat exchange device can be improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

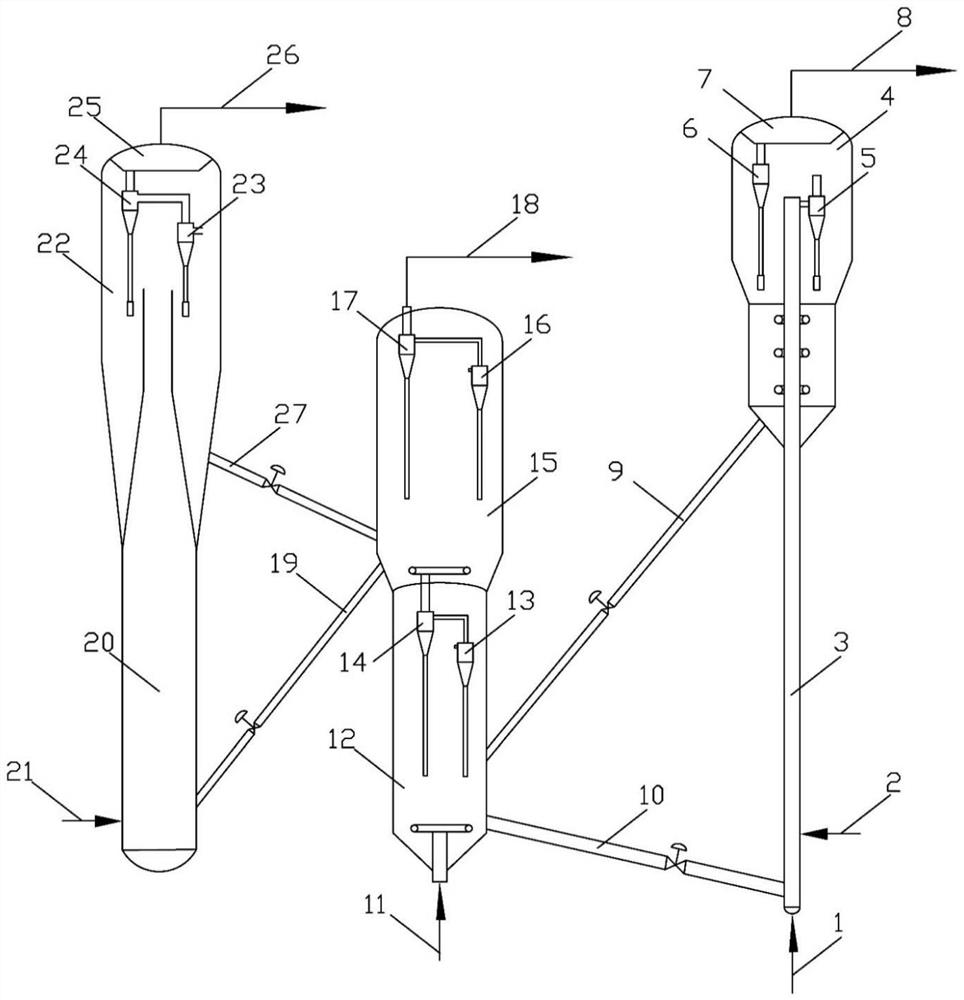

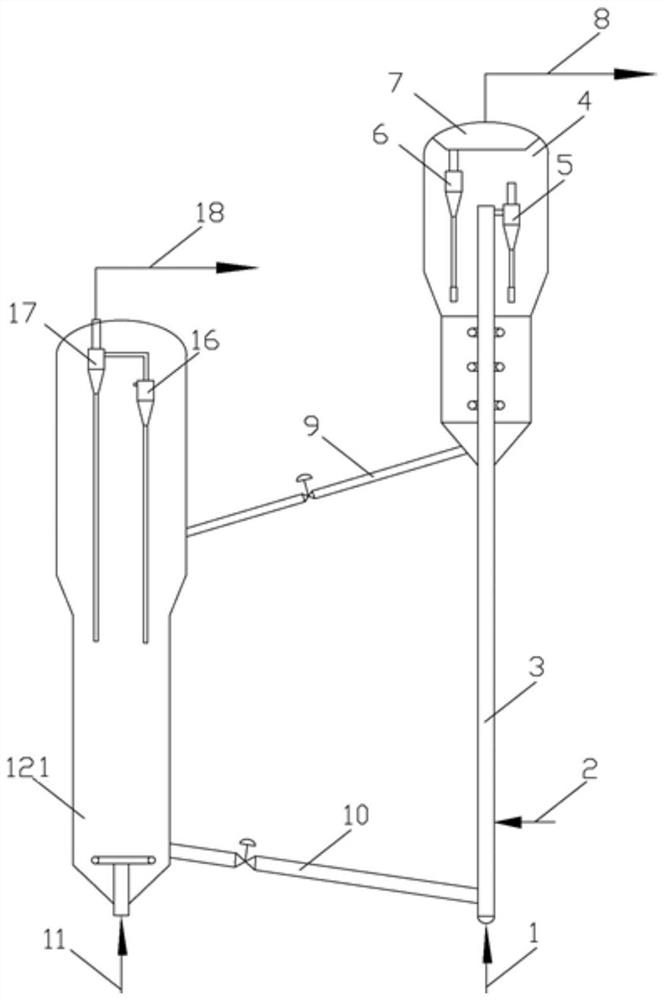

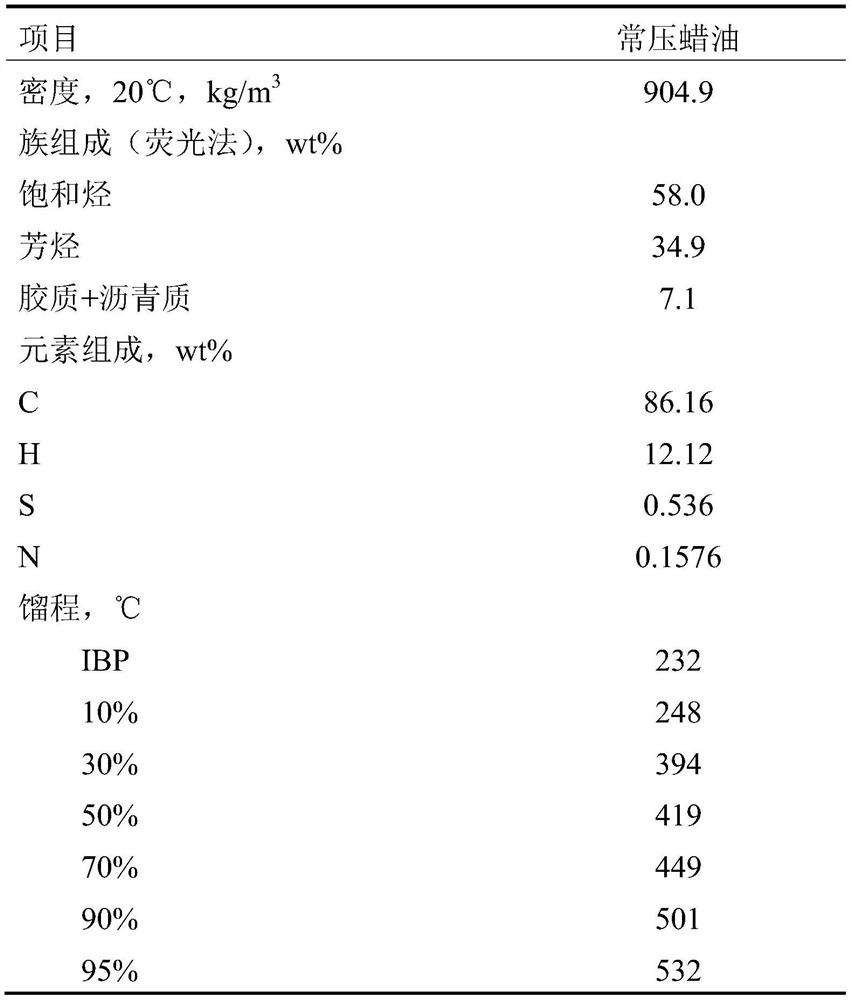

Device and method for increasing yield of low-carbon olefins

InactiveCN112939719AImprove reaction efficiencyHigh yieldHydrocarbonsBulk chemical productionAlkanePtru catalyst

The invention discloses a device and method for increasing the yield of low-carbon olefins, and belongs to the technical field of petroleum refining. According to the equipment, a first regenerator and a second regenerator which are connected in series are arranged, the first regenerator is connected with a catalytic cracking device, and the second regenerator is connected with an alkane dehydrogenation device, so that alkane dehydrogenation and catalytic cracking reaction are coupled, and the equipment is used for carrying out high-yield low-carbon olefin operation; the heat transfer problem of a fixed bed and a moving bed can be solved, continuous reaction regeneration is realized, the overall activity and the reaction efficiency of the alkane dehydrogenation catalyst are improved, the heat extraction cost and the heat supply cost are saved, and the process heat efficiency is remarkably improved; the alkane dehydrogenation reaction is maintained within the optimal reaction temperature by utilizing redundant heat of the catalytic cracking reaction, the reaction efficiency of alkane dehydrogenation is remarkably improved, in addition, alkane produced by the device can be recycled, the low-carbon olefin yield of the device is remarkably improved, meanwhile, hydrogen with the additional value higher than that of olefin is increased, and remarkable economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-level continuous polyaniline synthesis process

