High ground clearance front axle for plant protection machine with 50 horsepower

A technology for machinery and plant protection, applied in the directions of axles, wheels, control devices, etc., can solve the problems of insufficient height of the axle from the ground, reduced work efficiency, broken shafts and tooth punching, etc., to achieve good durability and practicability, and improve work. Efficient and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

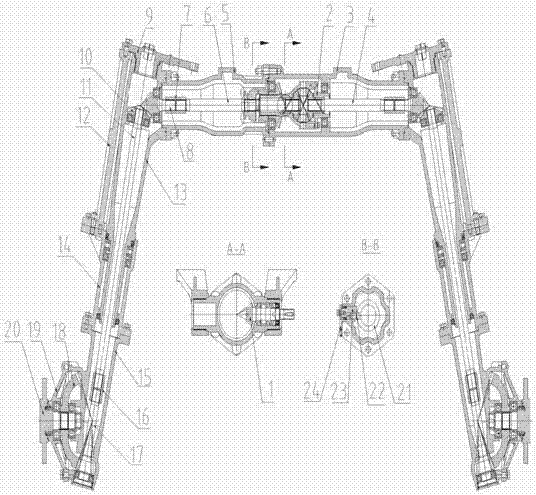

[0016] The main structure of the 50-horsepower plant protection machinery described in the present embodiment uses a high-lift front axle including: input gear shaft 1, differential gear assembly 2, main connecting pipe 3, first connecting half shaft 4, connecting pipe 5, The second connecting half shaft 6, the spline sleeve of the first half shaft 7, the active bevel gear 8, the upper cover of the connecting pipe 9, the passive bevel gear 10, the half shaft 11, the steering bracket 12, the reduction bridge tube 13, the steering Connecting pipe 14, steering housing 15, second half shaft spline sleeve 16, final reduction active pinion gear 17, final reduction passive large gear 18, steering housing cover 19, output flange shaft 20, differential lock coupling sleeve 21. Differential lock dial 22, differential lock dial shaft 23 and differential lock rocker arm 24; the main connecting pipe 3 is connected with the connecting pipe 5, and the right side of the main connecting pipe 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com