Heat-insulating color steel plate

A technology of color steel plate and color-coated steel plate, which is applied to roofs, building components, and roof coverings using flat/curved panels, can solve problems such as poor thermal insulation performance, and achieve improved thermal insulation performance and thermal insulation performance. Good, versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

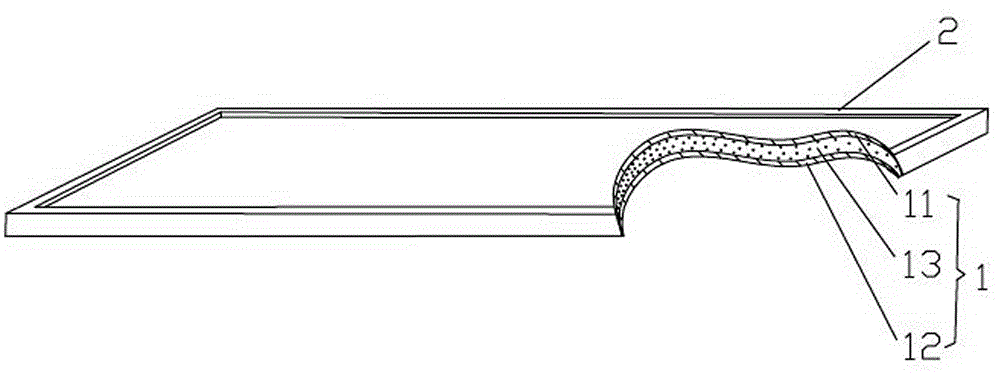

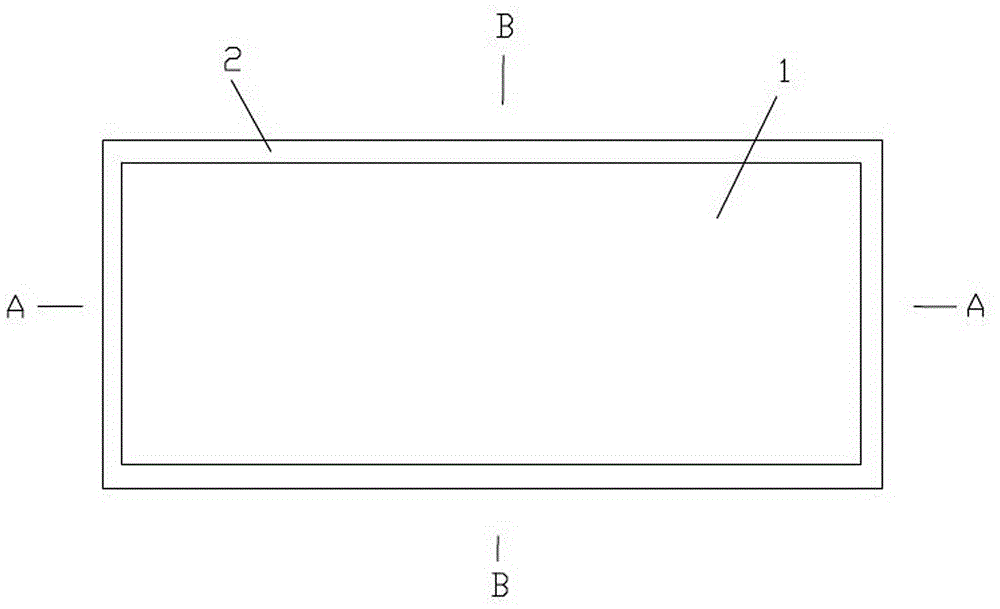

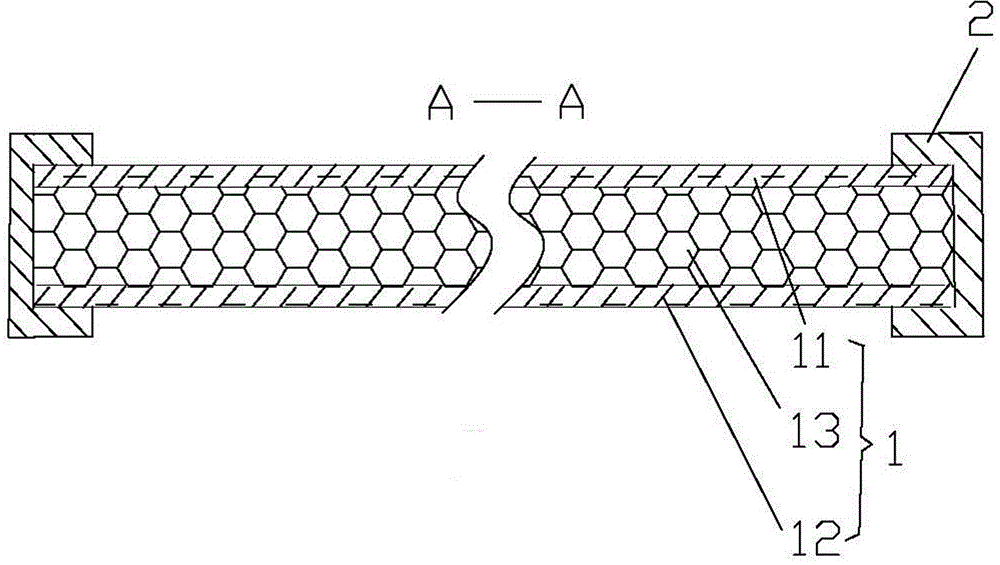

[0026] Such as Figures 1 to 5 As shown, a heat-insulating color steel plate includes a color steel plate 1, and the color steel plate is hemmed with a groove-shaped edging strip 2 made of a non-heat-conducting material, and the groove-shaped edging strip 2 forms an installation groove 21, The side edge of the color steel plate 1 is embedded in the installation groove 21 of the channel-shaped edging strip 2 .

[0027] The material of the grooved edge wrapping strip 2 is polyvinyl chloride (PVC).

[0028] Described color steel plate 1 comprises the first color-coated steel plate 11 and the second color-coated steel plate 12 that are arranged oppositely, and the middle sandwich layer 13 is set between the first color-coated steel plate 11 and the second color-coated steel plate 12, and the middle sandwich layer 13 Made of thermal insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com