The invention discloses a multi-level continuous polyaniline synthesis process, which comprises the following steps: under the condition of -20-50DEG C, continuously adding aniline monomers, an oxidant and medium acid water solution into a multi-level serial tubular reactor to generate polyaniline. According to the process, high-concentration raw materials can be used at low-temperature condition, the emission of waste liquid can be reduced, polyaniline prepared by adopting the process has high yield, the relative molecular weight of prepared polyaniline is intensively distributed, and the tubular reactor used for synthesizing polyaniline cannot be influenced by the ratio of heat transfer area to reaction volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Power plant variable-load coal-fired furnace desulfurization wastewater zero discharge system

PendingCN112125463ASolve runnabilitySolve heat transferRecuperative heat exchangersSpecific water treatment objectivesFlue gasPower grid

The invention discloses a power plant variable-load coal-fired furnace desulfurization wastewater zero-discharge system which comprises an adjustable low-temperature flue gas waste heat recycling system device, a desulfurization wastewater evaporation and concentration system using waste heat as a heat source, a desulfurization wastewater pretreatment system and a system for finally treating concentrated desulfurization wastewater to zero discharge. The system has the beneficial effects that the influence of furnace load adjustment automatically performed by most power plant coal-fired furnaces along with power grid load change on a furnace tail flue gas waste heat recovery device and a desulfurization flash evaporation concentration system can be conveniently adapted through system adjustment, so that the waste heat recovery system and the low-temperature flash evaporation concentration system are integrally stable in operation; by automatically adjusting the temperature difference between the wall surface temperature of the waste heat recovery device and the temperature of the flue gas, the waste heat exchange amount is basically unchanged, a higher energy-saving effect is achieved, the waste heat of the flue gas is fully utilized, desulfurization wastewater does not need to be subjected to dosing pretreatment, and the wastewater treatment operation cost is reduced.

Owner:青岛润扬环境科技有限公司

Industrial preparation method of iron oxide-loaded cation resin base composite adsorbent

ActiveCN107537449AStrong loadPromote dissolutionOther chemical processesWater contaminantsSorbentResin-Based Composite

The invention discloses an industrial preparation method of an iron oxide-loaded cation resin base composite adsorbent, and belongs to the industrial production field of composite resin adsorbents forwaste water treatment. The preparation comprises the following steps: (A) acidic cation resin is added into a ferric salt solution in batch with stirring; (B) filtering is carried out, and filtrate is recycled and reused in the step (A); (C) vacuum hot air and drying are carried out for a Fe3+ composite intermediate loaded cation resin base; (D) the material obtained in the step (C) is added intoa sodium hydroxide solution in batch for carrying out a reaction, and filtering is carried out; (E) hydrochloric acid is added into the solid obtained in the step (D) for adjusting the pH value, andfiltering is carried out; (F) filtered solids obtained in the step (E) are washed with water, and water is filtered and dried. In the industrial preparation method of the iron oxide-loaded cation resin base composite adsorbent, ferric salt solution, alkali solution, acid solution and other materials can be recycled and reused, production cost and environment pollution can be greatly reduced, the method accords with national energy saving and emission reduction industrial policy at present, and the method is suitable for industrial promotion.

