Hydraulic support

A technology of hydraulic support and pressure plate, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve problems such as high equipment maintenance costs, damage to balance jacks, and welding and falling off of stoppers, so as to improve work stability and improve The overall stability and the effect of preventing the welding from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

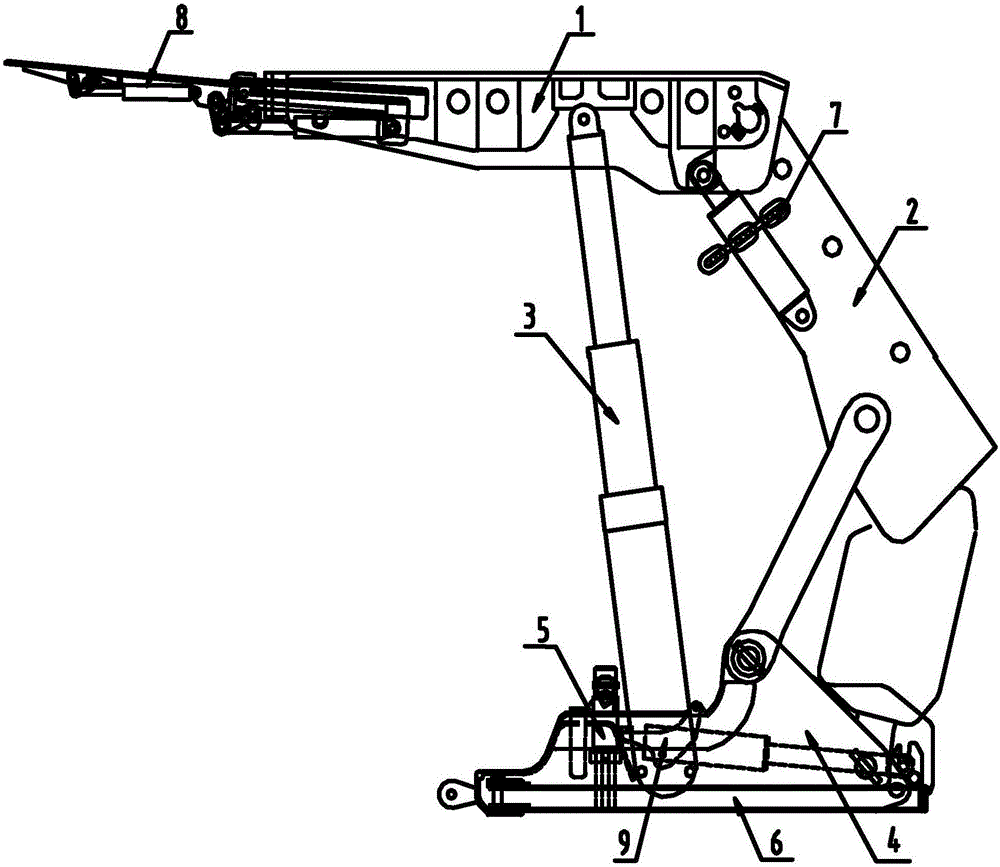

[0035] Such as Figure 1-2 As shown, a hydraulic support includes a top beam 1, a shield beam 2 and a base 4. At the joint between the shield beam 2 and the top beam 1, the length of the top plate of the shield beam 2 is greater than the length of the side plate, and the The difference between the above lengths is 40-60mm. When the hydraulic support is at the lowest height, the top plate end of the cover beam 2 is in contact with the top beam 1, which acts as a limit, protects the balance jack from damage, and helps to improve the overall stability sex.

