Bag collating and clamping linkage mechanism for three-dimensional packaging bags

A linkage mechanism and packaging bag technology, applied in packaging and other directions, can solve the problem that the bag management and bag clamping process cannot be integrated and linked, and achieve the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

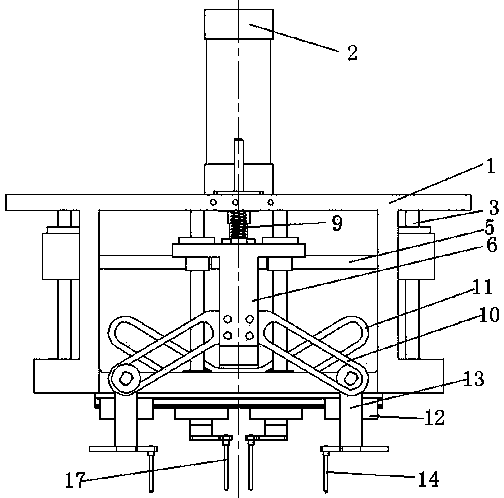

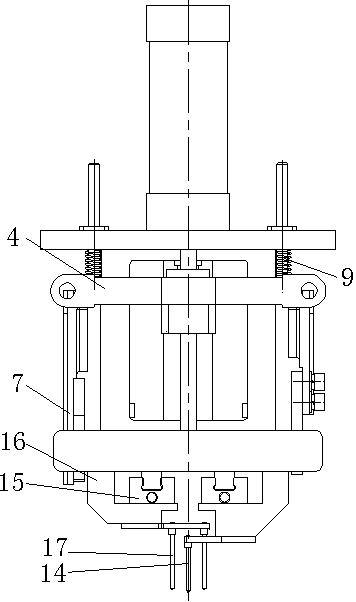

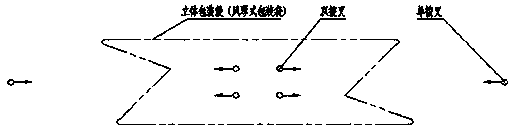

[0024] refer to Figure 1 to Figure 7 , the present invention relates to a bag sorting and bag clamping linkage mechanism for three-dimensional packaging bags, comprising a frame 1, the upper part of the frame 1 is provided with a longitudinally arranged cylinder 2, and the two sides of the frame 1 are respectively provided with vertical Linear guide rails 3, the two vertical linear guide rails 3 are respectively slidably connected with horizontally arranged driving rods 4, and the two driving rods 4 are linked and jointly driven and connected with the bag clamping mechanism arranged on the frame 1, the described The two drive rods 4 are connected by a transverse rod 5 connected with the cylinder piston rod; the middle part of the front side of the frame 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com