Ice storage tank with de-cold device of evaporative supercooled water continuous ice-making system

A technology of ice storage tank and supercooled water, which is applied in the direction of ice making, ice making, fixed filter element filter, etc., can solve the problems of complex device and reduce the ice storage rate of ice storage tank, and achieve simple structure, low cost and solution good cold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

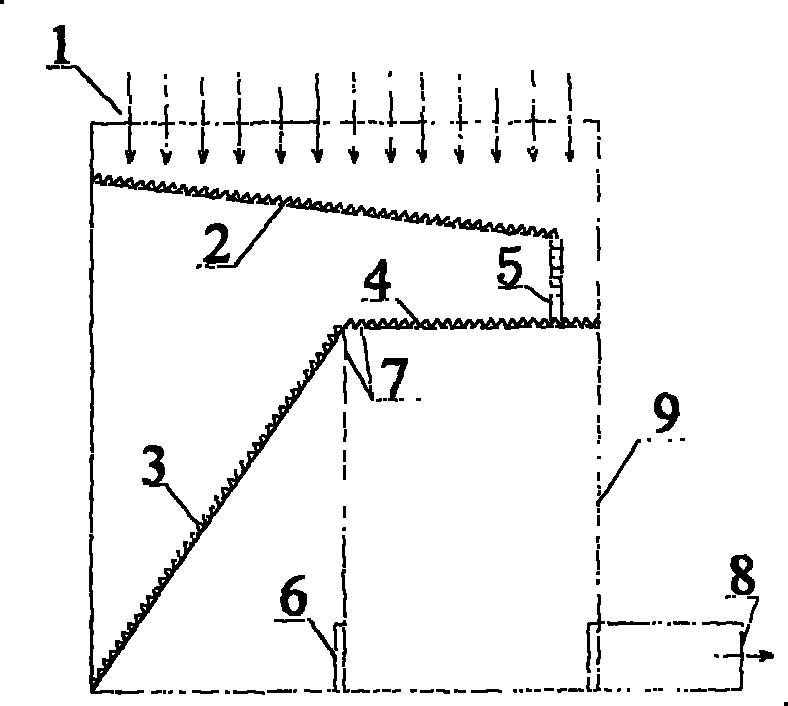

[0020] The structure of the present invention includes an ice storage tank body 9 provided with a supercooled water inlet 1 and a cold water outlet 8, the water retaining plate 7 is located in the ice storage tank body 9, and a filter screen is provided at the cold water outlet at the lower part of the water retaining plate 7 6. The decooling device 4 is installed horizontally on the water baffle 7, and the decooling device 3 is installed obliquely between the bottom of the ice storage tank and the cooling device 4; a spring device 5 is provided on the decooling device 4, and the decooling device 2 is inclined It is installed between the spring device 5 and the ice storage tank casing 9 walls.

[0021] Through the ice storage tank box body 9 with the cold water inlet 1 and the cold water outlet 8, the first piece of cooling device 2 is installed on the spring 5 with an inclination at a certain angle, and a certain distance is left between the end and the wall of the ice storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com