Bag unscrambler

A bag unscrambling machine and bag unscrambling technology, applied in the field of bag unscrambling machines, can solve problems such as unfavorable labor costs, large space, and inability to effectively compress non-woven bags, and achieve good bag unscrambling effects and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

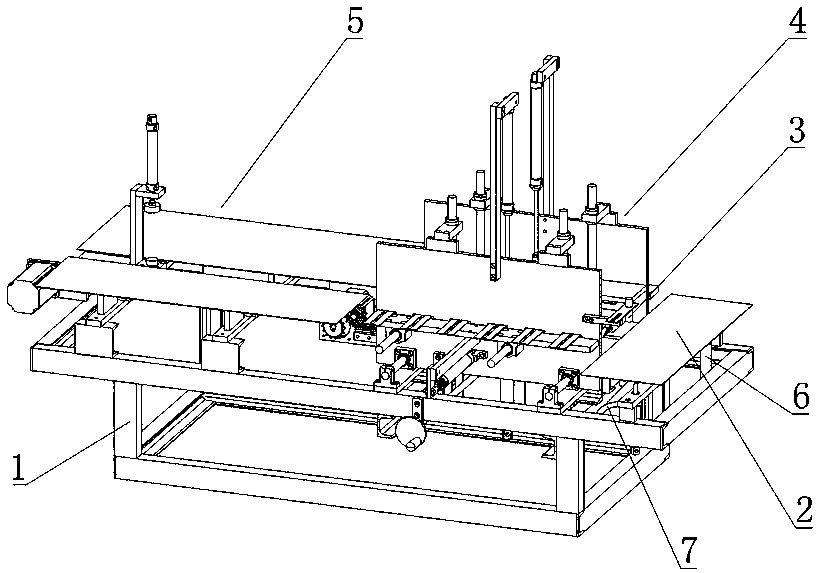

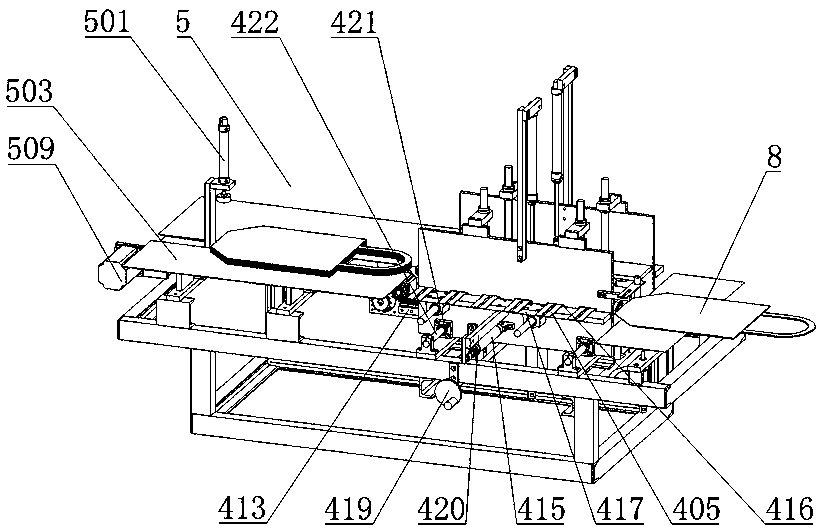

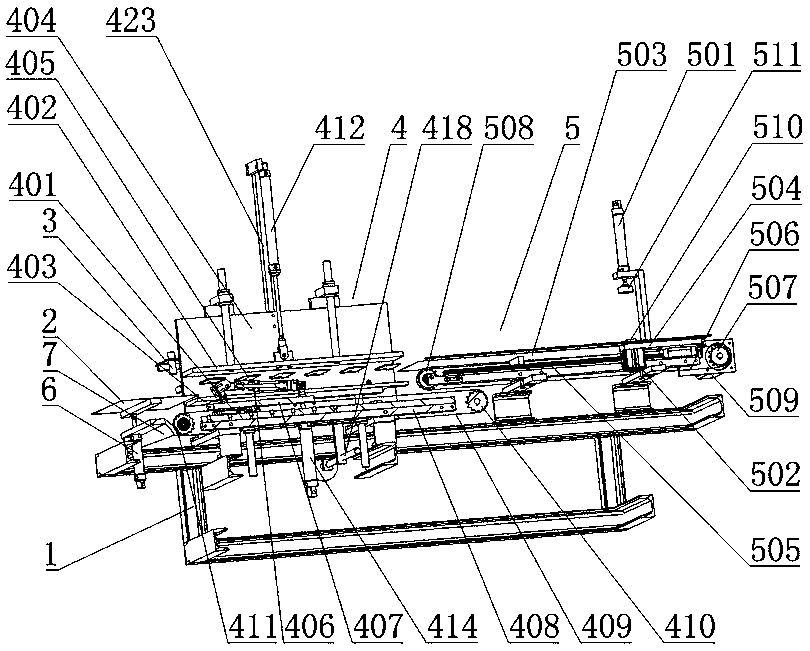

[0024] The first example is Figure 1-4 As shown, this bag sorting machine has a frame 1, the frame 1 is provided with a bag feeding plate 2, and an inductor 3 for inductive non-woven bag 8 is arranged above the bag feeding plate 2, so The output end of the bag feeding plate 2 is provided with a bag-pressing bag-feeding mechanism 4, and the bag-pressing bag-feeding mechanism 4 has a movable first clamp, and the first clamp includes a reversible pressure head 401, a first slider 407. Bag clamping cylinder 406, the pressure head 401 and the bag clamping cylinder 406 are both hinged on the first slider 407, the pressure head 401 is connected to the bag clamping cylinder 406, and the first slider 407 is installed On the first conveyor belt 409, the frame is provided with a first slide rail 408, the first slide block 407 is matched with the first slide rail 408, and the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com