Internal waverider-derived hypersonic inlet with ordered inlet and outlet shape and design method

A hypersonic, air inlet technology that is used in turbine/propulsion inlets, combustion air/combustion-air handling, engine components, etc. to widen the operating Mach number range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

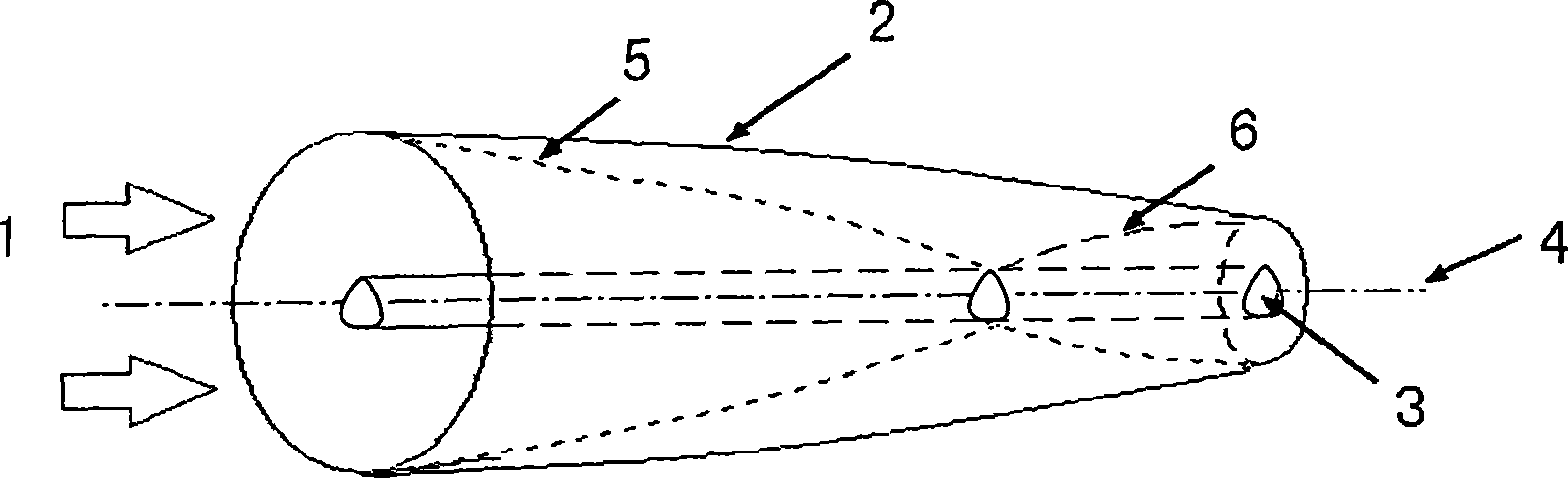

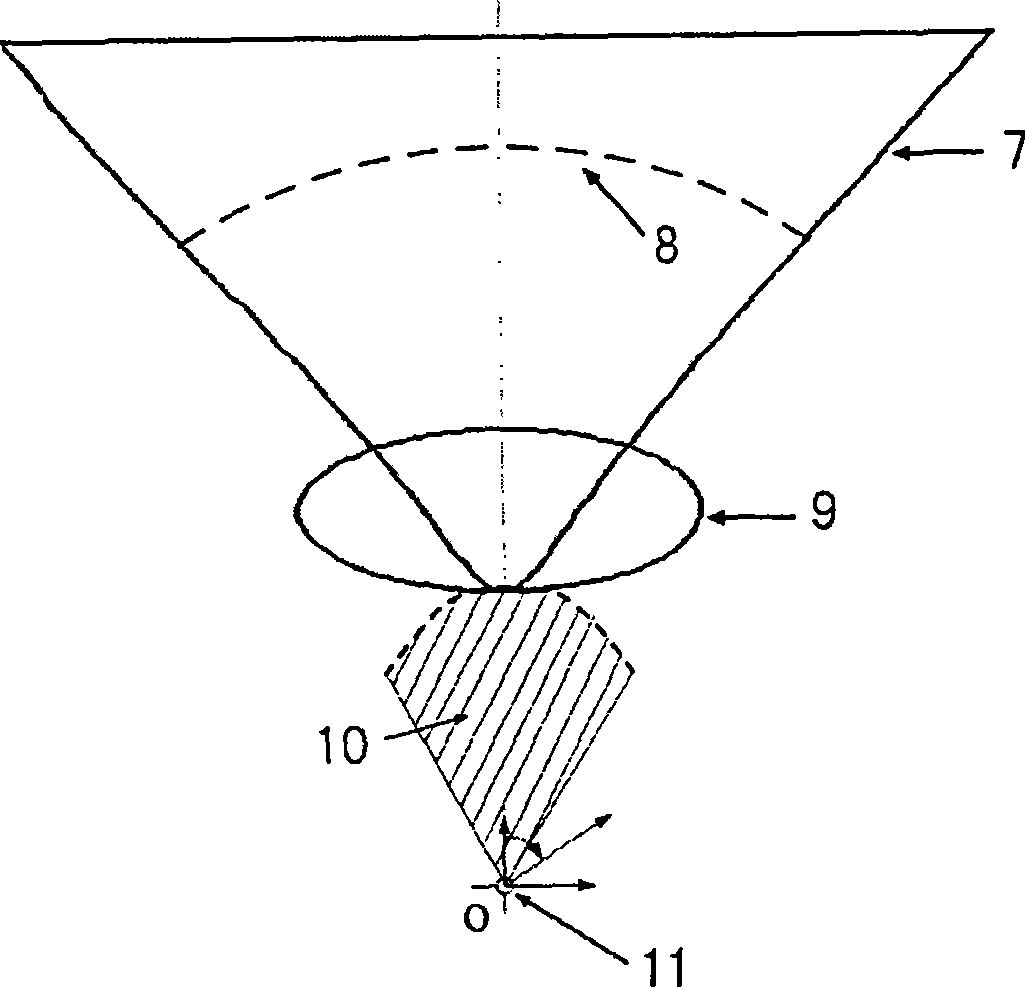

[0029] At the flow Mach number 5, the design such as figure 1A series of axisymmetric internal contraction basic flow fields are shown, the generatrix of the internal contraction turning wall is a cubic curve, and the initial internal contraction angle is 8 degrees. The design requirements for the shape of the inlet are: the outlet of the inlet is an ellipse with a specified long-short axis ratio of 2.5, and the projected shape of the inlet is a triangle (such as figure 2 ). Figure 3 is a three-dimensional profile of an inner waveriding hypersonic inlet (triangular inlet, elliptical outlet) whose inlet and outlet shapes can be customized. Under the design state of incoming flow Mach number 5, the calculation performance of the inlet is 13.2 for the average outlet pressure ratio, 2.72 for the outlet Mach number, 0.62 for the total pressure recovery, and 0.99 for the flow capture coefficient.

