Corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit

An evaporative cooling air-conditioning and fluid power technology, which is applied in air-conditioning systems, heating methods, mechanical equipment, etc., can solve problems such as blockage of spraying devices or heat exchange devices, shortening the service life of machines, and energy waste, so as to meet the requirements of the working environment , The effect of energy saving is obvious, and the effect of shortening the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

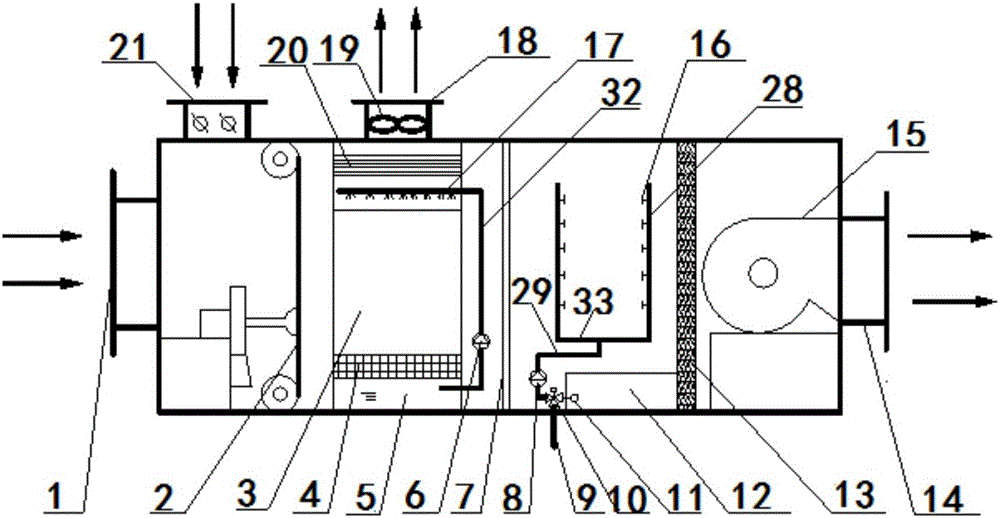

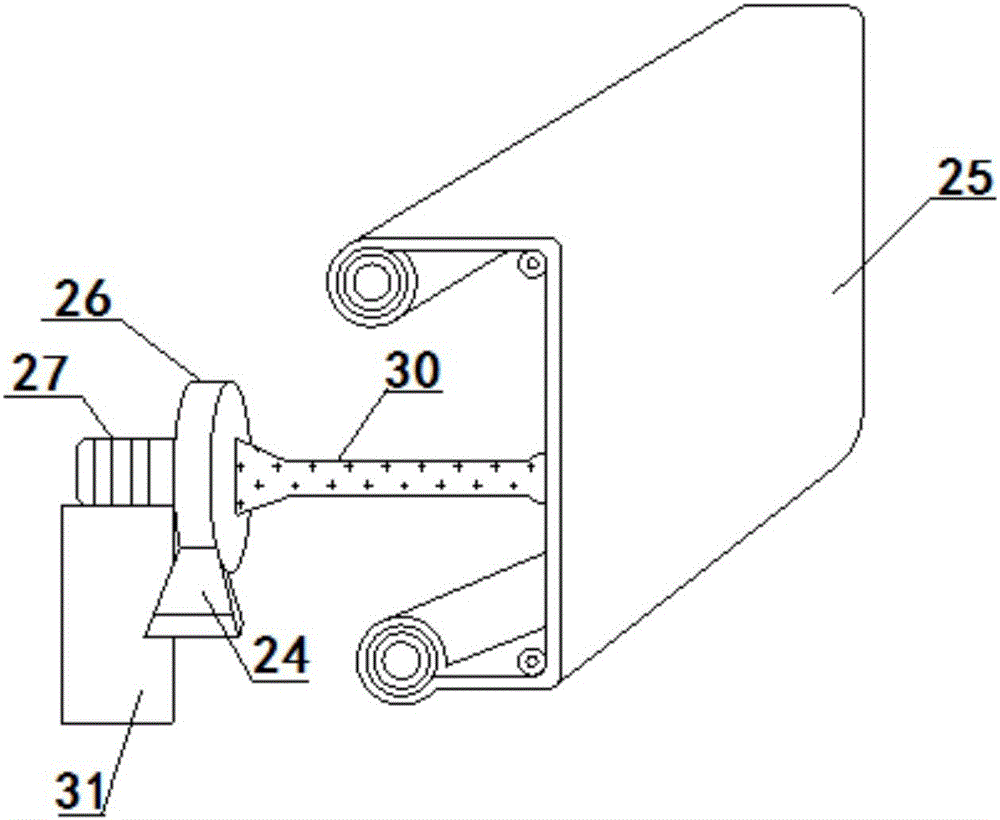

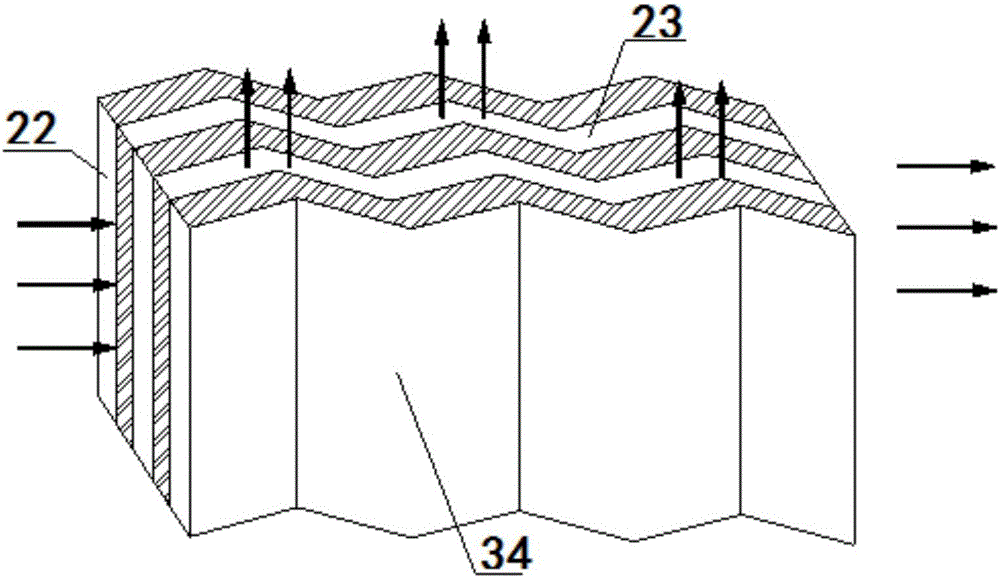

[0027] The composite evaporative cooling air conditioner unit of folding plate type indirect-hydrodynamic water spray chamber of the present invention, its structure is as follows figure 1 As shown, it includes the organic unit housing, and the opposite side walls of the unit housing are respectively provided with an air inlet 1 and an air supply port 14; the unit housing is sequentially provided with a new return air mixing-filter chamber, Folded-plate indirect evaporative cooler, flow equalizer 7, hydrodynamic water spray device, water baffle a13 and blower 15, new return air mixing-air return port 21 is set on the top wall of the unit shell corresponding to the filter chamber, folded-plate indirect A secondary air exhaust port 18 is provided on the corresponding top wall of the unit housing above the evaporative cooler.

[0028] Air volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com