Patents

Literature

60results about How to "Meet the requirements of the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

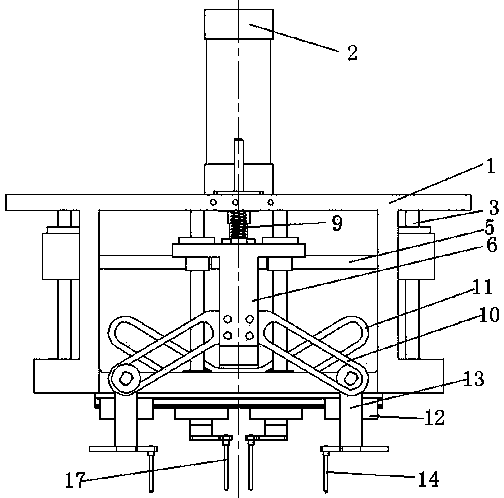

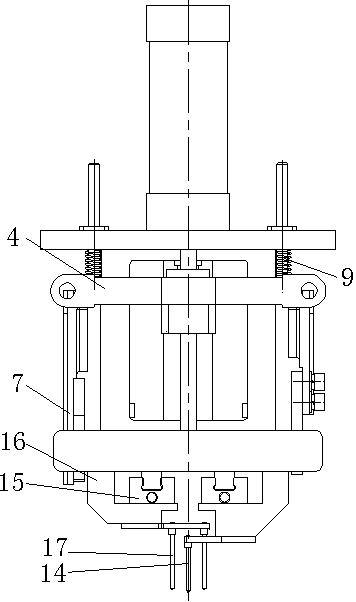

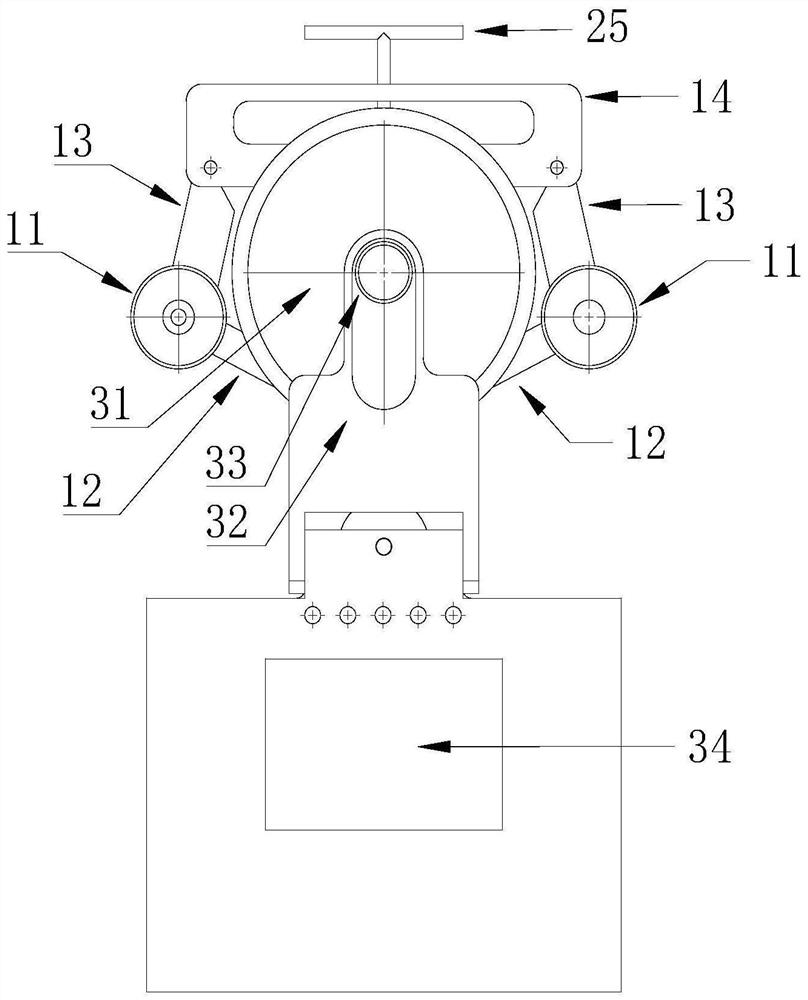

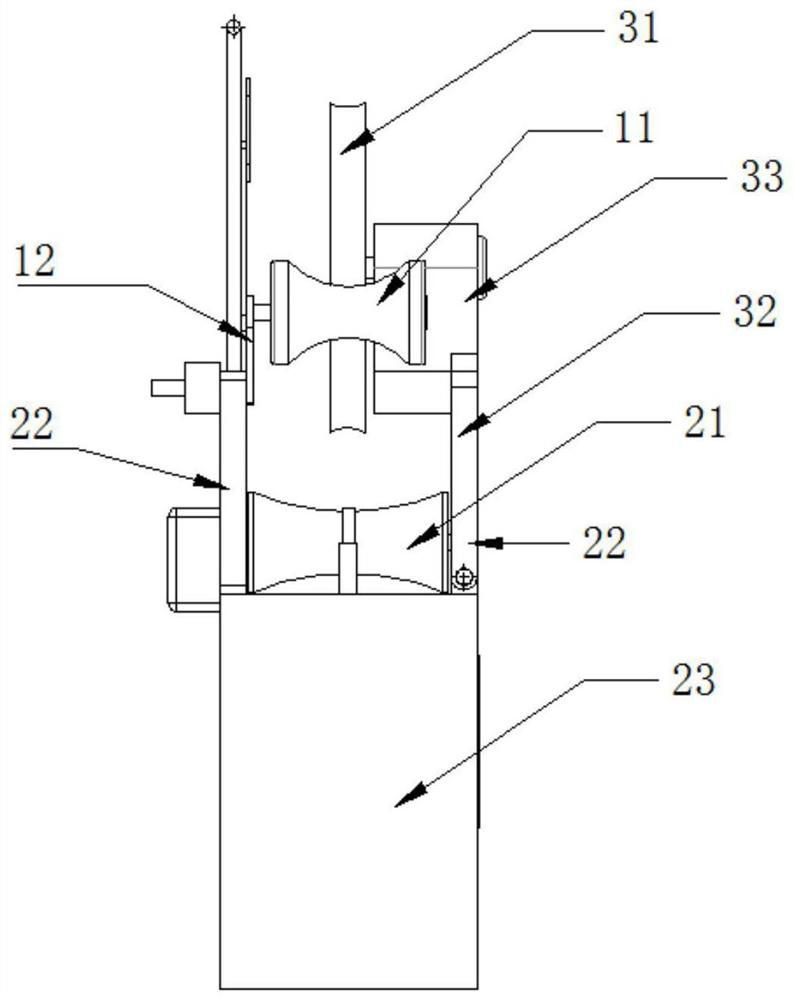

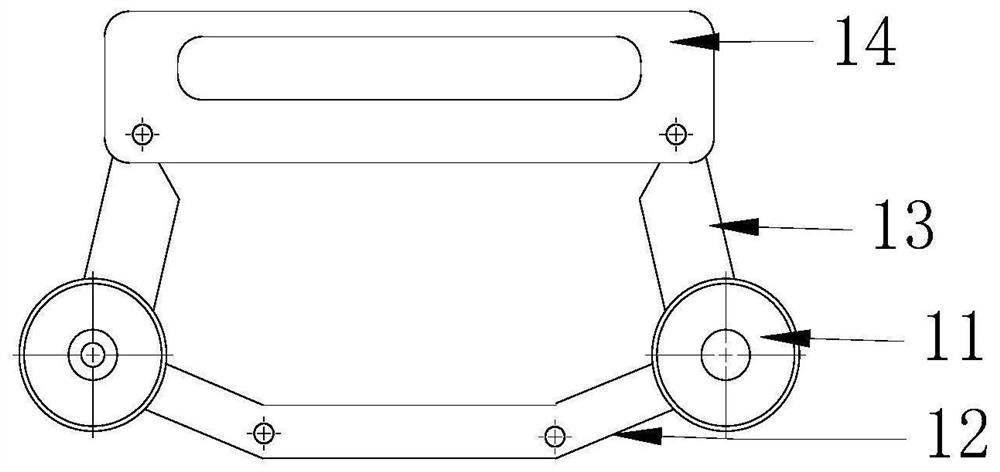

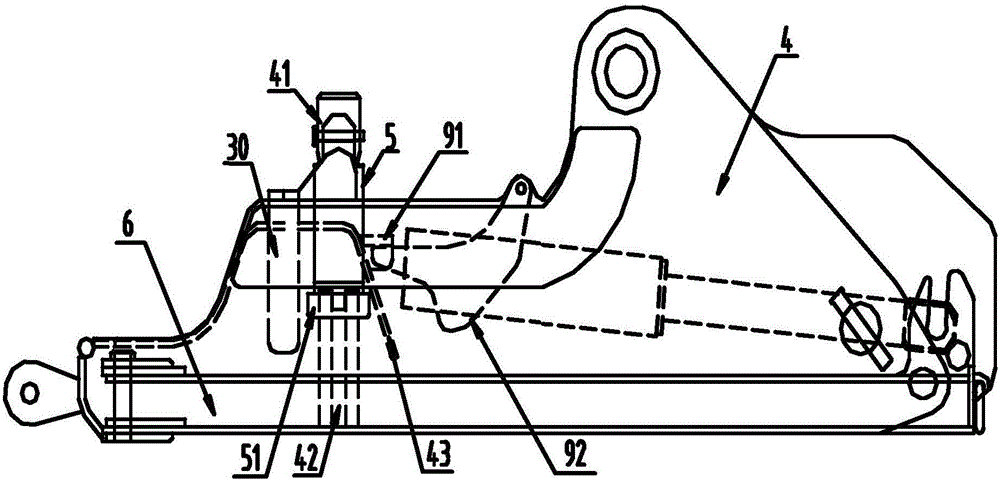

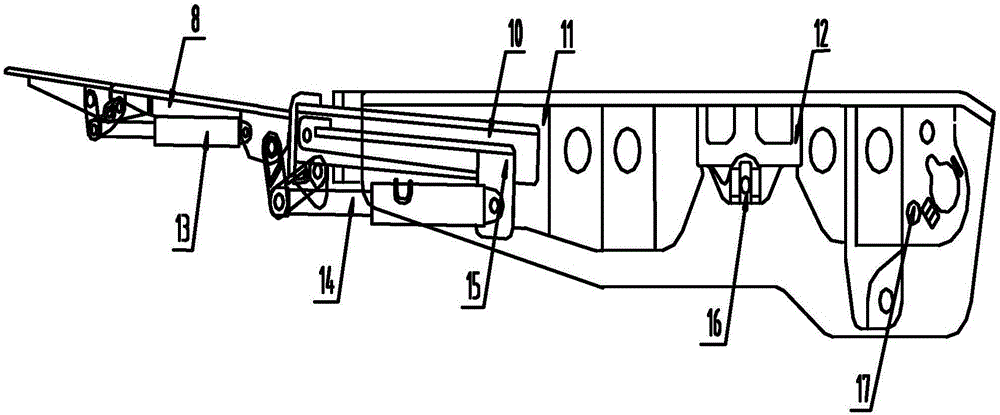

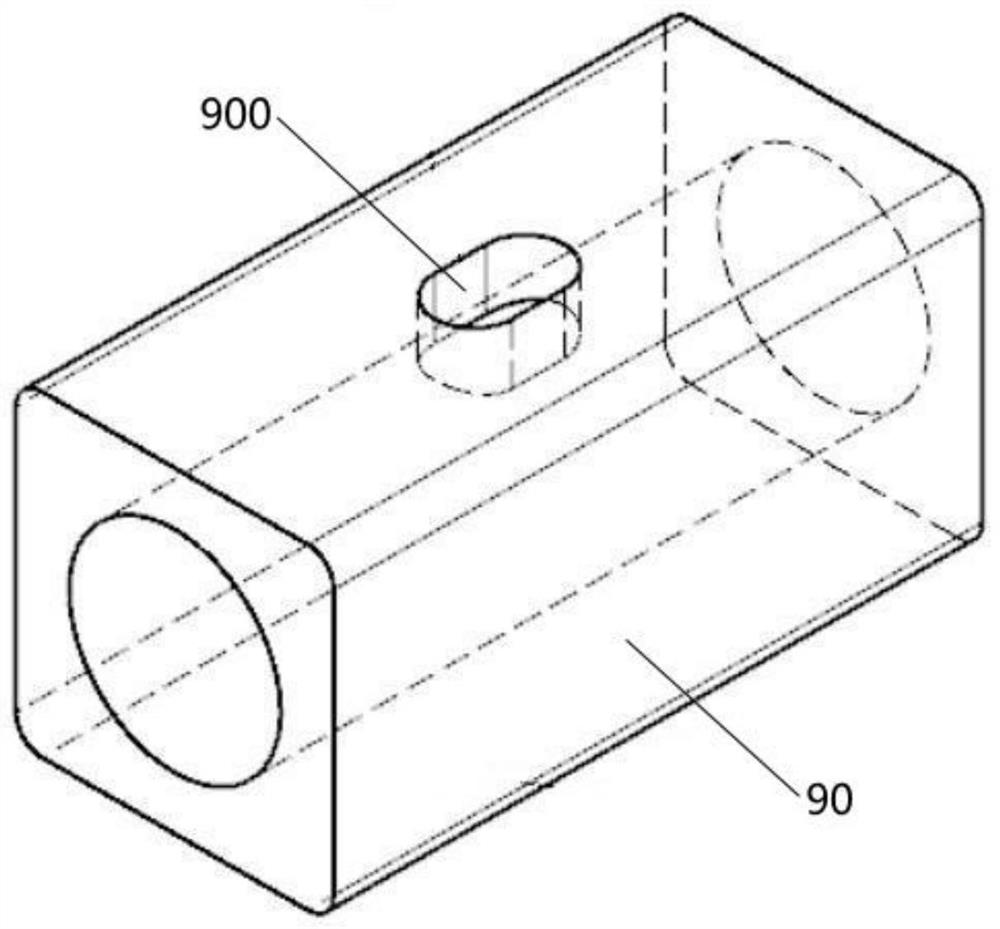

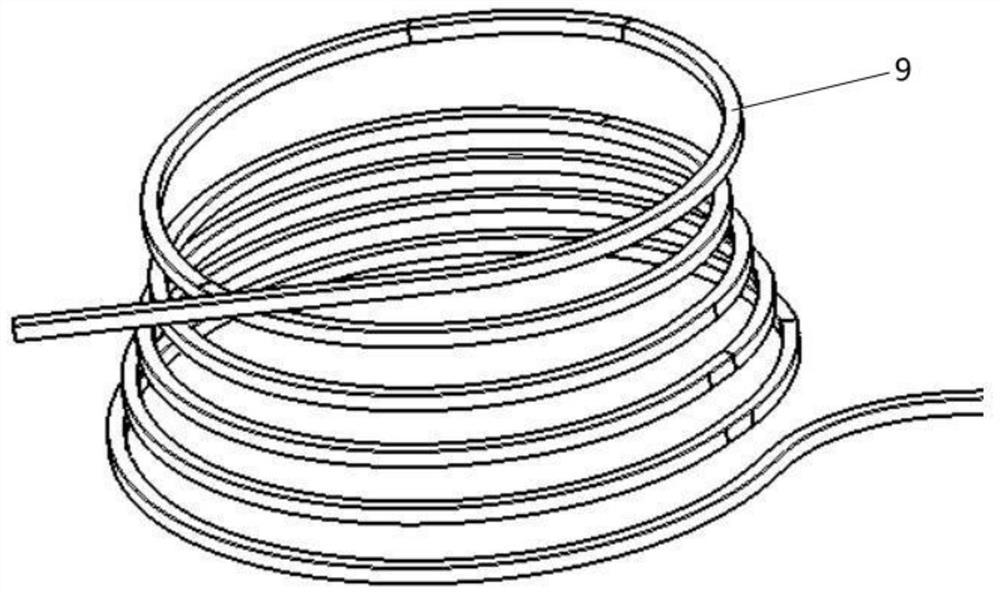

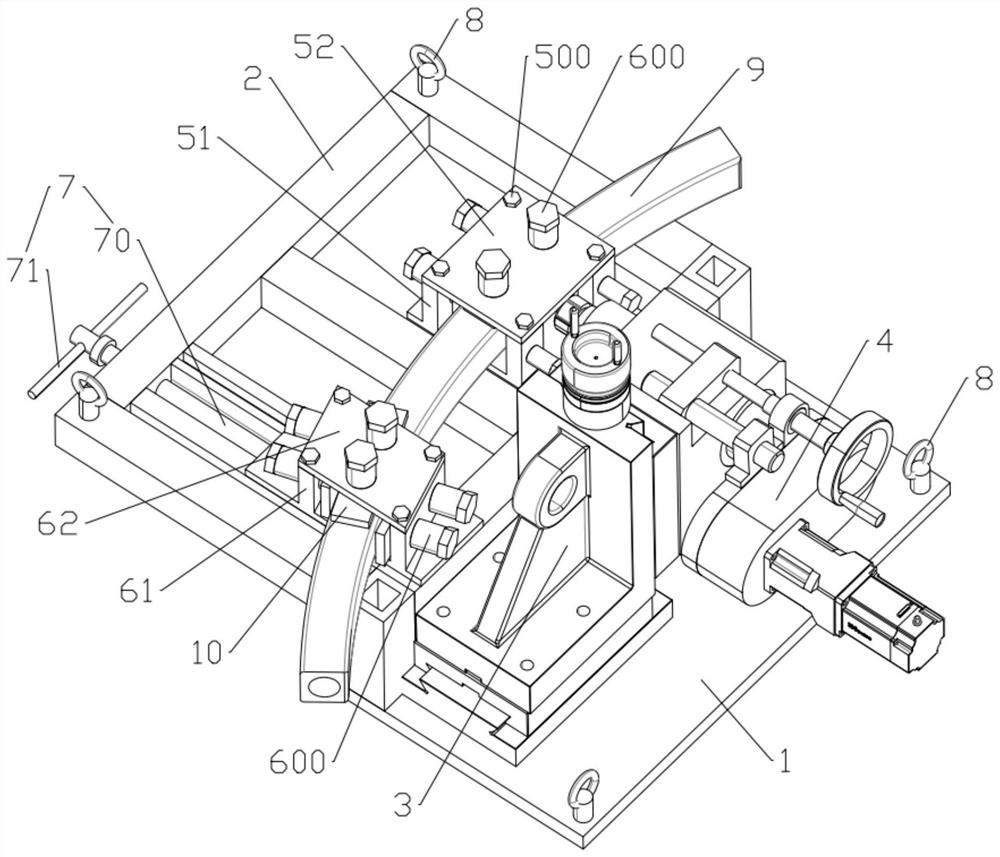

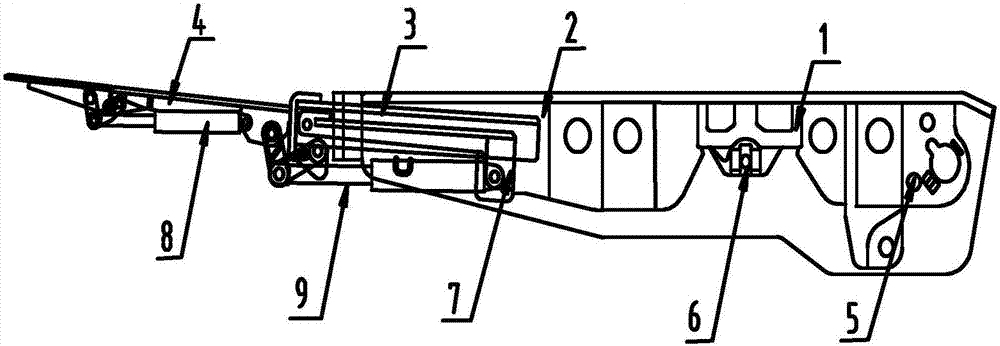

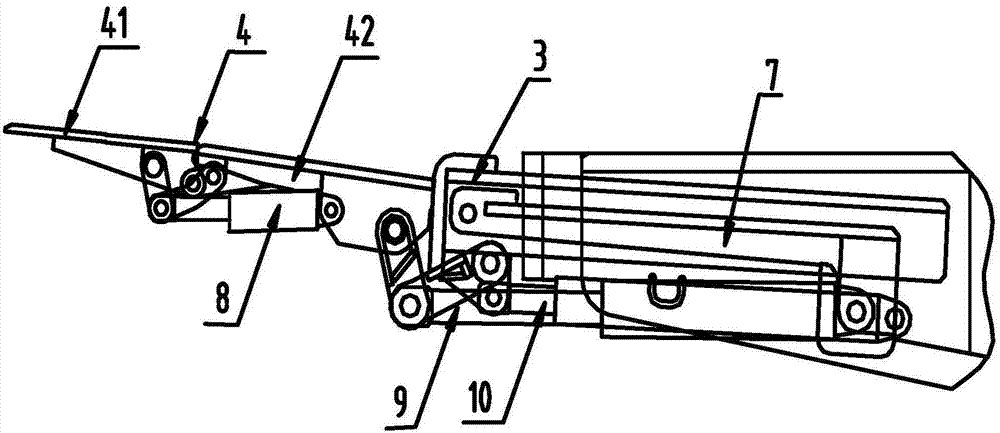

