Integrated design method for internal and external waveriders with controllable wall pressure

A design method and wave-riding technology, applied in the direction of sustainable transportation, geometric CAD, special data processing applications, etc., can solve problems such as shortage, and achieve the effect of broadening the range of working Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

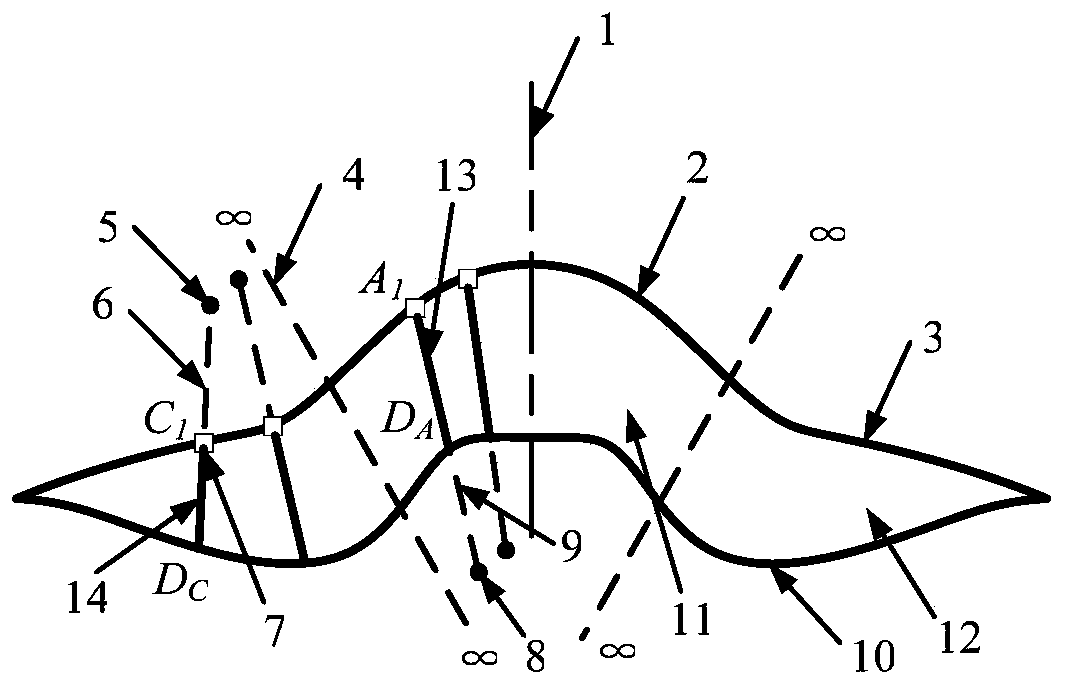

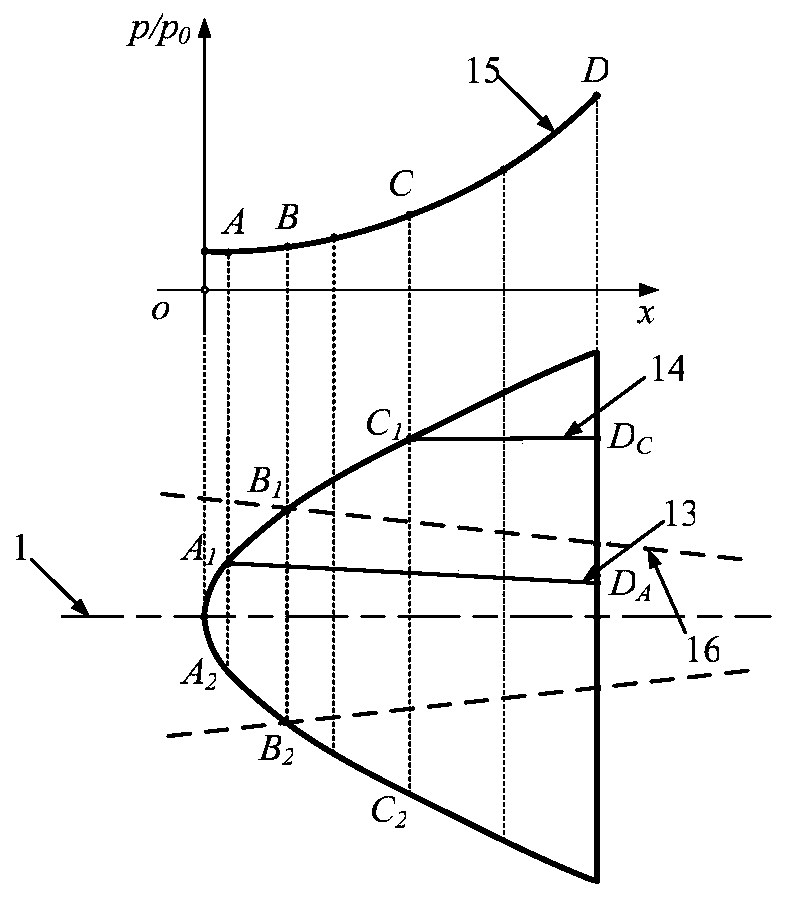

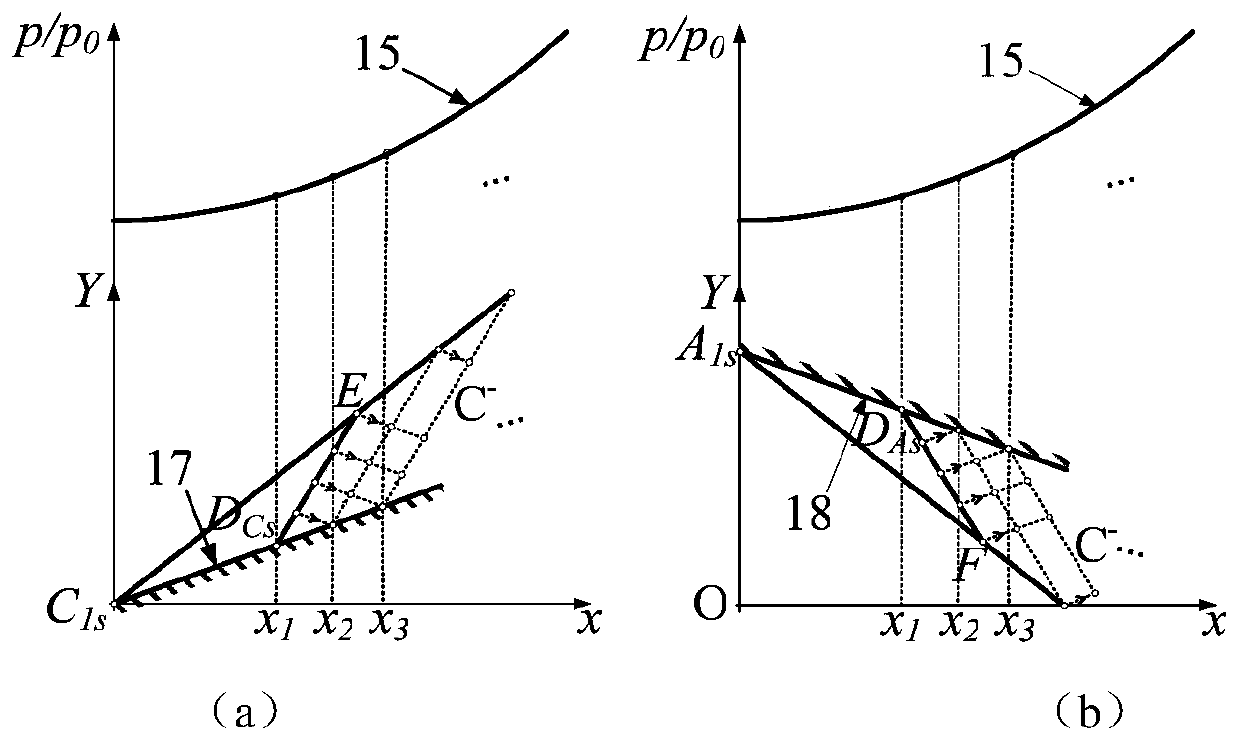

[0024] see Figure 1~6 , the main implementation steps of the integrated design method for internal and external waveriders with controllable wall pressure include:

[0025] (1) Specify the projection of the leading edge capture profile on the design section and the required pressure distribution according to the design requirements. The projection of the leading edge capture profile on the design section is divided into an outer multiplier band and an inner multiplier band, corresponding to curve 3 and curve 2 respectively, and the curvature and curvature center of each discrete point on the curve are calculated, among which the outer multiplier band and the inner multiplier band Transition through a binary plane of curvature ∞ multiplying band 16. Take the extrinsic band as an example, connect the discrete point 7 with the corresponding center of cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com