High-precision constant flow source circuit

A constant current source, high-precision technology, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems of low current accuracy and increased application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

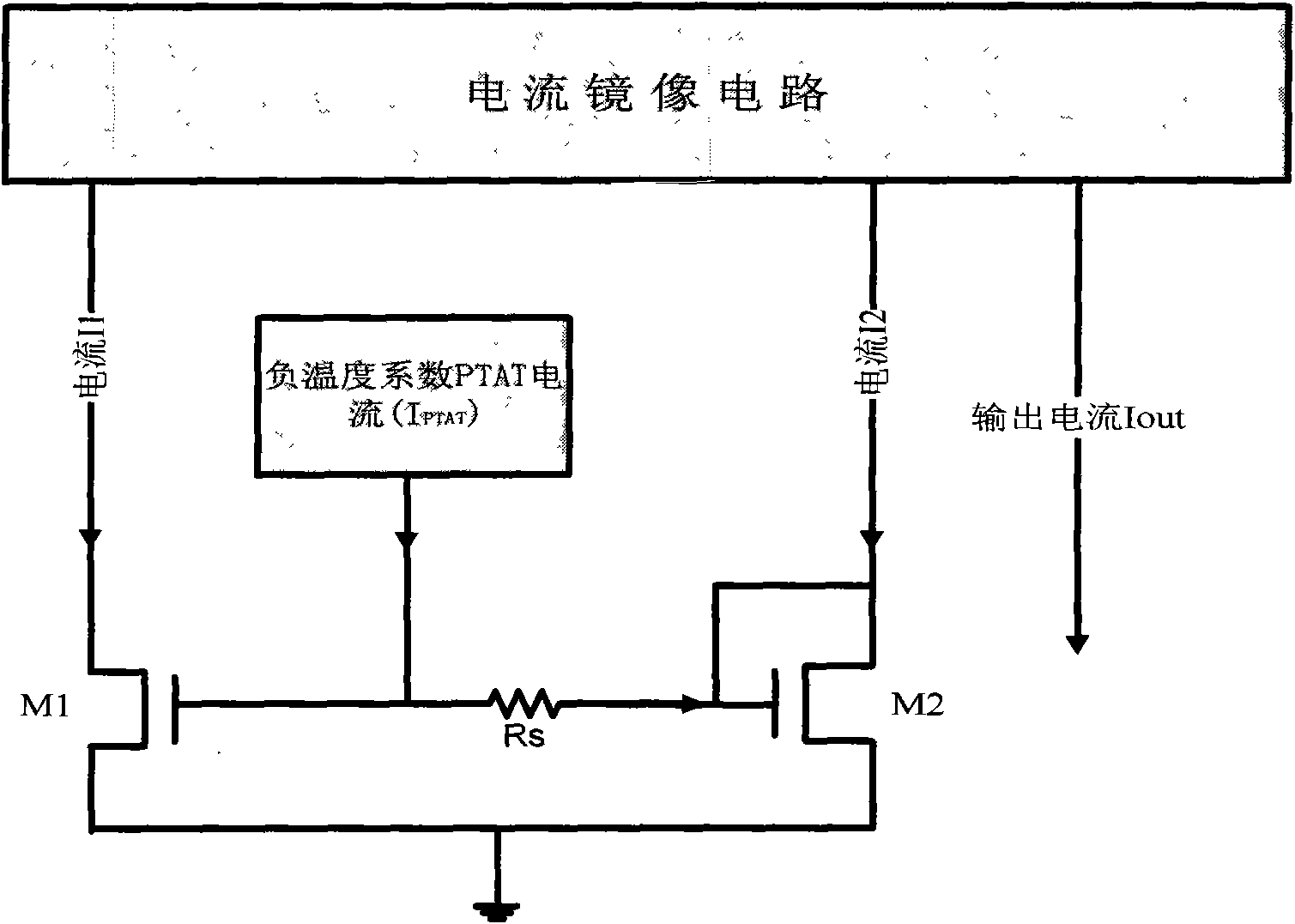

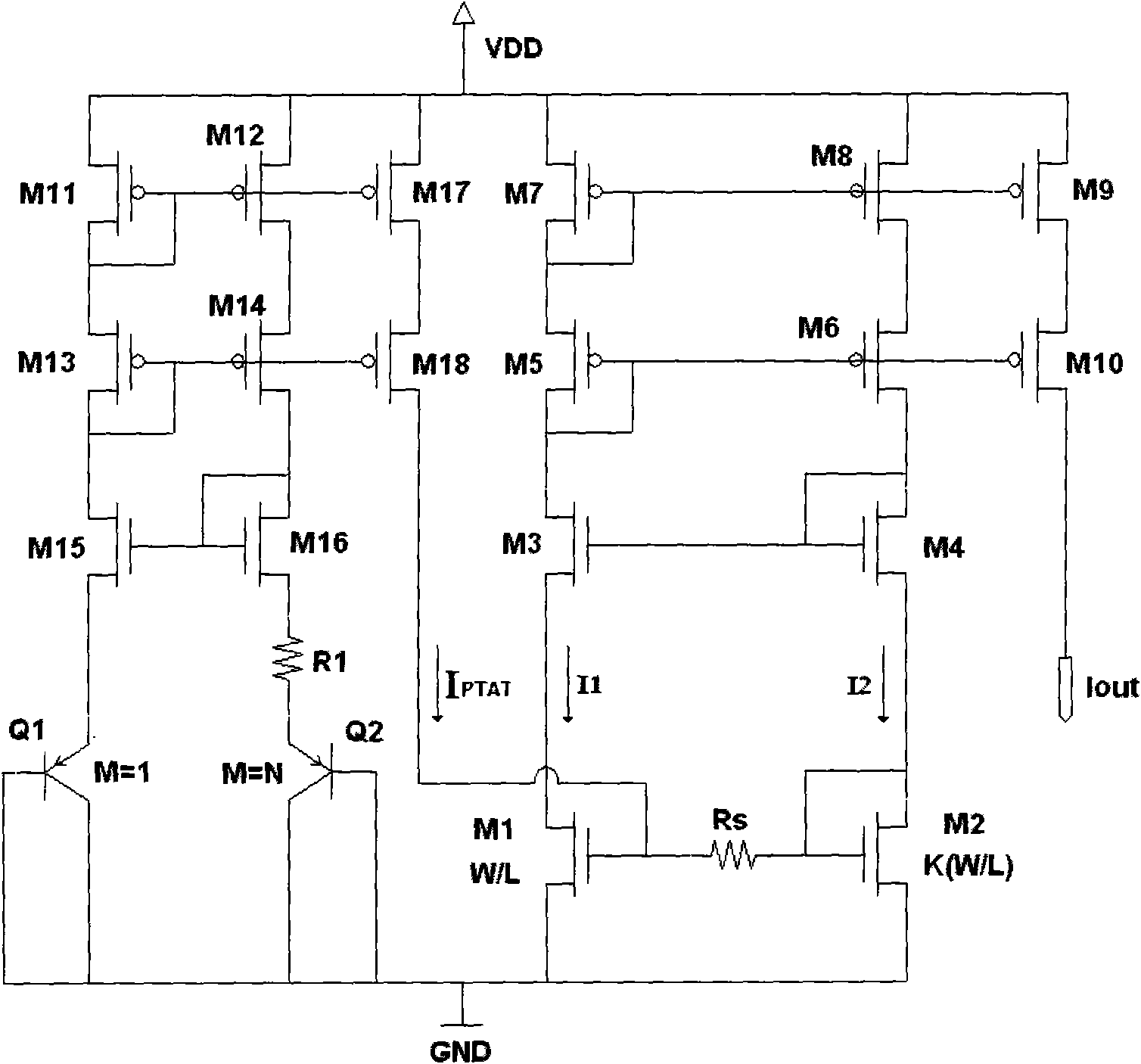

[0018] Such as figure 1 , 2 shows that the high-precision constant current source circuit disclosed in the present invention includes a PTAT (ProportionalTo Absolute Temperature, proportional to absolute temperature) current generation circuit and a core circuit, wherein the PTAT current generation circuit is based on a BANDGAP (bandgap reference) circuit The principle generates a PTAT current with a negative temperature coefficient for use by the core circuit, which is composed of bipolar transistors Q1, Q2, MOS transistors M11-M18 and resistor R1. The circuit produces a current I PTAT Can be expressed as:

[0019] I PTAT = V T · LnN R 1

[0020] where V T is the thermoelectric potential, N is the ratio of the areas of the two bipolar transistors Q2 and Q1, and R1 is a resistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com