Vertical shaft crusher with spirally arranged crushing space anvils

A vertical shaft crusher and crushing cavity technology, applied in grain processing and other directions, can solve the problems of affecting production efficiency, high replacement frequency, time-consuming and labor-intensive replacement, etc., and achieve the effect of improving production efficiency, simple replacement process, and large thrust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

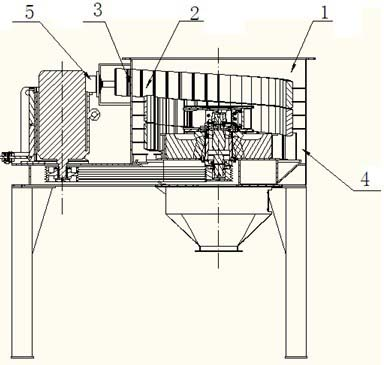

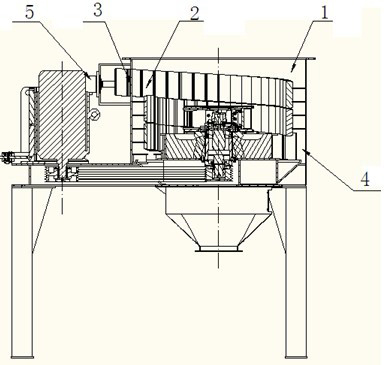

[0012] Embodiment: As shown in Figure 1, the working principle and rotor structure of the vertical shaft crusher are the same as those of the existing vertical shaft crusher. The change is that the anvils 2 are spirally arranged in the crushing chamber 1 according to the helical spiral pattern, and at the same time, an anvil loading port 3 is set at the top helical entry point of the crushing chamber 1, and an anvil inlet 3 is set at the bottom helical entry point of the crushing chamber 1. There is an anvil top exit 4. In order to realize the movement of the anvil 2, an anvil jacking device 5 is installed at the anvil loading port 3, and the anvil jacking device 5 can adopt a hydraulic oil cylinder, and the number of helical turns of the helical anvil 2 is one circle or More than one circle, preferably two circles (three circles in the picture, but two half circles above and below).

[0013] During use, when it is found that the anvil 2 in the crushing chamber 1 is severely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com