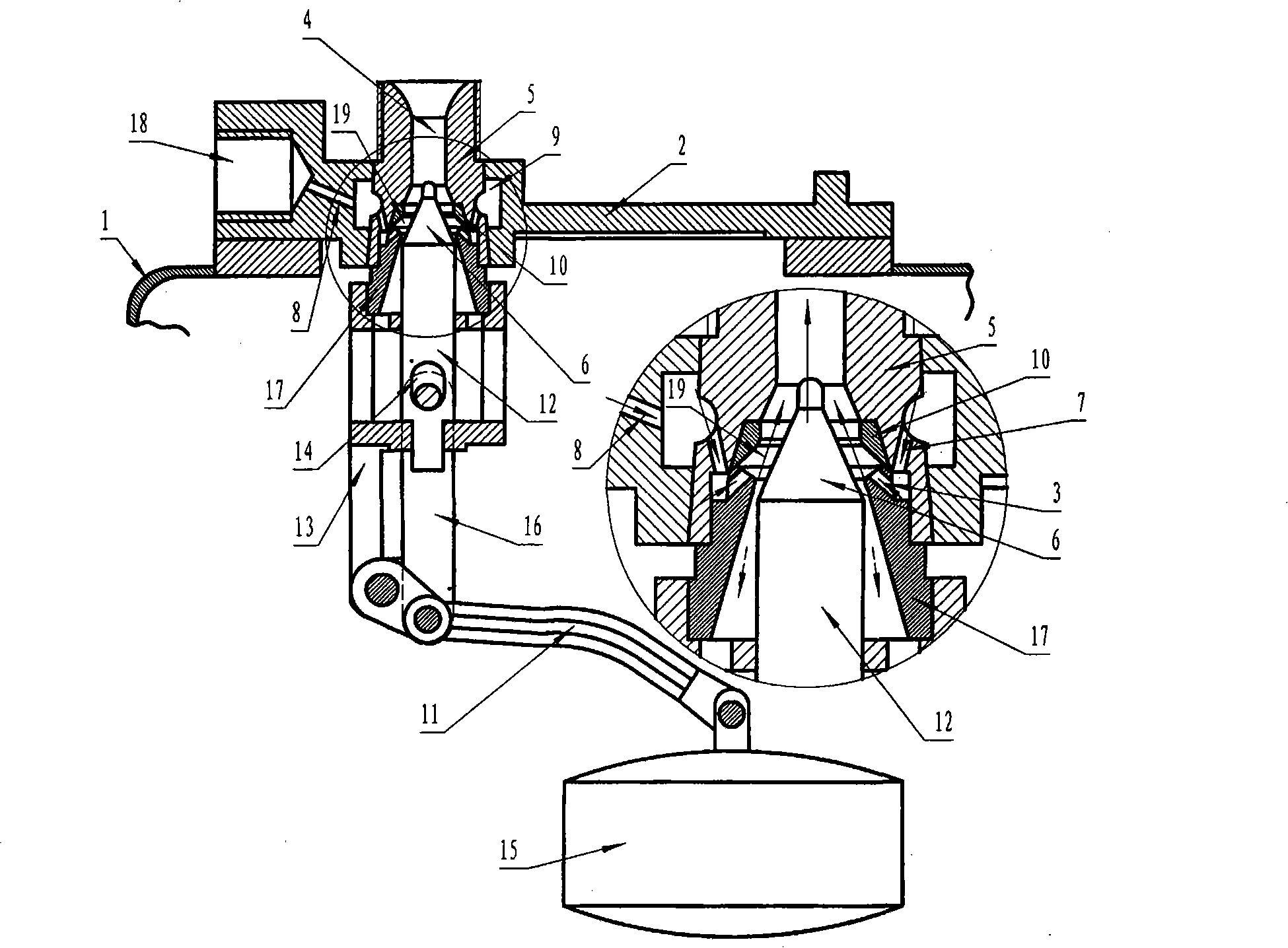

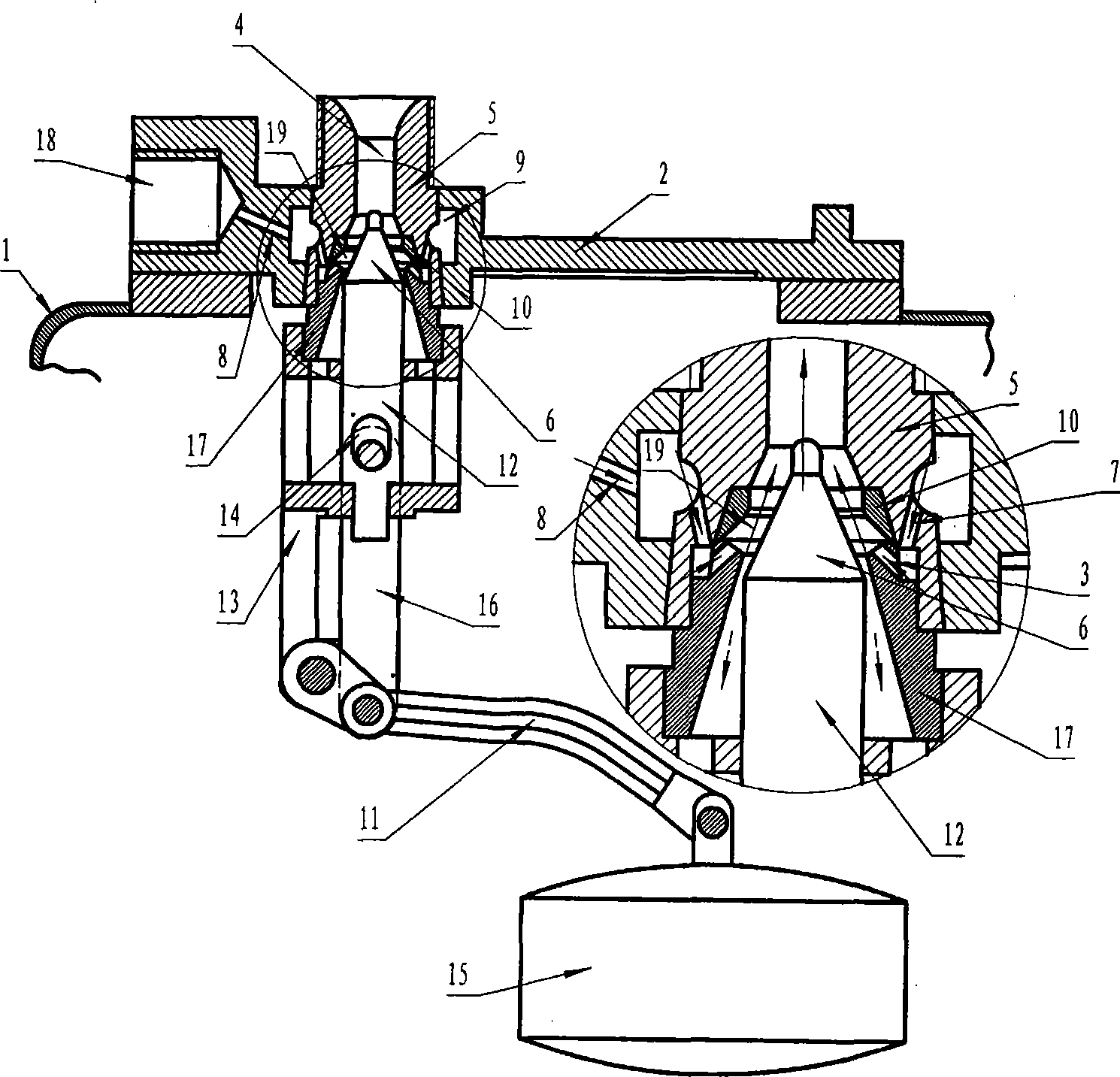

Bag collating and clamping linkage mechanism for three-dimensional packaging bags

ActiveCN103448962AGood bag sorting effectMeet the requirements of the working environmentPackagingClassical mechanicsEngineering

Owner:ZHANGZHOU JIALONG TECH INC

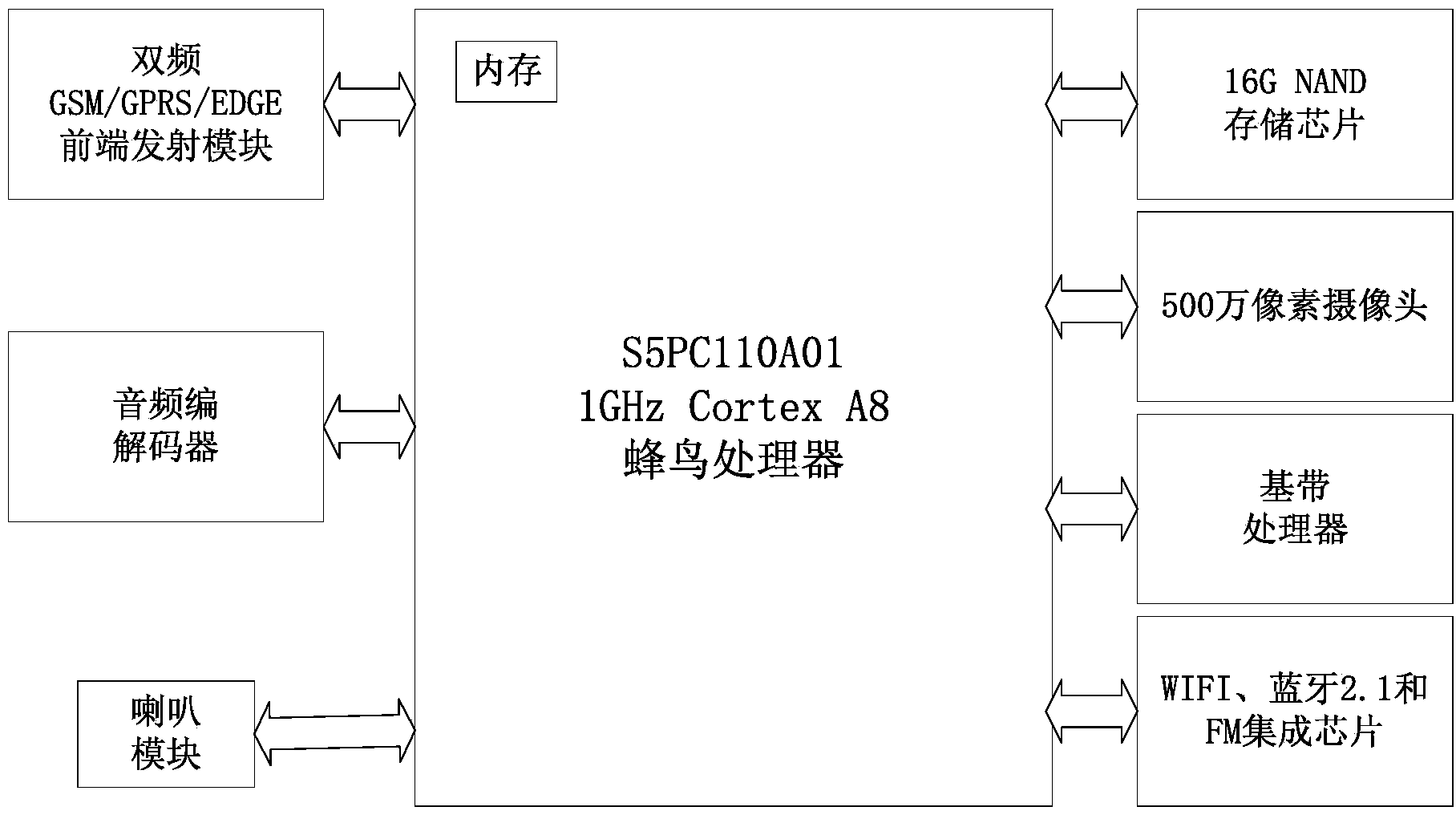

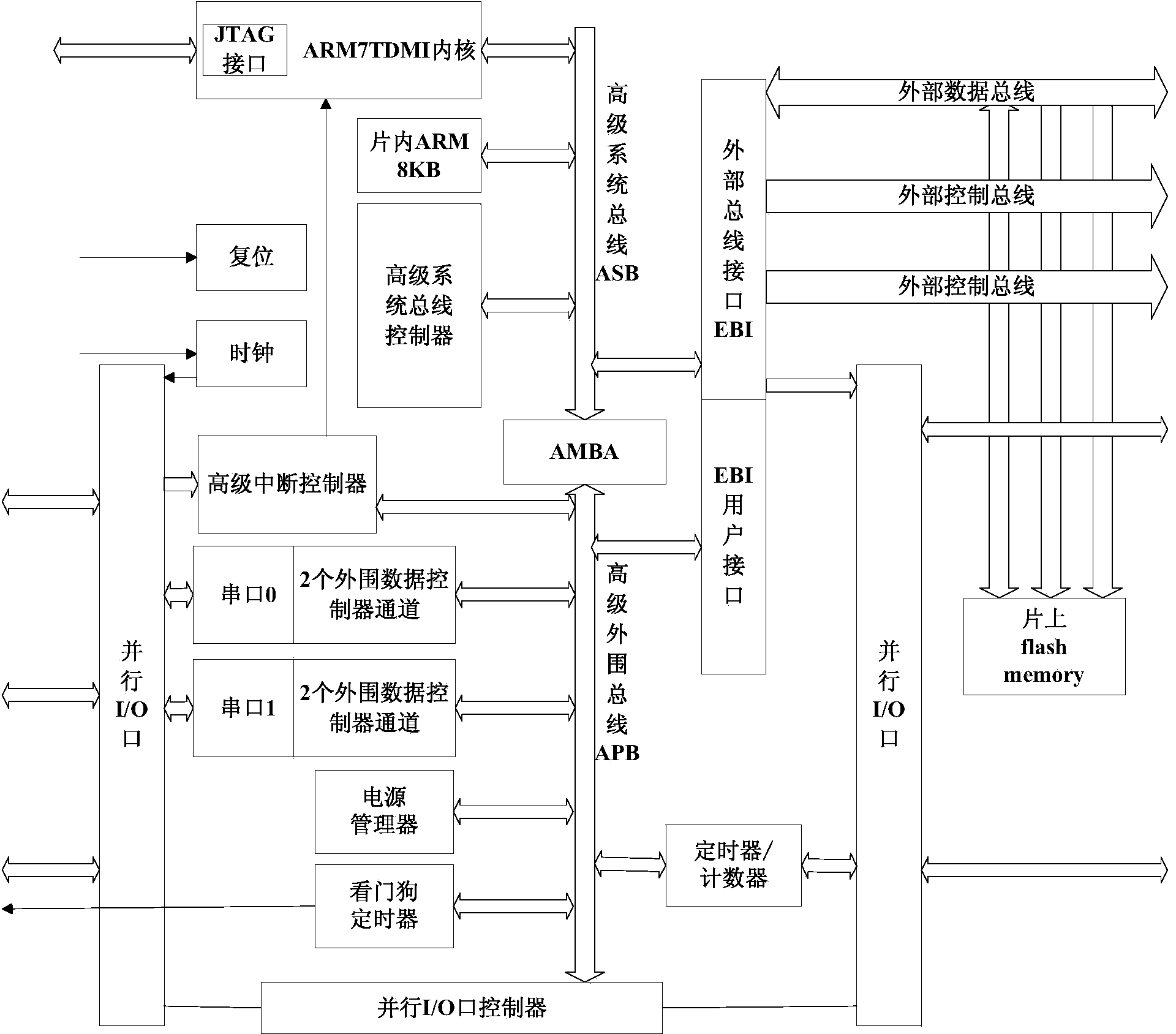

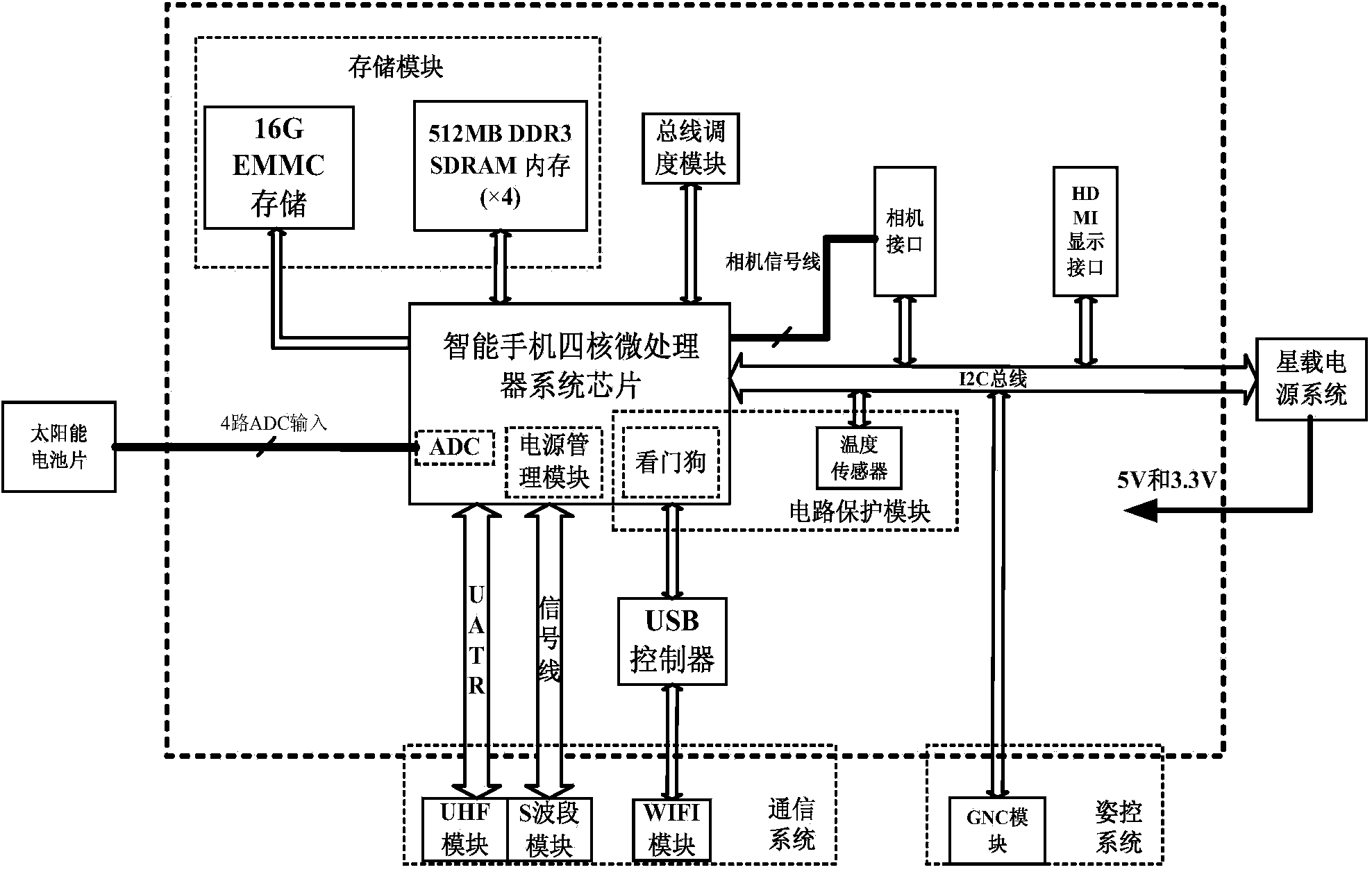

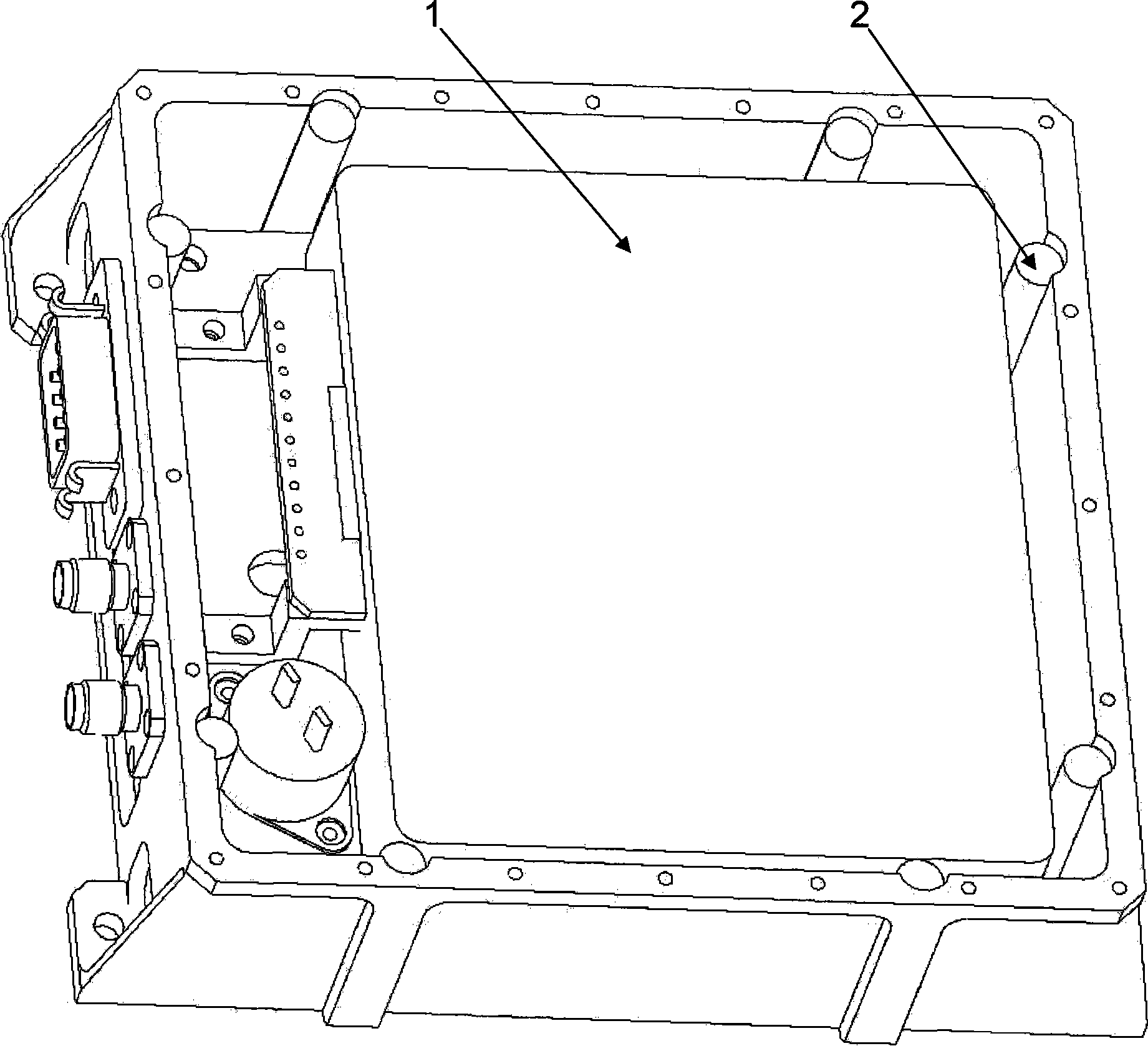

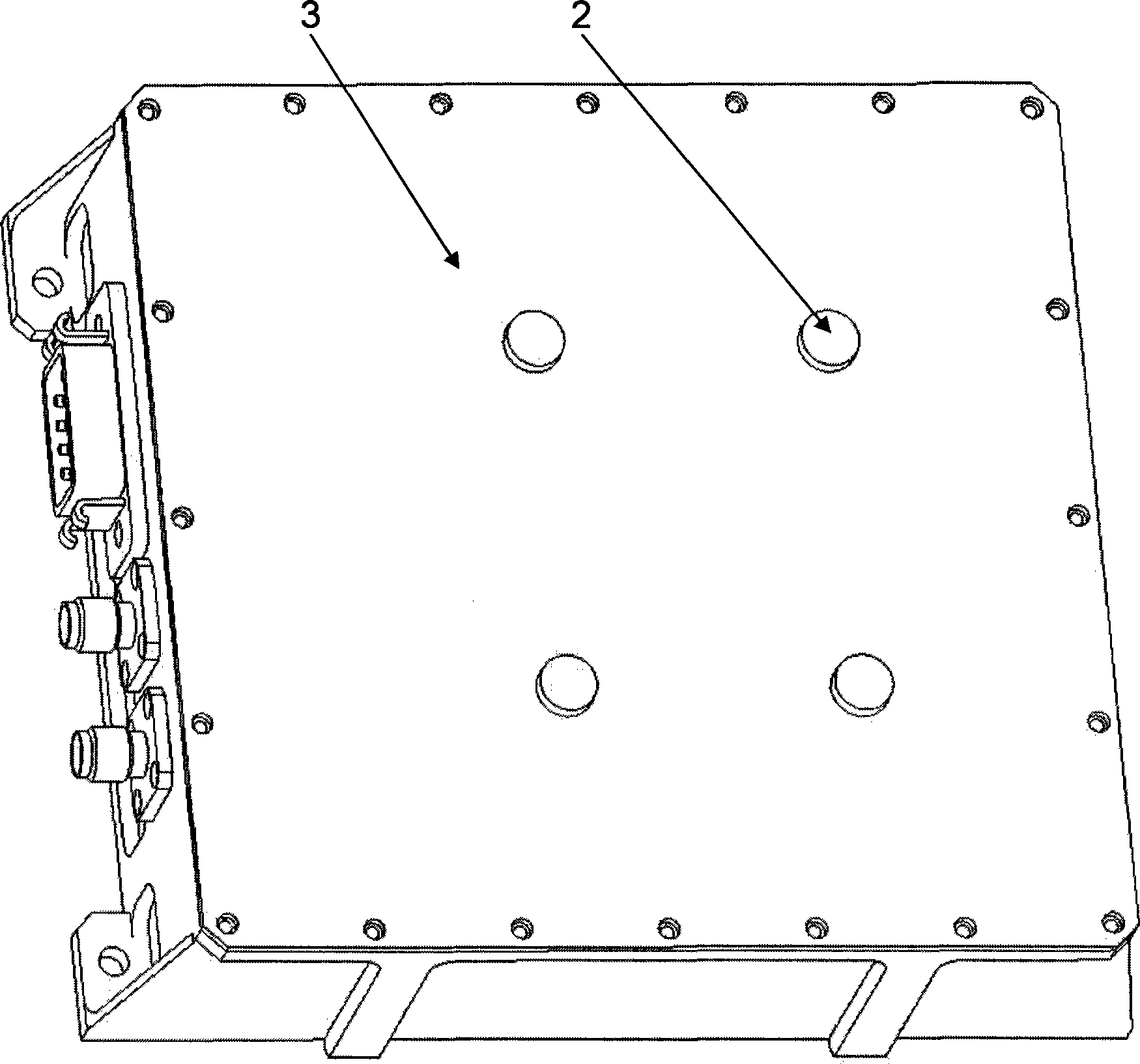

Pico-satellite computer system based on quad-core microprocessor of android mobile phone

