Water-cooling adjustable compensation hot cathode device

An adjustable and hot cathode technology, applied in the direction of electrothermal devices, heating by discharge, electrical components, etc., can solve the problems of inability to effectively shunt large current loads, reduce the excitation effect of electromagnetic fields, reduce the current capacity and life of electrode sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

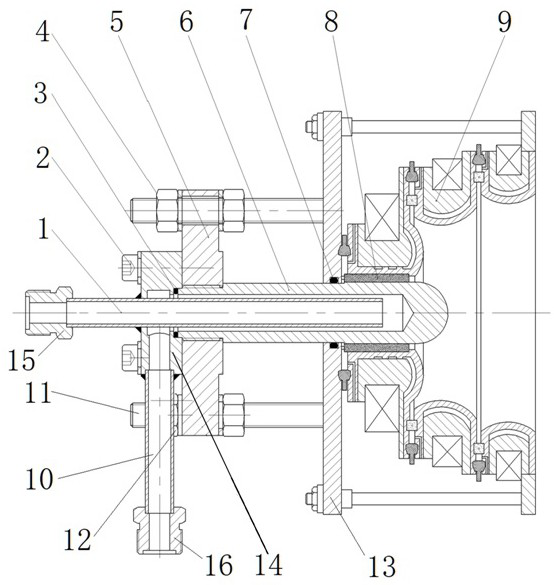

[0034]The lanthanum-tungsten electrode 6 of this embodiment is used as the central electrode of the multi-electrode 9, and the anti-ablation ability of the lanthanum-tungsten electrode 6 is used to make up for the low rotation speed of the arc on the surface of the central electrode, so as to improve the long-term operation capability, and the core area of the multi-electrode 9 is utilized The high-temperature radiation of the ion and the high temperature generated by the arc burning after the lanthanum-tungsten electrode 6 carries the current improve the current-carrying capacity of the lanthanum-tungsten electrode 6 and realize arc stability in a high-pressure environment. Between the lanthanum-tungsten electrode 6 and the flange 13 of the multi-electrode back cover, the sealing ring II 7 is used to realize the sealing of the high-pressure working gas inside the multi-electrode 9 . The connecting flange 5 and the lanthanum-tungsten electrode 6 are connected by threads, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com