Patents

Literature

247 results about "Constant-current diode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Constant-current diode is an electronic device that limits current to a maximal specified value for the device. It is known as current-limiting diode (CLD), current-regulating diode (CRD). These diodes consist of an n-channel JFET with the gate shorted to the source, which functions like a two-terminal current limiter or current source (analogous to a voltage-limiting Zener diode). They allow a current through them to rise to a certain value, and then level off at a specific value. Unlike Zener diodes, these diodes keep the current constant instead of the voltage constant. These devices keep the current flowing through them unchanged when the voltage changes. An example is the 1N5312. Note the negative VGS is required, as an example on the n-type junction-gate field-effect transistor 2N5457.

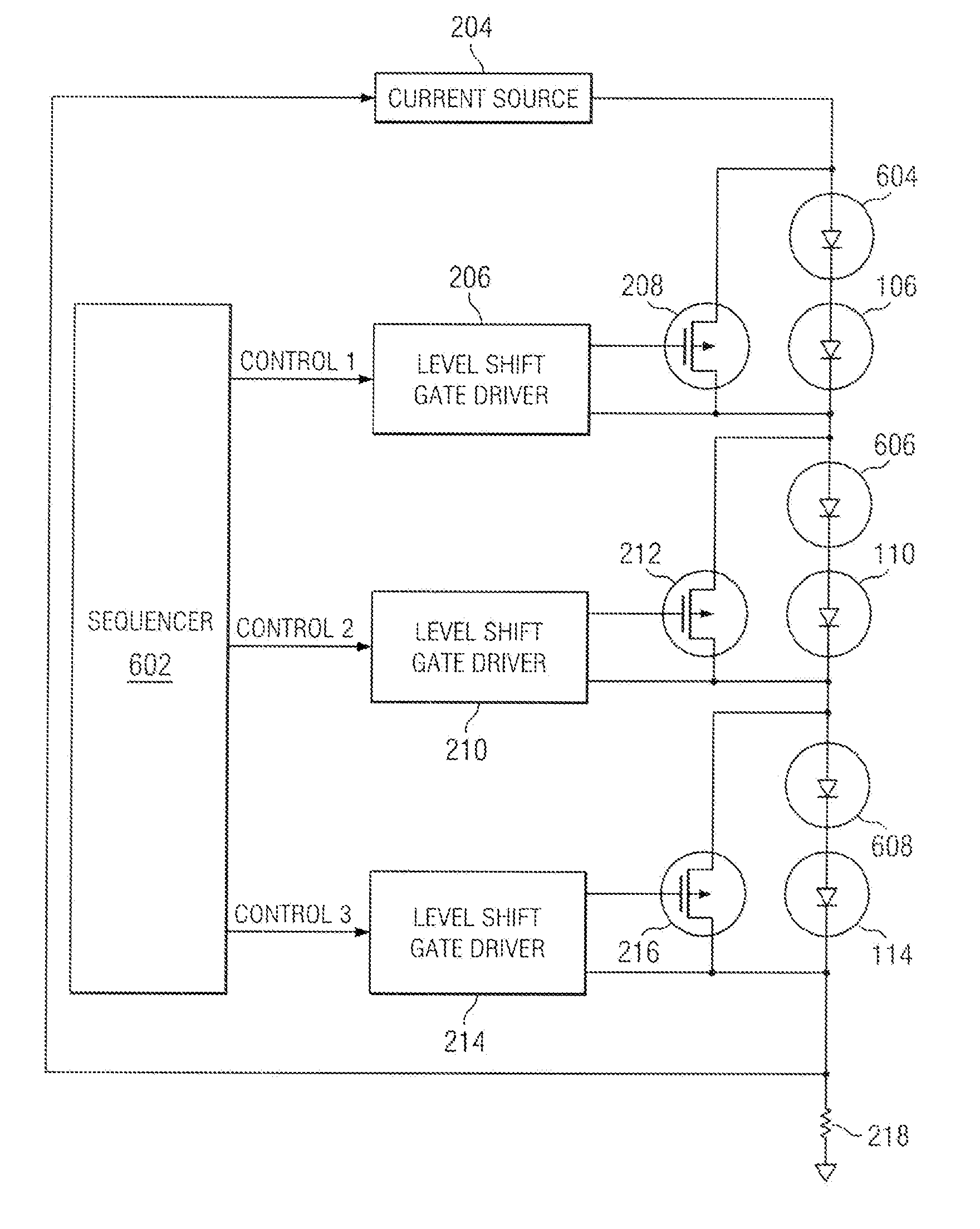

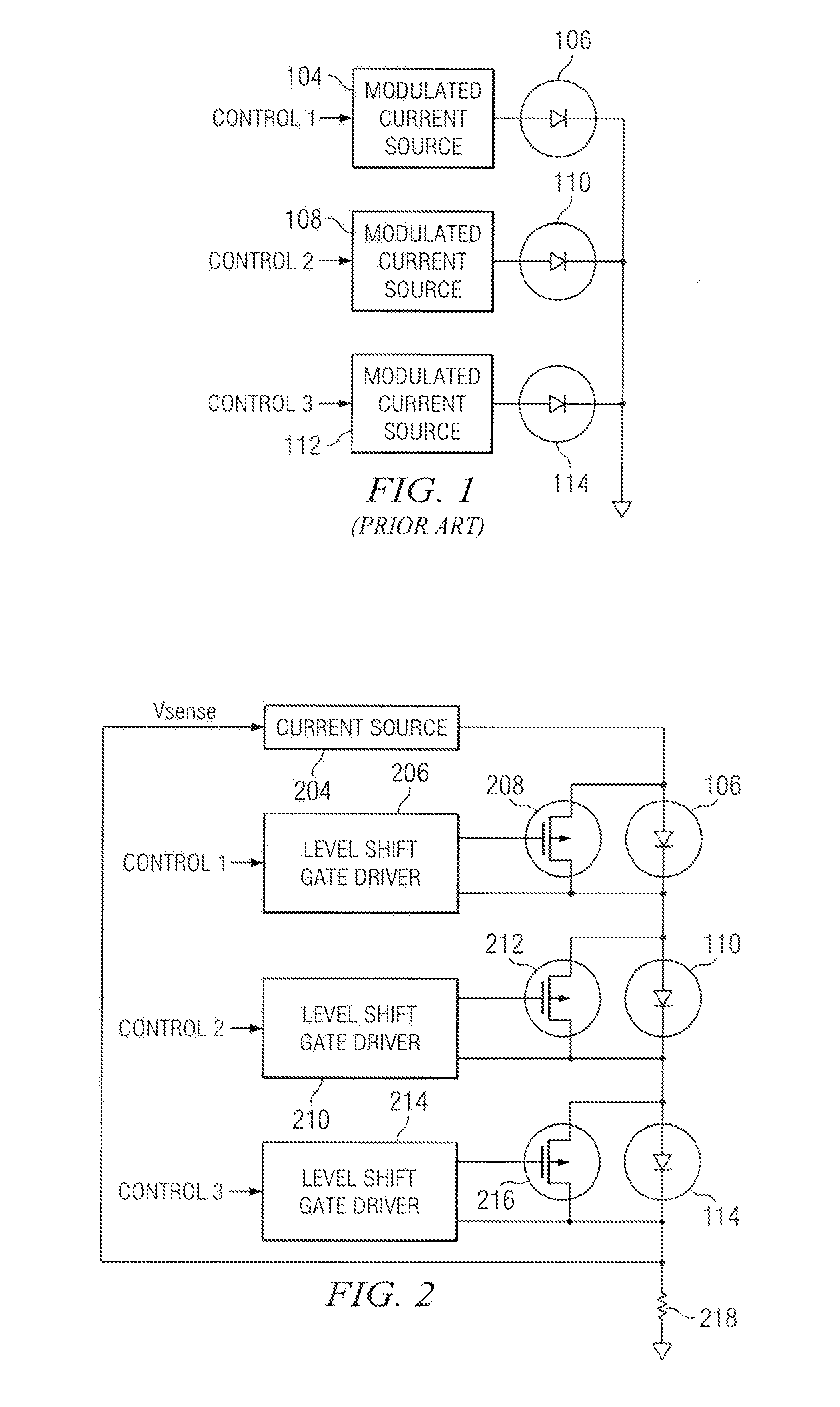

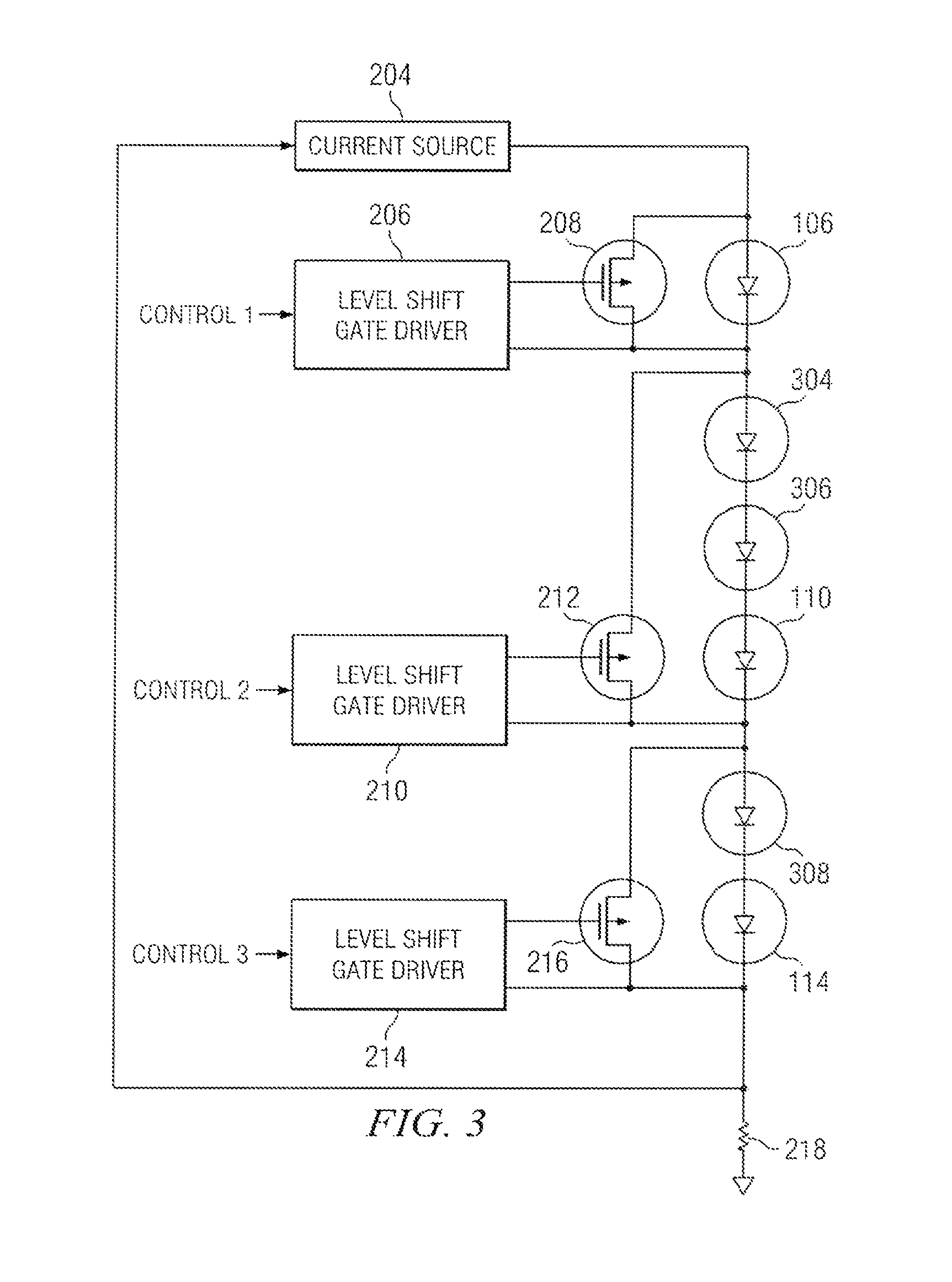

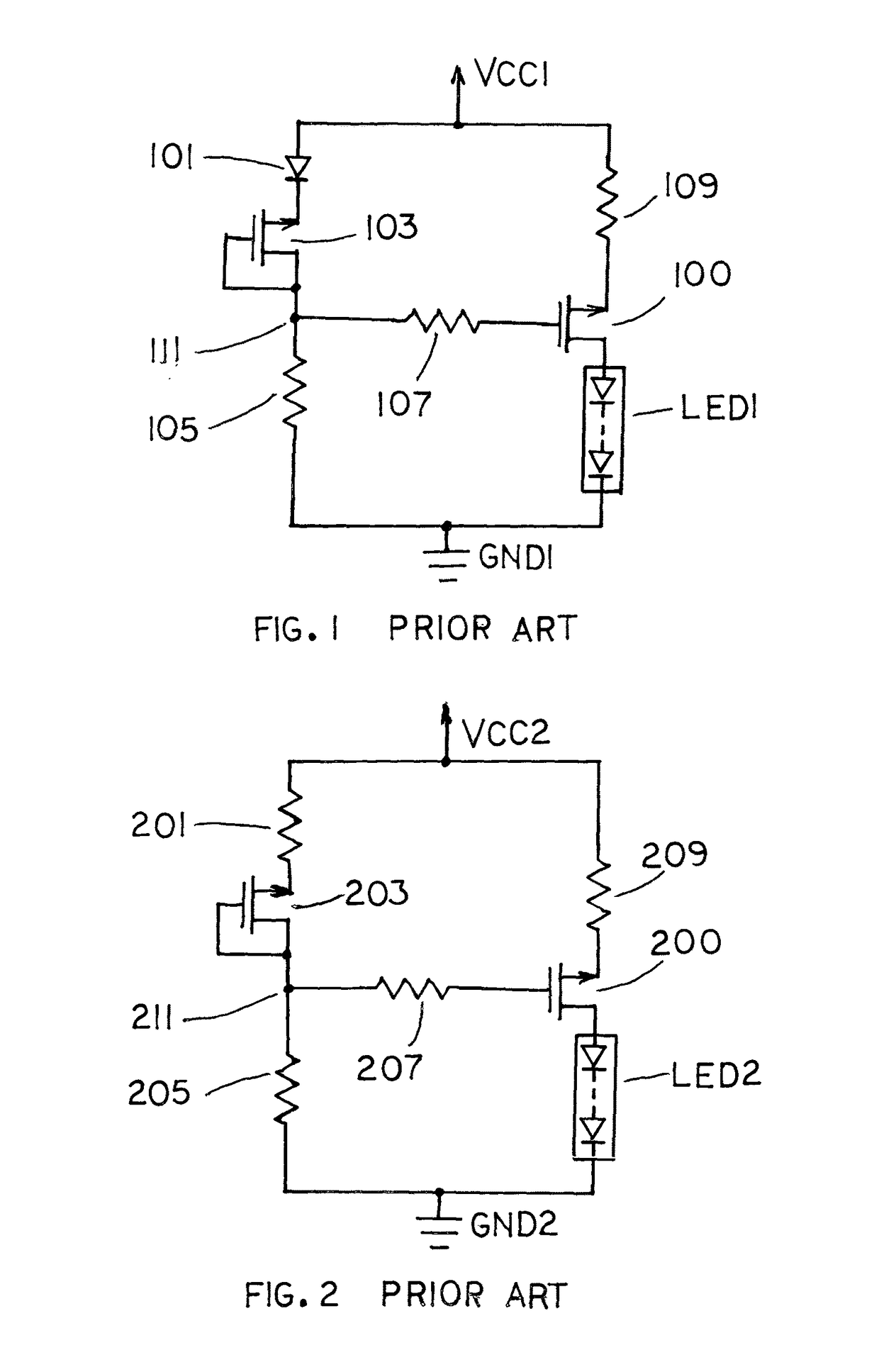

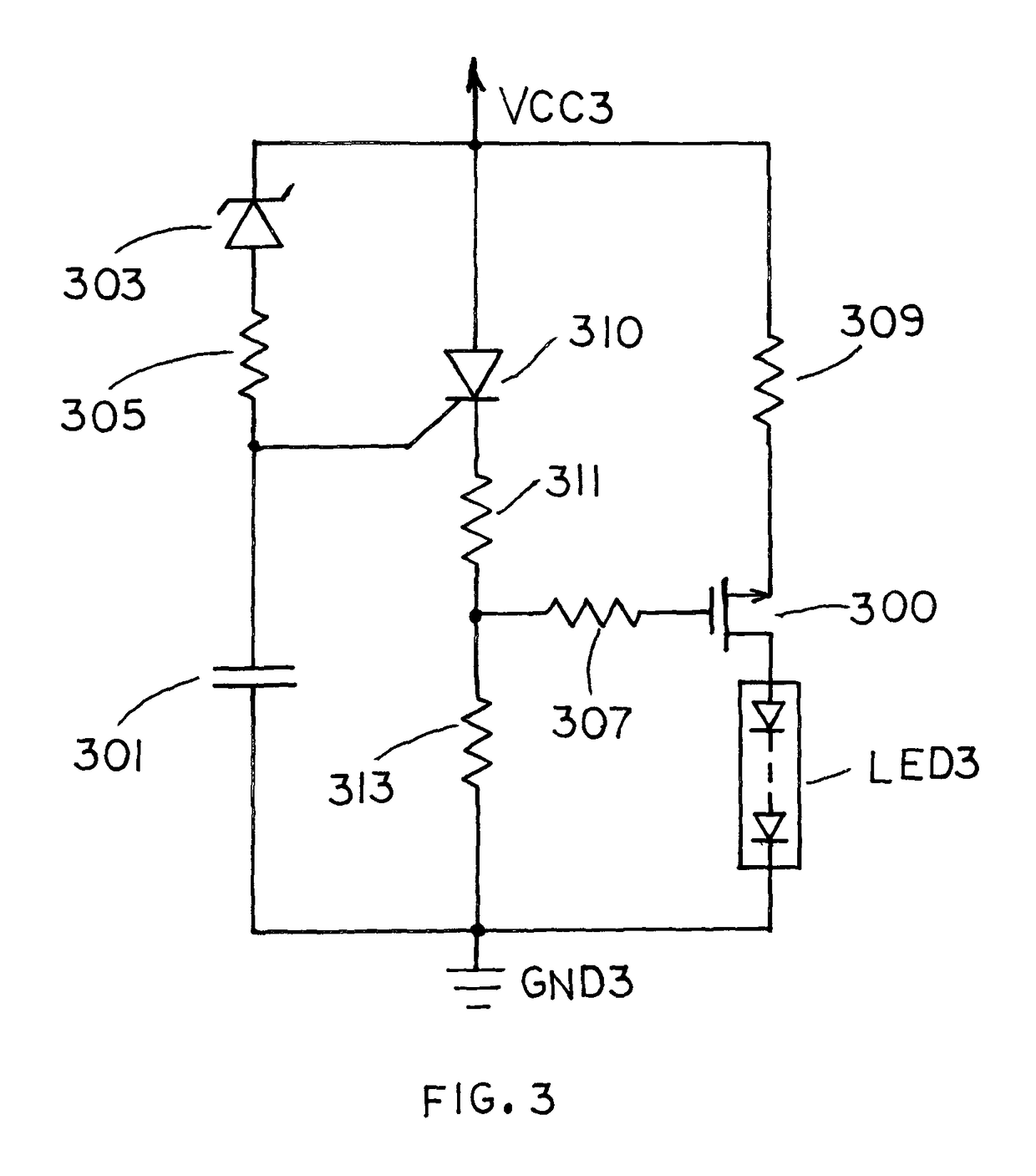

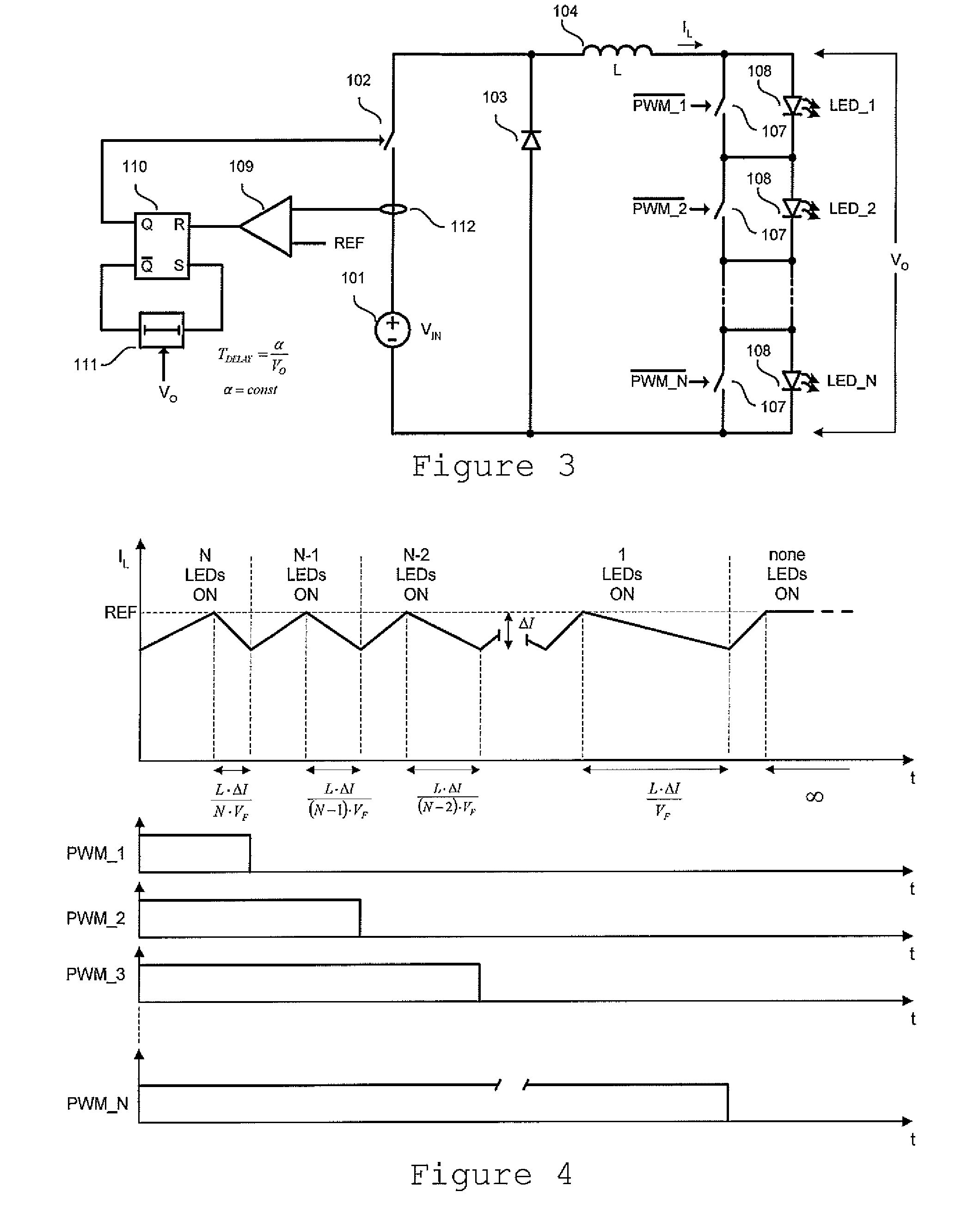

Highly efficient series string LED driver with individual LED control

ActiveUS7649326B2Increase brightnessStable changeElectrical apparatusElectroluminescent light sourcesControl signalField-effect transistor

A current source generates, with high efficiency, a current that is substantially constant over a wide range of output voltages. This current is injected into the first end of a series-connected string of LEDs, with the second end of the string connected through a resistor to ground. The voltage developed across this resistor, which is a measure of current flow in the series string, is fed back to the current source, wherein feedback maintains nearly constant current output over a wide range of output voltages. A field effect transistor (FET) is placed in parallel with each LED in the string. A level shift gate driver couples a pulse width modulated control signal to the gate of each FET. With the FET being coupled across a particular LED, the LED can be bypassed when the FET is actuated or receive current when the FET is deactuated. By modulating the duty cycle of each FET, the brightness of each associated LED may be varied smoothly over its full range.

