Smoke-fire actuating cylinder for nuclear power safety valve and laser welding method thereof

A technology of laser welding and actuating cylinder, which is applied in the field of pyrotechnics, can solve the problems of low temperature embrittlement, pollution, long-term storage aging, etc., and achieve the effect of improving structural strength and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawings and examples.

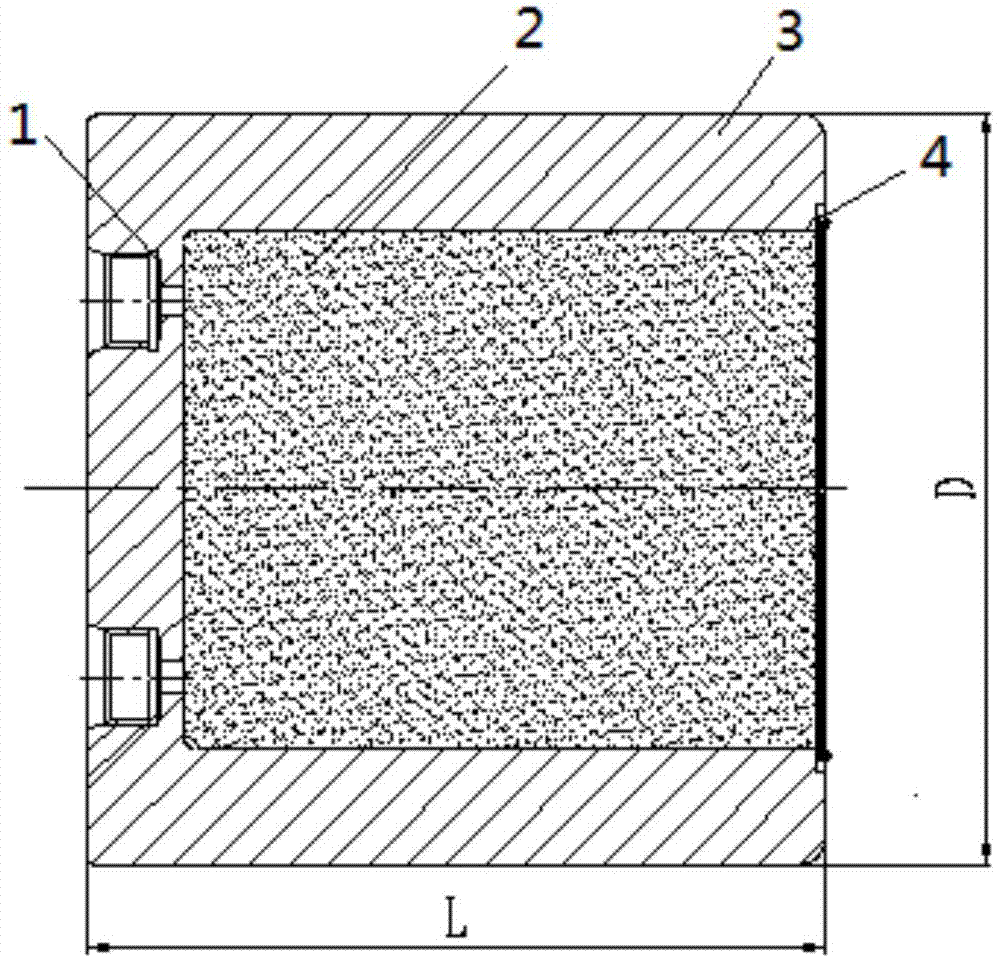

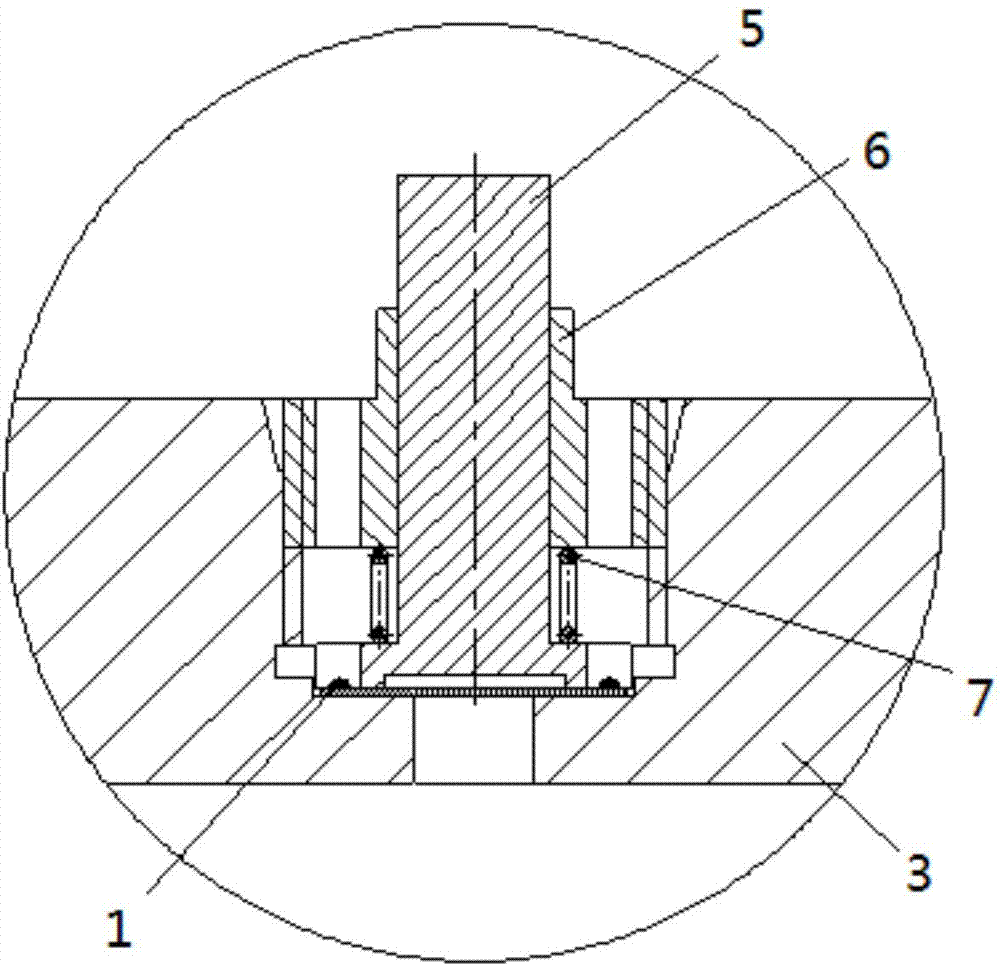

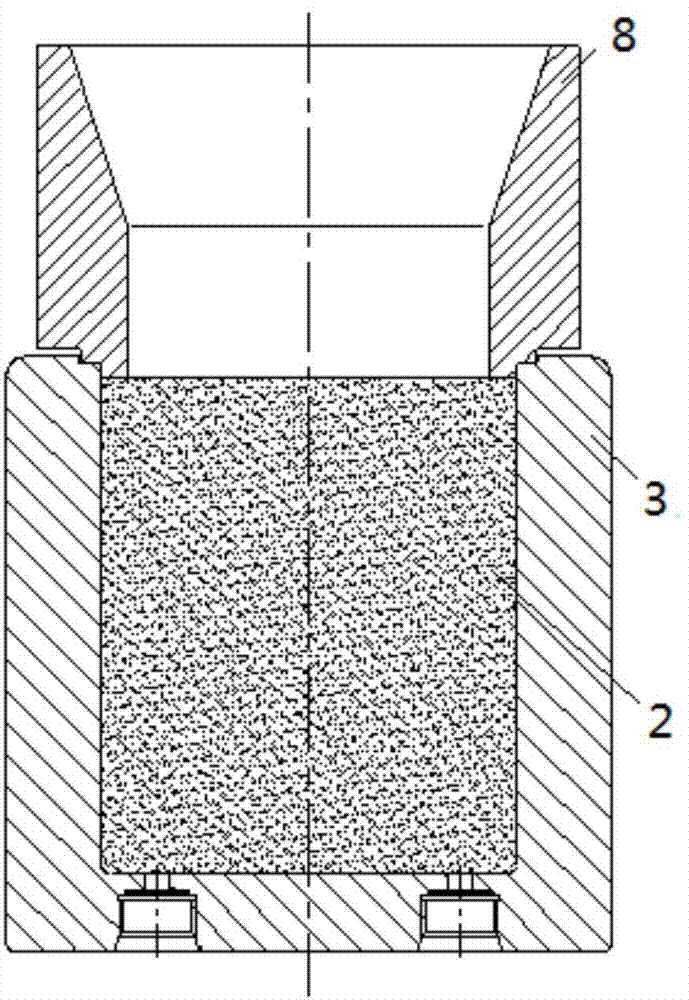

[0027] A pyrotechnic actuator for a nuclear power safety valve, comprising an input cover 1, a high-temperature-resistant propellant 2, a casing 3 and an output cover 4, one side of the casing 3 has an interface for installing an igniter (more than one can be installed), and the interface The bottom is a counterbore laser welded plane with a central hole, on which the input cover 1 is welded. The inside of the casing 3 is a hollow cylinder, which contains a high-temperature-resistant propellant 2 , and the output cover 4 is welded on the laser welding plane at the output end of the casing 3 .

[0028] A laser welding method for a pyrotechnic actuator for the nuclear power safety valve, comprising the following steps:

[0029] (1) Determine the laser welding process parameters; the laser welding machine setting parameters include current intensity, laser pulse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com