Montejus equipped with injector

A technology of ejector and liquid device, applied in the field of pressure gas lifter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

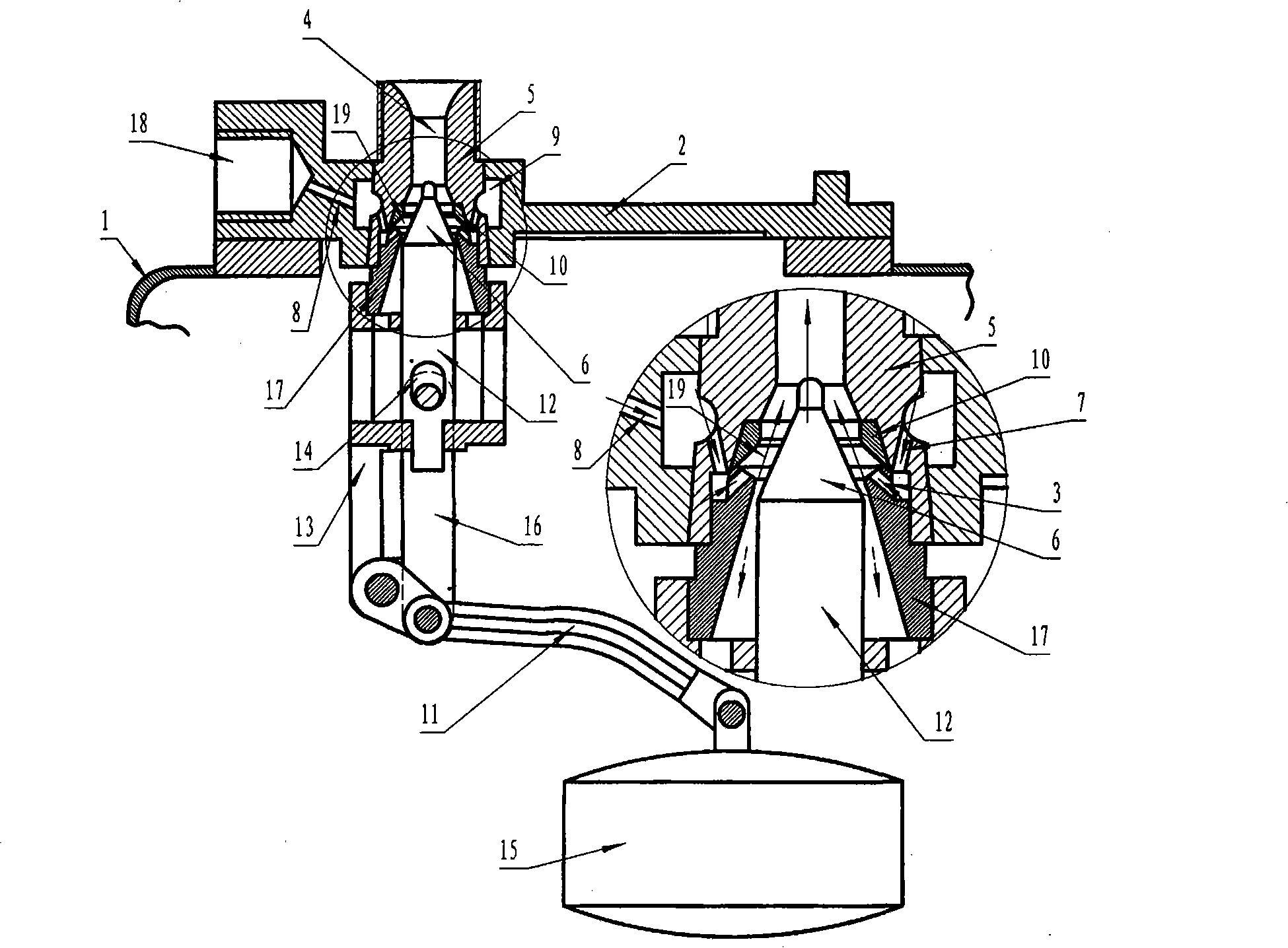

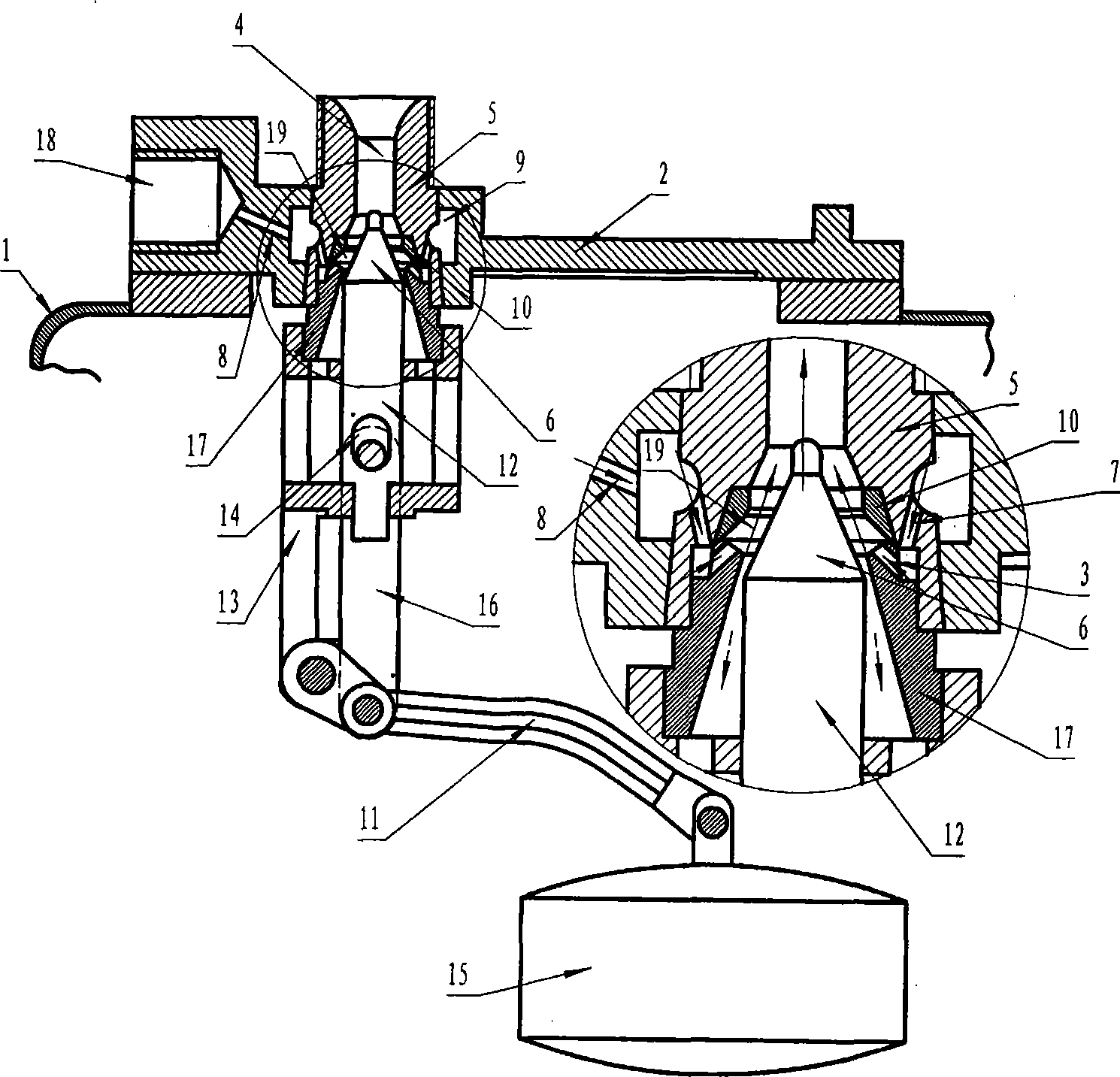

[0010] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0011] As shown in the figure: In this embodiment, an installation opening is opened on the upper end of the pump body 1, which is sealed by the control cover plate 2.

[0012] The control cover plate 2 is provided with a compressed air inlet 18, an air intake channel 8 and a tapered installation hole, the installation hole runs through the upper and lower ends of the control cover plate 2, and the middle part is an annular air chamber 9, which is connected with the annular air chamber 9. The compressed air inlet 18 communicates with the air inlet passage 8, and the pipe diameter of the air inlet passage 8 is smaller than the pipe diameter of the compressed air inlet 18, so as to increase the pressure of the gas and increase the flow rate. The distribution box is installed on the tapered mounting hole of the control cover plate 2. The distribution box is mainly composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com