Owner:NANJING UNIV +1

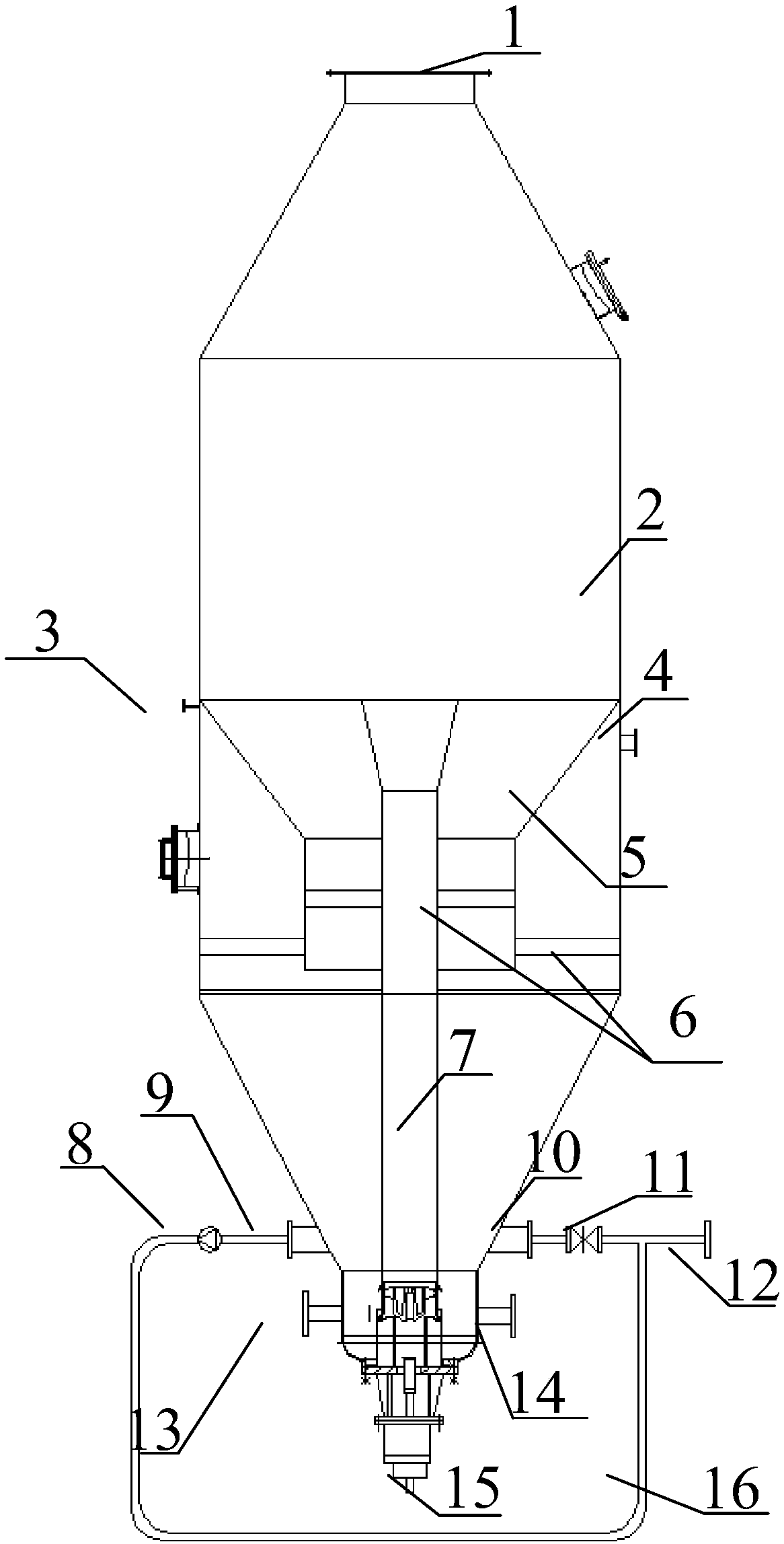

Continuous vacuum cooling crystallization device with lifting diversion

ActiveCN109045745ASolve inner wall foulingSolve heat transferSolution crystallizationCrystallization by component evaporationSlurryEngineering

The invention discloses a continuous vacuum cooling crystallization device with lifting diversion, comprising a crystallization chamber, a guide cylinder, a lifting cylinder, a forced circulation agitator and a slurry reflux circulation system. The guide cylinder and the lifting cylinder are installed inside the crystallization chamber, the forced circulation agitator is installed at the bottom end of the crystallization chamber, and a slurry return tube of the slurry reflux circulation system communicates with the bottom of the crystallization chamber. A hot material enters from two hot material inlets at the bottom of the crystallization device, and conducts vacuumed flash evaporation in the vicinity of the liquid surface after being lifted in the lifting cylinder by the forced circulation agitator. After the flash evaporation, mother liquid and crystal nucleus enter the lower part of the crystallization chamber along the guide cylinder for crystal growth and development, and the bottom slurry reflux system forms a partial reflux of the slurry. The continuous vacuum cooling crystallization device with lifting diversion utilizes an internal lifting diversion structure to increasethe reaction residence time, solves problems in the conventional batch production that the production efficiency is low, the over-saturation cannot be effectively controlled, and an external circulation heat exchanger and a circulation pipe are easy to scale. At the same time, the solid content in the crystallization device is effectively maintained, the equipment operation is stable, and the cleaning cycle is prolonged.

Owner:自然资源部天津海水淡化与综合利用研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com