Inverse Design Method of Full 3D Inverted Inlet Based on Bending Shock Wave Theory

A technology of curved shock wave and inlet, which is applied to the inlet of turbine/propulsion device, combustion air/combustion-air treatment, charging system, etc., which can solve the lack of full three-dimensional internal rotation inlet reverse design method , reduce the geometrical structure range of the inlet, limit the selection range of the basic flow field, etc., to achieve the effect of broadening the design range, broadening the working Mach number range, and widening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

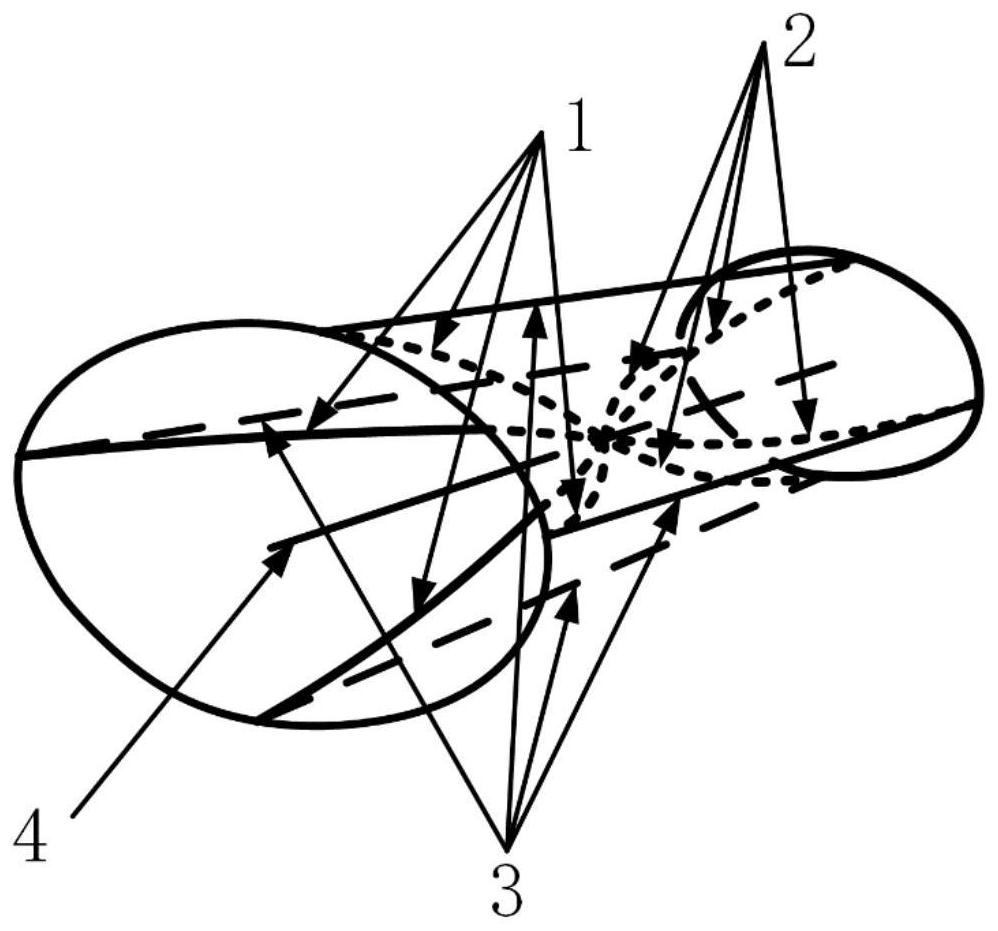

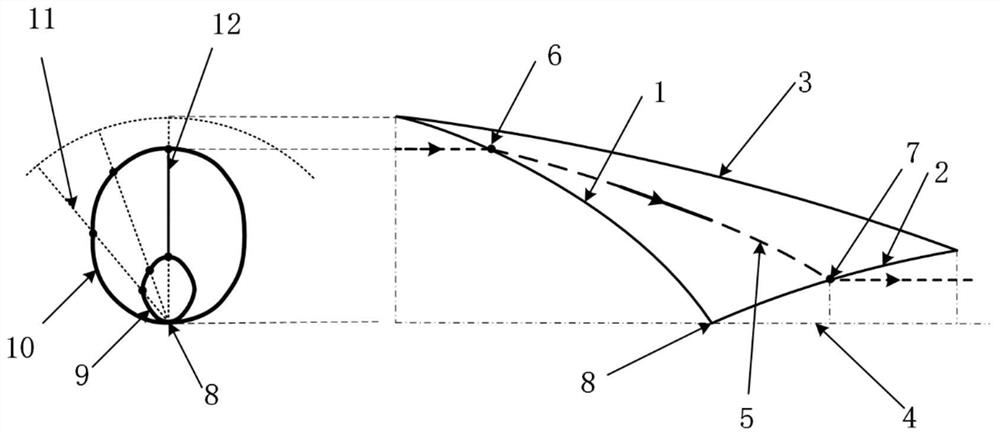

[0033] like Figure 1~6 As shown, the reverse design method of the full three-dimensional inward turning inlet based on the bending shock wave theory includes the following steps:

[0034] 1) The full three-dimensional incident shock wave 1 in the full three-dimensional reference flow field is specified according to the design requirements, and the full three-dimensional incident shock wave 1 is designed with an ellipse or other non-axisymmetric shape; among them, due to the non-axisymmetric nature of the full three-dimensional reference flow field, different The profiles of the full three-dimensional incident shock wave 1 in the reference plane are not the same, and similarly, the compression profile 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com