Waste edge mechanism of loom

A loom and transmission mechanism technology, applied in looms, leno shedding mechanisms, textiles, etc., can solve problems such as insufficient use of heald frames, limit the weaving process, and affect the overall performance of the loom, so as to achieve stable shedding movement and improve overall performance. Performance, the effect of improving variety adaptation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

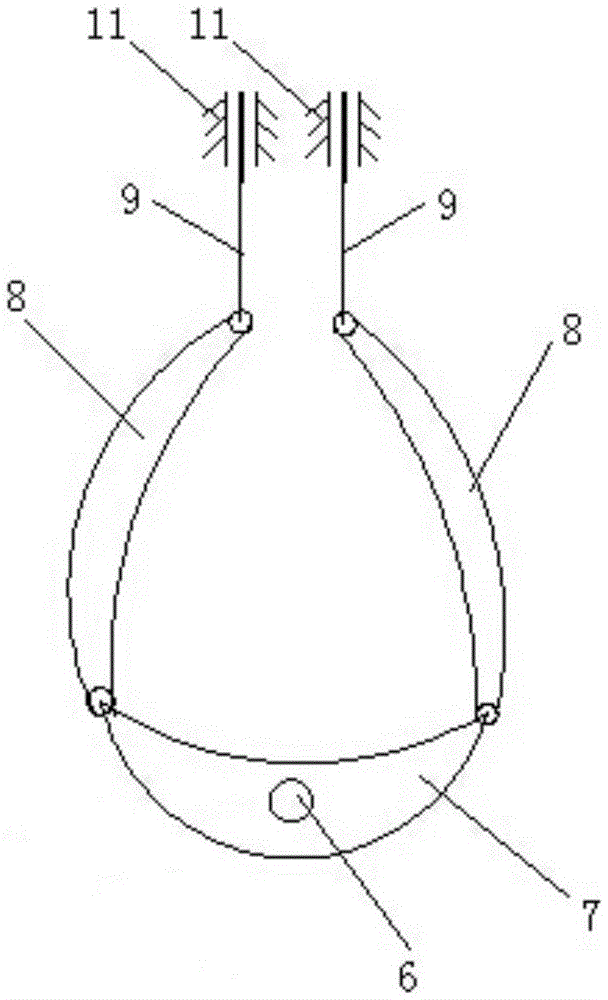

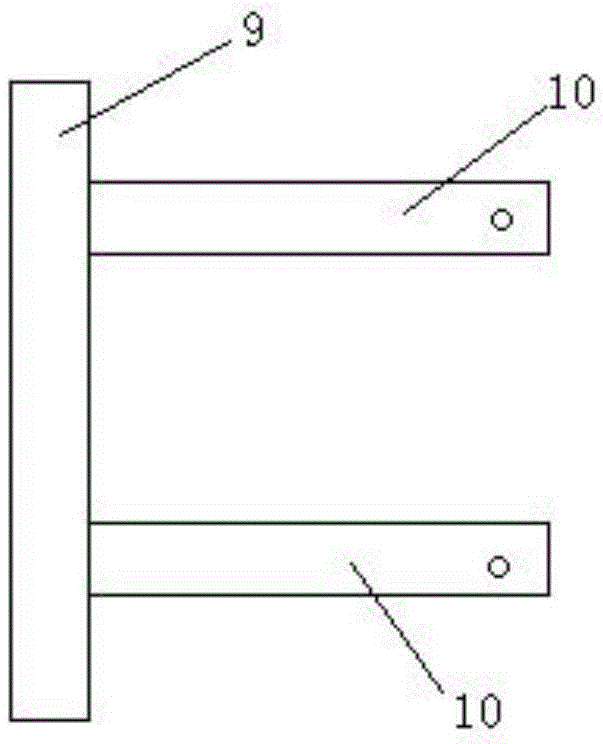

[0030] A waste edge mechanism of a loom is mainly composed of a heald frame piece chute, a heald frame piece, a heald frame piece support, a heald frame transmission shaft and a transmission mechanism.

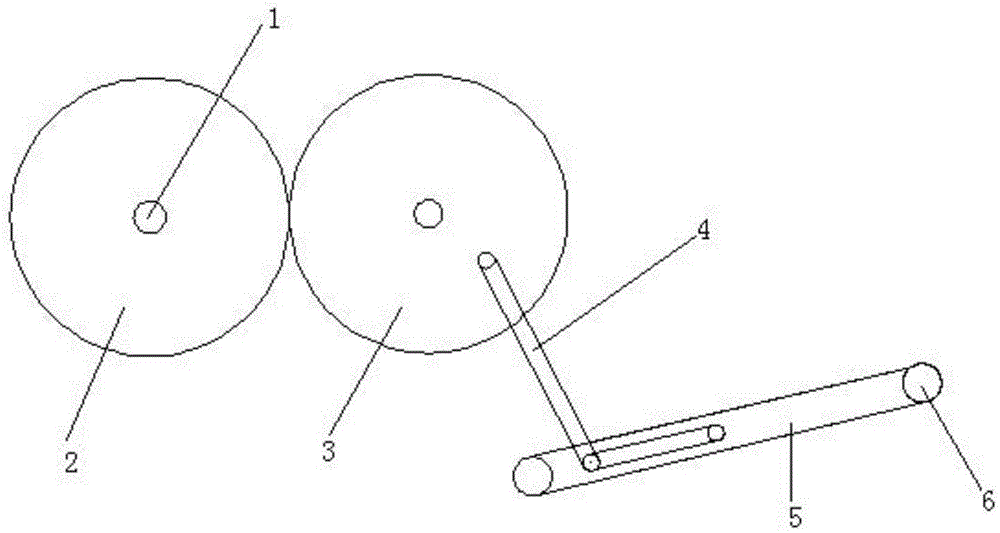

[0031] 1. Heald frame transmission shaft and transmission part

[0032] The schematic diagram of the transmission mechanism of the independent waste edge mechanism is as follows figure 1 shown. The first gear 2 is installed on the central axis 1 of the loom, and the first gear 2 transmits the second gear 3. A connecting rod 4 is installed on the second gear 3. The other end of the connecting rod 4 is connected with the swing rod 5. On the swing rod 5 There is a long slot, and the position of the connecting rod 4 on the swing rod 5 can be adjusted. With the rotation of the central shaft 1, the gear drives the connecting rod 4 to reciprocate, thereby driving the swing rod 5 to swing up and down. The swing rod 5 is fixed on the heald frame transmission On the shaft 6, through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com