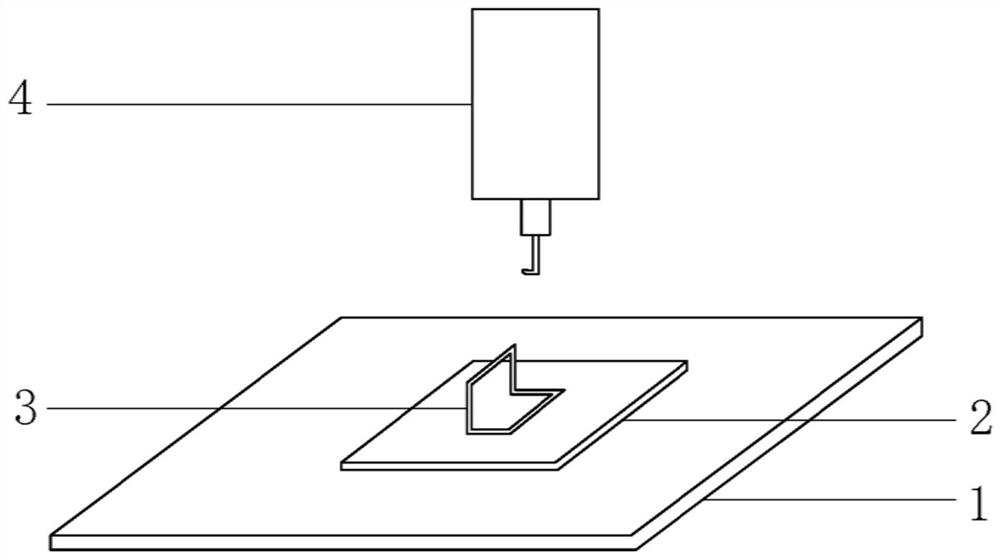

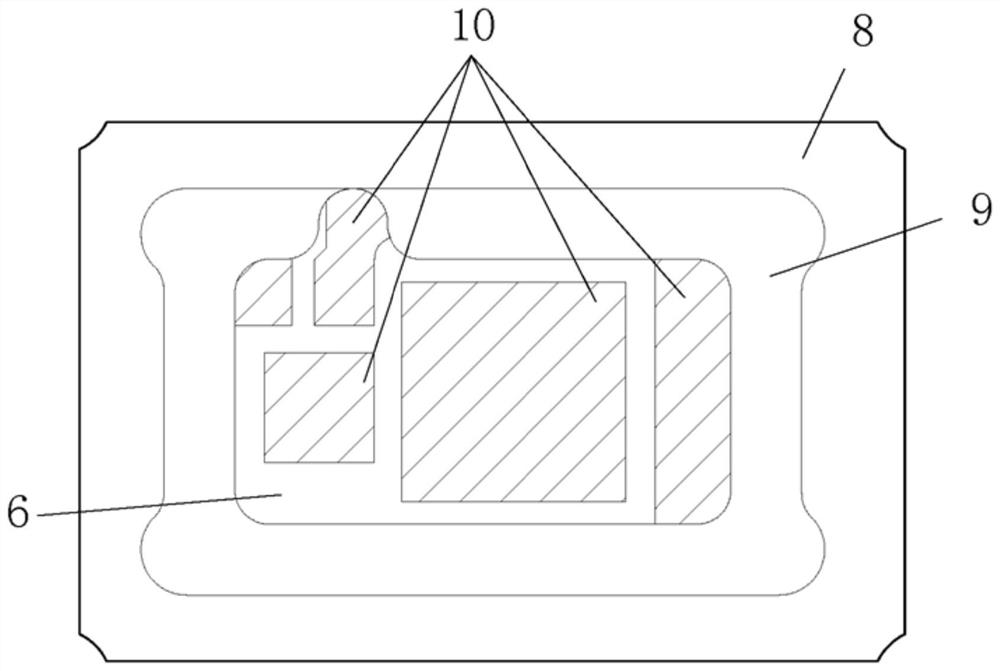

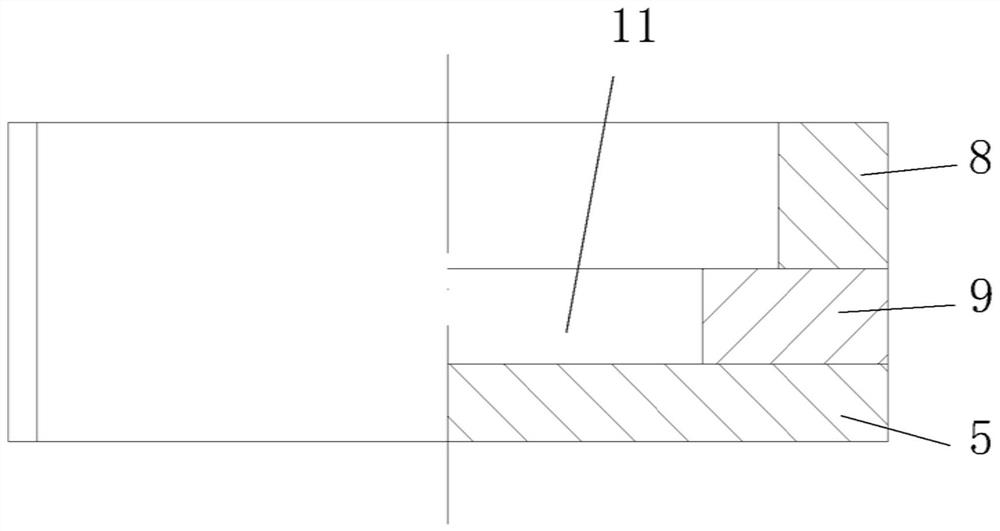

A ceramic package base

A ceramic packaging and base technology, used in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as poor bonding with aluminum nitride ceramics, achieve low wiring resistance, and solve the problem of heat dissipation , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The content of the present invention will be further described in detail below through specific embodiments. Unless otherwise specified, the raw materials, reagents or devices used in the examples and comparative examples can be obtained from conventional commercial channels, or can be obtained by methods of the prior art. Unless otherwise specified, test or test methods are routine in the art.

[0072] The samples of Examples and Comparative Examples were prepared by using tungsten paste and aluminum nitride ceramic paste for testing. Among them, the tungsten paste is made of tungsten powder, Al 2 O 3 Powder and Rare Earth Oxides M 2 O 3 , and add an appropriate amount of organic solvent, polymer and additives to mix and formulate; among them, inorganic components (tungsten powder, Al 2 O 3 Powder and Rare Earth Oxides M 2 O 3 ) is about 80% by mass in the tungsten paste. After the tungsten paste is sintered and formed, a tungsten conductive layer is obtained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com