Owner:TEXAS INSTR INC

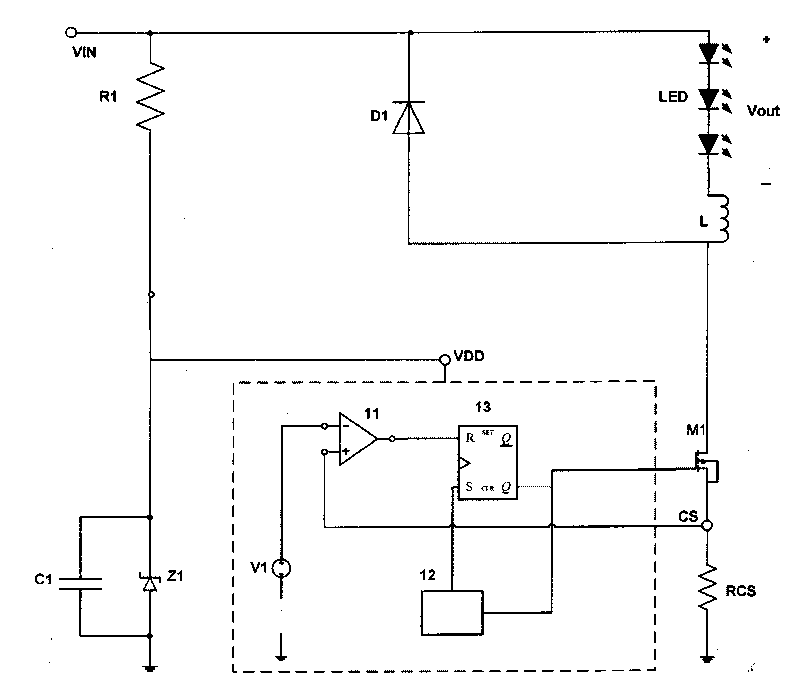

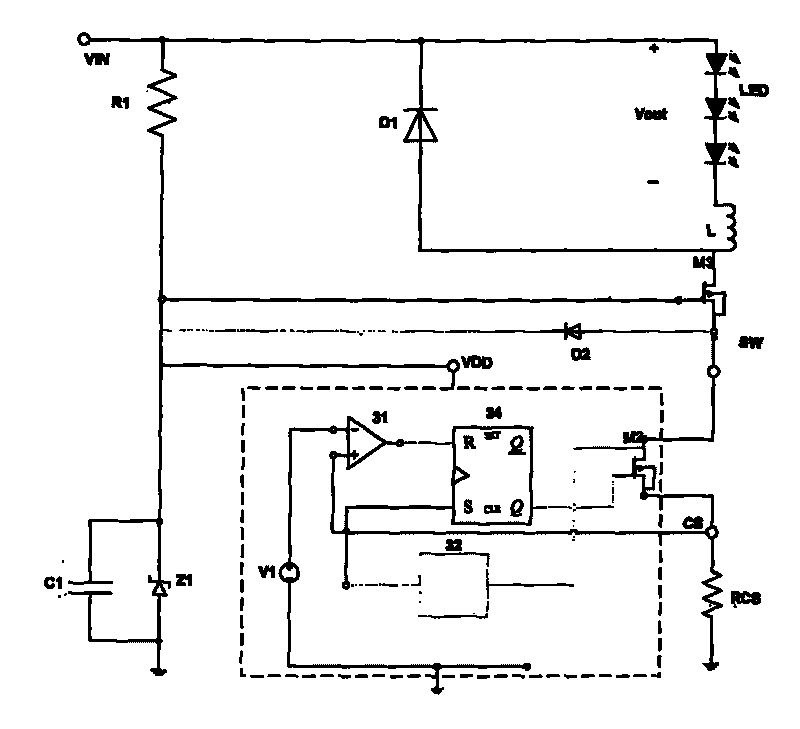

LED drive circuit of source driver with change of output voltage and induction quantity keeping constant current

ActiveCN101707837AReduce complexityLow costElectric light circuit arrangementEngineeringVoltage reference

The invention relates to an LED drive circuit of a source driver with the change of the output voltage and the induction quantity keeping constant current, which comprises a resistor R1, a voltage stabilizing tube, a capacitor, a flywheel diode D1 and an inductor and also comprises a first MOS transistor, wherein a grid electrode is connected with the negative pole of the voltage stabilizing tube, a drain electrode is connected between the inductor and the D1, a source electrode is connected with the positive pole of a current feed diode D2, and the negative pole of the D2 is connected with the negative pole of the voltage stabilizing tube; the source electrode drives a control circuit, and the control circuit comprises a second transistor, an RS trigger, a comparator and an inductive current zero-crossing detector. When the inductive current zero-crossing detector detects that inductive current crosses zero, the inductive current zero-crossing detector generates a setting signal and outputs the signal to the S input end of the RS trigger, so the second transistor is conducted; when output current is increased to enable the voltage of the positive input end of the comparator to be equal to reference voltage, the comparator turns over and controls the second transistor to be closed. According to the drive circuit, the output current is free from the influence of the induction quantity and the output voltage, the stability is enhanced, and the complexity and the cost of the circuit are lowered.