InactiveCN104216846AReduce power consumptionFast data processingData resettingEnergy efficient computingAttitude control systemSatellite

The invention relates to a pico-satellite computer system based on a quad-core microprocessor of an android mobile phone, which aims at solving the technical problem of poor information processing capacity of the existing pico-satellite computer system. The pico-satellite computer system adopts the technical scheme that the system comprises a computer processing module, a storage module, a power source management module, a bus scheduling module and a circuit protection circuit, wherein the computer processing module is used for controlling running attitudes, arbitrating states, and sending control commands, and can realize communication with an attitude control system, a communication system, a satellite-borne power source system, the storage module, a function debugging module and a power source protection module through the bus scheduling module. The commercial quad-core microprocessor has the advantages that the power consumption is low, the data processing speed is high, the on-chip available resources are rich, the property is optimum, and the operation temperature meets the requirement of working environment of pico-satellites, so the cost of spacecrafts is reduced, the development and manufacturing period is shortened, and the requirements of small size, low power consumption, high reliability and high data processing speed of the satellite-mounted computer system by the pico-satellites are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

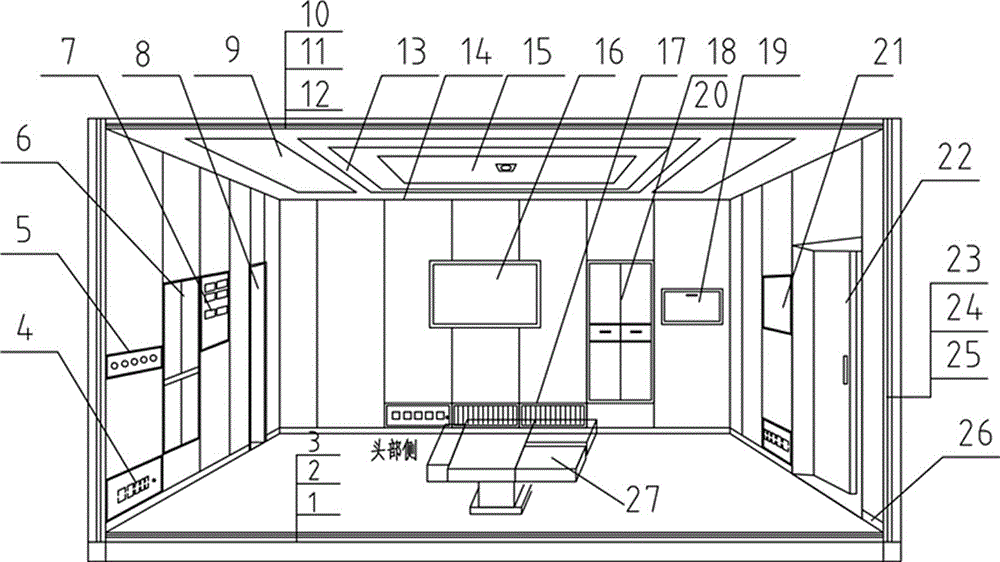

Glass operating room

InactiveCN105220907AMeet the requirements of the working environmentFireproofCovering/liningsWallsFloor slabPolyvinyl chloride

A glass operating room comprises a facade formed by assembling four walls. A ceiling integrally connected with the walls is mounted above the walls. Painted glass wall panels are spread on the outer surfaces of the walls. Painted glass top panels are spread on the outer surface of the ceiling. Seamless rubber or PVC (polyvinyl chloride) floor slabs are spread on the ground. By providing the glass operating room, the problem that an existing operating room is inconvenient to wash and poor in assembly tightness can be solved; the glass operating room is fireproof, attractive, scrub resistant, disinfection resistant, simple to construct, environment-friendly and energy-efficient and meets the requirements of operating room work environments.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

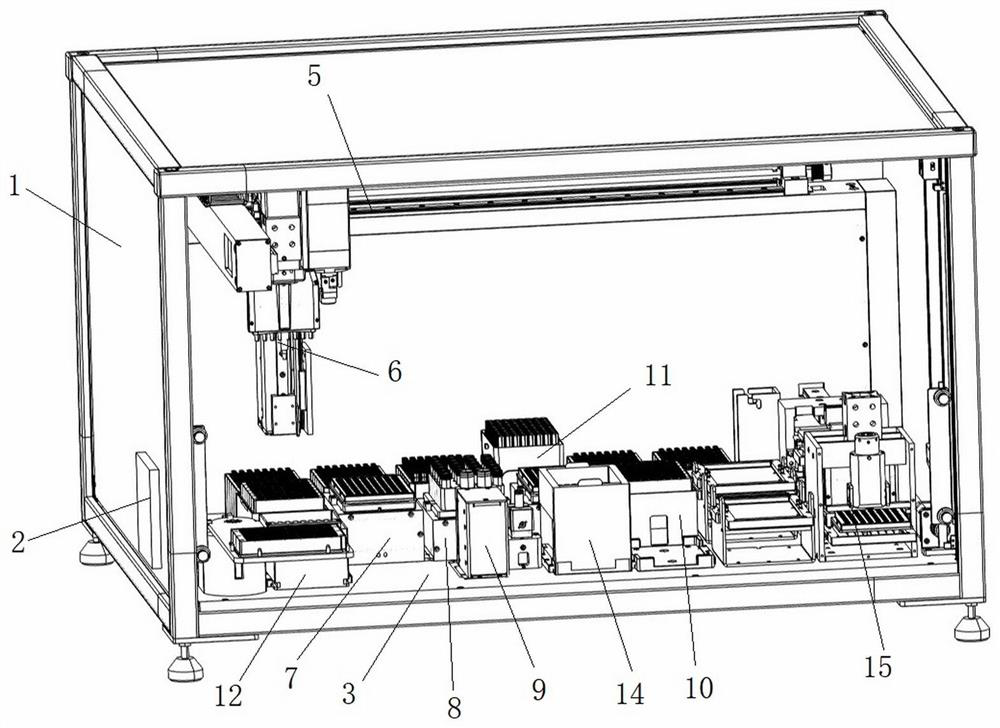

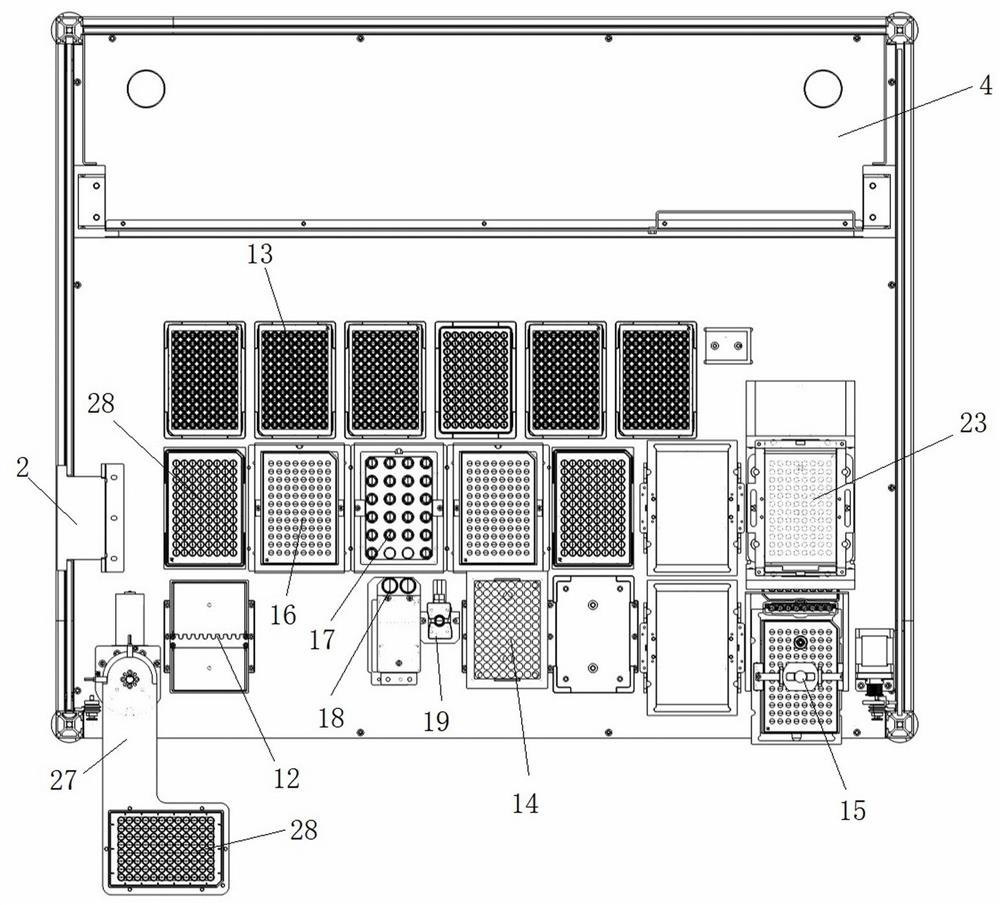

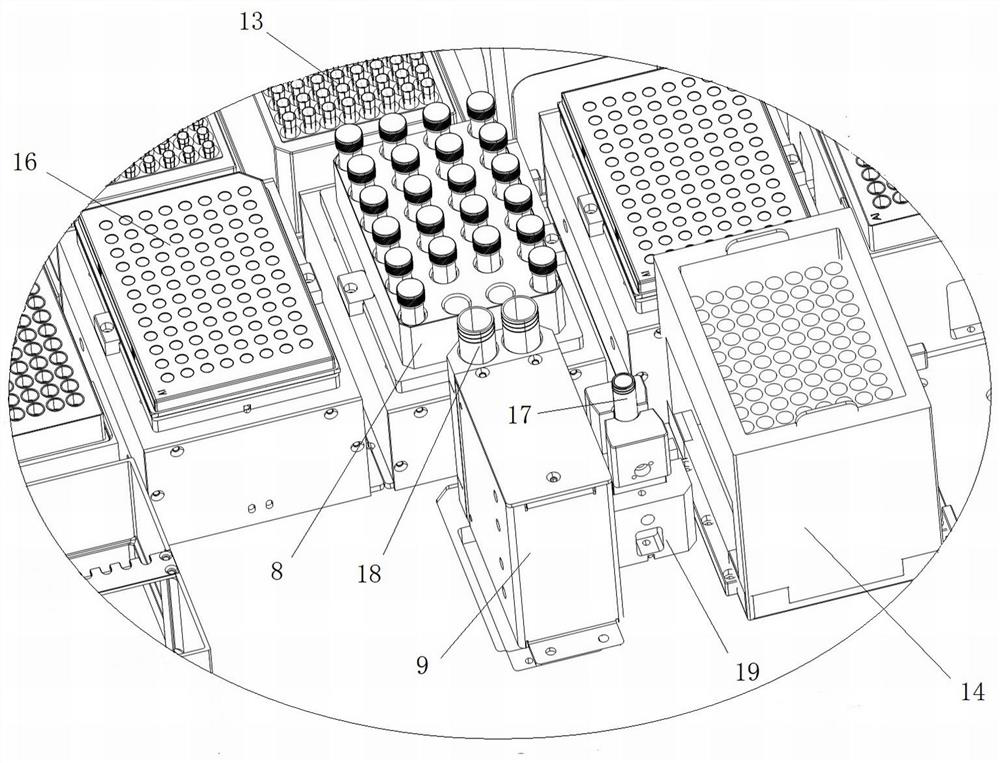

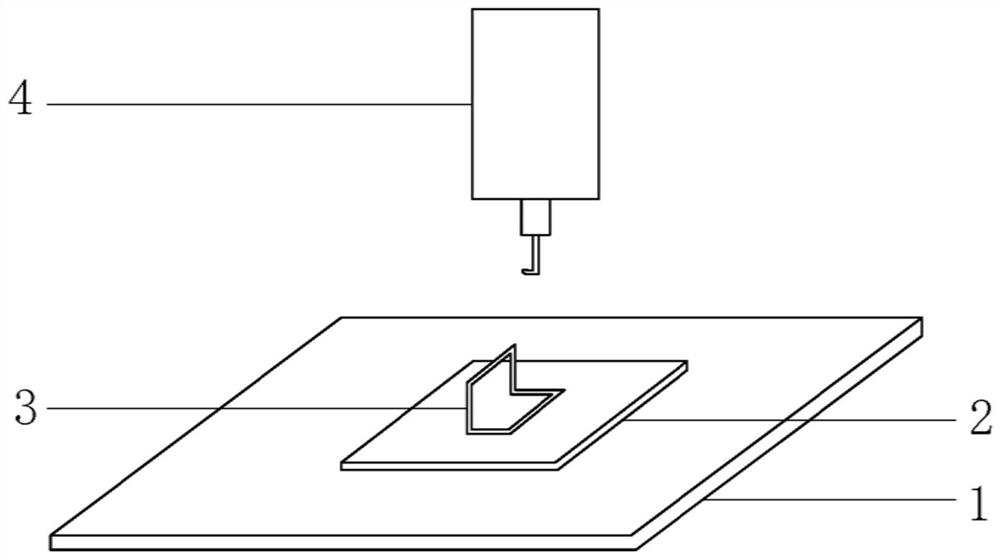

PCR detection virus pretreatment device and method

PendingCN112457972AEasy to controlMeet the requirements of the working environmentBioreactor/fermenter combinationsBiological substance pretreatmentsPretreatment methodAutomatic control

The invention relates to the technical field of automatic control equipment, and discloses a polymerase chain reaction (PCR) detection virus pretreatment device. The device comprises a worktable and adriving mechanism arranged above the worktable; the worktable is provided with PCR tray racks, a reaction liquid bottle rack, a mixed liquid bottle rack, virus DNA tray racks, suction head racks anda discarded suction head box; refrigeration components are arranged on the reaction liquid bottle rack and the PCR tray racks; suction head boxes of different specifications are arranged on the suction head racks; the driving mechanism is provided with a pipette; each PCR tray rack is provided with a PCR pore plate; the reaction liquid bottle rack is provided with a plurality of reaction liquid bottles; the mixed liquid bottle rack is provided with mixed liquid bottles; and each virus DNA tray rack is provided with a virus DNA pore plate. The invention further discloses a virus pretreatment method. According to the device and the method, the virus pretreatment process is automatically operated, so that the detection efficiency is improved, and potential safety hazards are reduced.

Owner:BAYSSIAN INTELLIGENT TECH (SUZHOU) CO LTD

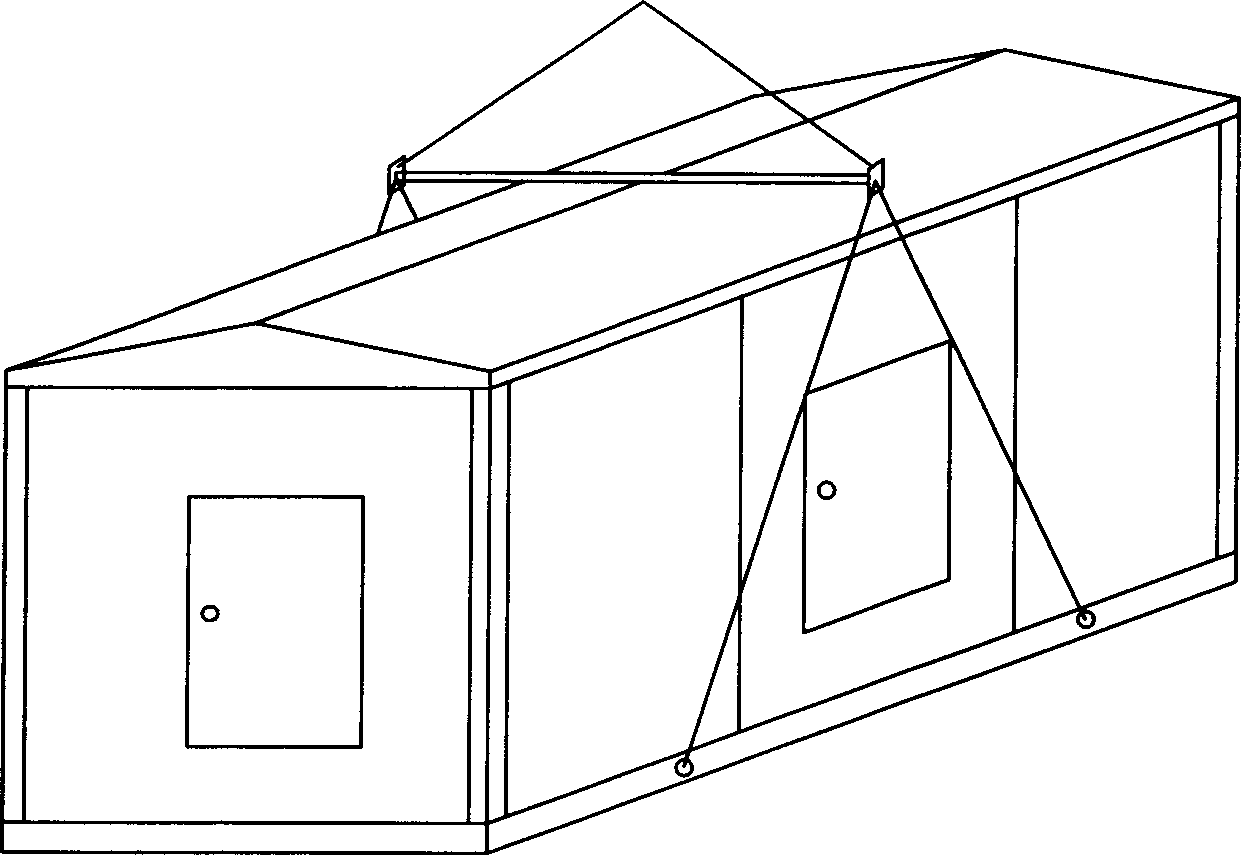

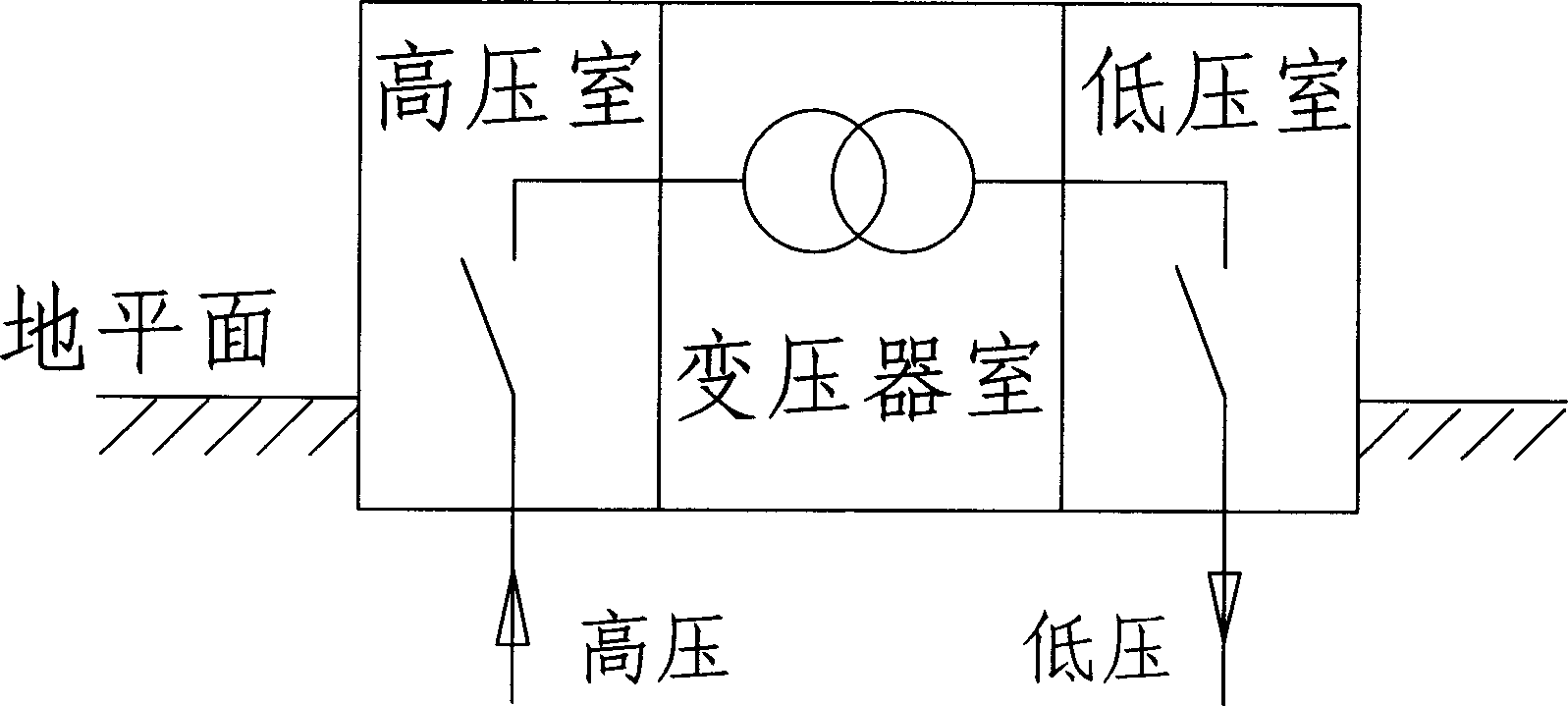

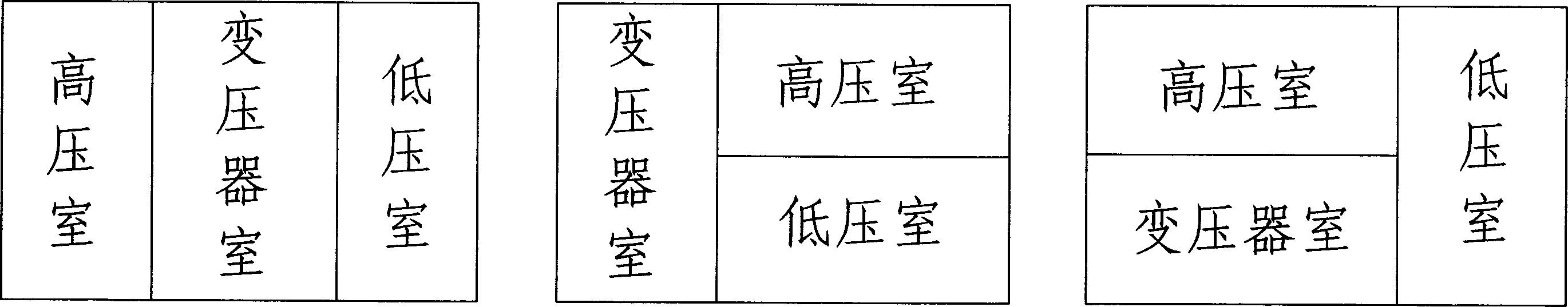

Preinstalled transformer substation

InactiveCN1412905AImprove operational reliabilitySmall footprintSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsNatural ventilationTransformer

The pre-assembled converting station includes high-voltage chamber, low-voltage chamber and transformer chamber, the described high-voltage chamber and low-voltage chamber are placed over the transformer chamber, the upper portion of said transformker chamber is equipped with a ventilating radiation window exposed to the weather, and when it is used, the half of the transformer chamber is embedded under the ground, the ventilating radiation window is positioned on the ground surface so as to implement natural ventilation and radiation of transformer.

