Low resistance thermosensitive ceramic material as well as preparation method and application thereof

A heat-sensitive ceramic and ceramic powder technology, applied in the field of electronic ceramic components, can solve the problems of low lift-to-resistance ratio and high resistivity, and achieve the effects of increasing temperature coefficient, reducing synthesis temperature and high temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

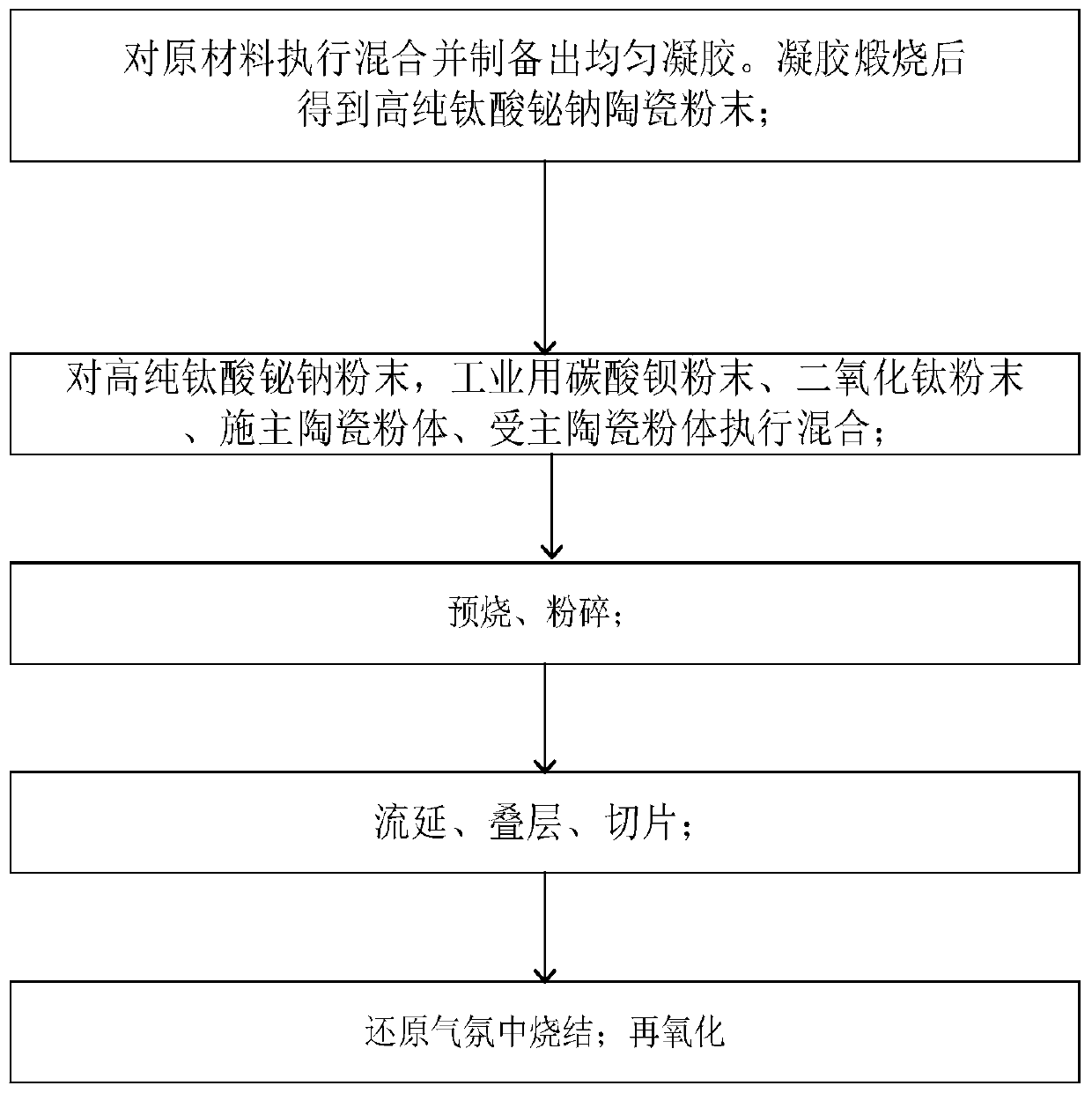

[0040] The preparation method of the thermosensitive ceramic material comprises the following steps:

[0041] (1) Mix bismuth oxide, alkali metal oxide or alkali metal carbonate, and titanium dioxide according to the molar ratio (0.98-1.02):(0.99-1.03):4, preferably according to the molar ratio of 1:1:4 and add an appropriate amount Organic monomers, using the polymerization of organic monomers to obtain a gel-like mixture after mixing, and calcining the gel-like mixture to obtain high-purity sodium bismuth titanate or potassium bismuth titanate ceramic powder; the organic monomer is propylene A mixture of amide and methylenebisacrylamide; wherein the mass ratio of acrylamide and methylenebisacrylamide is 20-28:1; the organic monomer undergoes a polymerization reaction under the action of a catalyst and an initiator; preferably , the catalyst is ammonium persulfate, and the initiator is tetramethylethylenediamine; the mixing method is preferably mixed by ball milling, and wate...