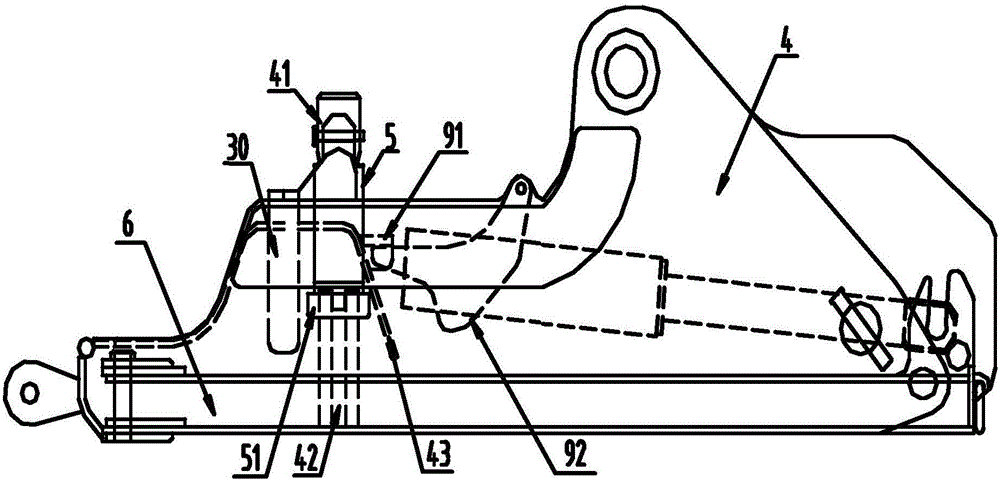

[0036] The base 4 is provided with a lifting jack 5 and a push rod 6, and the base 4 is located above the push rod 6 and a limit bridge 30 is arranged, and the limit bridge 30 and the push rod 6 are arranged in a non-parallel structure , the maximum distance from the bottom of the limiting bridge 30 to the upper surface of the push rod 6 is less than the maximum distance from the piston end of the lifting jack 5 to the upper...

Embodiment 2

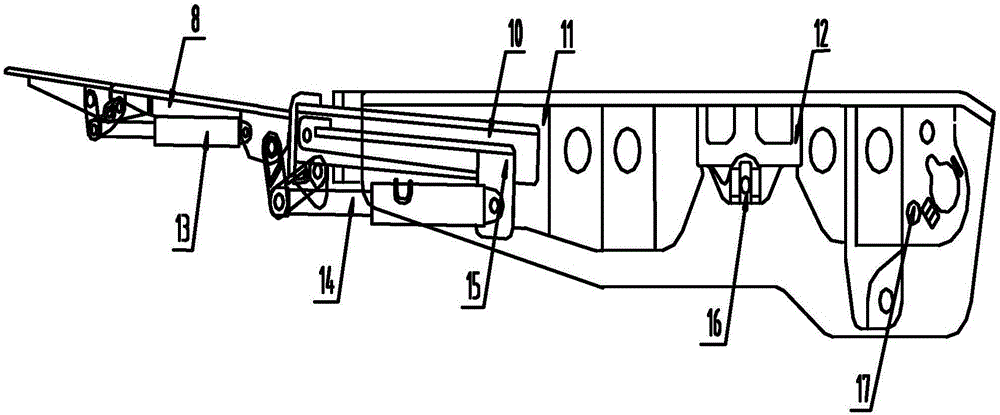

[0042] Such as figure 1 , Figure 3-6 As shown, one end of the top beam 1 is set as a box structure 12, and the other end is set as a cavity structure 11, and the cavity structure 11 is provided with a side protection mechanism 8 and a telescopic beam 10, and the box structure A limit mechanism 17 is set at 12, and the limit mechanism 17 is set as a limit block, the limit block is located at the bottom of the top beam 1, and the limit block is located at 1 / 4-1 / 3 of the top beam 1 At the height, a balance jack is arranged between the top beam 1 and the cover beam 2, and when the hydraulic support is at the highest position, the limit mechanism 17 limits the angle between the cover beam 2 and the top beam 1, It can not only effectively avoid damage to the balance jack, but also enhance the supporting effect of the hydraulic support on the roof and reduce equipment maintenance costs.

[0043] The side protection mechanism 8 includes a first-level side protection board 81 and a ...

Embodiment 3

[0048] Such as Figure 1-8 Shown, the specific working process of described a kind of hydraulic support is as follows:

[0049] (1) Inject the hydraulic medium into the column 3, carry out the lifting operation of the hydraulic support until the top beam 1 is in contact with the top plate above the working surface, and at the same time, start the balance jack to impel the limit mechanism 17 Contact with the cover beam 2, and limit the angle between the cover beam 2 and the top beam 1;

[0050] (2) The telescopic beam 10 performs an extension operation, drives the side protection mechanism 8, and the follow-up limit mechanism 15 to move, starts the jack 2 14, realizes the extension operation of the side protection mechanism 8, and starts the jack -13, to realize the extension operation of the primary side guard 81 until the mechanical limit of the junction of the first level side guard 81 and the second level side guard 82, and the junction of the second level side guard 82 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com