A top beam and a hydraulic support comprising the top beam

A technology of roof beams and telescopic beams, applied to roof beams supporting mine roofs, mining equipment, earthwork drilling and mining, etc., can solve problems such as coal wall slabs, roof shedding, poor roof conditions, and low safety factors, and achieve Improve stability and reliability, avoid damage to the balance jack, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

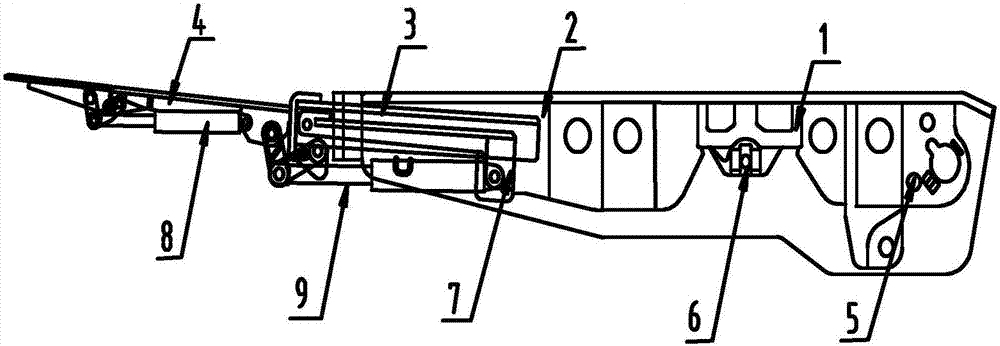

[0033] Such as Figure 1-2 As shown, a top beam is provided with a telescopic beam 3 inside, one end of the top beam is set as a box structure 1, and the other end is set as a cavity structure 2, and a limit mechanism is set at the box structure 1 5. The limit mechanism 5 is set as a limit block, the limit block is located at the bottom of the top beam, and the limit block is located at the height of 1 / 4-1 / 3 of the top beam, and the top beam and A balance jack is arranged between the cover beams. When the hydraulic support is at the highest position, the limit mechanism 5 limits the angle between the cover beam and the top beam, which can effectively avoid damage to the balance jack and strengthen the hydraulic support. It can effectively support the roof and reduce equipment maintenance costs.

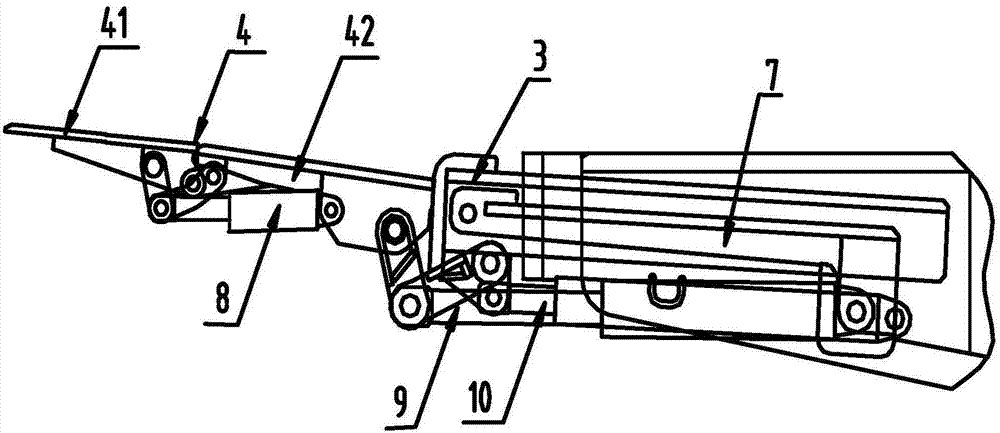

[0034] The cavity structure 2 is provided with a side protection mechanism 4, and the side protection mechanism 4 includes a first-level side protection board 41 and a second-level s...

Embodiment 2

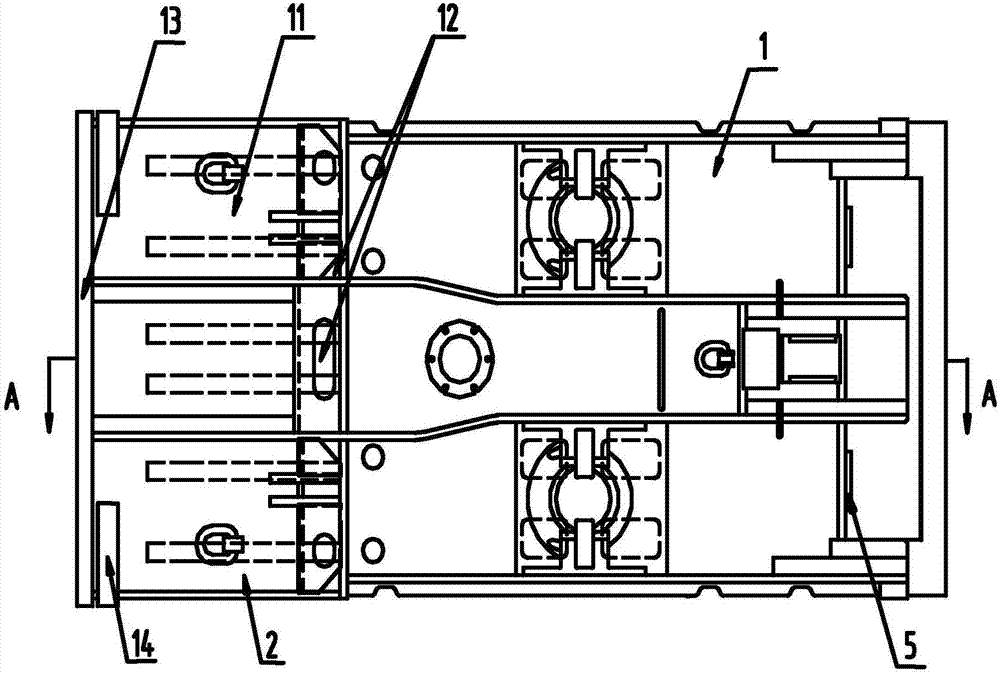

[0038] Such as Figure 2-4As shown, the cavity structure 2 includes at least one chamber 11. In this embodiment, the cavity structure 2 is set as a five-chamber structure, and the telescopic beam 3 is located in the cavity 11. The cavity structure 2 The bottom is provided with a coal drop hole 12, and the coal powder brought into the top beam by the telescopic beam 3 during the extension and retraction operation can be discharged through the coal drop hole 12 to improve the performance of the hydraulic support. The coal drop hole 12 Set as one or several combinations of common geometric figures, preferably, the coal drop holes 12 located at the corners of the cavity structure 2 are set to polygonal structures, such as triangles, squares or rectangles, etc., which help to reduce the dead ends of coal drop , The diameter of the circumscribed circle of the coal drop hole 12 is 8-12mm, and the size of the coal drop hole 12 is optimized to ensure that the strength of the top beam m...

Embodiment 3

[0042] Such as Figure 1-6 As shown, a hydraulic support includes the above-mentioned top beam, and the specific working process of the hydraulic support is as follows:

[0043] Firstly, through the anti-falling device, the top beams of different hydraulic supports are connected to enhance the overall stability;

[0044] Secondly, the lifting operation is performed, and when the hydraulic support reaches the highest position, the limit mechanism 5 limits the angle between the top beam and the shield beam;

[0045] Again, according to the needs of the actual fully mechanized mining face, start the telescopic beam jack 10, the jack 2 9 and the jack 1 8 respectively to realize the extension of the telescopic beam 3, the secondary side guard 42 and the primary side guard 41. Exit / retract operation, change support area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com