Embodiment 1

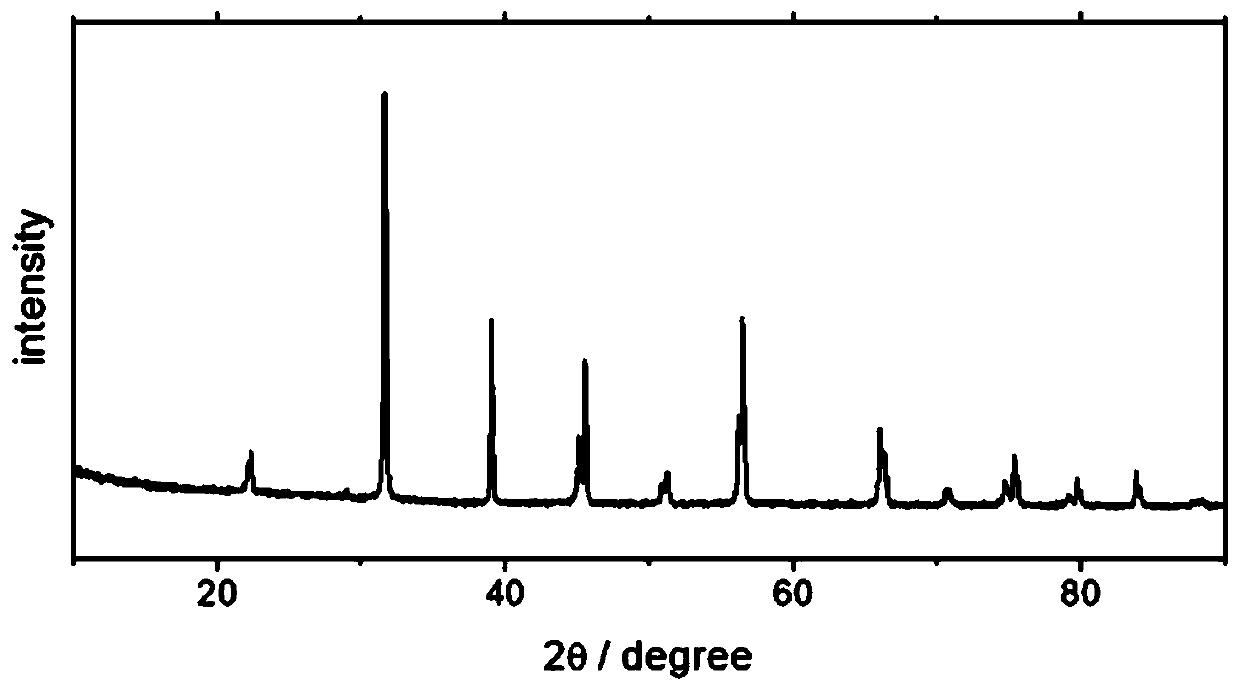

[0048] S1: 58.245g of bismuth oxide, 13.249g of sodium carbonate, 39.94g of titanium dioxide and organic monomers (21.395g of acrylamide, 0.873g of methylenebisacrylamide) were ball milled and mixed evenly. Using the polymerization of organic monomers, a uniform gel can be obtained after standing. Ammonium persulfate and tetramethylethylenediamine were used in the gelation process to speed up the gelation process. The gel was calcined at 820°C for 1 hour to obtain high-purity sodium bismuth titanate ceramic powder.

[0049] S2: Take 98.470g of barium carbonate, 0.244g of lanthanum oxide, 39.957g of titanium dioxide and 0.106g of sodium bismuth titanate and mix them uniformly by ball milling.

[0050] S3: The ceramic slurry is taken out from the ball mill jar, dried in an oven for 12 hours, and then taken out. After taking it out, grind the block into powder. Transfer the powder to a horse boiling furnace, raise the temperature to 1150°C at a rate of 300°C / hour and keep it w...

