Method for combined production of ammonium sulfate and ammonia water through heat pump flash evaporation, stripping and deamination

An ammonium sulfate and flash steam technology, applied in chemical instruments and methods, ammonia preparation/separation, heating water/sewage treatment, etc., can solve problems such as waste of raw materials, reduce consumption, and solve the effect of high steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

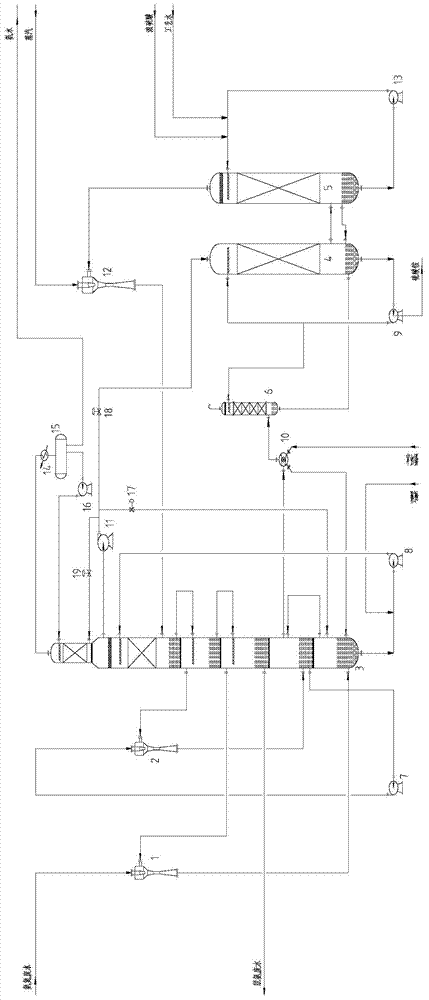

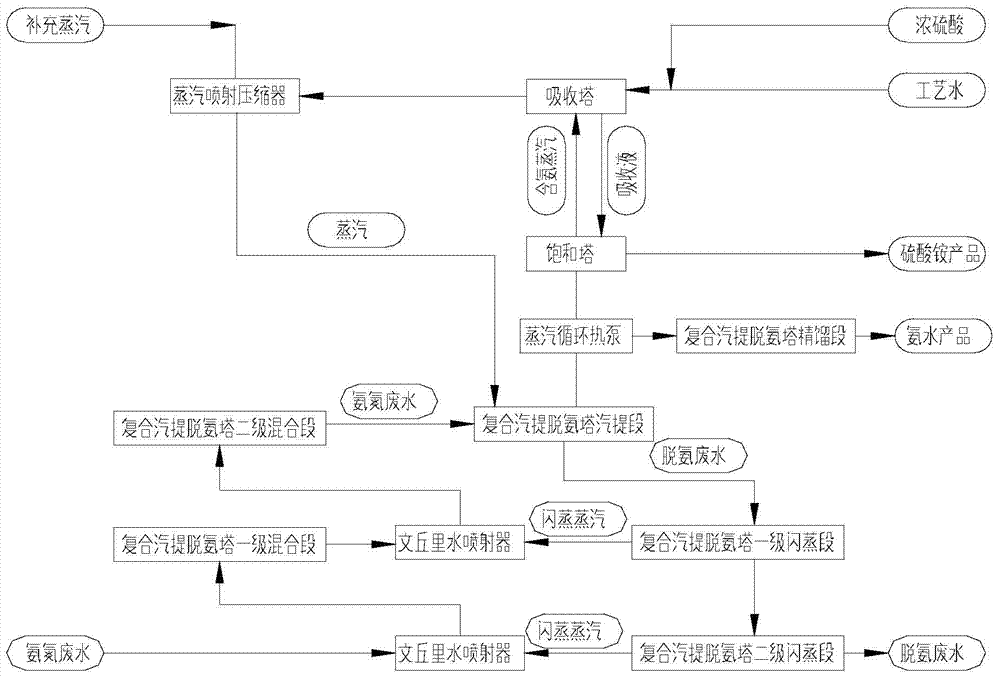

[0051] to combine figure 1 with figure 2 , the present embodiment is used to illustrate the method for the co-production of ammonium sulfate and ammonia by heat pump flash steam stripping and deaminization of the present invention, and the method comprises the following steps:

[0052] (a) The ammonia nitrogen wastewater is sent to the first Venturi water injector 1, and the ammonia nitrogen wastewater is subjected to vapor-liquid quenching and heat exchange with the steam ejected from the secondary flash section of the compound stripping deamination tower 3, and then enters the compound stripping The first vapor-liquid separation is carried out in the primary mixing section of the deamination tower 3; the non-condensable gas in the secondary flash section of the compound stripping deamination tower 3 is extracted by the liquid ring vacuum pump 10, and the non-condensable gas is extracted by the tail gas absorption tower 6 The ammonia gas carried out is absorbed and discharg...

Embodiment 2

[0062] This example is used to illustrate the method of the present invention for the co-production of ammonium sulfate and ammonia water by heat pump flash stripping and ammonia removal.

[0063] According to the method of Example 1, the difference is that in step (c), in the process of generating ammonia water, the generated ammonia water is refluxed to the top of the rectifying section of the compound stripping deamination tower 3 through the reflux pump 16 with a reflux ratio of 2, and finally The ammonia water product concentration that produces is 15% by weight.

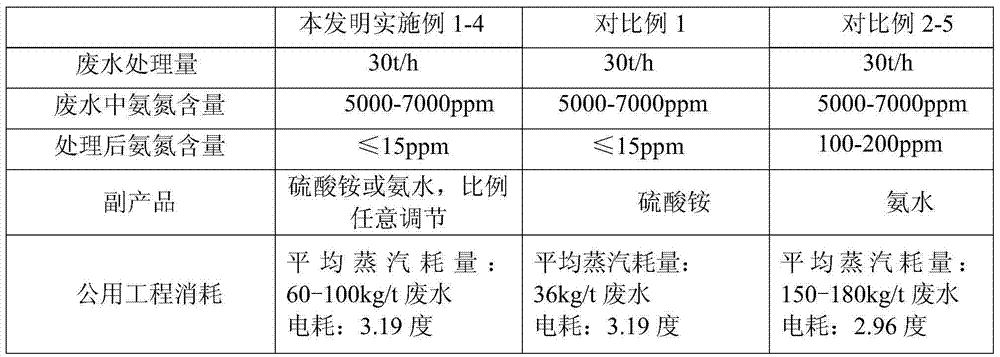

[0064] See Table 1 for the results of wastewater treatment volume, ammonia nitrogen content in wastewater, ammonia nitrogen content after treatment, by-products, and public works consumption in this embodiment.

Embodiment 3

[0066] This example is used to illustrate the method of the present invention for the co-production of ammonium sulfate and ammonia water by heat pump flash stripping and ammonia removal.

[0067] According to the method of Example 1, the difference is that in step (c), during the process of generating ammonia water, the generated ammonia water is refluxed to the top of the rectifying section of the compound stripping deamination tower 3 through the reflux pump 16 at a reflux ratio of 0, and finally The concentration of the ammonia water product produced was 3% by weight.

[0068] See Table 1 for the results of wastewater treatment volume, ammonia nitrogen content in wastewater, ammonia nitrogen content after treatment, by-products, and public works consumption in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com