Owner:刘爱和

Preparation technology of silicon carbide-based castable

The invention discloses a preparation technology of silicon carbide-based castable. The preparation technology comprises the steps such as raw material preparation, mould pouring, drying and heating curing treatment. By combining silica sol with silicon carbide castable, the erosion of melts on the furnace bottom and hearth and the temperature change can be adapted to relatively well, and the harsh requirements on the working environment during in-furnace service are effectively met; and the material has relatively good thermal conductivity, the temperature around and inside the material can be guided out in time through a furnace shell cooling wall, thus the ambient temperature around the material is effectively reduced, and relatively stable melts and even a molten iron layer are formed in a molten iron leakage channel formed by burn-through of the furnace bottom.

Owner:任海涛

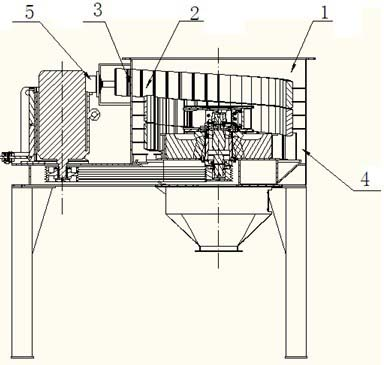

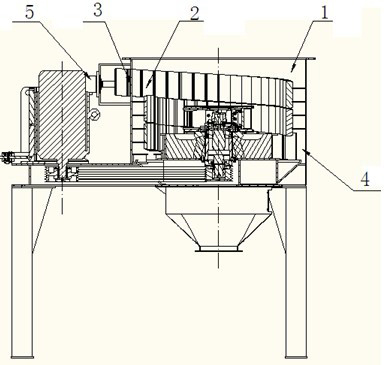

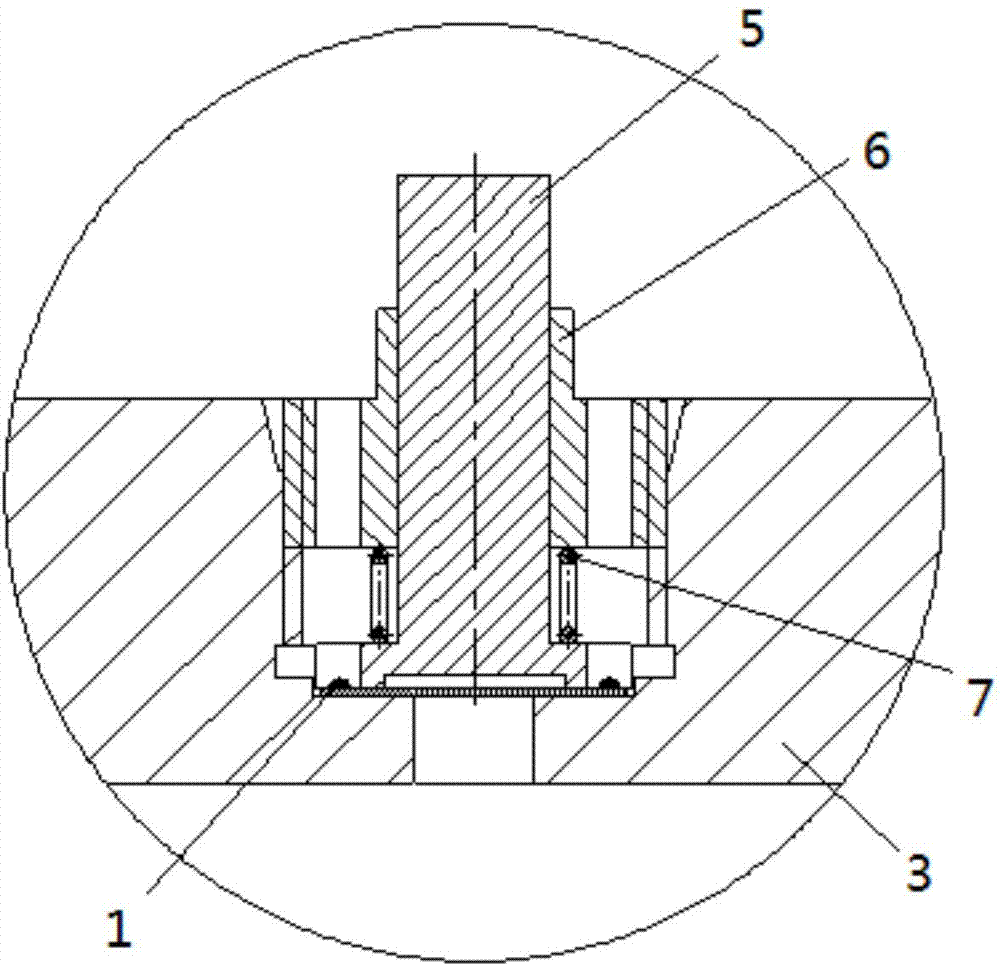

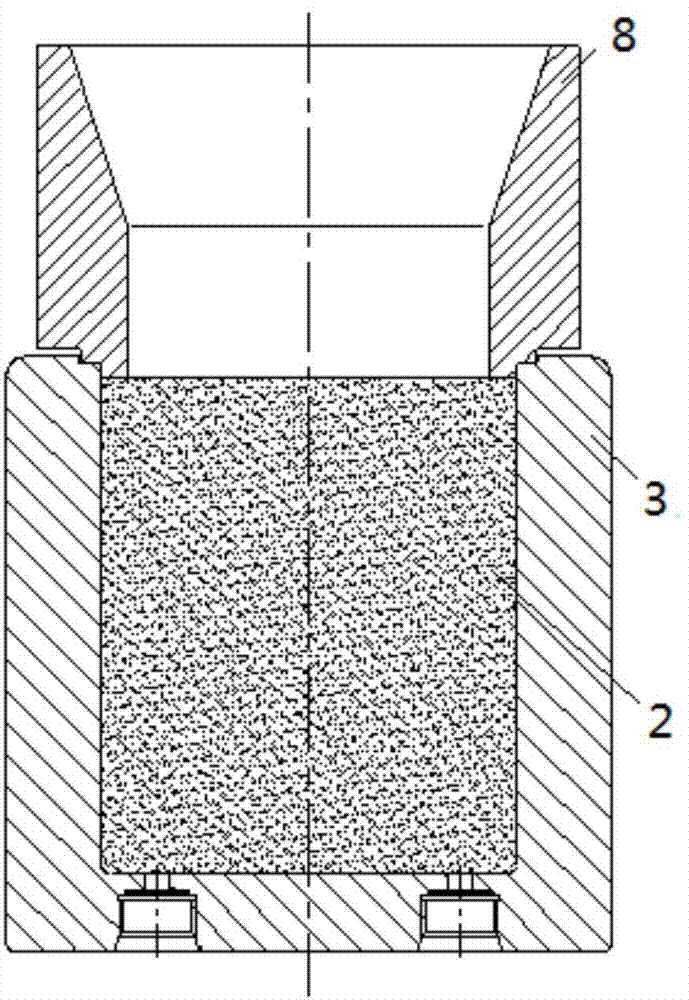

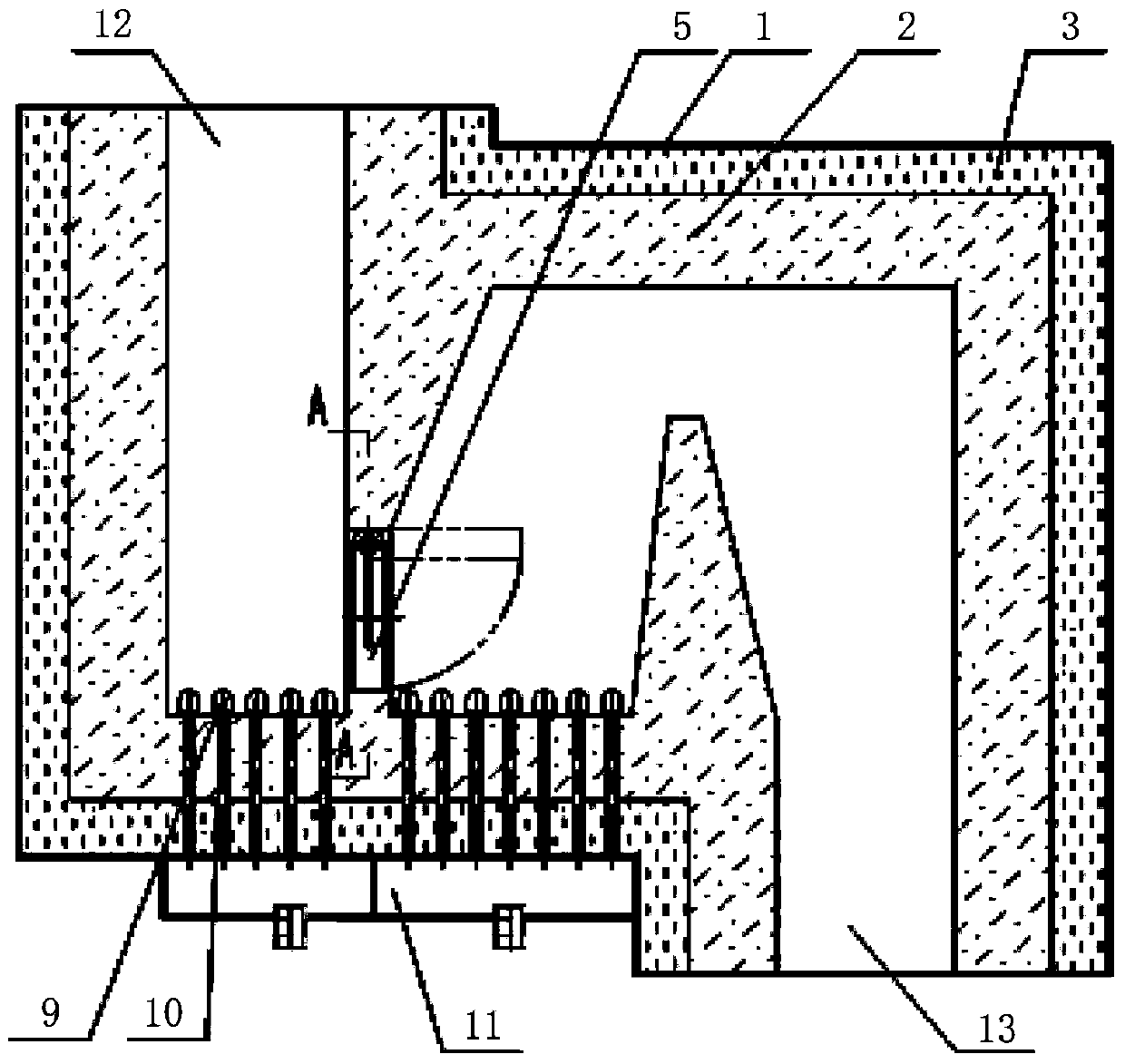

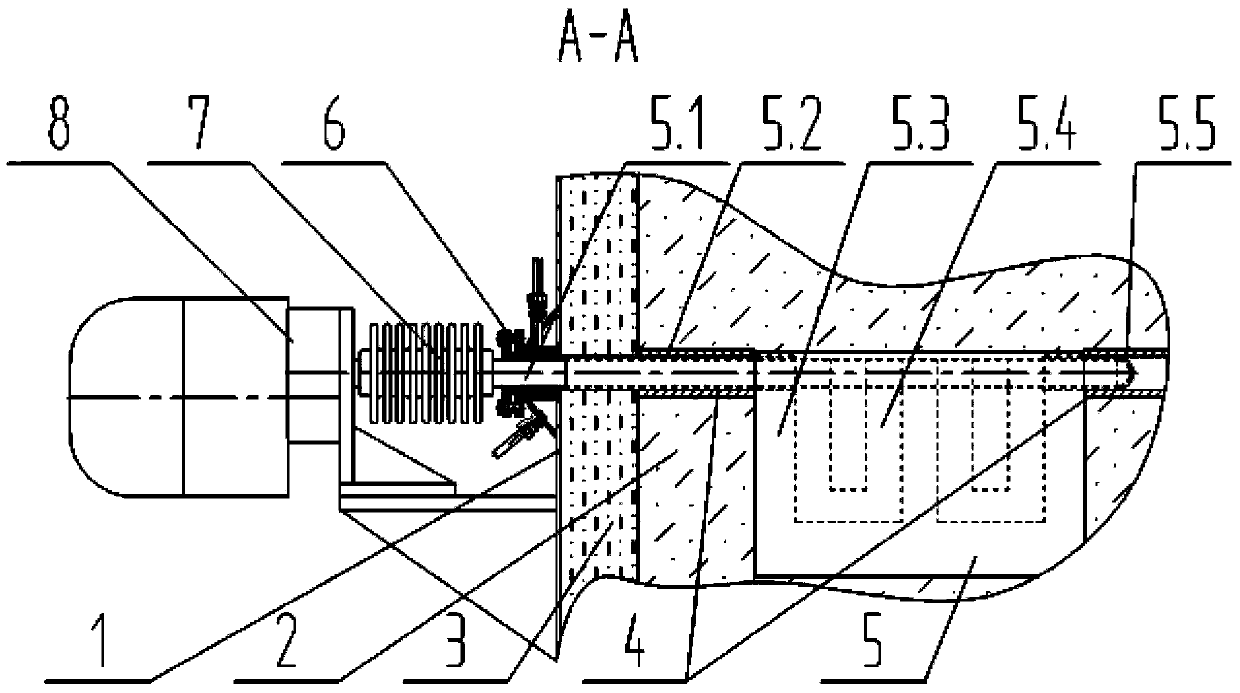

Vertical shaft crusher with spirally arranged crushing space anvils

ActiveCN102580816ALarge thrustLow working environment requirementsGrain treatmentsEngineeringCrusher

The invention discloses a vertical shaft crusher with spirally arranged crushing space anvils. The vertical shaft crusher comprises a crushing space (1) of the vertical shaft crusher, wherein the anvils (2) are provided and spirally arranged in the crushing space (1); anvil inlets (3) are arranged at a spiral line entry point on top of the crushing space (1); and anvil propping outlets (4) are arranged at the spiral line entry point at the bottom of the crushing space (1). According to the vertical shaft crusher disclosed by the invention, the anvils mounted on the internal wall of the crushing space are spirally arranged; and anvil inlets and the anvil propping outlets are arranged on the crushing space, and thus when the worn anvils in the crushing space are to be replaced due to wear, anvils can be fed from the anvil inlets; the anvils in the crushing space are driven to spirally move by an anvil propping inlet device so as to replace the anvils; and the anvils can be replaced without stopping the machine and opening the top cover. Compared with existing replacing processes, the process disclosed by the invention is simpler, saves force and time, and improves the production efficiency.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

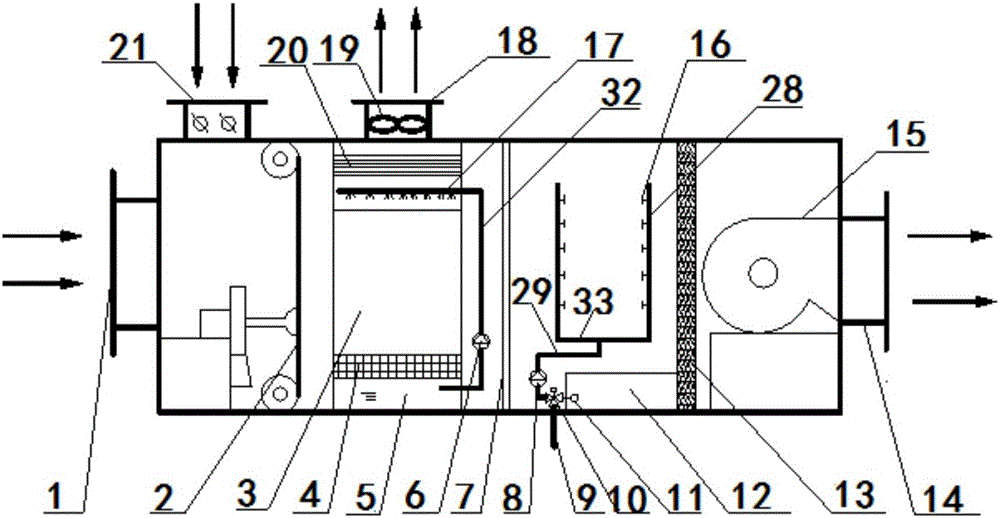

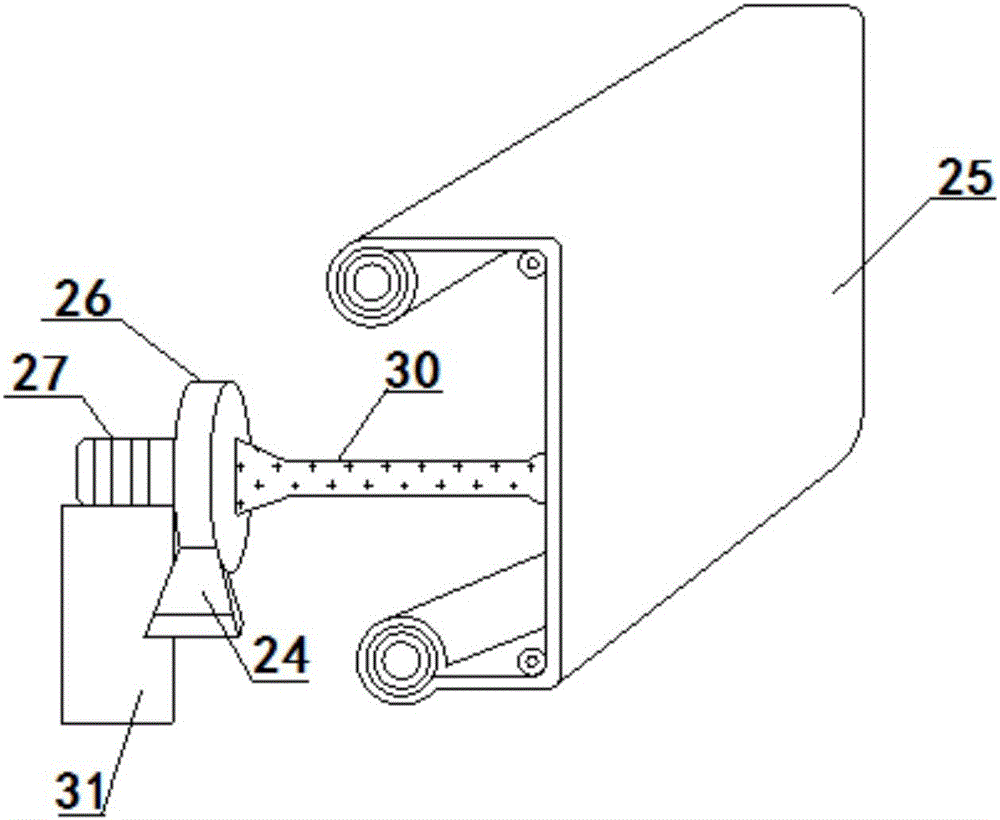

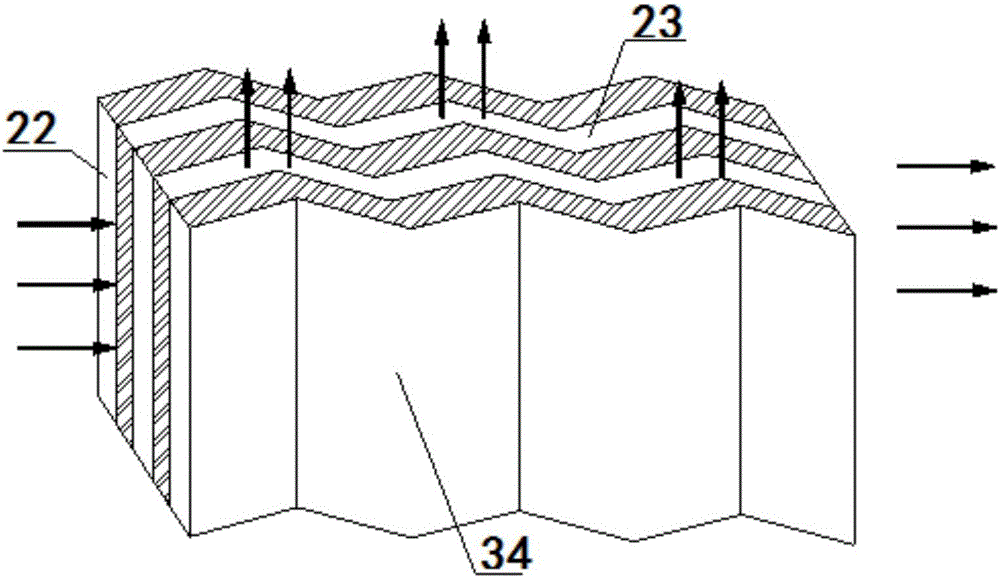

Corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit

InactiveCN105042735AImprove the cooling effectReduce running timeMechanical apparatusLighting and heating apparatusFiberTextile mill

