Method for preparing sodium-glucose co-transport enzyme inhibitor intermediate through utilization of micro-reactor

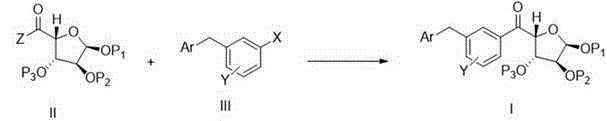

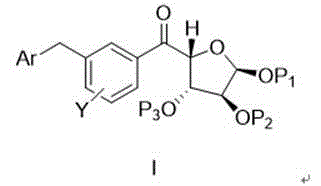

A kind of technology of microreactor and glucose is applied in the field of intermediate I preparing antidiabetic drug Sotagliflozin, and achieves the effect of reducing loss, shortening production time and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

[0035] Compound IV (150.3 g, 0.55 mol) was dissolved in THF (150 mL), and 1.3 mol / L tert-butylmagnesium chloride solution (44.6 mL) was added dropwise at room temperature, and stirred for 30 minutes to form a THF solution of Compound IIa.

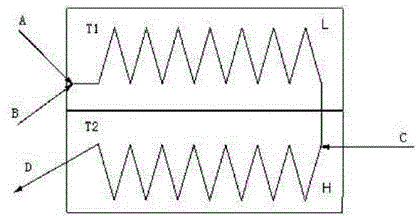

[0036] Prepare 163 ml (162.8 g, 0.5 mol) of 1 g / mL compound IIIa in tetrahydrofuran, and pass the above tetrahydrofuran solution into material channel A, and control the flow rate to 0.1 ml / min. At the same time, 200 milliliters of 2.5 mol / liter n-butyllithium solutions were passed into the material channel B, and the control flow rate was 0.12 milliliters / minute, wherein the preset temperature T1 of the micro-reaction unit L was minus 80 ~ minus 75 ° C . Subsequently, the tetrahydrofuran solution of the above-mentioned compound IIa is passed into the material channel C, and the flow rate is controlled at 0.3 ml / min, wherein the preset temperature T2 of the micro-reaction unit H is minus 80 ~ minus 70 ° C. After the reaction is...

Embodiment 2

[0038]

[0039] Prepare 932 ml (186.3 g, 0.5 mol) of THF solution of compound IIIb at 0.2 g / mL, and pass the above THF solution into material channel A, and control the flow rate at 1 ml / min. Simultaneously feed 250 milliliters of isopropyl lithium chloride magnesium chloride solution of 2 mol / liter in material passage B, control flow rate to be 0.25 milliliters / minute, wherein the preset temperature T1 of micro reaction unit L is 0~minus 5 ℃ . Subsequently, 693 milliliters (277 grams, 0.55 moles) of the 0.4 g / ml toluene solution of the above-mentioned compound IIb was passed into the material channel C, and the control flow rate was 0.4 ml / min, wherein the preset temperature T2 of the micro-reaction unit H was 0~ 5°C. After the reaction is completed, pass the reaction liquid flowing out of outlet D into saturated ammonium chloride solution (1 liter), control the temperature at 15-25 °C, and when the system is completely passed through, stir for 1 hour, extract with toluen...

Embodiment 3

[0041]

[0042] Compound V (239.0 g, 0.55 mol) was dissolved in toluene (1500 ml), and thionyl chloride (77.3 g, 0.65 mol) was added dropwise at room temperature, stirred at 60-65 °C for 2 hours, and concentrated under reduced pressure to The total volume was 650 mL, resulting in a solution of compound IIc in toluene.

[0043] Prepare 932 ml (186.3 g, 0.5 mol) of THF solution of compound IIIc at 0.2 g / mL, and pass the above THF solution into material channel A, and control the flow rate at 1 ml / min. Simultaneously feed 250 milliliters of isopropyl lithium chloride magnesium chloride solution of 2 mol / liter in material passage B, control flow rate to be 0.25 milliliters / minute, wherein the preset temperature T1 of micro reaction unit L is 0~minus 5 ℃ . Subsequently, 693 milliliters (277 grams, 0.55 moles) of the 0.4 g / ml toluene solution of the above-mentioned compound IIb was passed into the material channel C, and the control flow rate was 0.4 ml / min, wherein the preset t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com