Owner:SHANGHAI BRIGHT POWER SEMICONDUCTOR CO LTD

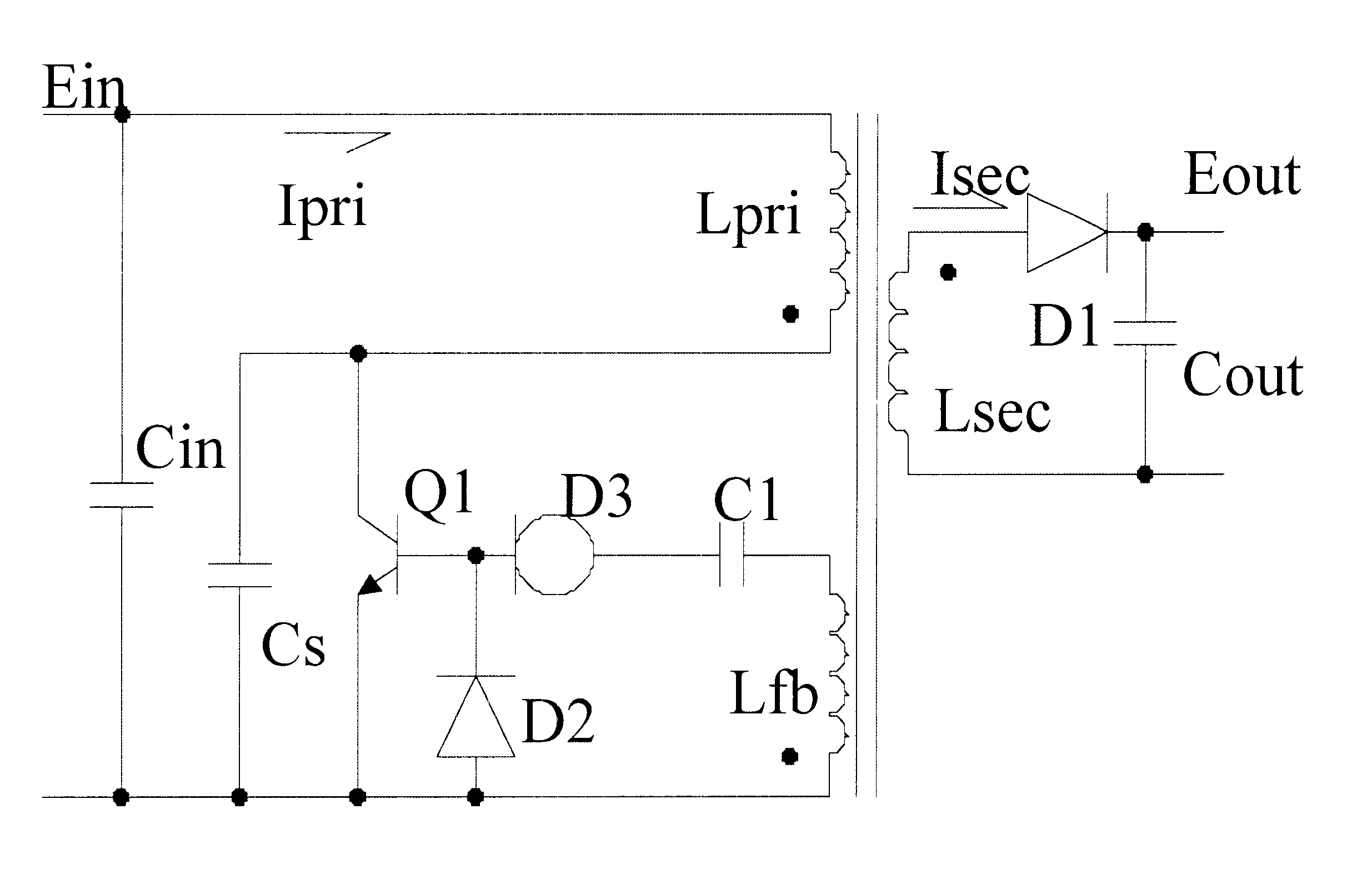

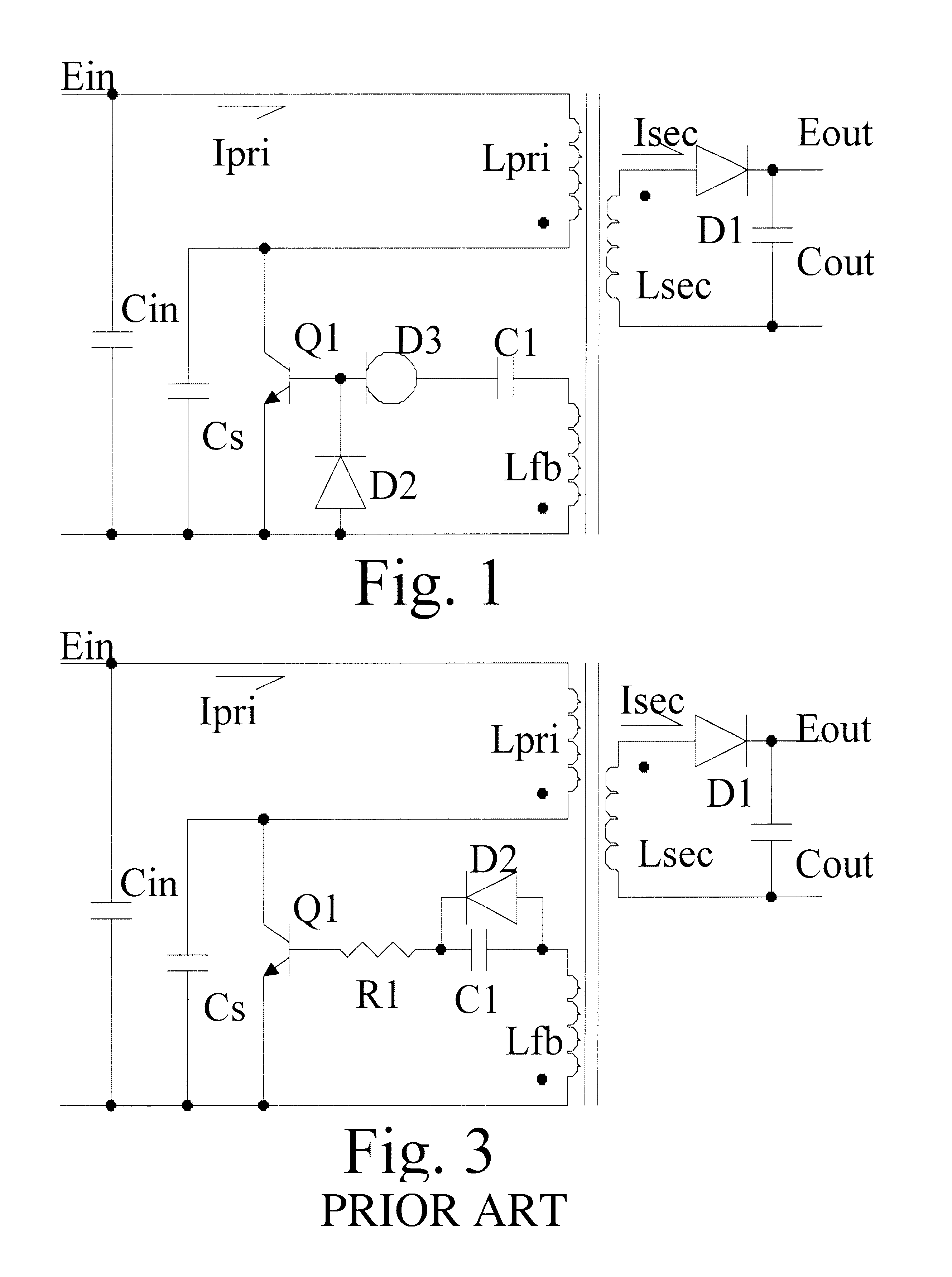

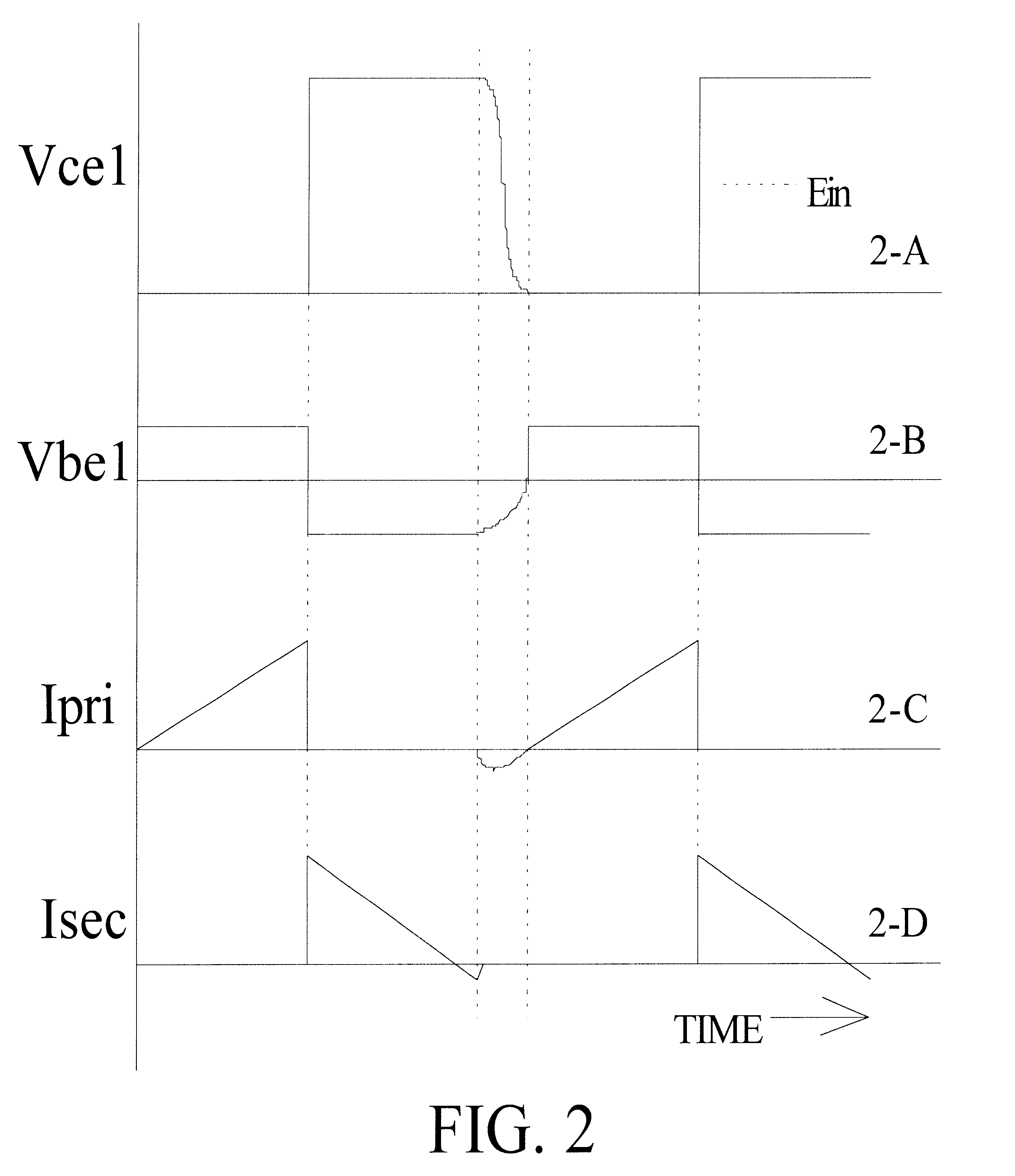

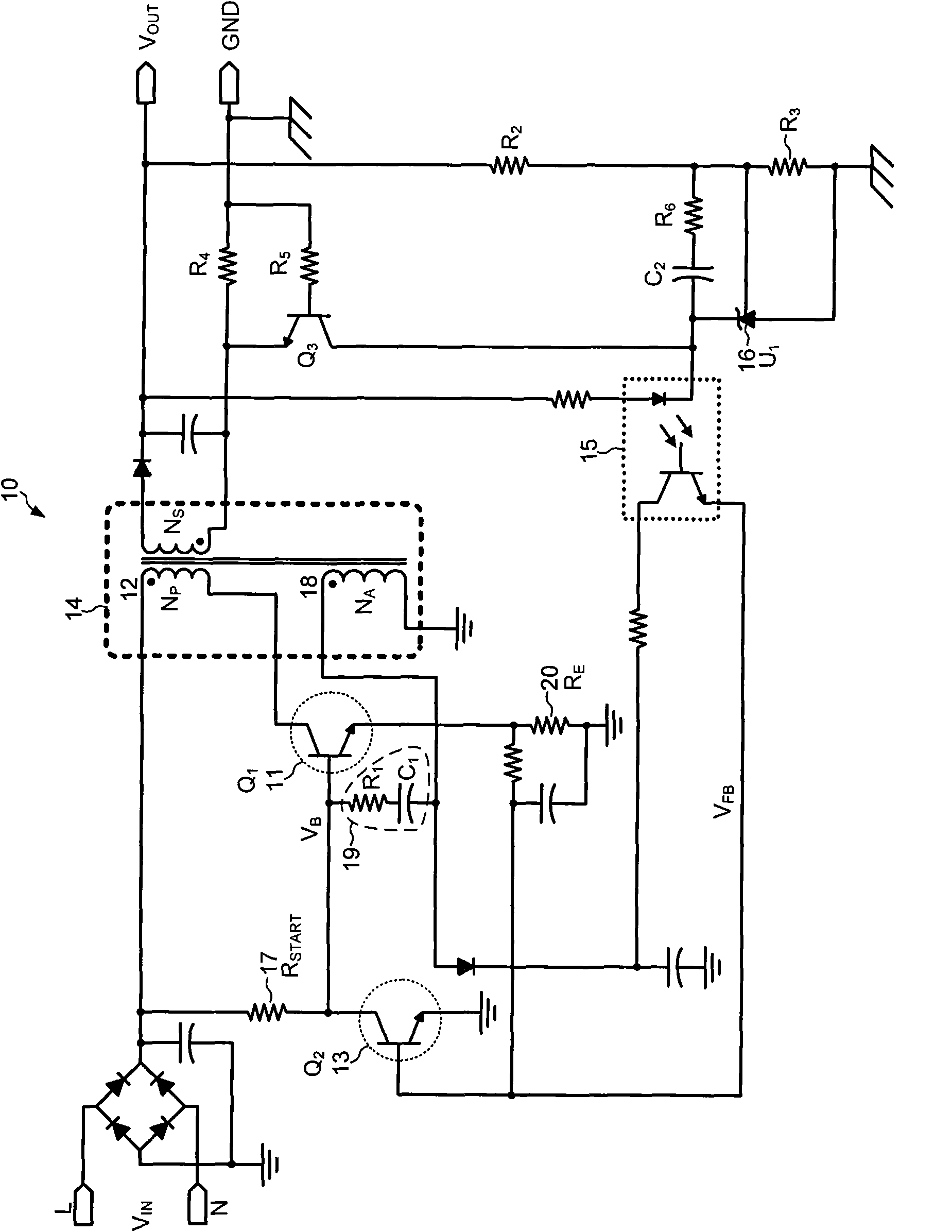

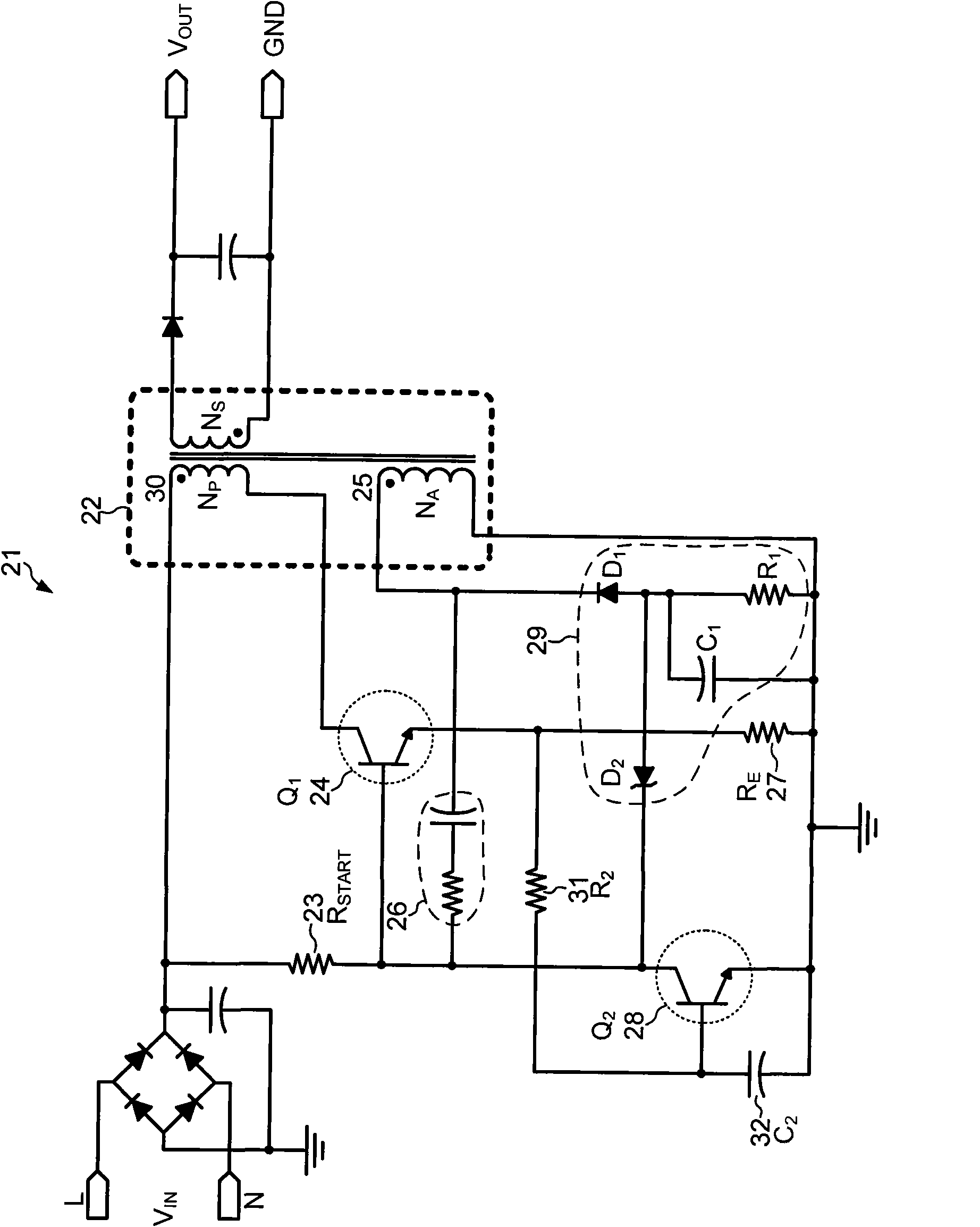

Self-oscillation type resonant flyback converter utilizing charge stored effect of the P-N diode

InactiveUS6404654B1Increase powerEasy to switchEfficient power electronics conversionEmergency protective circuit arrangementsSelf-oscillationConductor Coil

A self-oscillation type resonant flyback converter includes a series combination of a primary winding and a switching transistor. A secondary winding is connected to a power diode and to an output capacitor. A feedback winding is connected to a delay driving circuit comprising a delay diode, a constant-current diode and a capacitor. The delay driving circuit is provided to delay a positive feedback signal from said feedback winding, so that when said power diode becomes non-conducting, said delay diode becomes in the reverse conduction state, starting a free resonance period that concludes when the said delay diode becomes non-conducting and the switching transistor is achieved at zero voltage switching.