The invention discloses a corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit. The air conditioning unit comprises a unit shell. An air inlet and an air outlet are formed in the two opposite side walls of the unit shell respectively. A fresh-air-and-returning-air mixing-filtering chamber, a corrugated-plate indirect evaporative cooler, a flow equalizing plate, a hydrodynamic force water spraying device, a water stop plate a and an air feeder are sequentially arranged in the unit shell in the flowing direction of entering air. An air returning opening is formed in the portion, corresponding to the fresh-air-and-returning-air mixing-filtering chamber, of the top wall of the unit shell. A secondary air exhausting opening is formed in the portion, corresponding to the portion above the corrugated-plate indirect evaporative cooler, of the top wall of the unit shell. According to the corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit, a self-cleaning winding type filter is adopted, dust and cotton fibers in returning air can be effectively filtered out accordingly, and therefore the returning air can be effectively used; and indirect evaporative cooling and hydrodynamic-force water spraying cooling are combined, and therefore the temperature in workshops of a textile mill can be effectively reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

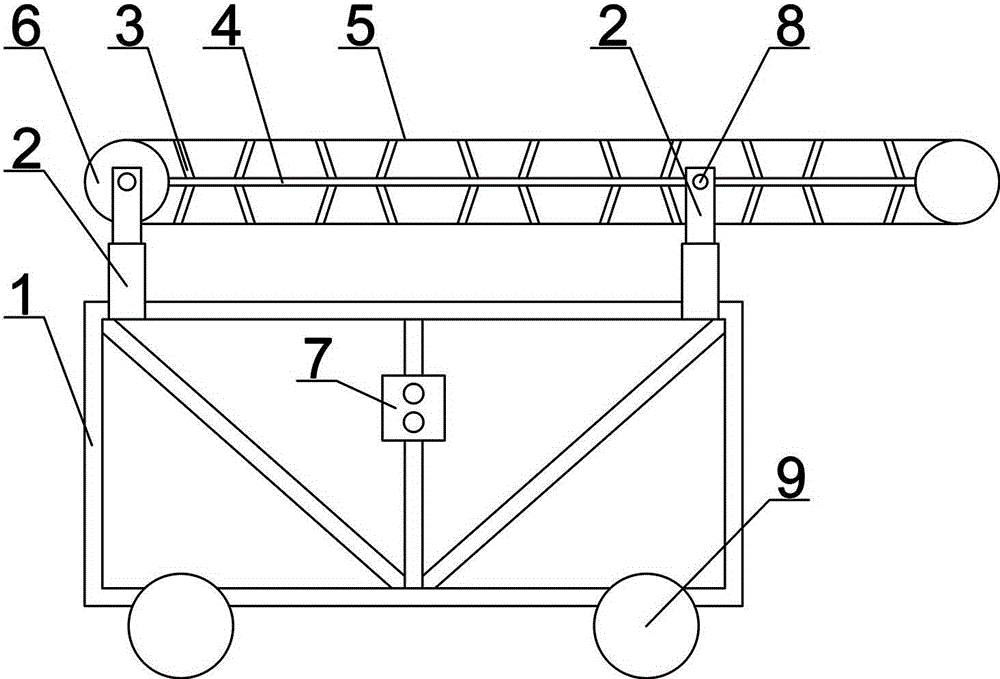

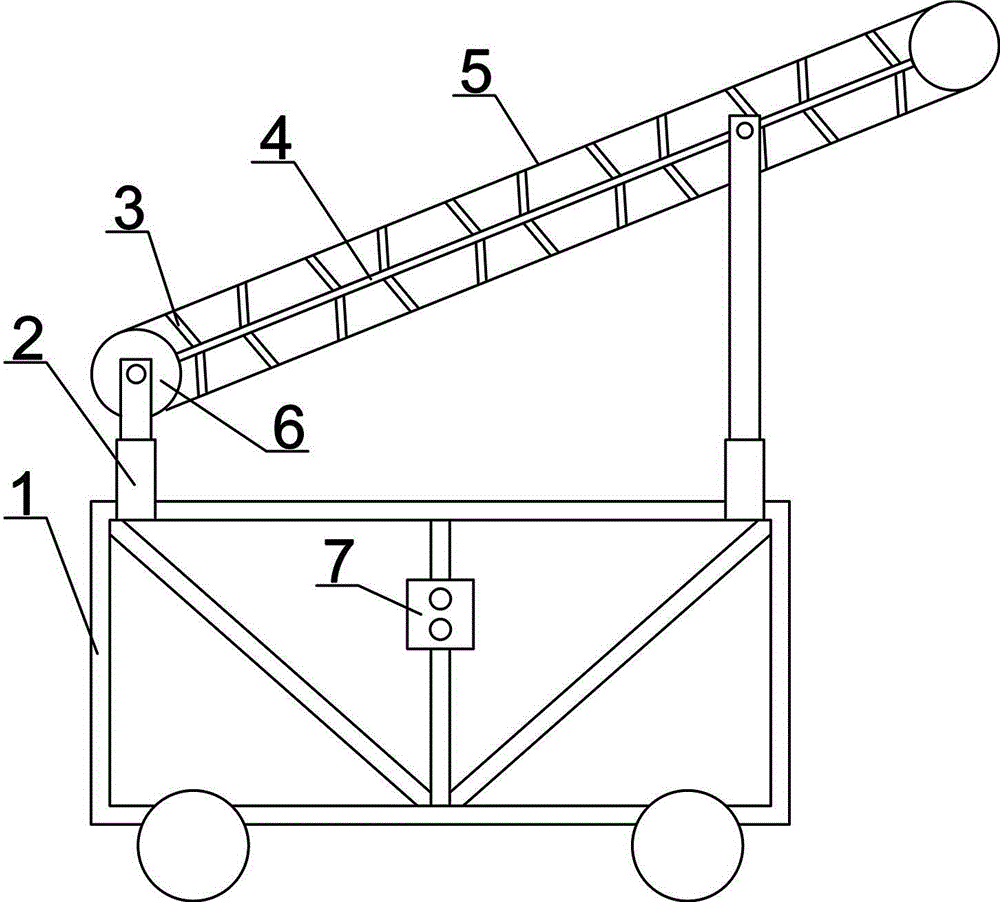

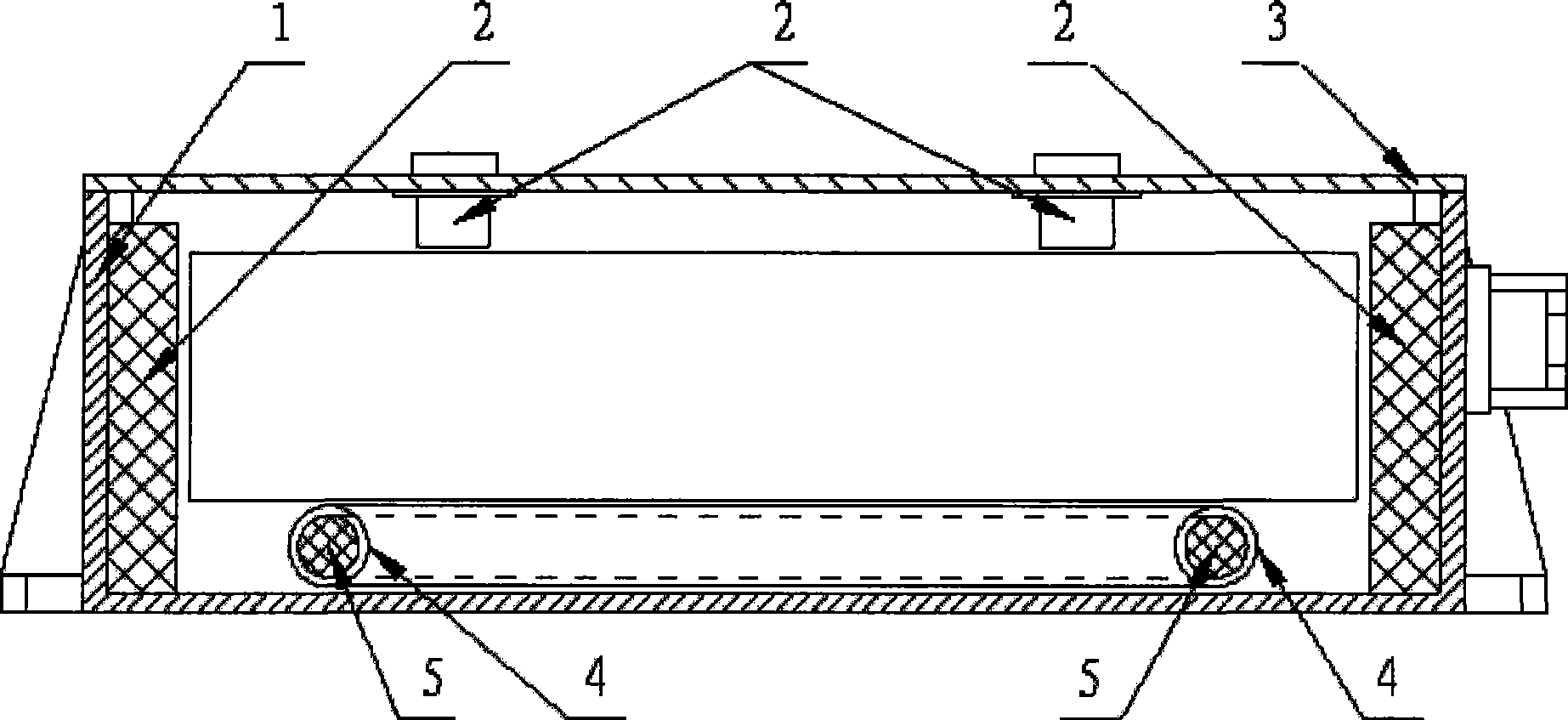

Hydraulic lifting and descending belt conveyor

InactiveCN106395294AEasy to transportHeight adjustableSupporting framesVehicle frameWorking environment

The invention discloses a hydraulic lifting and descending belt conveyor which comprises a frame, a first hydraulic supporting rod, a second hydraulic supporting rod and a belt, wherein the first hydraulic supporting rod and the second hydraulic supporting rod are arranged on the frame; the first hydraulic supporting rod and the second hydraulic supporting rod are connected with a belt bracket; the belt is arranged on the belt bracket; a guide rail parallel to the belt surface is arranged in the belt bracket; the first hydraulic supporting rod is hinged to the center of a rotating wheel at one end of the belt bracket; a horizontal sliding rod is arranged at the top end of the second hydraulic supporting rod in a hinged manner; and the sliding rod is arranged on the guide rail. By the adoption of the structure, the heights of the hydraulic supporting rods can be adjusted according to the height of a cargo and unloading of the cargo, so that the height and the inclination angle of the whole belt surface can be adjusted, and the requirements of various working environments can be met; meanwhile, the belt end can extend into a truck to facilitate transportation of the cargo and improve the working efficiency; and by the adoption of a motor capable of rotating in two directions, after loading of the truck is completed, the motor is directly controlled to rotate anticlockwise to drive the belt to rotate anticlockwise for unloading, so that the hydraulic lifting and descending belt conveyor is very convenient.

Owner:YIDU LINLONG MINING MACHINERY

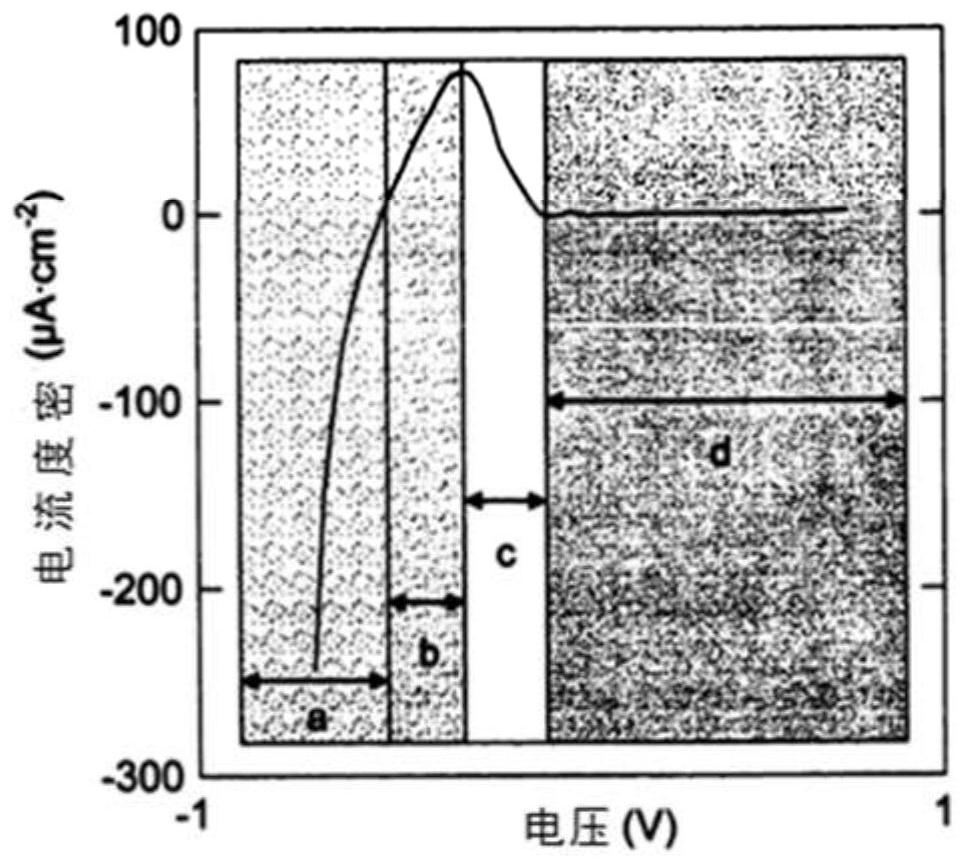

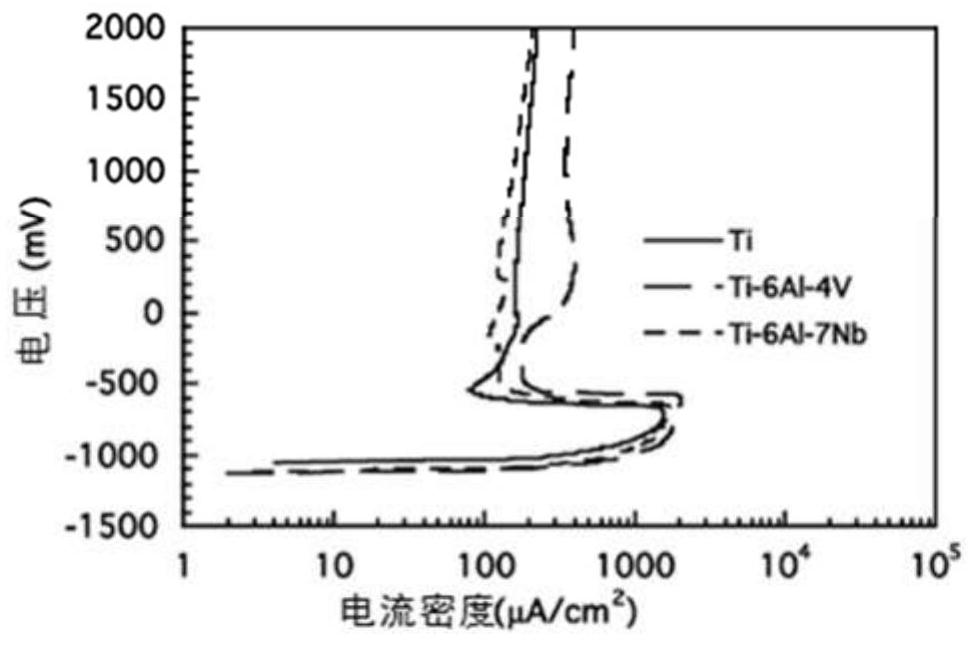

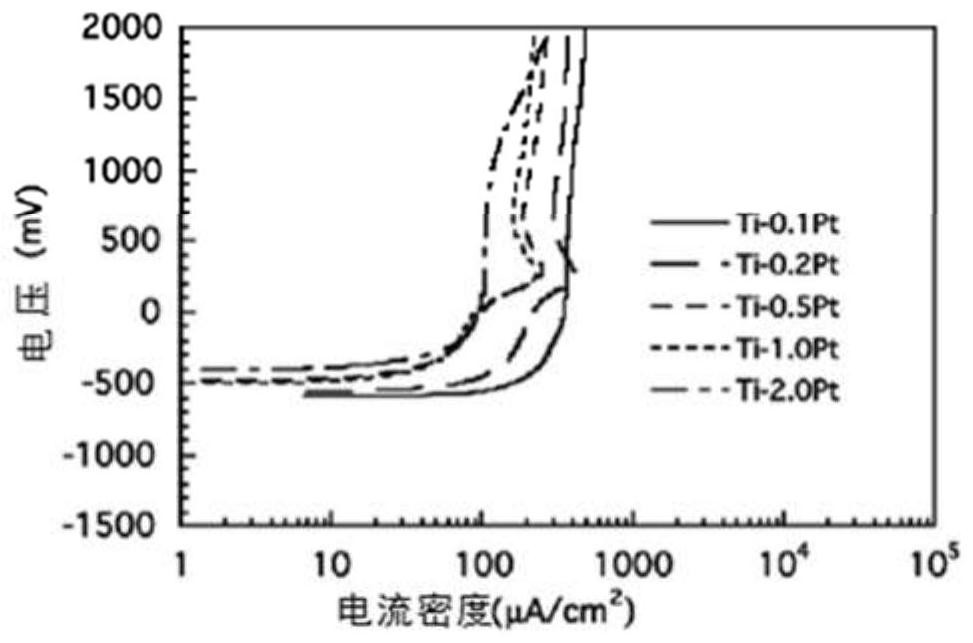

Electrode capable of reversing polarity, and application thereof

PendingCN113337845AImprove corrosion resistanceImprove bindingWater/sewage treatmentElectrodialysisElectrolysisElectrical polarity

The invention discloses an electrode capable of reversing polarity, and application thereof. The electrode comprises a substrate, a middle layer and a catalyst layer, wherein the substrate comprises metal or alloy thereof; the middle layer is arranged on the substrate and comprises platinum group metal and platinum group metal oxide; and the catalyst layer is disposed on the middle layer, and the catalyst layer includes a mixed metal oxide. The electrode can be used as an electrode for electrolysis, electrodialysis or electroplating. The electrode can meet the working environment requirements of the cathode and the anode at the same time, the environmental tolerance is improved, and the protection of the substrate is realized; and polarity reversal can be carried out, and sediments on the surface of the electrode can be quickly and efficiently cleaned.

Owner:MAGNETO SPECIAL ANODES SUZHOU CO LTD

Smoke-fire actuating cylinder for nuclear power safety valve and laser welding method thereof

InactiveCN103486306AImprove sealingSatisfied that the leak rate does not exceed 1×10

<sup>-5</sup>

cm

<sup>3</sup>

/s requestEqualizing valvesSafety valvesHigh humidityNuclear power

The invention provides a smoke-fire actuating cylinder for a nuclear power safety valve and a laser welding method thereof. The input end of a shell is provided with at least one joint for installing an igniter; the bottom part of the joint is a countersunk laser welding plane with a central through hole; an input cover piece is welded at one side of the input end of the countersunk laser welding plane; the igniter is arranged at the outer side of the input cover piece; the inner part of the shell is a cylindrical cavity with an opening at one end; a high-temperature-resistant propelling agent is filled in the cavity; a laser welding plane being 1mm in depth is processed at the output end of the cavity; and an output cover piece is welded on the laser welding plane. The smoke-fire actuating cylinder provided by the invention is applicable to being used for a nuclear power unit, can resist the environment with long-time high temperature, high humidity and irradiation and can be used as a power source of the nuclear power safety device. The smoke-fire actuating cylinder provided by the invention has the advantages of simple process, safe operation, good sealing property and environmental adaptability and the like.