Embodiment 2

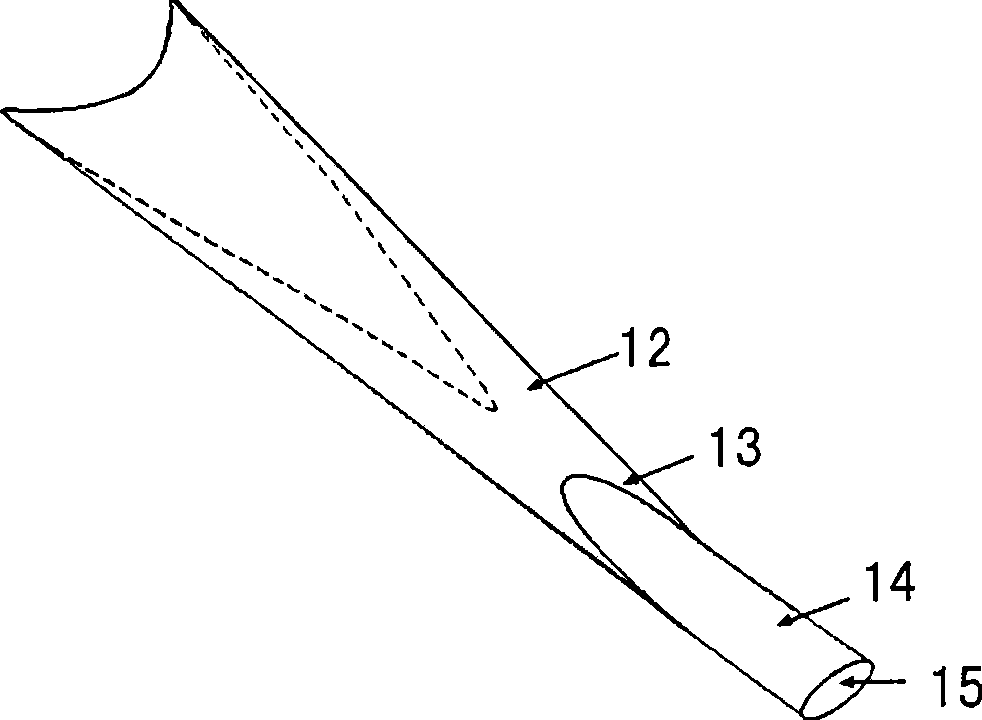

[0031] At the flow Mach number 5, the design such as figure 1 A series of axisymmetric internal contraction basic flow fields are shown, the generatrix of the internal contraction turning wall is a cubic curve, and the initial internal contraction angle is 8 degrees. The design requirements for the shape of the inlet are: the outlet of the inlet is an ellipse with a specified long-to-short axis ratio of 2.5, and the projected shape of the inlet is approximately square (such as Figure 4 ). The shape of the inlet and outlet can be customized. The three-dimensional contour of the inner waveriding hypersonic inlet (approximately square inlet, oval outlet) (as shown in Figure 5). Under the design state of incoming flow Mach number 5, the calculated performance of the inlet is 14.0 for the average outlet pressure ratio, 2.75 for the outlet Mach number, 0.62 for the total pressure recovery, and 0.99 for the flow capture coefficient. In the wind tunnel experiment of Mach 5, the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com