Owner:INTEGRATED PROGRAMMABLE COMM

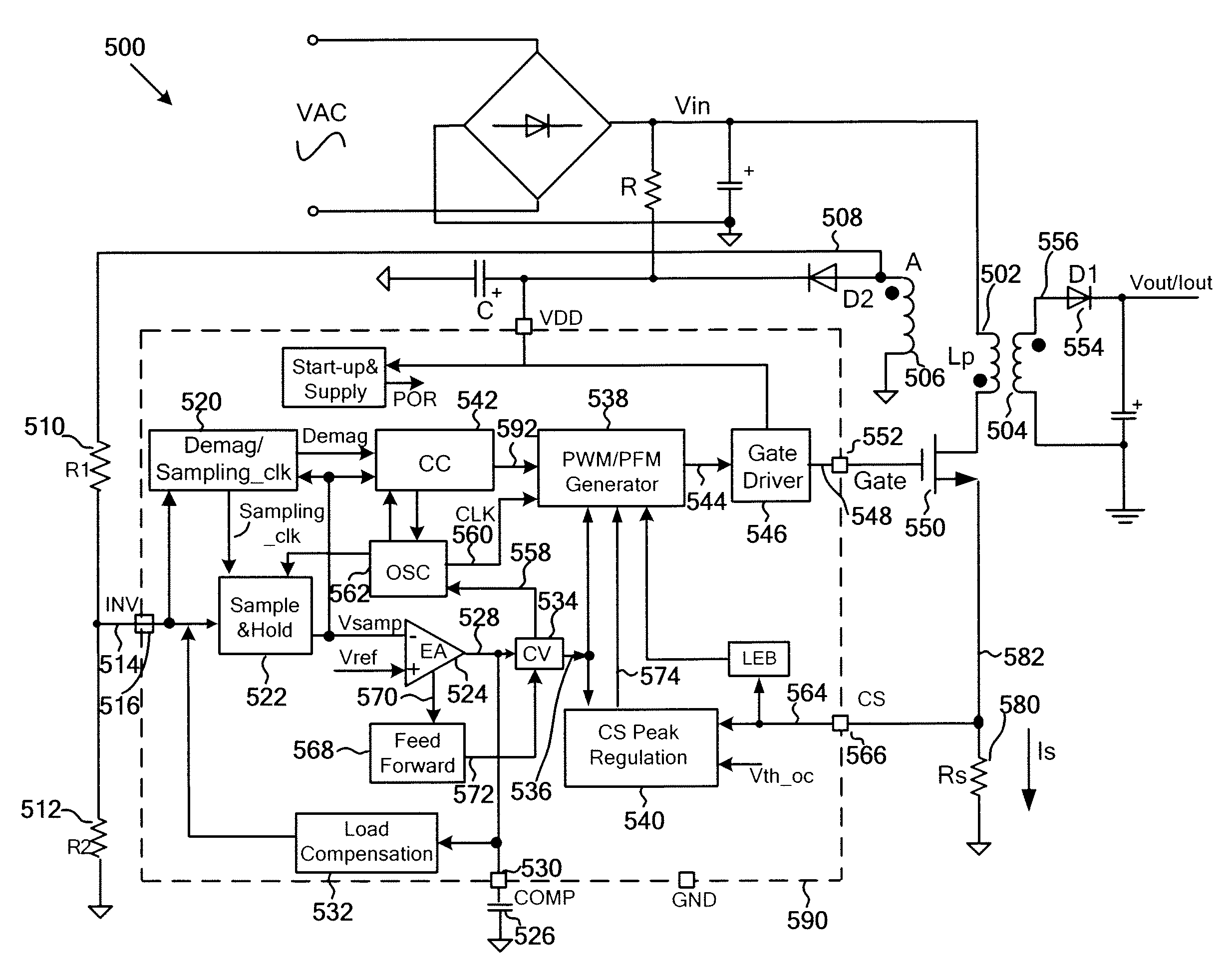

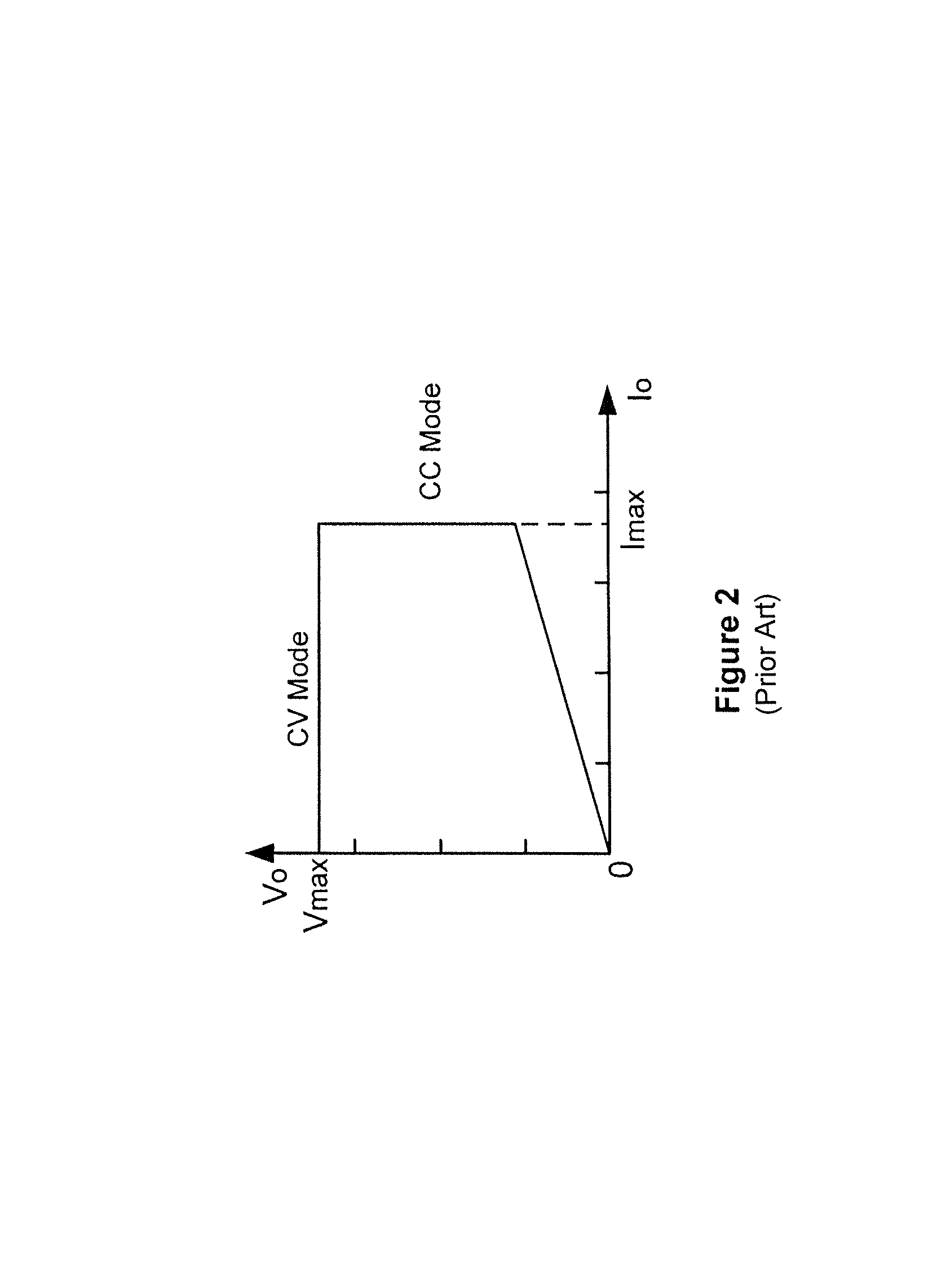

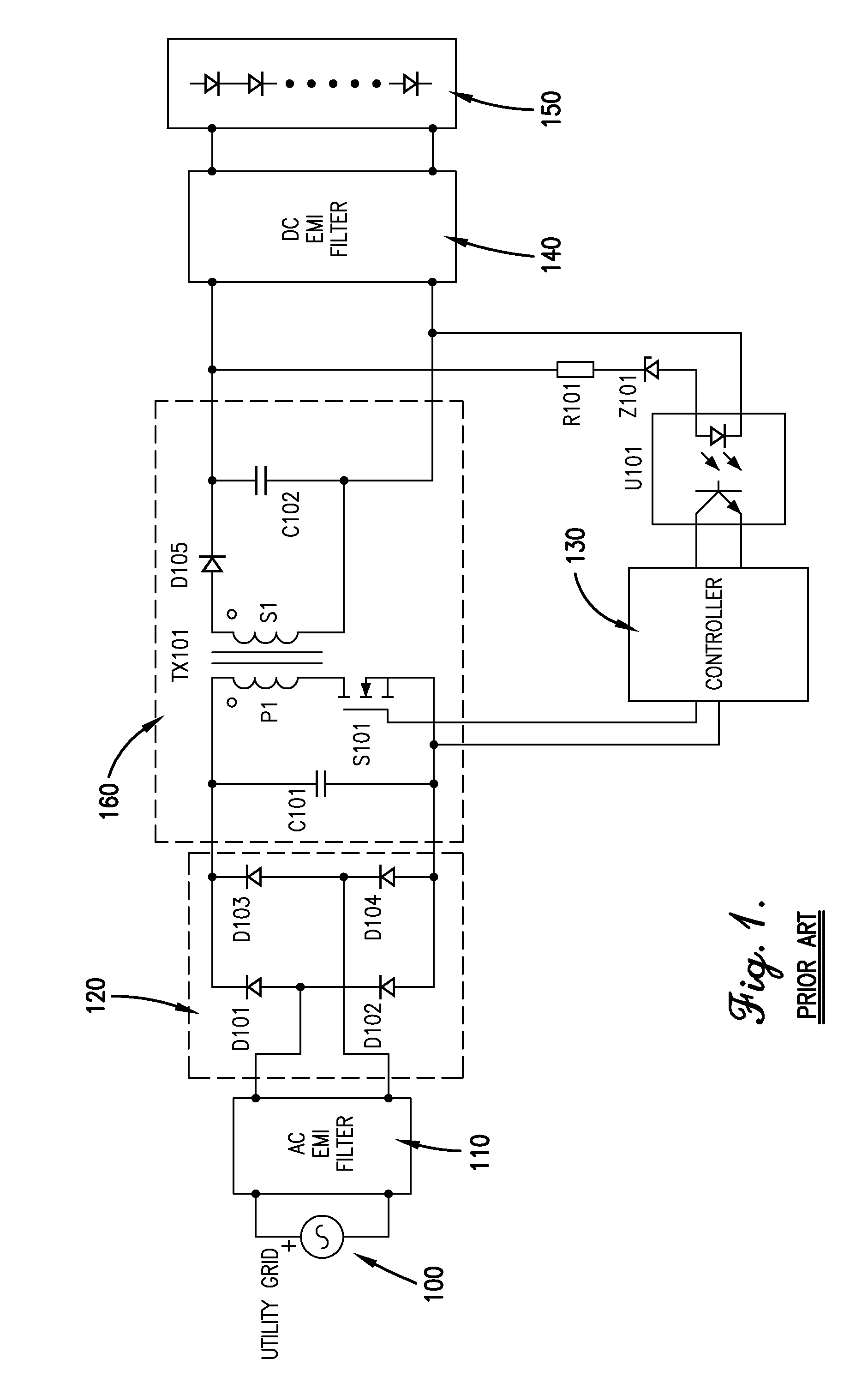

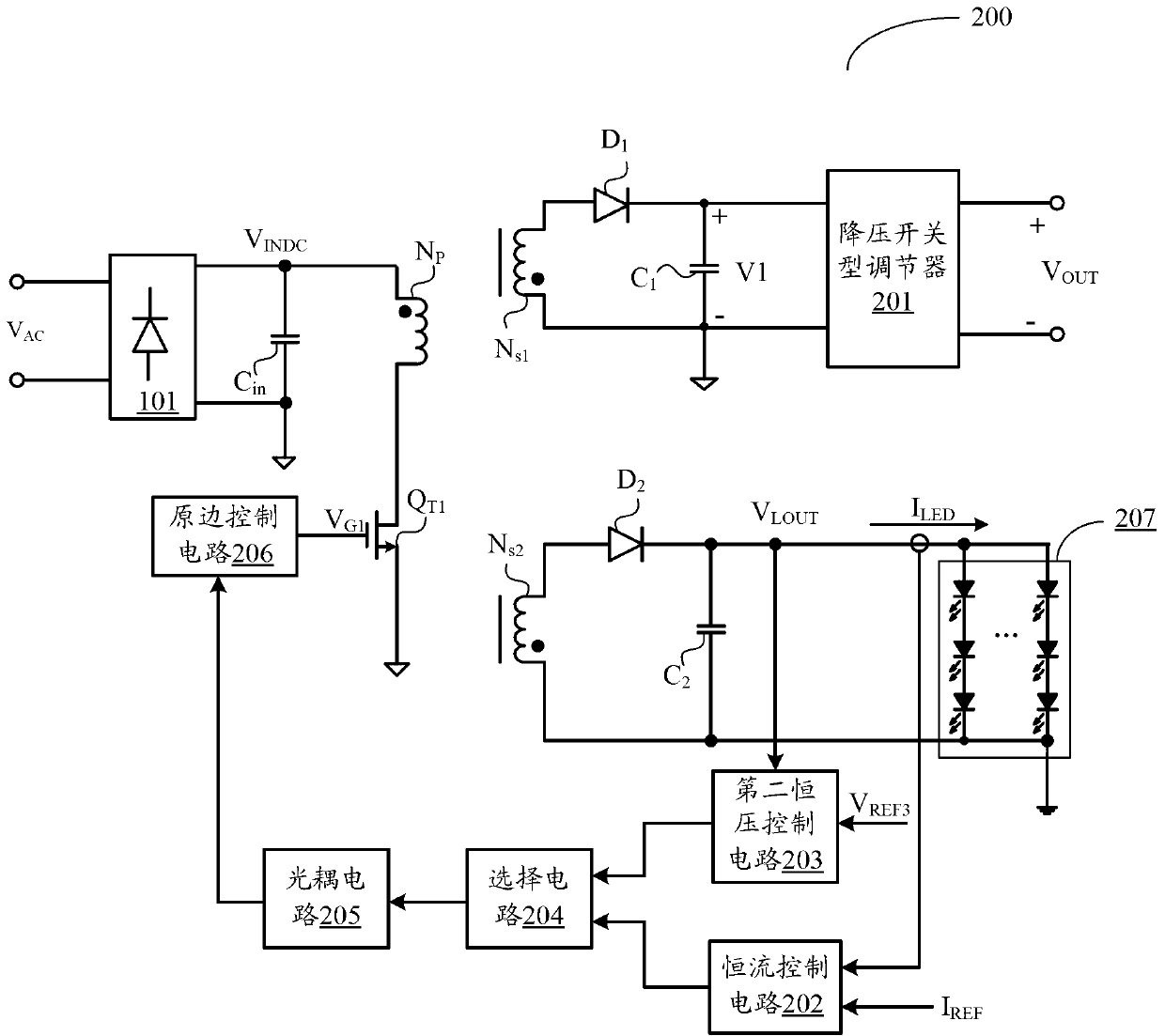

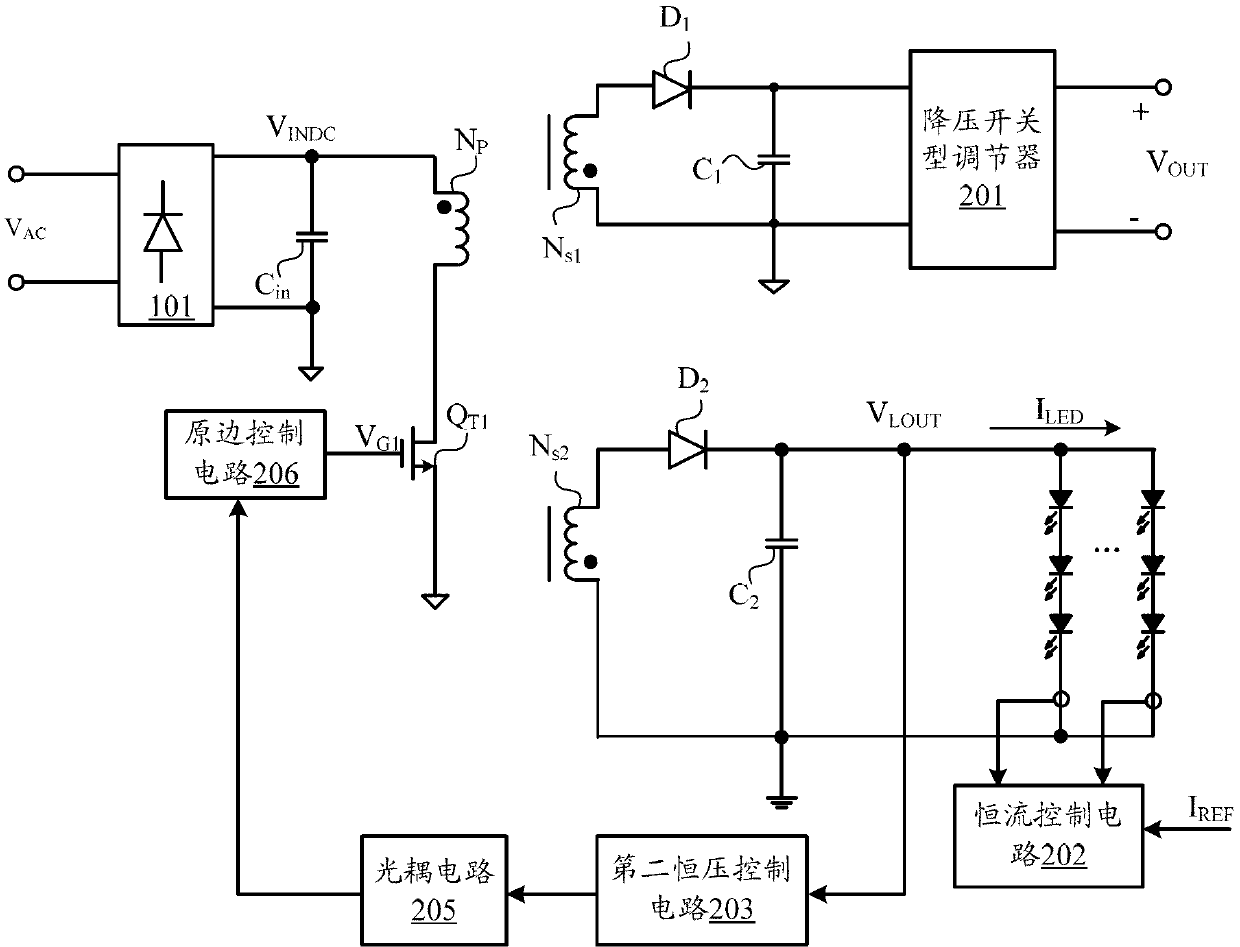

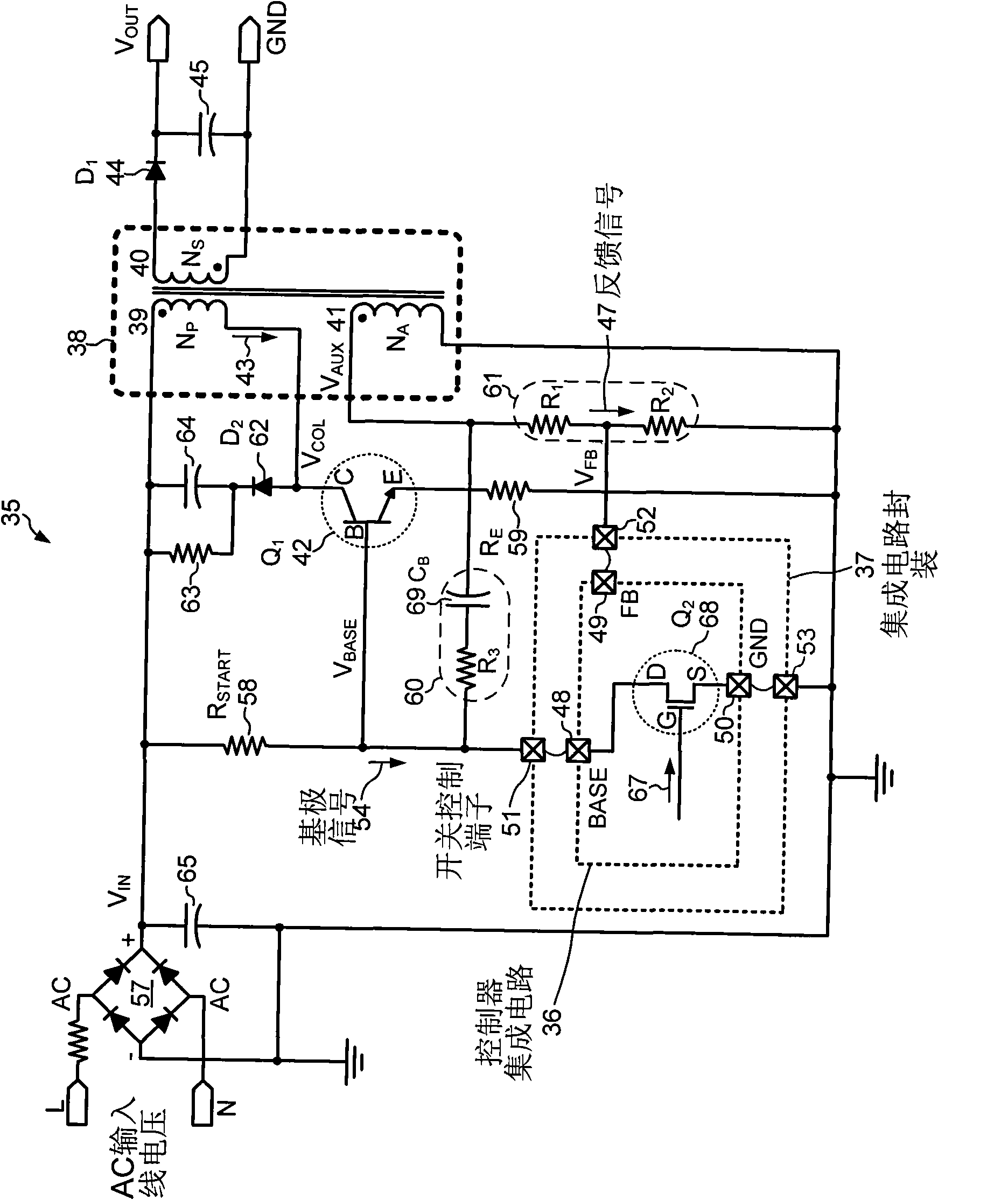

Systems and methods for constant voltage mode and constant current mode in flyback power converter with primary-side sensing and regulation

ActiveUS8526203B2Simple circuit designShorten the counting processDc-dc conversionElectric variable regulationEngineeringSignal generator

System and method for regulating a power converter. The system includes a first signal generator configured to receive at least an input signal and generate at least a first output signal associated with demagnetization and a second output signal associated with sampling. Additionally, the system includes a sampling component configured to receive at least the input signal and the second output signal, sample the input signal based on at least information associated with the second output signal, and generate at least a third output signal associated with one or more sampled magnitudes. Moreover, the system includes an error amplifier configured to receive at least the third output signal and a first threshold voltage and generate at least a fourth output signal with a capacitor, the capacitor being coupled to the error amplifier.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