Owner:中国兵器工业第二一三研究所

Device for measuring distance between conducting wire and ground wire of power transmission line

PendingCN112444222AEasy to installEasy to operateMechanical measuring arrangementsApparatus for overhead lines/cablesDisplay deviceDamper

The invention relates to a device for measuring distance between a conducting wire and a ground wire of a power transmission line, and belongs to the technical field of transmission line conducting wire and ground wire length measurement. The device comprises a pressing component, a rolling component and a counting component, wherein the pressing component comprises a pressing roller, a pressing roller bracket, a connecting hinge and a handle, the rolling component comprises a roller, a roller bracket and a box body, and the counting component comprises a counting roller, a counting sensor, acounting roller bracket and a counting display device. According to the invention, the measuring device is easy to operate, universal, flexible, convenient to carry, suitable for measuring the lengthof conducting wires and ground wires with various sections and capable of meeting the requirement for the high-altitude operation environment; and the device is an effective and practical novel guideand ground wire length measuring tool, effectively solves the problem that no special distance measuring tool exists when the damper is installed and reset and the installation position of the spaceris determined, and greatly improves the working efficiency and safety guarantee of power transmission line operation and maintenance personnel.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

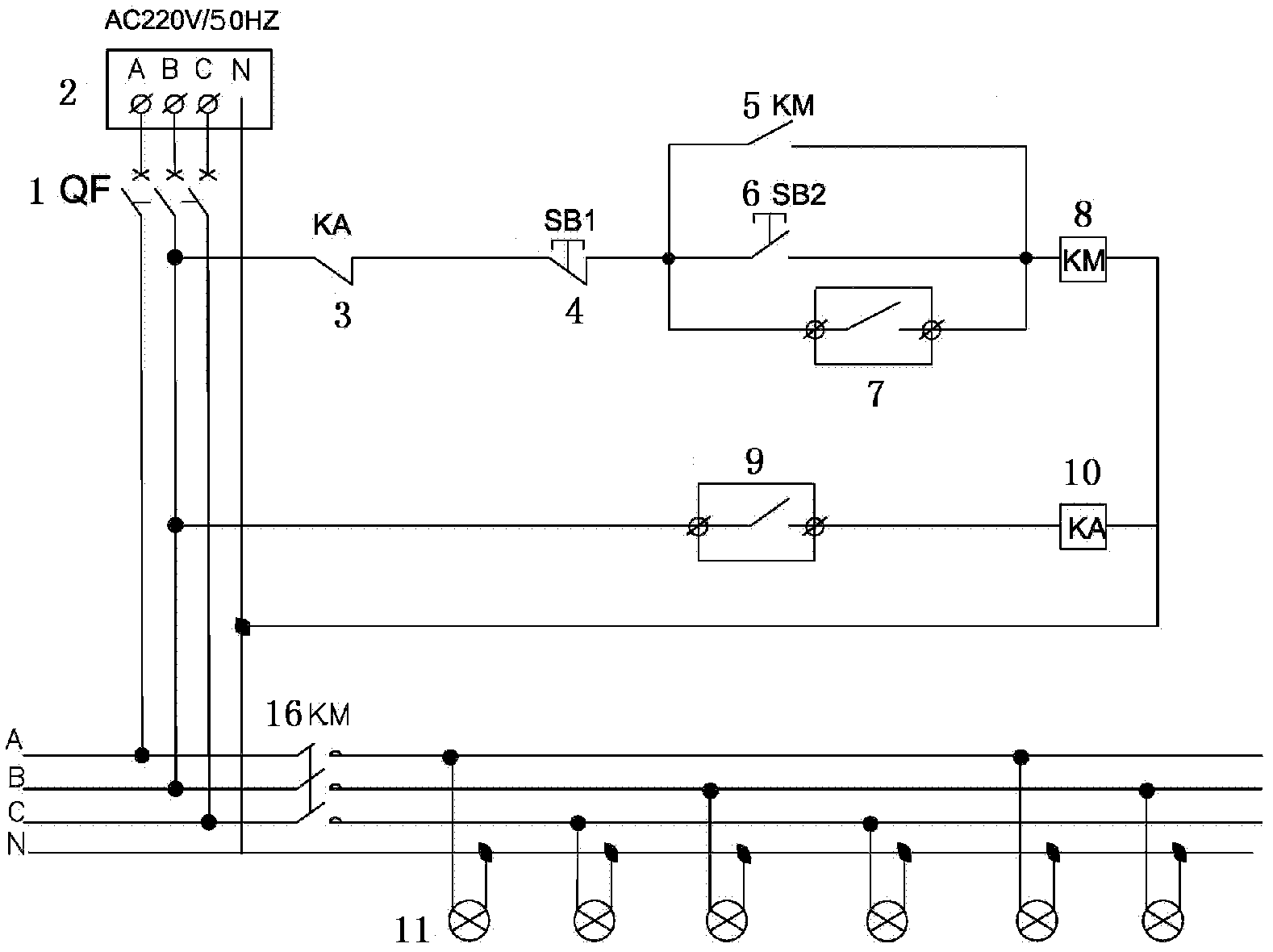

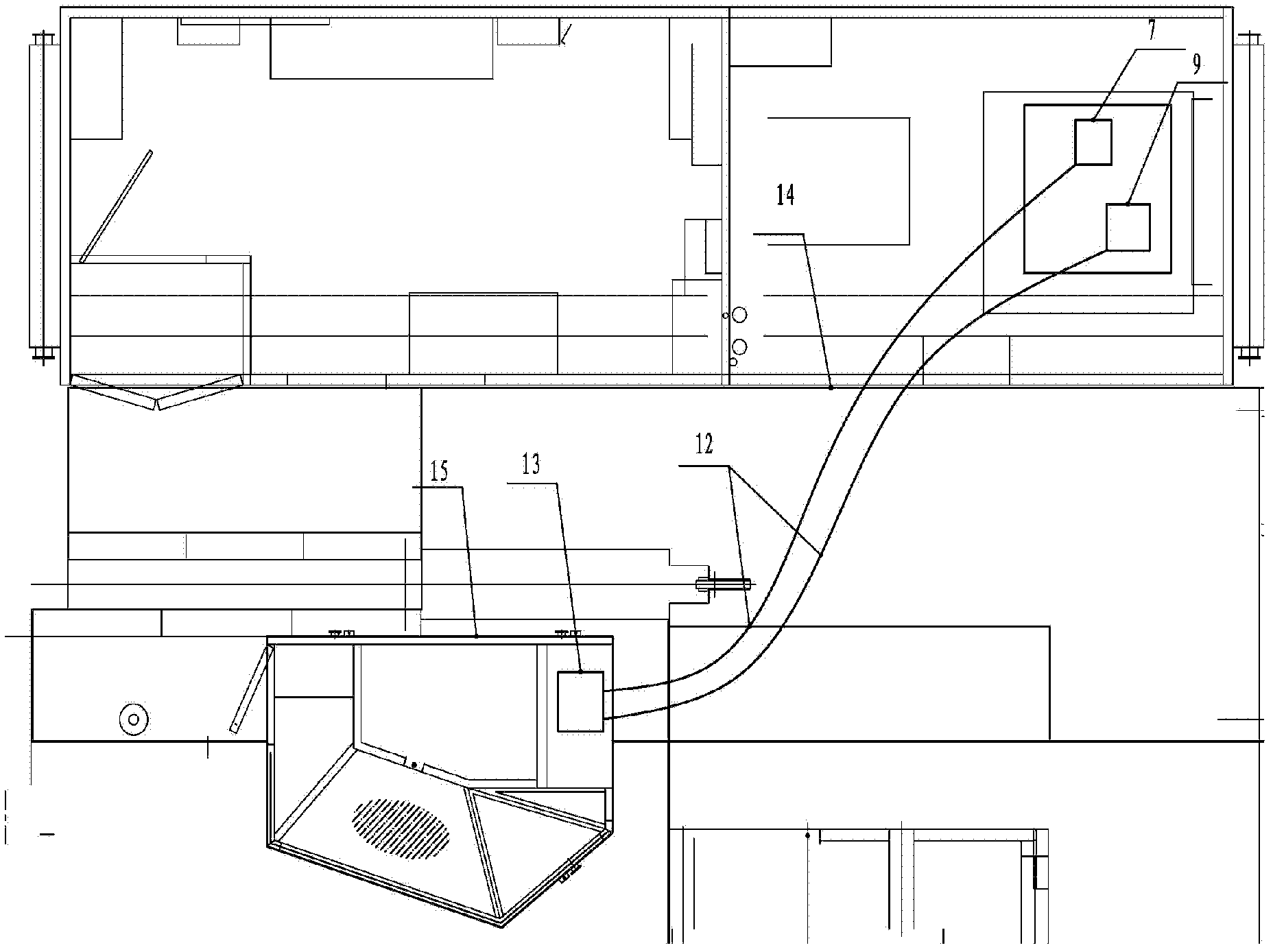

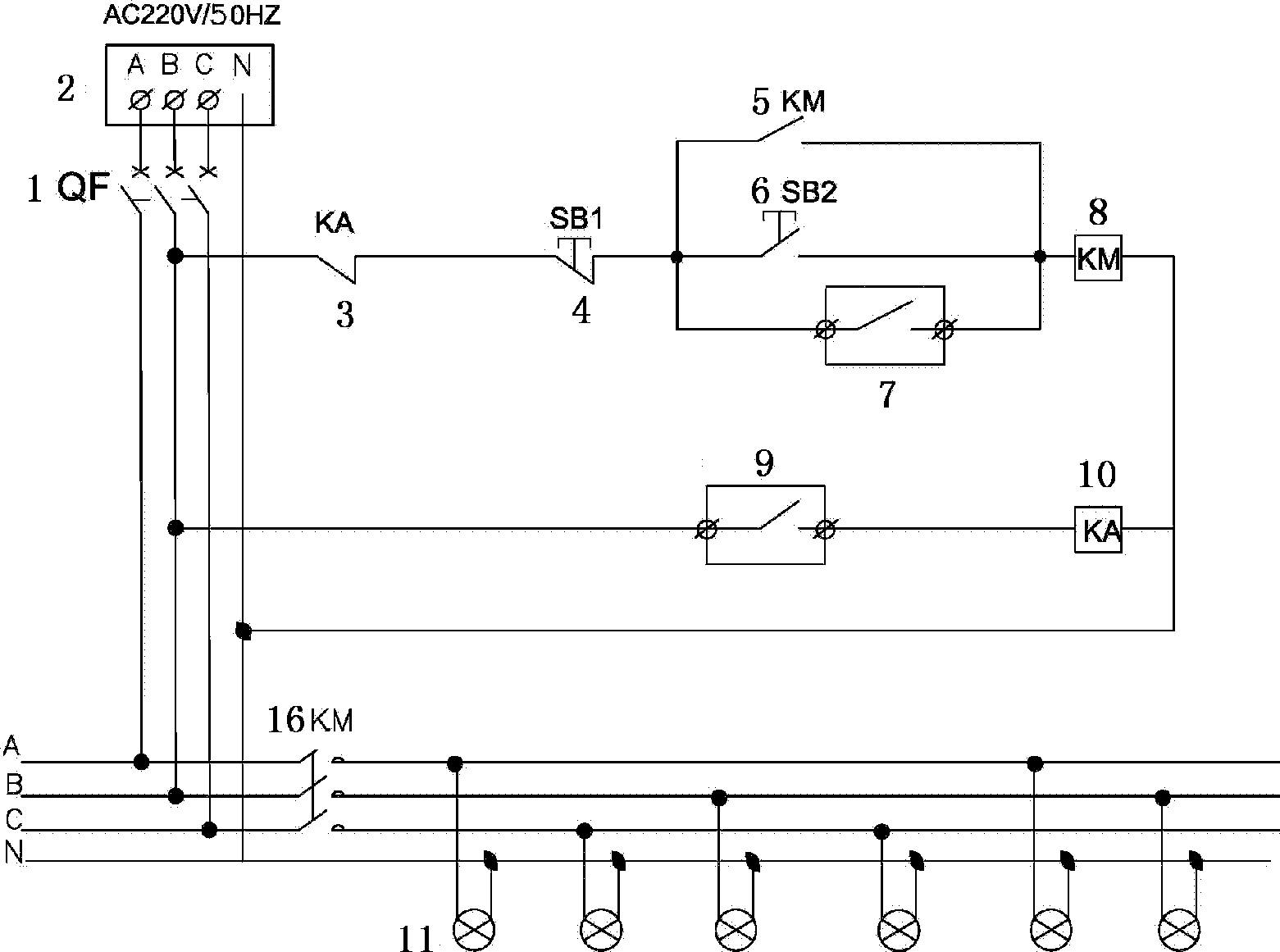

Explosion-proof light-induced lighting control device

InactiveCN102665334AReduce power consumptionLow costElectric light circuit arrangementPhase leadElectric energy

The invention discloses an explosion-proof light-induced lighting control device. A circuit breaker is arranged on a three-phase output line of a power supply, an intermediate relay KA contact and a second photosensor contact are respectively connected with a B phase line at an output end of the circuit breaker, the intermediate relay KA contact is connected with a self-locking button, an output end of the self-locking button is connected with an intermediate relay KM contact, a self-resetting button and a first photosensor contact simultaneously, and output ends of the intermediate relay KM contact, the self-resetting button and the first photosensor contact are connected with an intermediate relay KM coil simultaneously; the second photosensor contact is connected with an intermediate relay KA coil; an output end of the intermediate relay KM coil and an output end of the intermediate relay KA coil are connected with a zero line of the power supply simultaneously; and a second circuit breaker is installed on a working line which is connected with the power supply. By the aid of the device, the natural light is used to the maximum extent, the electric energy consumption is reduced, and the cost is reduced for users.

Owner:BAOJI PETROLEUM MASCH CO LTD

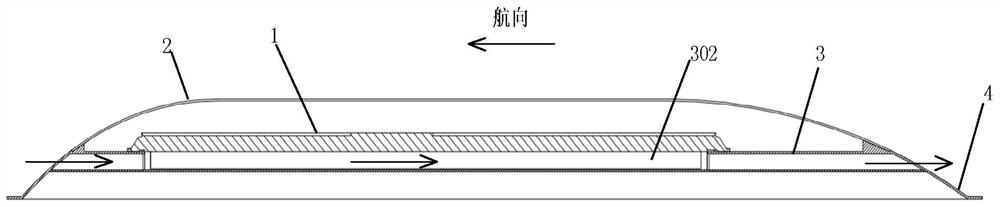

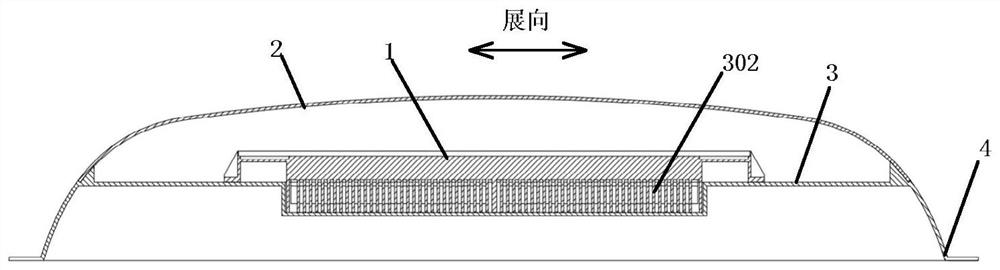

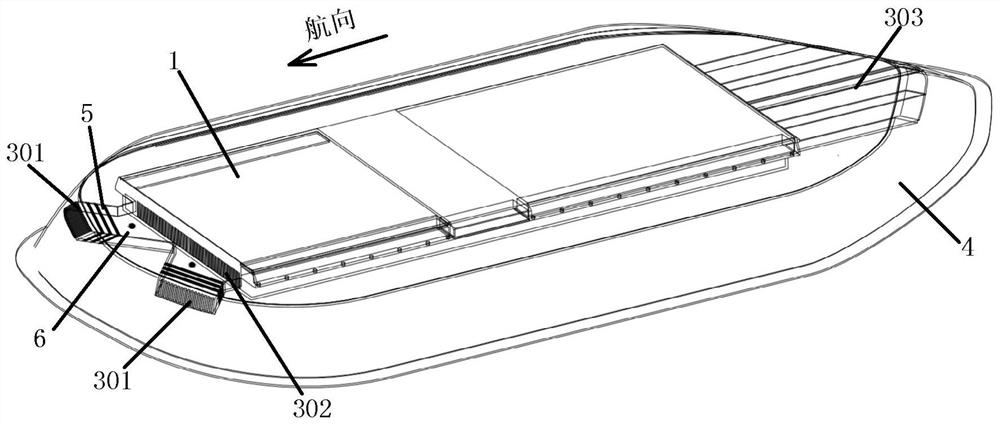

High-speed airflow through type air-cooled heat dissipation airborne antenna

ActiveCN113782940AProtection of enclosed spacesHigh ability to resist harsh environmentAntenna adaptation in movable bodiesRadiating element housingsCold airEngineering

A high-speed airflow through type air-cooled heat dissipation airborne antenna disclosed by the invention is resistant to a severe environment and high in heat dissipation efficiency. According to the technical scheme, a fairing and a radome define a closed space for protecting an antenna body, and the fairing is in smooth transition connection with the radome through an outer wall ring of a carrier plate; an air inlet area is designed at the front end of the carrier plate along the heading direction, and the antenna body is embedded in the rectangular concave cavity of the carrier plate through a middle rectangular concave cavity and a rear end air exhaust area and is buckled on the upper surface of the concave cavity of the carrier plate to form a heat dissipation functional area; and an antenna body is embedded into the concave cavity of the carrier plate and is provided with strip-shaped heat dissipation teeth along the course, heat generated by the antenna is conducted to the heat dissipation teeth of the antenna, the heat is taken away by blowing airflow generated in the high-altitude flight process of an aerial carrier, and high-speed cold air entering from air inlets in the left side and the right side of the inclined front end of the course converges at the rear end of the air inlet area, flows through the heat dissipation air channel and is discharged from the air outlet, and the air directly blows the surfaces of the heat dissipation teeth to discharge the heat dissipated by the antenna to the atmosphere.

Owner:10TH RES INST OF CETC

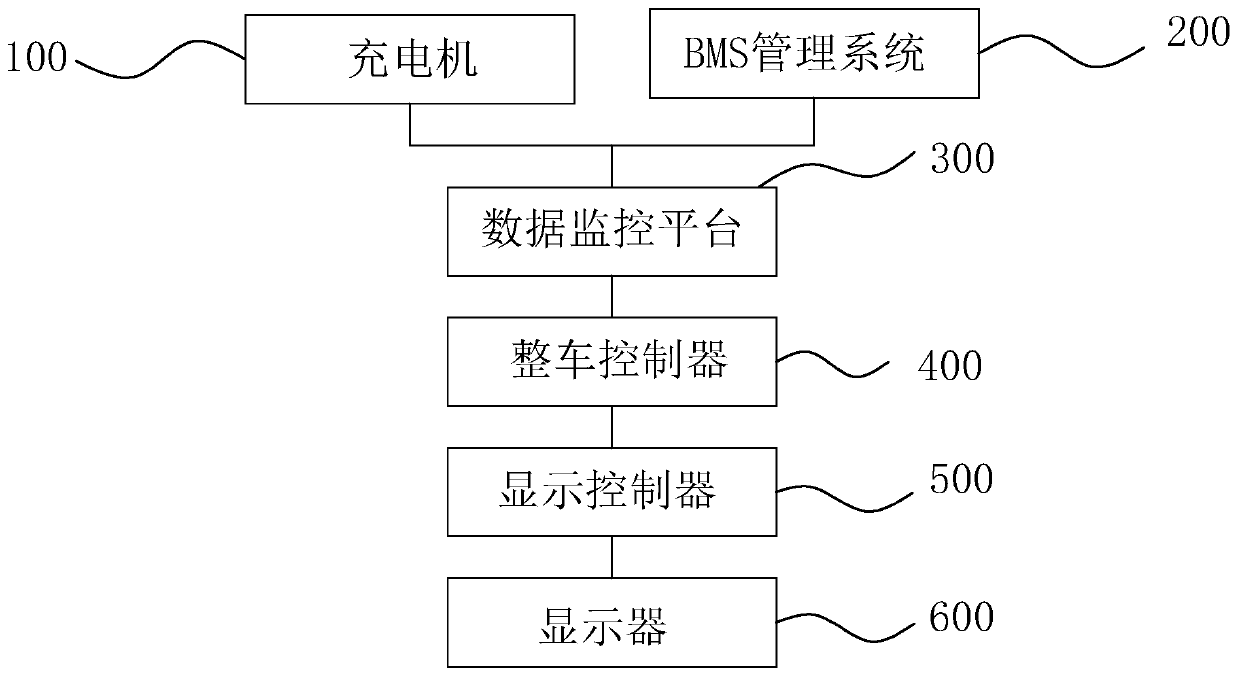

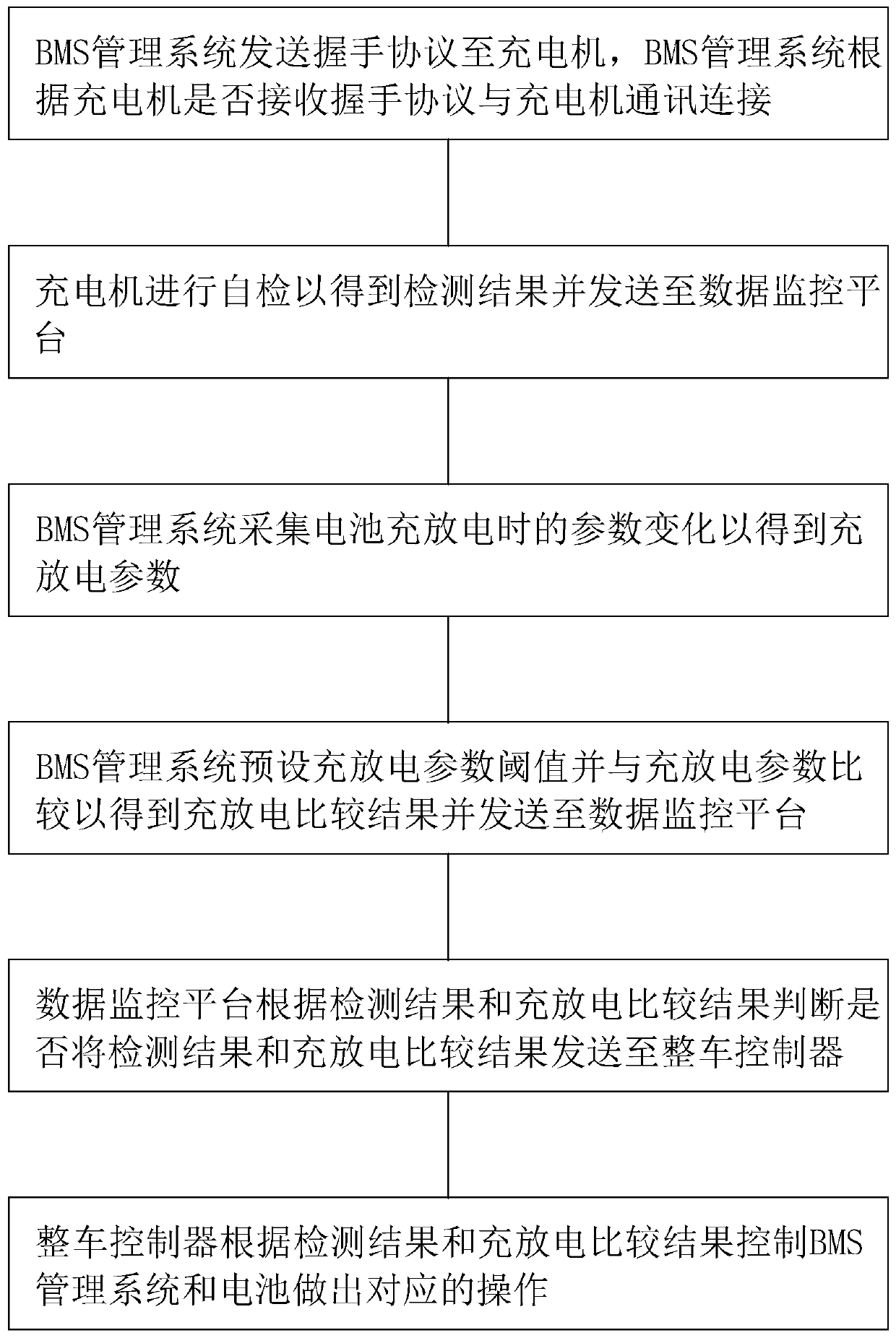

Explosion-proof automobile battery safety management method and system

InactiveCN111422098AImprove securityNormal charge and dischargeCharging stationsElectric devicesElectrical batteryVehicle control

The invention discloses an explosion-proof automobile battery safety management method and system. The method comprises the steps that a BMS management system is in communication connection with a charger according to whether the charger receives a handshake protocol or not; the charger performs self-inspection to obtain a detection result and sends the detection result to a data monitoring platform; the BMS management system collects charging and discharging parameters; the BMS management system presets a charging and discharging parameter threshold value and compares the charging and discharging parameter threshold value with the charging and discharging parameter to obtain a charging and discharging comparison result and send the charging and discharging comparison result to the data monitoring platform; the data monitoring platform judges whether to send the detection result and the charging and discharging comparison result to the vehicle control unit or not; and the vehicle control unit controls the BMS management system and the battery to perform corresponding operation according to the detection result and the charging and discharging comparison result. If the charger performs self-inspection, the BMS management system detects whether the charging and discharging parameters exceed the preset charging and discharging parameter threshold, the data monitoring platform sends the result to the vehicle control unit, and the vehicle control unit performs corresponding operation according to the detection result and the charging and discharging comparison result, so that the safety of the battery is improved.

