A shotcrete equipment for filling tunnel pre-cut grooves

A pre-grooving and spraying technology, applied in tunnels, mining equipment, tunnel lining, etc., can solve problems such as cavities and corner vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

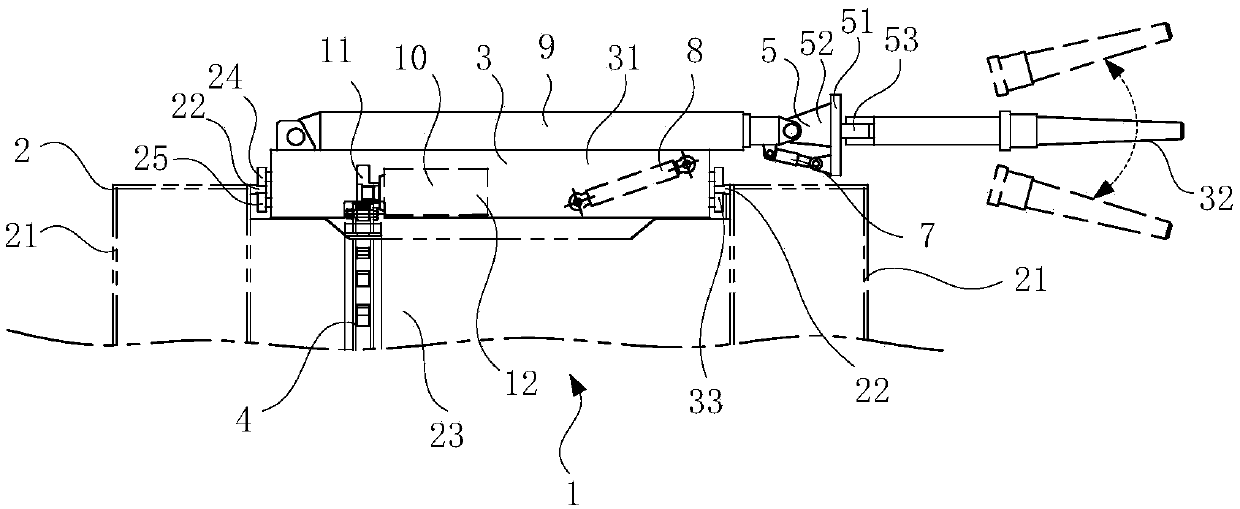

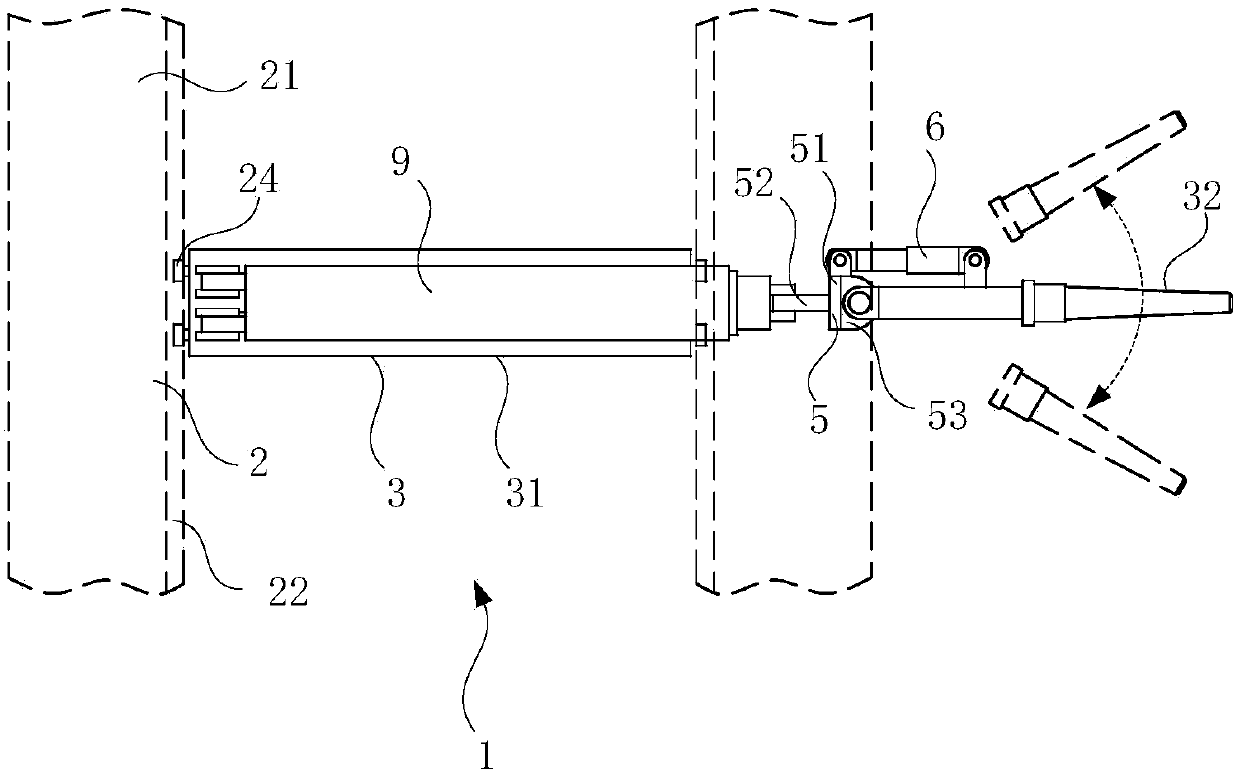

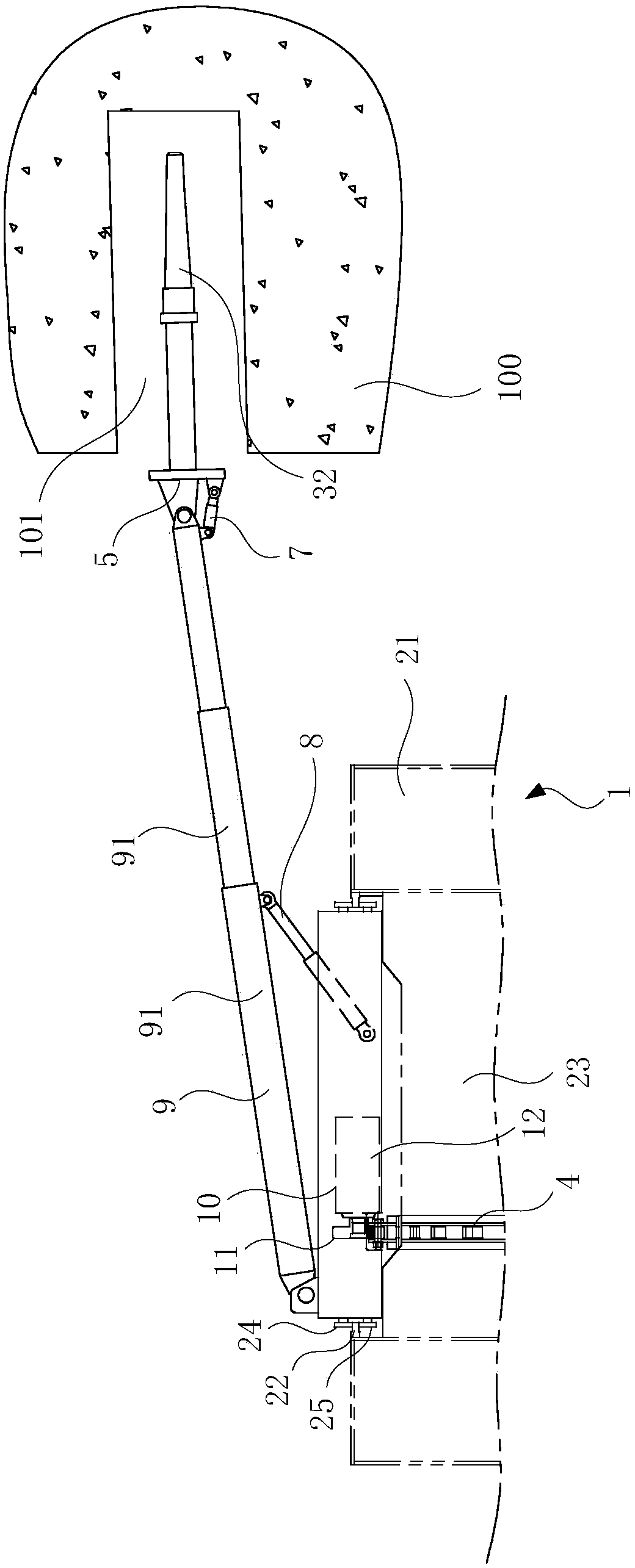

[0023] Such as figure 1 As shown, the grouting equipment 1 for filling the tunnel pre-cut groove includes a support 2 and a grouting device 3 installed on the support 2 . Arched tracks 22 are arranged on the bracket 2 . The shape of the track 22 matches the shape of the arcuate pre-cut groove 101 which has been cut in advance. The arch is usually a round arch. The pre-groove 101 may be formed by cutting the formation 100 with a tunnel pre-groove machine. The grouting device 3 can walk along the arched track 22, and the grouting device 3 is provided with a nozzle 32 extending forward. The extension direction of the spray head 32 is perpendicular to the track 22 . After the nozzle 32 is inserted in the pre-cut groove 101, and when the grouting device 3 is walked along the track 22, the nozzle 32 can spray cement slurry into the arched pre-cut groove 101, and the nozzle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com