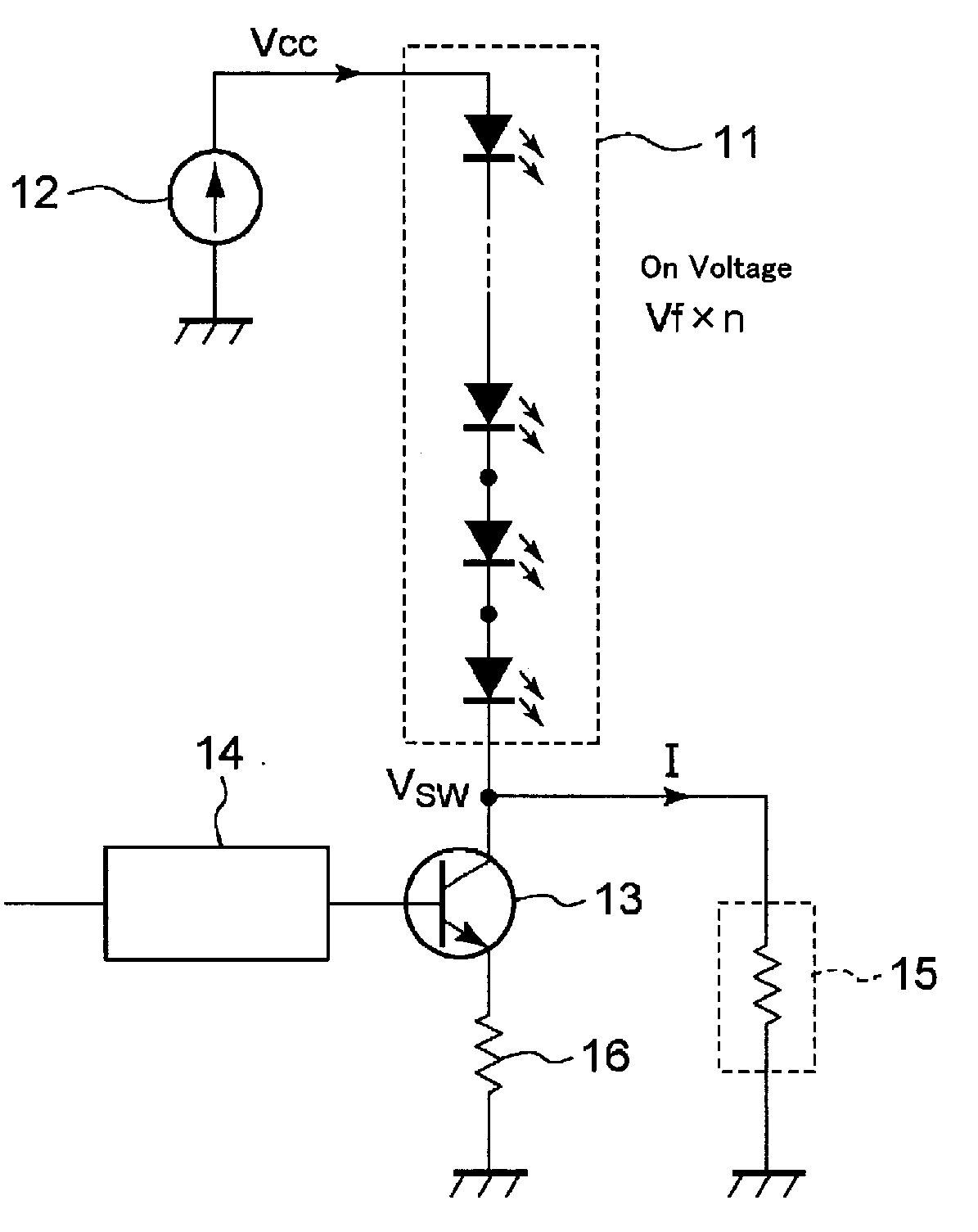

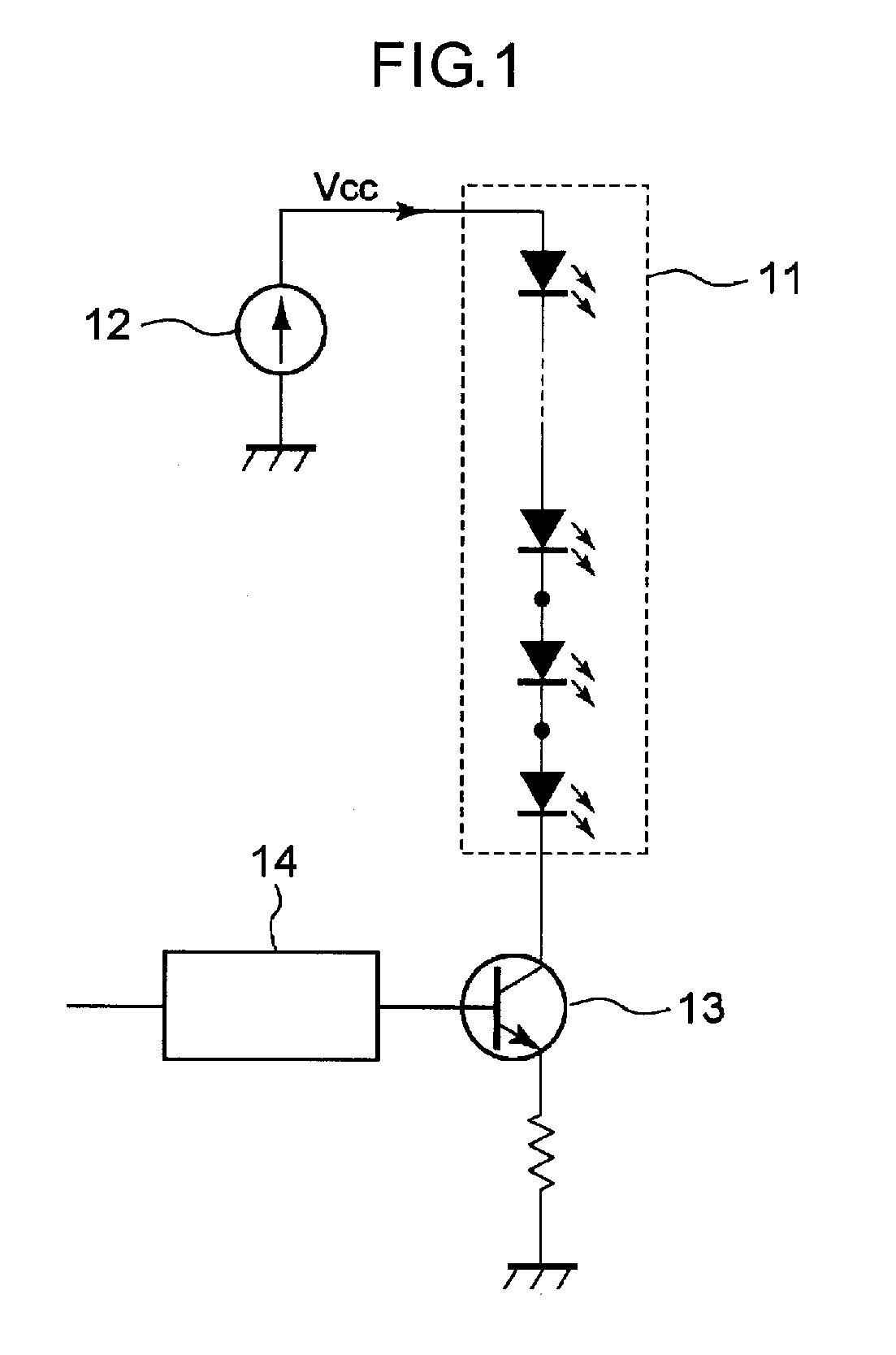

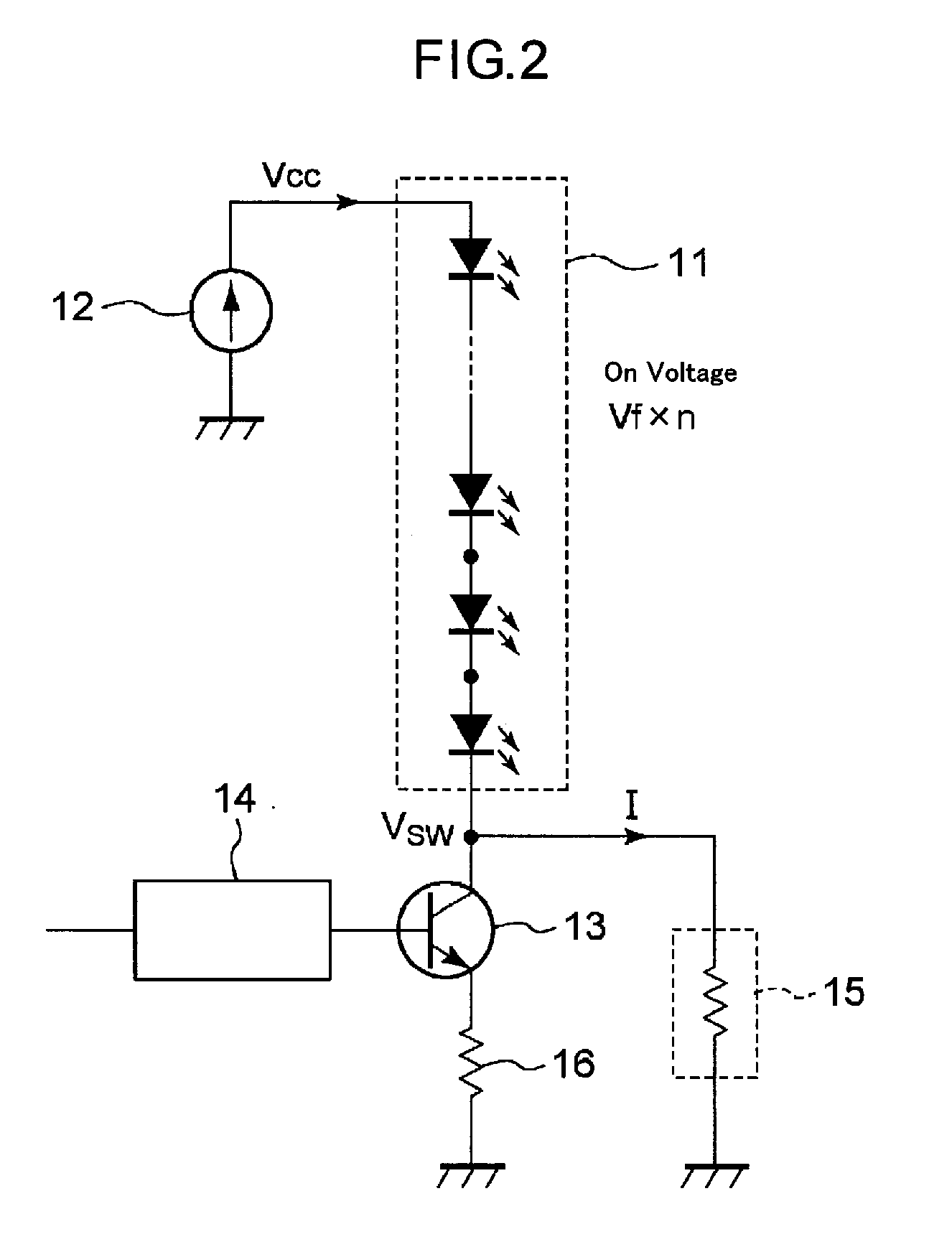

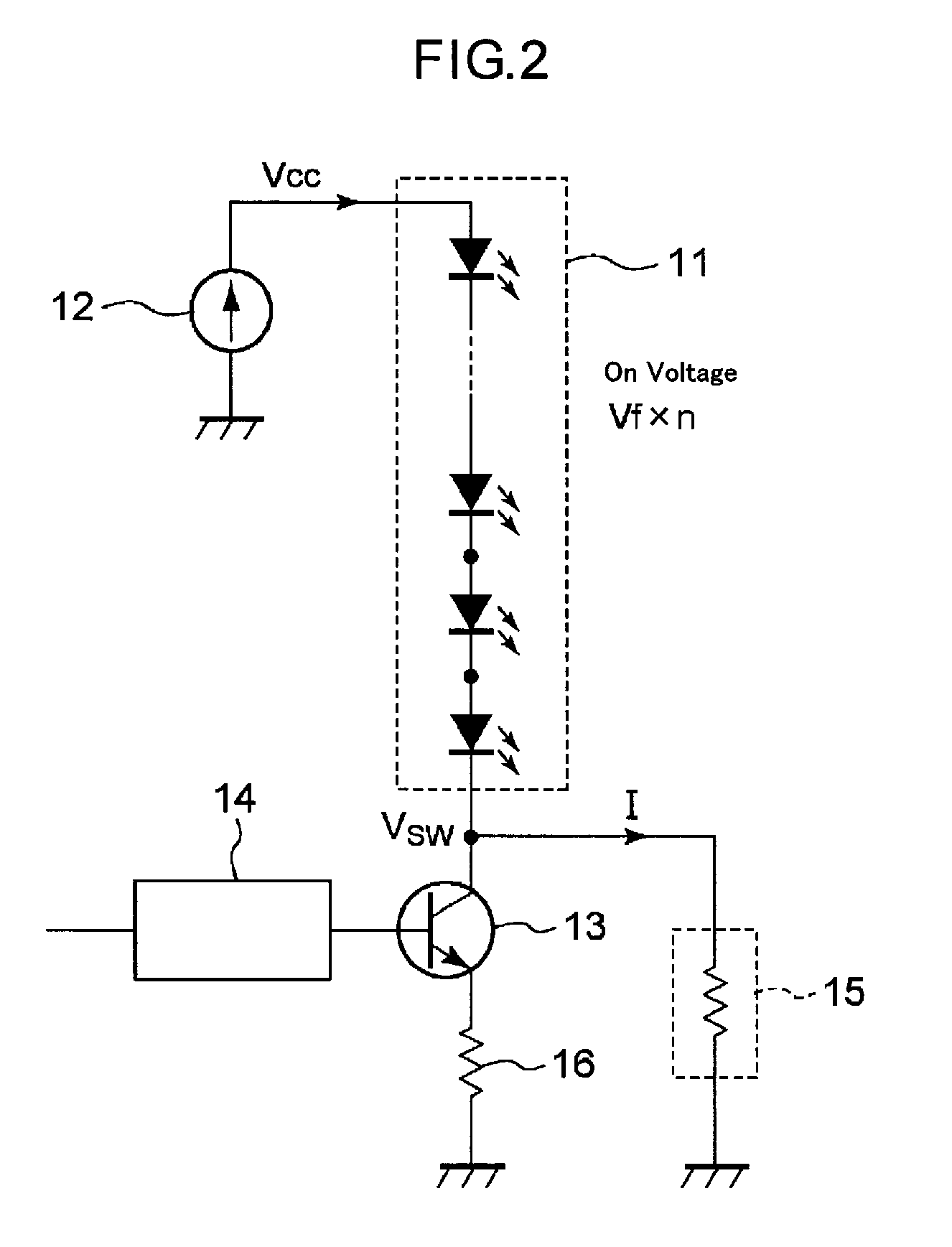

LED driving circuit

InactiveUS20100072898A1Increase the number ofChange LED light volume widely and accuratelyElectrical apparatusElectroluminescent light sourcesLED circuitConstant-current diode

An LED driving circuit is provided for making it possible to economically drive a serially connected LED circuit by means of a switching device with a relatively low withstanding voltage even if the number of serially connected LED devices increases. In an LED driving circuit provided with a serially connected LED circuit (11) in which many LED devices are serially connected and a switching device (13) serially connected with the serially connected LED circuit (11) to control that an electrical current flowing through the serially connected LED circuit (11) is turned on or off, wherein a circuit device (15), which comprises a resistor, a constant voltage diode, a constant current diode, or the like, is connected in parallel with the switching device to make a minute current flow through the serially connected LED circuit (11) to the extent that the LED devices are not turned on when the switching device is turned off.

Owner:KOA CORP

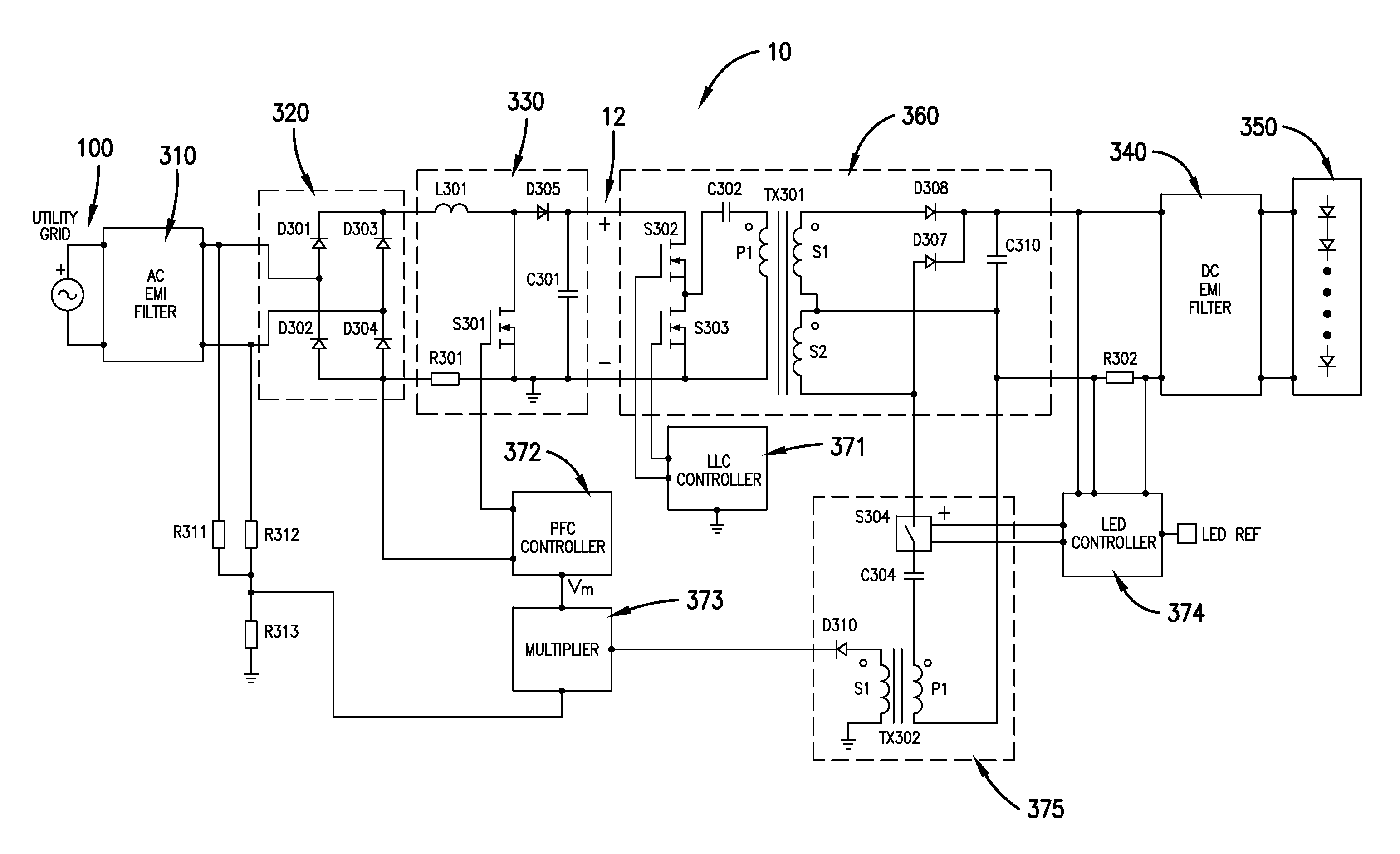

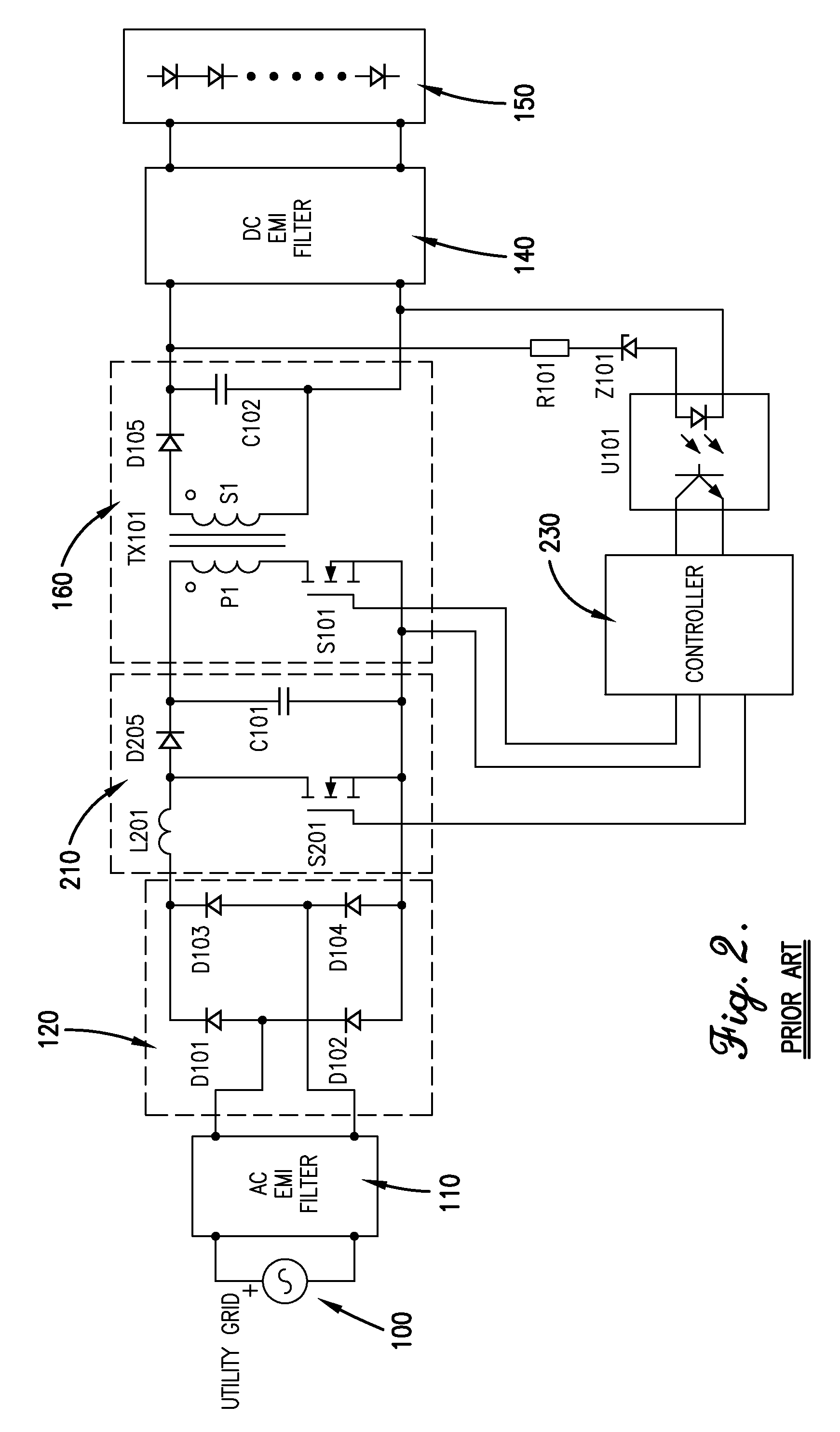

LED driver

ActiveUS20150195878A1Extend your lifeEasily trade switching lossElectrical apparatusElectroluminescent light sourcesConstant powerAverage current

