Double-wall cooling structure of hyperbolic turbulent flow column with air film holes

A cooling structure, air film hole technology, applied in the direction of combustion methods, lighting and heating equipment, continuous combustion chamber, etc., can solve the problems of high pressure loss of cold air, large internal flow resistance, etc., to reduce damage, weaken flow resistance, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

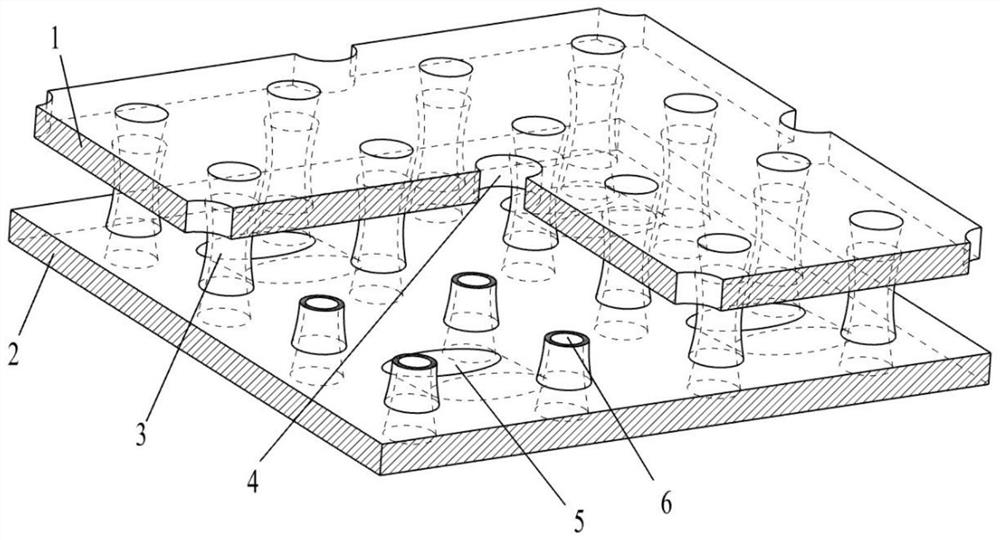

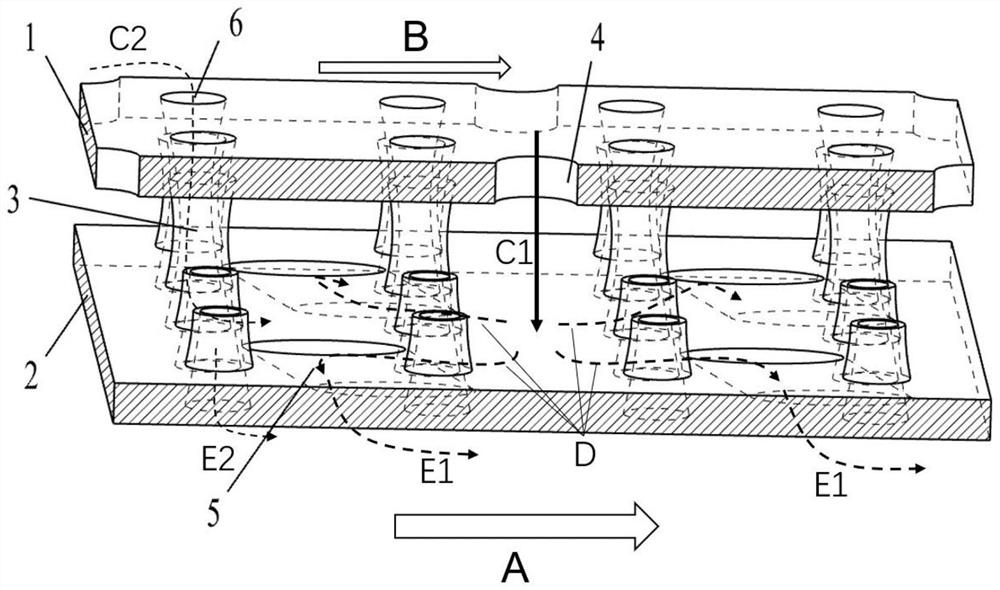

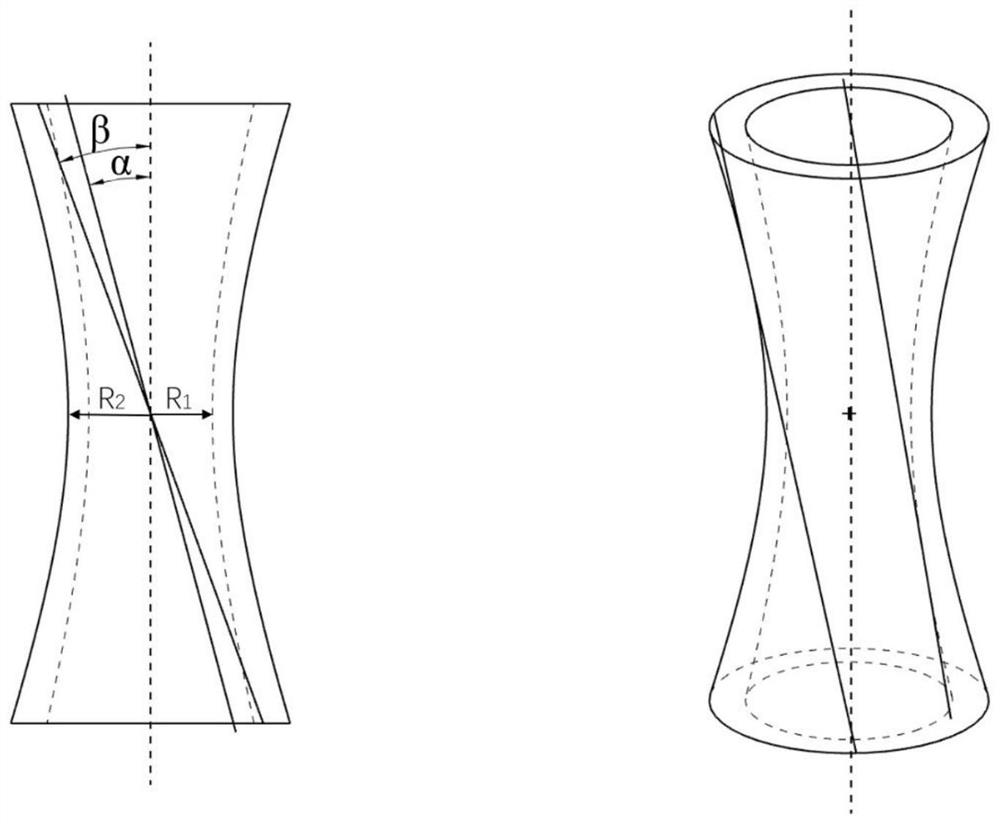

[0034] This embodiment is a double-walled cooling structure with a hyperbolic spoiler column with air film holes. The thickness of impact orifice plate and air film orifice plate is 1.5mm. Impact hole diameter D f 3mm, forming an angle of 90° with the impact orifice plate, the impact distance is 4mm, and the hole spacing and hole row spacing are both 2.7D f . The air film hole and the airflow in the inner channel form a 30° inclination angle, and the diameter of the air film hole is D f 3mm, hole spacing and hole spacing are both 2.7D f . Air film holes and impact holes are arranged alternately; hyperbolic spoiler columns are arranged between air film holes and impact holes, and air film hole channels in hyperbolic spoiler columns are separated by a certain distance R from the axis of the columns. 1 And the straight line forming a certain angle α on the axis is rotated around the axis of the column to obtain, R 1 Take it as 0.25D f , α is taken as 15°; the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com