Embodiment 2-7

[0057] The preparation steps of this example are the same as those of Example 1, except that different amounts of barium carbonate, sodium bismuth titanate and donor doping are used in step S2. The amount of donor doping depends on the values of x and y. For this group of examples, the amount of donor added per 1 mol of material is 0-0.3 mol%. The holding temperature in step S5 is 1125°C.

[0058] The main component of the thermosensitive ceramic material that present embodiment prepares is ((Bi 0.5 Na 0.5 ) x Ba 1-x )TiO 3 , the value of x and the electrical properties of the finished electronic components are shown in Table 1:

[0059] Table 1

[0060]

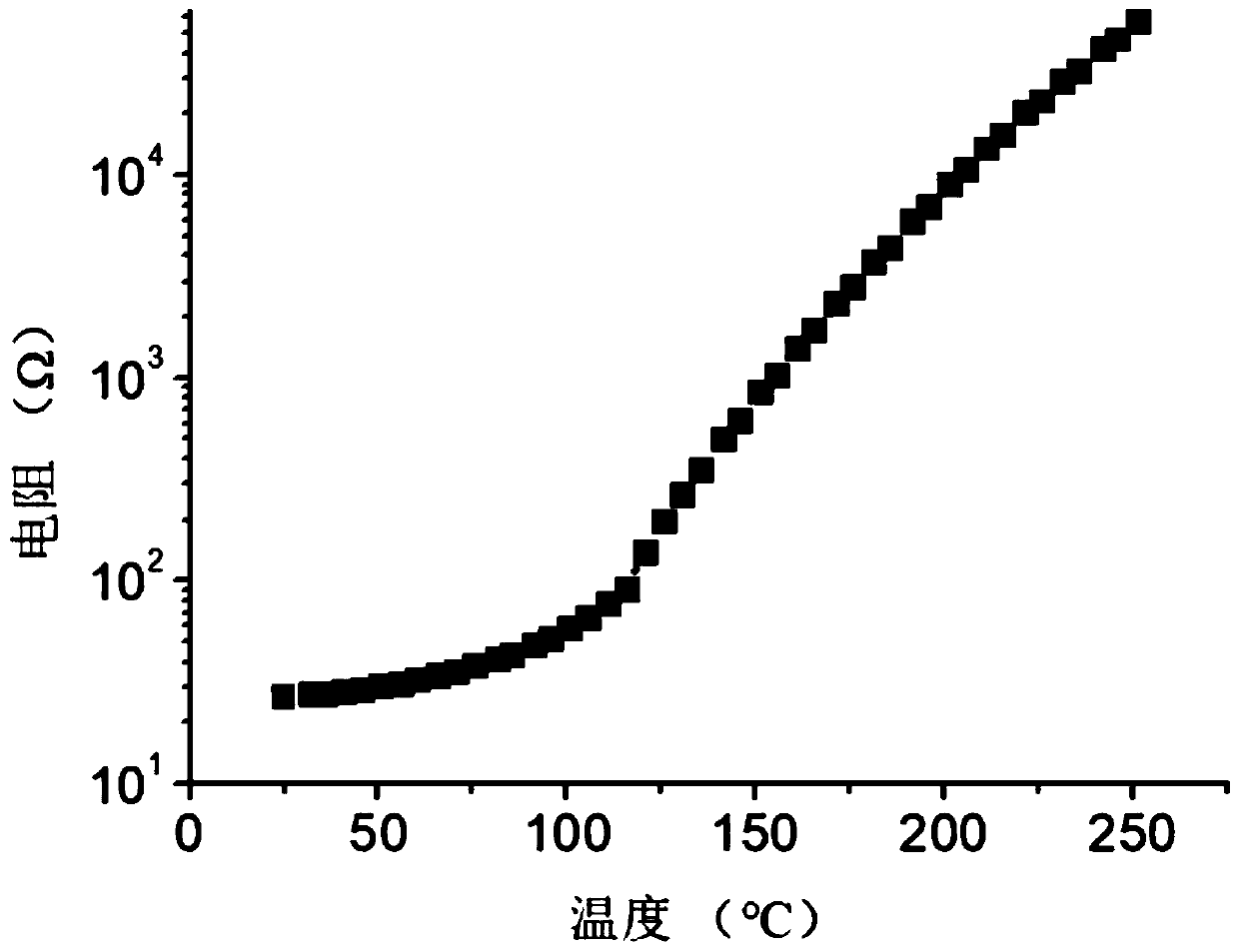

[0061] image 3 is the resistance-temperature curve of the barium titanate-based thermistor prepared in Example 3 of the present invention. Depend on image 3 It can be seen that the prepared heat-sensitive ceramic element has low room temperature resistance, obvious heat-sensitive effect, and excellent comprehe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com