An LED driver having an input to receive AC power from an AC power source, a semiconductor switch and an inductor controlled to produce a sinusoidal current drawn from the AC power source, and a large non-electrolytic (e.g. film) capacitor energy storage component. The semiconductor switch operates with a varying pulse-width-modulation frequency to regulate the voltage across the non-electrolytic capacitor energy storage component in such a way that a ripple current through the inductor is substantially smaller than a pulse-width-modulation cycle average current through the inductor. A DC-to-DC converter couples the energy from the non-electrolytic energy-storage capacitor to an LED string. A feedback loop allows the LED string to be regulated in either constant current mode or constant power mode and information for the feedback regulation is fed back across a high-voltage boundary using a low-cost signal transformer.

Owner:GARRITY POWER SERVICES

Led thyristor switched constant current driver

ActiveUS9820344B1Maximum service lifeMaterials is relatively shortElectrical apparatusElectroluminescent light sourcesMOSFETPower flow

A circuit for controlling power to a load from a rectified AC supply is disclosed. The load like an LED or another type is driven by a power device such as a MOSFET or a transistor. The power device is biased from a resistive string which also includes a thyristor switch in series combination. At a specific trigger or conduction angle of the thyristor switch the proper bias for the power device is obtained to enable the load current to remains fairly constant with AC supply voltage fluctuations or loading. Furthermore the trigger circuit of the thyristor switch is properly configured in order for the load current to stay constant or even change with ambient temperature variations as well.

