Device and method for performing front-wheel turning function inspection without jacking aircraft

A technology of front wheel turning and functional inspection, which is applied in the field of aviation industry, can solve the problems of wide range of work, heavy operation, and difficult interpretation, and achieve the effect of lowering the technical threshold, saving procedures, and widely promoting the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

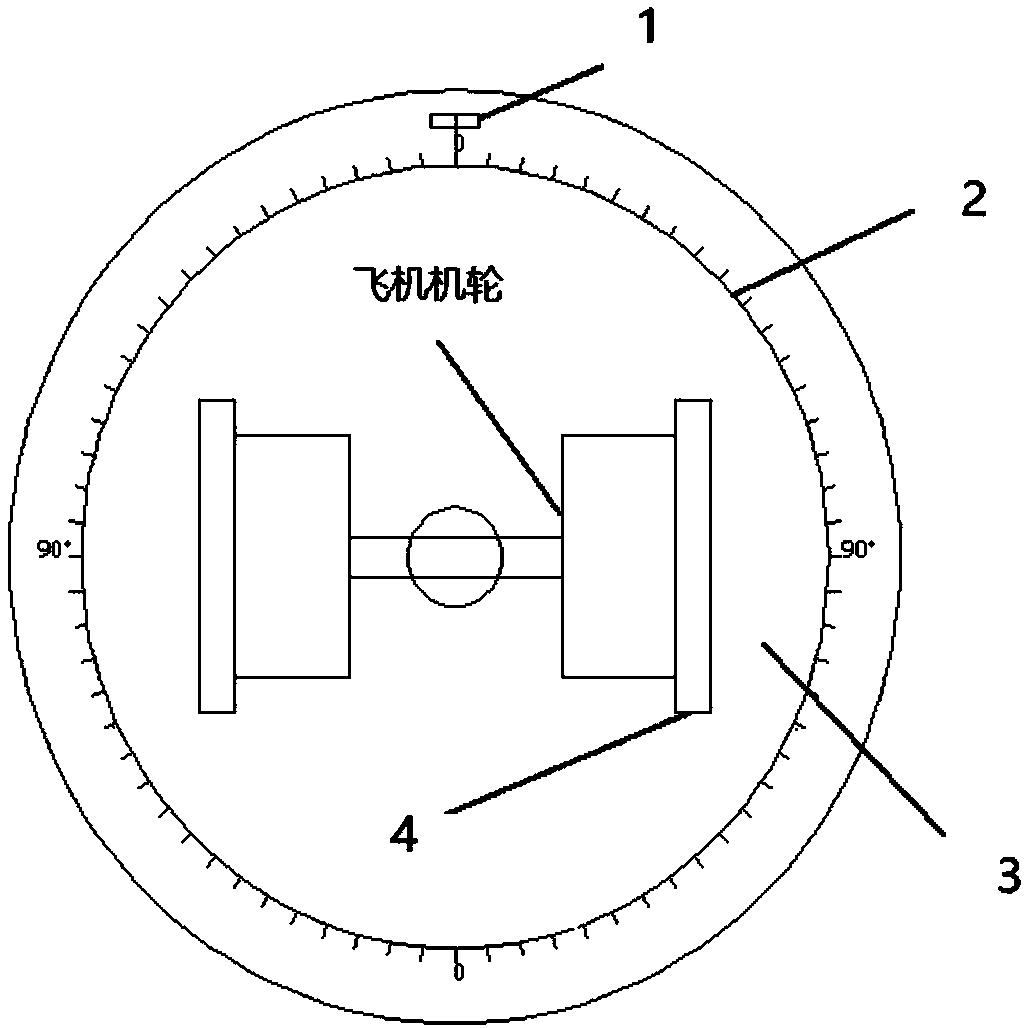

[0021] Such as figure 1 and figure 2 As shown, a detection device flush with the ground is designed, which can conveniently tow the aircraft to the upper surface of the front wheel turntable 3. The front wheel turntable 3 meets the technical requirements for parking the aircraft, and avoids the need to push the aircraft when the nose wheel turning function inspection is performed. Complicated and complicated work steps; its surface is equipped with an adjustable locking device 4 for fixing the front wheel of the aircraft. Relative movement occurs between the front wheel and the front wheel turntable 3, resulting in measurement errors; there is an adjustable ring-shaped high-precision angle indicator 2 outside the front wheel turntable 3, which is convenient for the aircraft to enter from any angle and quickly adjust the measurement angle. Large, so the measurement accuracy can be improved, and the measured angle can be accurately and clearly reflected; it has a zero point ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com