Owner:SHENZHEN DELTA EXPLOSION PROOF ELECTRIC VEHICLE CO LTD

Extremely high temperature resistant and adjustable pneumatic loop sealing valve device

ActiveCN104180053APrevent material surgeSolve the problem of adjusting the amount of feeding and dischargingSpindle sealingsOperating means/releasing devices for valvesThermal insulationTungsten

The invention belongs to the technical field of chemical engineering and particularly relates to an extremely high temperature resistant and adjustable pneumatic loop sealing valve device. According to the extremely high temperature resistant and adjustable pneumatic loop sealing valve device, a high-temperature resistant thermal insulation layer is arranged on the casing inner wall in a lining manner; a high-temperature resistant lining is built in the wall body; a feed opening is formed in the left side at the top of the casing; a discharge opening is formed in the right side at the bottom of the casing; an extremely high temperature resistant rotating valve body is fixedly mounted on the wall between curved passages connecting the feed opening with the discharge opening; a tungsten rod shaft and a U-shaped tungsten plate are adopted as a frame; then corundum casting materials are adopted to cast the frame into the rotating valve body which satisfies the valve size requirement; the left end of the tungsten rod shaft extends out of the casing and is fixedly connected with a driving sleeve shaft of an electric actuator. Through the adoption of the extremely high temperature resistant and adjustable pneumatic loop sealing valve device, the material flushing phenomenon is effectively prevented and the working requirement for valves in extremely high temperature aerobic atmosphere is satisfied.

Owner:SHENYANG XINBO IND TECH

Shovel tooth and preparation method thereof

PendingCN113718163AMeet the requirements of special working environmentMeet the requirements of the working environmentFoundry mouldsSoil-shifting machines/dredgersHeat treatedShovel

The invention discloses a shovel tooth and a preparation method thereof. The method comprises the following steps: smelting raw materials to obtain molten iron, wherein the molten iron comprises the following components: C, Mn, Si, Cr, Al, Mo, Cu, Ni, Sb, V and iron; spheroidizing, inoculating and slagging off the molten iron, cooling the molten iron to 1350-1380 DEG C, then carrying out pouring, and performing heat treatment to obtain the shovel tooth, wherein the heat treatment comprises the following steps: carrying out heating to 950-1100 DEG C, keeping the temperature for 10-30 minutes, performing air cooling to room temperature, carrying out heating to T DEG C, keeping the temperature for t min, wherein T is equal to 870-910, and t is equal to 80-110; placing the unfinished product into a nitrate solution at 220-300 DEG C, keeping the temperature for 100-200 minutes, performing water quenching at room temperature for 30-45 minutes, cooling the unfinished product in liquid nitrogen at -200 DEG C to -190 DEG C for 100-150 minutes, and standing to room temperature. The method provided by the invention is simple in process, and the obtained shovel tooth is high in hardness, good in impact toughness, excellent in wear resistance and long in service life.

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

Shock-absorbing device

ActiveCN101363497AImprove cooling effectImprove seismic performanceNon-rotating vibration suppressionRubidiumEngineering

The invention relates to a vibration absorber and is characterized in that: the vibration absorber comprises a box which is matched with the shape of an article to be treated with vibration damping, the side wall of the box and a cover board at the top of the box are embedded or attached with vibration damping material, the bottom of the box is provided with a damping ring which is evenly wound with heat dispersing materials and is equipped with a lining board, and the article to be treated with vibration damping is fixed on the lining board; wherein, the preparing process of the heat dispersing materials is as follows: firstly the inner core of a shielding wire is drawn out to obtain an external shield metal mesh; then the external shield metal mesh is planished and shortened segment by segment to obtain the heat dispersing materials. The invention overcomes the defects of the prior art and provides the vibration absorber which can meet the operating environment requirements of a product needing both vibration damping and heat dissipation; the vibration absorber is especially suitable for the vibration damping of the small-scale articles with high accuracy requirements such as rubidium clocks, etc.

Owner:中国航天科技集团公司第五研究院第五〇四研究所

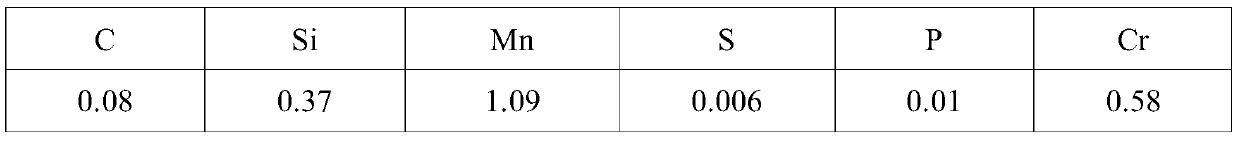

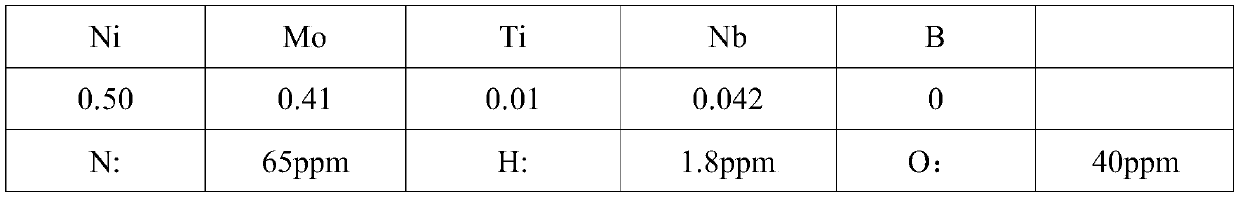

ZG-SY09MnCrNiMo RE steel and method for manufacturing casting of ZG-SY09MnCrNiMo RE steel

ActiveCN110468329AMeet the requirements of the working environmentHigh strengthMechanical propertySteel casting

The invention discloses a ZG-SY09MnCrNiMo RE steel and a method for manufacturing a casting of the ZG-SY09MnCrNiMo RE steel. The ZG-SY09MnCrNiMo RE steel comprises the following components in percentage by mass: 0.06%-0.10 % of C, 0.25%-0.4 % of Si, 1.3%-1.6 % of Mn, 0.4%-0.6 % of Ni, 0.01%-0.02 % of Ti, 0.03%-0.06 % of Nb, 0.4%-0.6 % of Cr, 0.35%-0.5 % of Mo, less than or equal to 0.02% of P, less than or equal to 0.01% of S and the balance Fe, wherein the percentages of the components add up to 100%. The method comprises the steps of 1, carrying out melting, oxidizing and primary reducing byusing an electric furnace; 2, refining by using an LF refining furnace; 3, pouring; and 4, normalizing and tempering the steel casting. The steel and the casting of the steel have excellent mechanical properties and good application prospects.

Owner:MCC SFRE HEAVY IND EQUIP

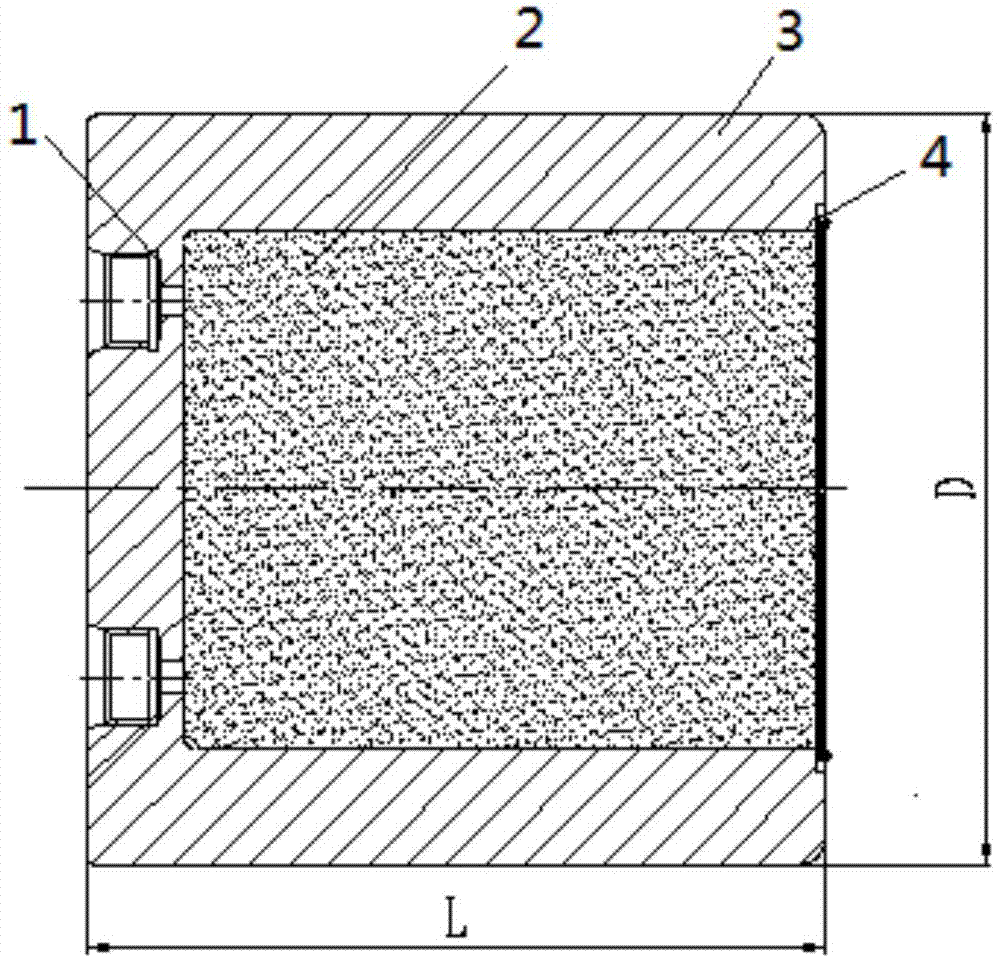

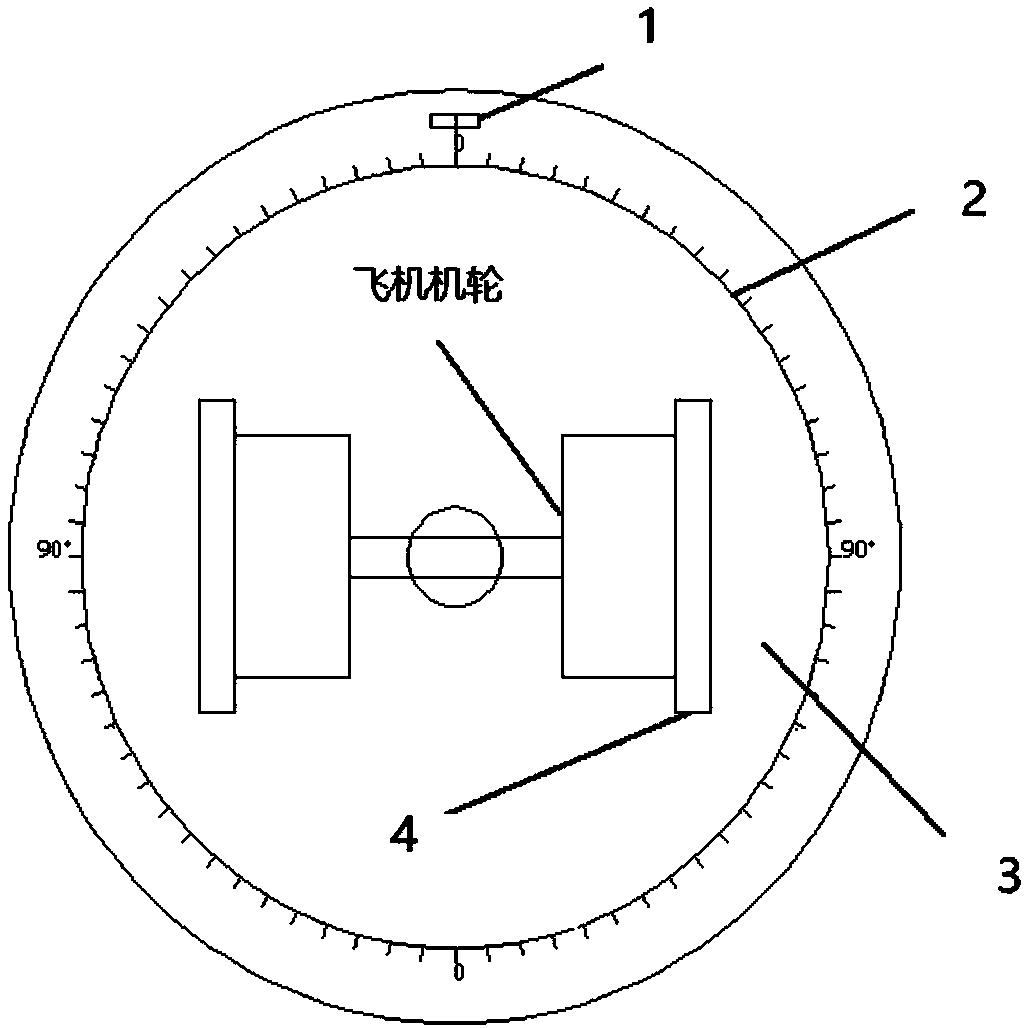

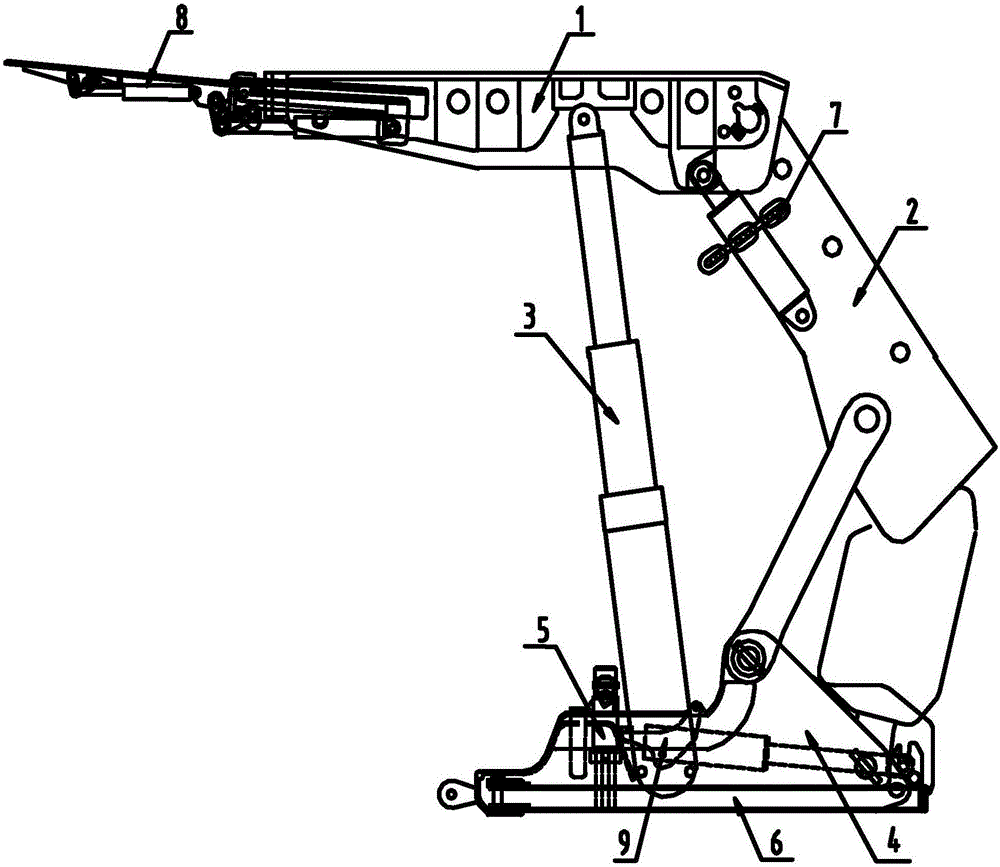

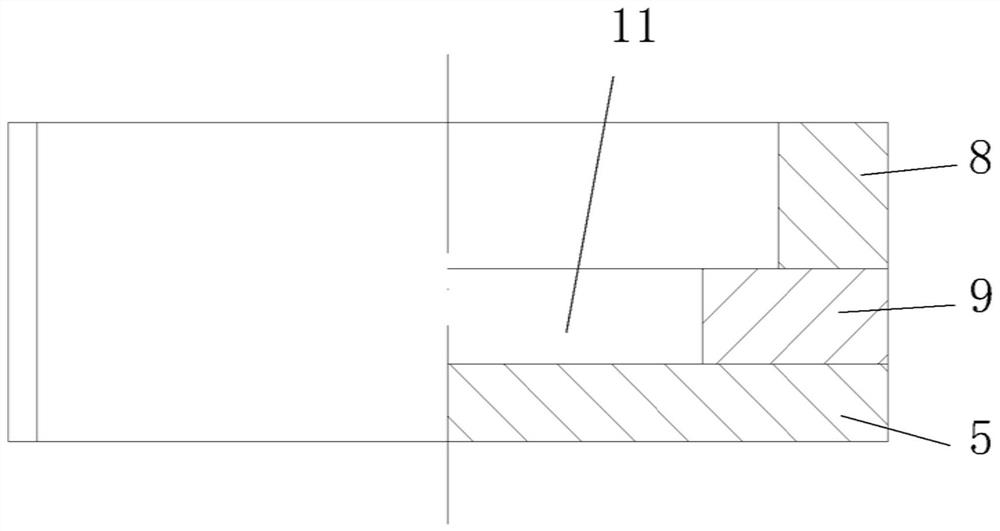

Device and method for performing front-wheel turning function inspection without jacking aircraft

InactiveCN109774966AImprove accuracyImprove effectivenessAircraft components testingWheel arrangementsEconomic benefitsAirplane

The invention relates to a device for performing front-wheel turning function inspection without jacking an aircraft. The device comprises a laser calibration device (1), an angle indicator (2), a front-wheel rotating disc (3) and a locking device (4); the device is characterized in that the front-wheel rotating disc (3) is a body part of the device for performing front-wheel turning function inspection without jacking the aircraft, and the annular angle indicator (2) and the laser calibration device (1) are arranged on the outer side periphery of the front-wheel rotating disc (3) as measuringparts; the locking device (4) is arranged on the front-wheel rotating disc (3) as an auxiliary part. Under the condition of not jacking the aircraft, the aircraft front-wheel turning function is inspected, workers are greatly reduced, the working procedure of jacking the aircraft is omitted, and the condition requirement for using tools is reduced; the workers can be effectively reduced, the production efficiency is improved, the technological threshold is lowered, economic benefits are improved, and abrasion to the aircraft and the tools is reduced.

Owner:中航通飞华南飞机工业有限公司

SY15MnNiCrMoVNbTi steel and preparing method of structural component of same

ActiveCN105018858AMeet the requirements of the working environmentHigh strengthWorking environmentPerformance index

The invention discloses SY15MnNiCrMoVNbTi steel. The SY15MnNiCrMoVNbTi steel consists of the following components in percents by mass: 0.16-0.20 of C, 0.20-0.50 of Si, 1.40-1.60 of Mn, smaller than or equal to 0.025 of P, smaller than or equal to 0.025 of S, 1.00-1.20 of Cr, 0.40-0.60 of Mo, 1.30-1.50 of Ni, 0.05-0.10 of V, 0.03-0.06 of Nb, 0.02-0.20 of Ti, smaller than or equal to 0.006 of B and the balance of Fe, wherein the sum is 100%. The invention further discloses a preparing method of the structural component of the SY15MnNiCrMoVNbTi steel. The material and the steel structural component reach mechanical performance meeting design requirements through adjusting alloy elements and adopting a reasonable thermal treatment technology, so that the requirement on the work environment in which the steel structural component is positioned is met; and the performance indexes of the steel structural component, such as strength, rigidity, stability, cold and hot processing moldability and weldability, are improved, and the service life of the steel structural component is prolonged.

Owner:MCC SFRE HEAVY IND EQUIP

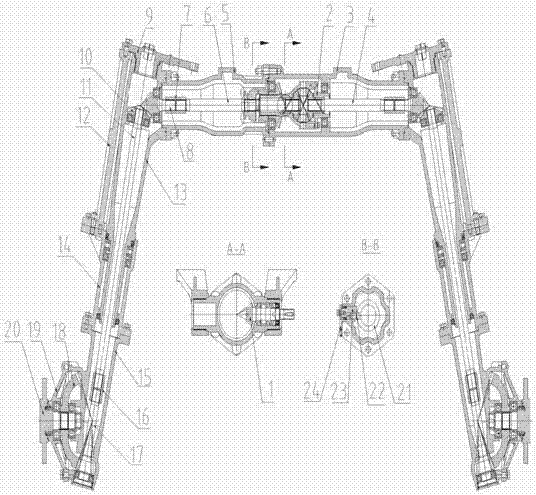

Hydraulic support

ActiveCN105781600APlay a protective effectPlay a guiding roleMine roof supportsArchitectural engineeringCross bridge

The invention relates to a hydraulic support and belongs to the technical field of coal mining equipment. The hydraulic support comprises a top beam, a shield beam and a base. The base is provided with a base lifting jack and a pushing rod. A limiting crossing bridge is arranged in the position, above the pushing rod, of the base. The base is provided with a lug plate. The cylinder end of the base lifting jack is connected with the lug plate. A sliding block is arranged at the piston end of the base lifting jack. The position, corresponding to the sliding block, of the inner wall of the base is provided with a sliding way. The base is further provided with a vertical pillar fixing part. The hydraulic support has the characteristics that the contact performance of the base lifting jack and the pushing rod is good, the stability of the base lifting jack and a vertical pillar is improved, the maintenance probability is reduced, the work efficiency is improved, and the security coefficient is high.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Small milling machine for workpiece positioning

InactiveCN113751767AImprove machining accuracyImprove processing efficiencyMilling machinesPositioning apparatusElectrical conductorSuperconducting Coils

The invention discloses a small milling machine for workpiece positioning. The small milling machine comprises a milling machine mechanism, a crane base and a clamp support arranged at one end of the crane base, a fixed clamp and a movable clamp are installed on the clamp support, and the movable clamp is movably installed on the clamp support through a lead screw mechanism; the fixed clamp and the movable clamp are used for clamping a conductor coil, and the movable clamp can move front and back in the Y-axis direction under driving of the lead screw mechanism so as to be matched with the curvature of the conductor coil; the milling machine mechanism is installed on the crane base and used for tapping in the conductor coil winding process. and a plurality of suspension rings are also arranged at the end parts of the crane base and the clamp support. The small milling machine is suitable for machining special workpieces, and compared with existing milling machine equipment, the small milling machine is compact in structure, large in rigidity and high in precision, can meet the working environment requirement of coil winding field tapping, improves the machining precision and efficiency of helium holes, and provides equipment guarantee for superconducting coil helium hole drilling.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

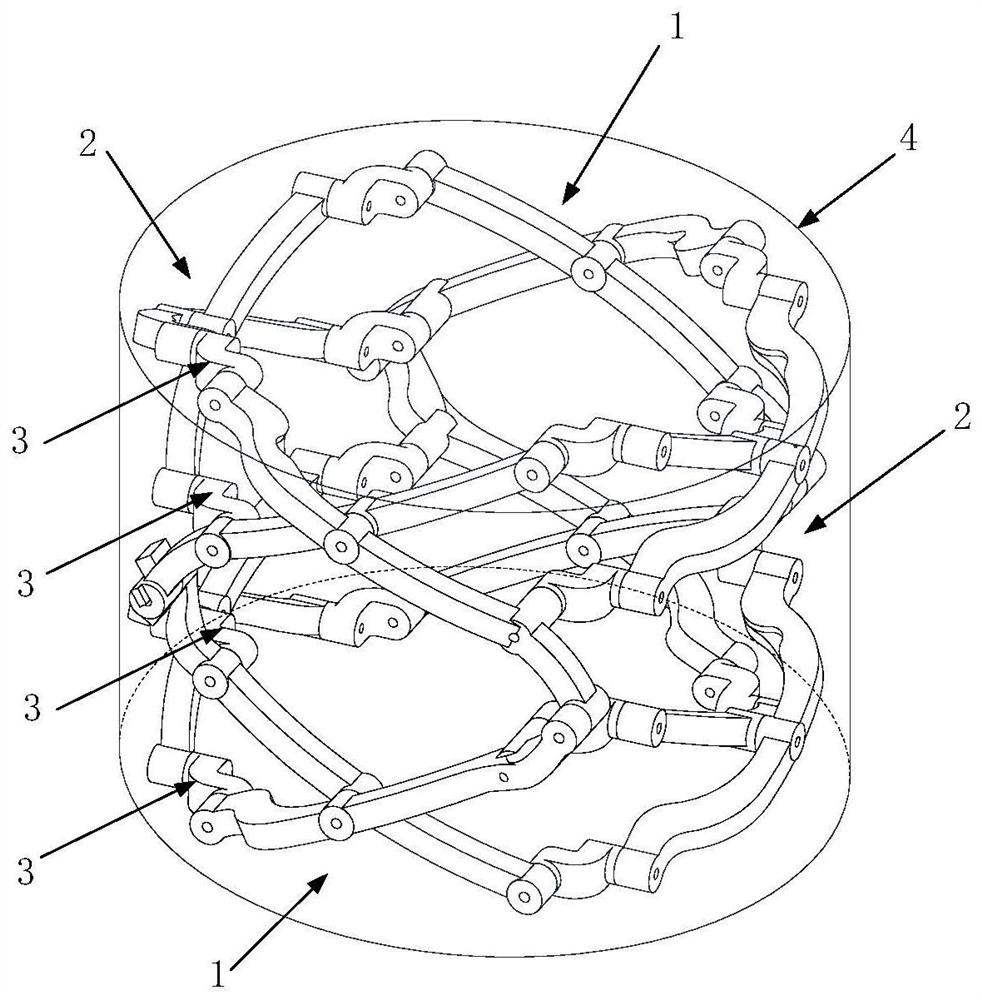

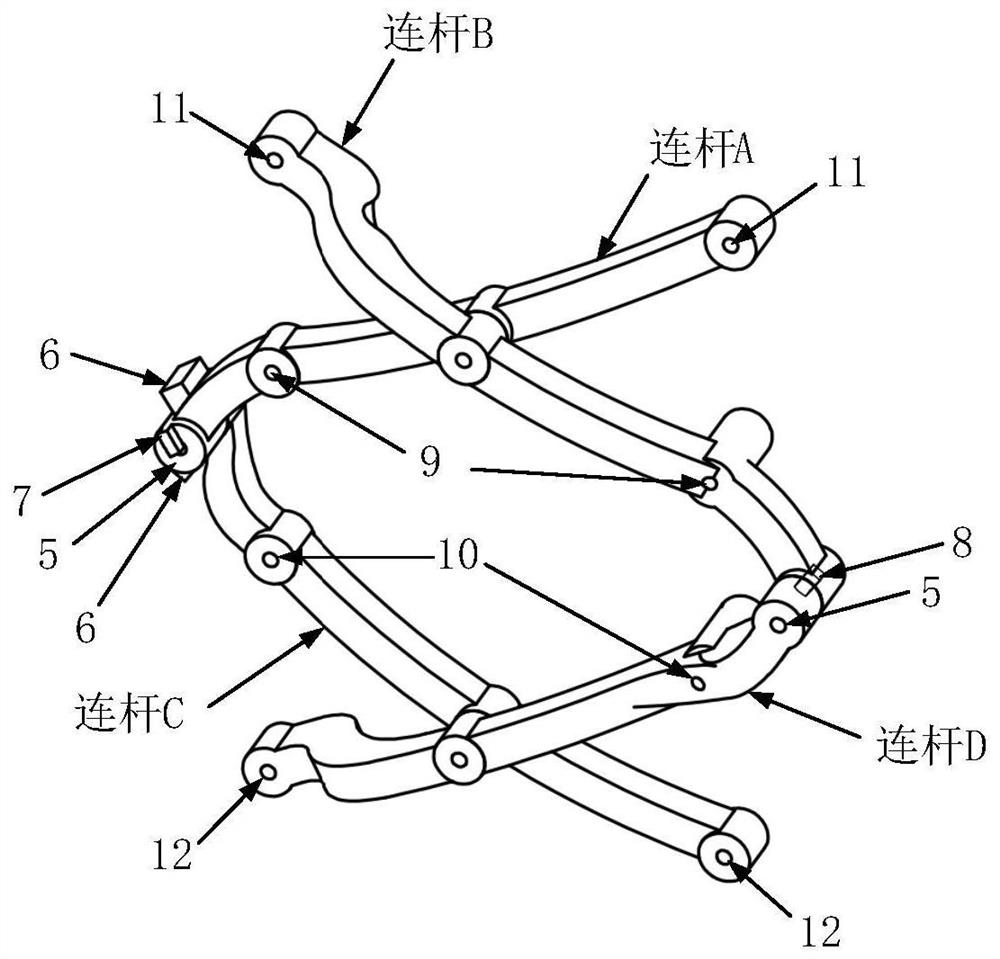

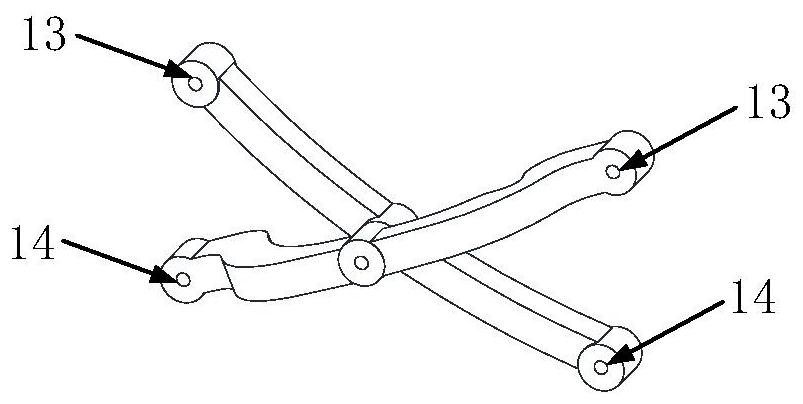

Pipeline environment operation oriented reconfigurable folding and unfolding mechanism

ActiveCN113374981AAdapt to operational requirementsGood movement reliabilitySurgeryEndoscopesClassical mechanicsEngineering

The invention discloses a pipeline environment operation oriented reconfigurable folding and unfolding mechanism. The whole mechanism is composed of metamorphic shear fork mechanisms on the front side and the rear side and auxiliary shear fork mechanisms on the two side, wherein each side is provided with two pairs of auxiliary shear fork mechanisms. Each metamorphic shear fork mechanism is composed of four connecting rods, and all rods pieces are connected to form revolute pairs. The auxiliary shear fork mechanisms on the two sides are each composed of two connecting rods which are connected through a rotating pair. The metamorphic shear fork mechanisms are connected with the auxiliary shear fork mechanisms on the two sides through connecting pieces, and the connecting mode is also revolute pair connection. In order to better adapt to pipeline environments, each rod piece of the mechanism is designed to be in an arc shape. Therefore, the reconfigurable folding and unfolding mechanism with two motion modes is formed, and the reconfigurable folding and unfolding mechanism can be bent in a folded state so as to pass through pipeline environments with different curvatures; after reaching a target position, the reconfigurable folding and unfolding mechanism can be switched from the bending motion mode to the folding and unfolding motion mode so as to adapt to pipeline environments with different inner diameters; and the degree of freedom of the mechanism in the two motion modes is one, and motion and switching control in the two modes can be achieved only through one drive.

Owner:BEIHANG UNIV

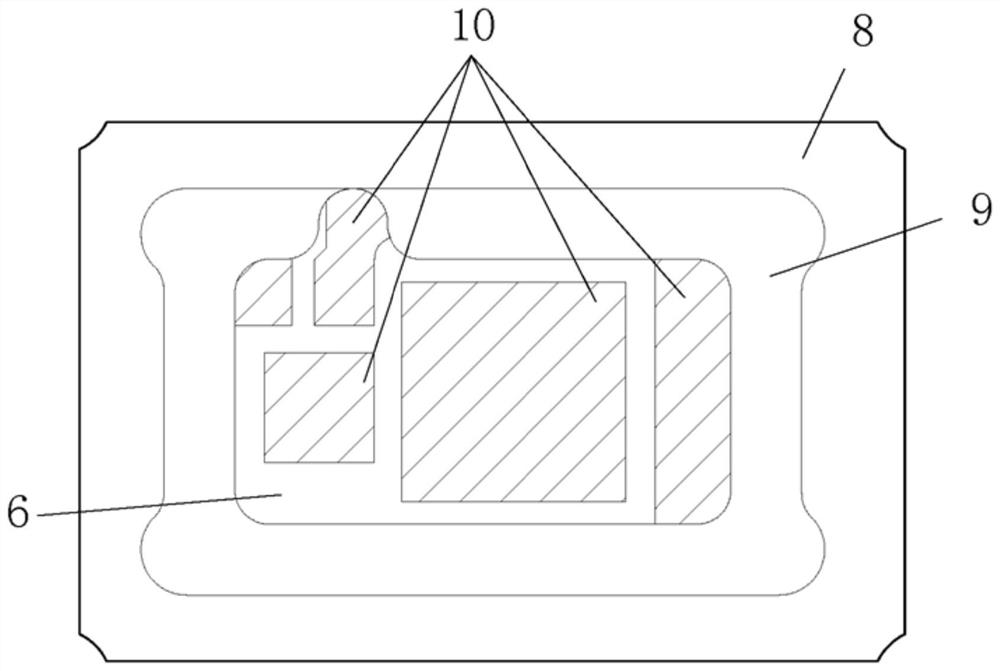

Water-cooling adjustable compensation hot cathode device

ActiveCN114071819AMeet the requirements of the working environmentExtended service lifeElectric discharge heatingMaterials scienceElectrical current

The invention discloses a water-cooling adjustable compensation hot cathode device. The device comprises a water-cooled electrode mounted on the central axis of the multiple electrodes, a position adjusting device for adjusting the position of the water-cooled electrode extending into the multiple electrodes, and a rotary air inlet device mounted at the front part of the water-cooled electrode. A lanthanum tungsten electrode in the device is inserted into the center of a multi-electrode, electrode cooling is achieved through a water cooling device connected with the tail in a sealed mode, the inner length extending into the multi-electrode is adjusted through a position adjusting device, and rotary shunting of high-pressure argon is achieved through matching of spiral notch grooves evenly distributed in the circumferential surface of the front section of the lanthanum tungsten electrode and a ceramic cylinder. Under the combined action of water cooling, argon protection and electric arc firing, the front end surface of the lanthanum tungsten electrode has a good current bearing capacity within a large temperature range below 3000 DEG C, the electrode shunting capacity of multiple electrodes under high air pressure can be improved, high-voltage, large-current and long-time stable operation of the sheet type electric arc heater is achieved, and the device is suitable for carrying out a heat protection test.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

A ceramic package base

ActiveCN113161297BHigh thermal conductivityReduce wire resistanceSemiconductor/solid-state device detailsSolid-state devicesRare-earth elementElectrical resistance and conductance

The invention discloses a ceramic packaging base. This ceramic package base includes an insulating base and a tungsten conductive layer; the tungsten conductive layer is disposed on at least one surface of the insulating base; the insulating base is formed of aluminum nitride ceramics; wherein, the tungsten conductive layer includes W, Al and M, where M represents rare earth elements. The aluminum nitride ceramic package base prepared by the invention has high thermal conductivity, good bonding force of the conductive layer and low wiring resistance. This aluminum nitride ceramic package base is suitable for the sensor field, especially the high-power TOF module package, which not only solves the problem of heat dissipation, but also meets the requirements of the TOF working environment.

Owner:CHAOZHOU THREE CIRCLE GRP

A kind of sy15mnnicrmovnbti steel and its structural parts preparation method

ActiveCN105018858BMeet the requirements of the working environmentHigh strengthWorking environmentPerformance index

The invention discloses SY15MnNiCrMoVNbTi steel. The SY15MnNiCrMoVNbTi steel consists of the following components in percents by mass: 0.16-0.20 of C, 0.20-0.50 of Si, 1.40-1.60 of Mn, smaller than or equal to 0.025 of P, smaller than or equal to 0.025 of S, 1.00-1.20 of Cr, 0.40-0.60 of Mo, 1.30-1.50 of Ni, 0.05-0.10 of V, 0.03-0.06 of Nb, 0.02-0.20 of Ti, smaller than or equal to 0.006 of B and the balance of Fe, wherein the sum is 100%. The invention further discloses a preparing method of the structural component of the SY15MnNiCrMoVNbTi steel. The material and the steel structural component reach mechanical performance meeting design requirements through adjusting alloy elements and adopting a reasonable thermal treatment technology, so that the requirement on the work environment in which the steel structural component is positioned is met; and the performance indexes of the steel structural component, such as strength, rigidity, stability, cold and hot processing moldability and weldability, are improved, and the service life of the steel structural component is prolonged.

Owner:MCC SFRE HEAVY IND EQUIP

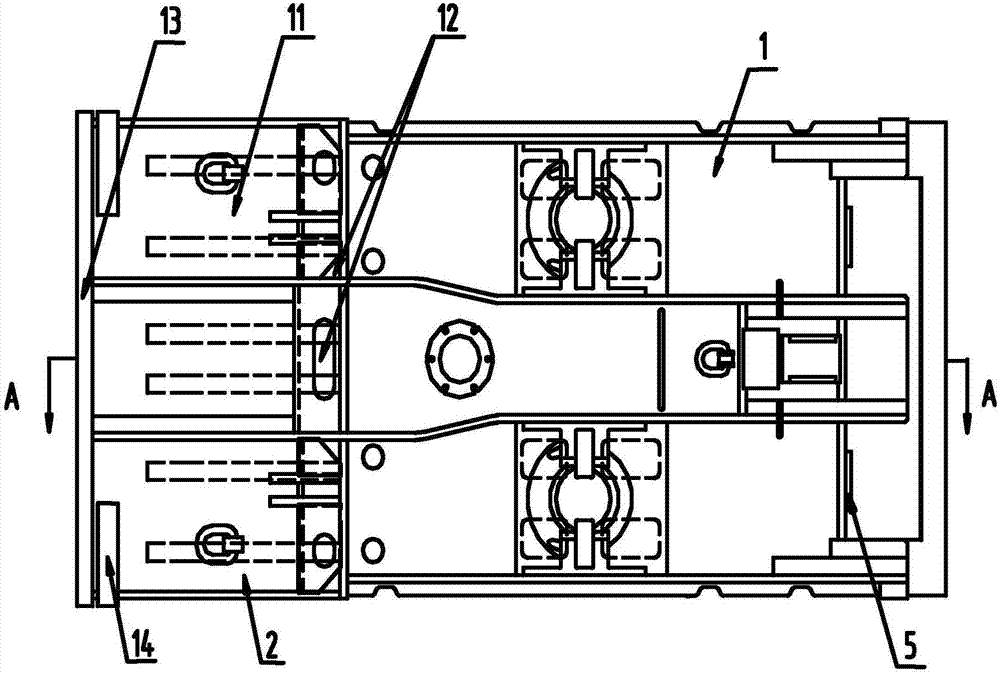

High ground clearance front axle for plant protection machine with 50 horsepower

InactiveCN107054077AEffective protectionMeet the requirements of the working environmentAxle unitsControl devicesManufacturing technologyWorking environment

The invention belongs to the technical field of motor vehicle drive axle equipment manufacturing and relates to a high ground clearance front axle for a plant protection machine with 50 horsepower. The high ground clearance front axle can be widely applied to the plant protection machine. The main structure of the high ground clearance front axle comprises a differential assembly, a main connecting pipe, connecting pipes, edge decelerating active bevel gears, connecting pipe upper covers, half shafts, steering supports, decelerating axle pipes, steering connecting pipes, steering shell bodies, final-stage decelerating active pinions, final-stage decelerating passive large gears, steering shell covers and the like. The main connecting pipe is connected with the connecting pipes. The right side of the main connecting pipe and the left sides of the connecting pipes are connected with the decelerating axle pipes correspondingly. The lower portions of the decelerating axle pipes on the left side and the right side are connected with the steering connecting pipes correspondingly. The steering supports are mounted on the upper portions of the steering connecting pipes on the left and right sides correspondingly. The lower portions of the steering connecting pipes on the left and right side are connected with the steering shell bodies correspondingly. The main structure of the high ground clearance front axle is simple, the design and conception are ingenious, mounting and using are convenient, machining manufacturing is easy, the working environment is friendly, and market prospects are wide.

Owner:山东卫禾传动股份有限公司

A top beam and a hydraulic support comprising the top beam

The invention relates to a top beam and a hydraulic bracket with the top beam, and belongs to the technical field of coal mine equipment. The top beam is internally provided with a telescopic beam; one end of the top beam is of a box body structure; the other end of the top beam is of a cavity structure; a side protecting mechanism is arranged at the cavity structure; coal falling holes are formed in the bottom of the cavity structure; and a flow-up limiting mechanism is arranged at the telescopic beam. The top beam has the characteristics of stability, high reliability, low equipment repairing expense, good practicability, tight contact with a top plate and long service life.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

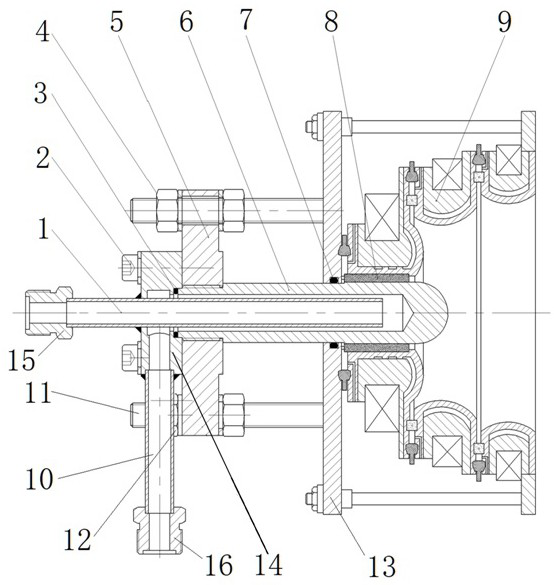

Montejus equipped with injector

ActiveCN101109397BTo achieve the purpose of raising liquidEfficient jettingPressure pumpsMachines/enginesWater dischargePneumatic valve

The invention relates to a pneumatic fluid lifter with an injector. On a pump body, a control console is installed, which is provided with an compressed air inlet, an air admission channel and an installation hole, in which a distribution box is installed. The compressed air enters into the distribution box through a control cover board, is injected into the exhaust port through an injection hole; negative pressure is produced in the pump body to suck out the air in the pump body, the water-sucking one-way valve opens, the water is sucked into the pump from the pump bottom; the float in the pump raises to push the cone of the pneumatic valve to rise, when the water level reaches to the designed height, the cone closes the exhaust port, the compressed air transfers into the press-in pump, the water-suction port closes, the water discharging port opens, the water is pressed out from the pump body. As the pneumatic fluid lifter has no rotary part, compressed air is used to suck and discharge water, and water is sucked and discharged automatically depending upon the water level, so un-attended operation is achieved, labor is saved. The pneumatic fluid lifter is of simple structure, easy to maintain, low cost, and can work normally at low water level. The pneumatic fluid lifter has no electric apparatus, is explosive proof, is applicable for working in pits of coal mines and environment with explosive gas.

Owner:洛阳百克特科技发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com