Owner:PAPANICOLAOU ELIAS S

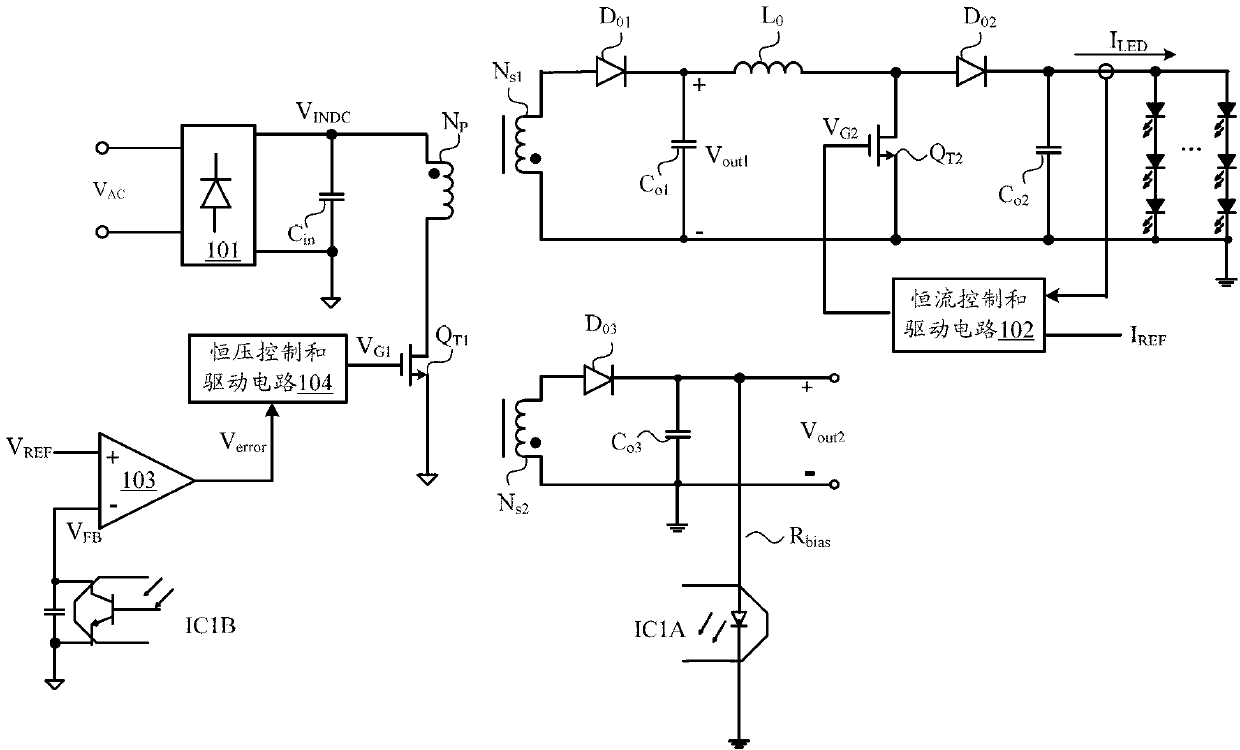

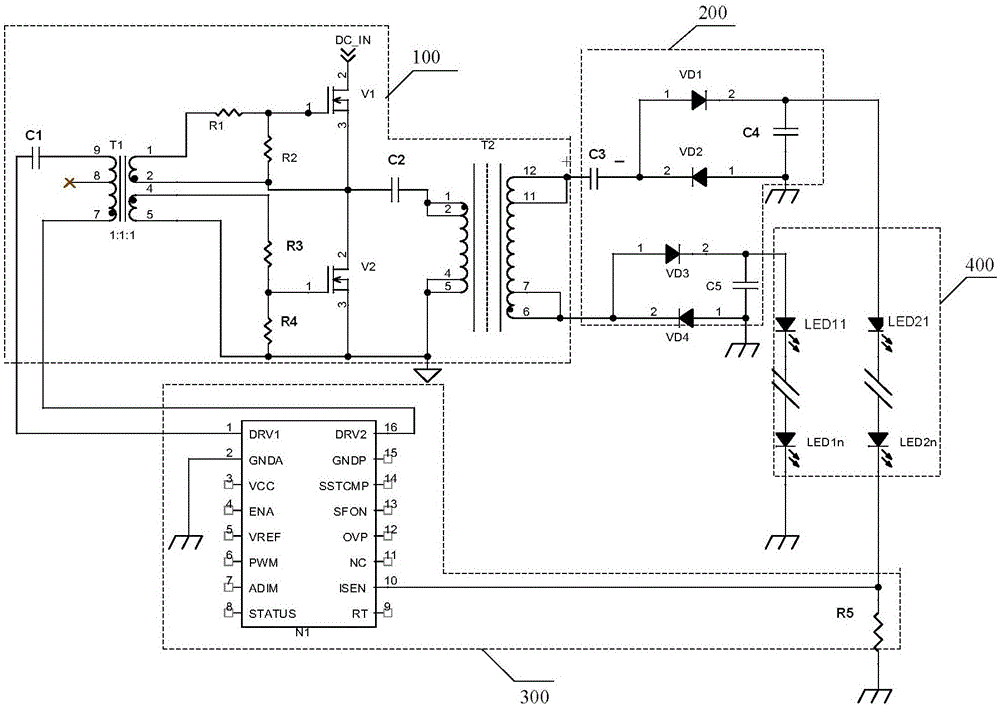

Constant current and constant voltage output multi-channel power supply system

ActiveCN103281823AEffective protectionReduce power lossDc-dc conversionElectric light circuit arrangementDriving currentEngineering

The invention provides a constant current and voltage output multi-channel power supply system, which comprises a transformer formed by (m+n) secondary side windings and primary side windings, m first output circuits and n second output circuits, wherein each primary side winding receives a half sine wave DC (Direct Current) voltage, and each first output circuit is used for driving an LED (Light Emitting Diode) load formed by one channel or multiple channels of LED lamp strings; m constant current control circuits are used for controlling the drive current of the LED load to keep constant, and n step-down switching regulators are correspondingly connected with n second output circuits and are used for receiving the output voltage of the second output circuits and controlling the output voltage of the step-down switching regulators to keep constant.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

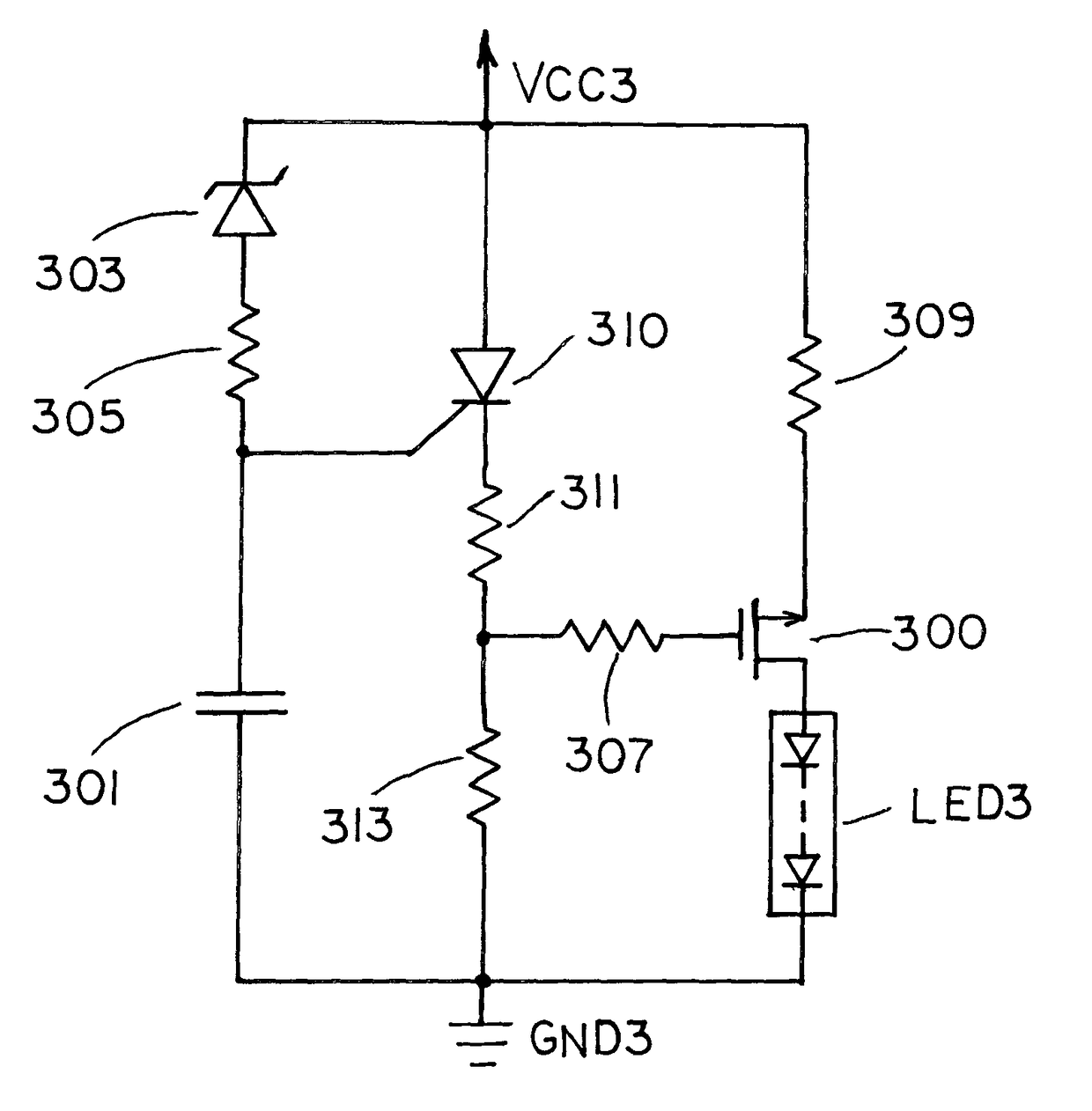

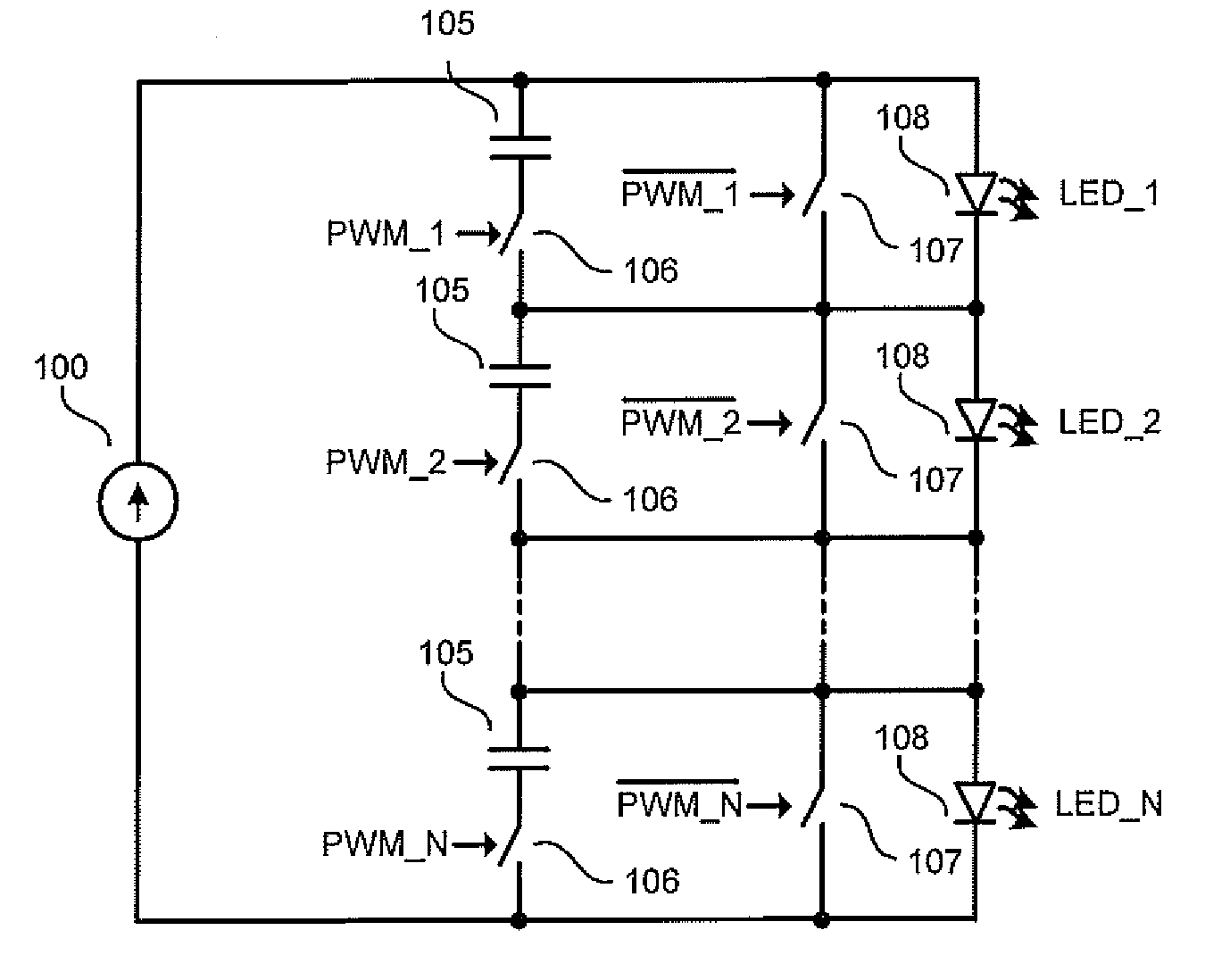

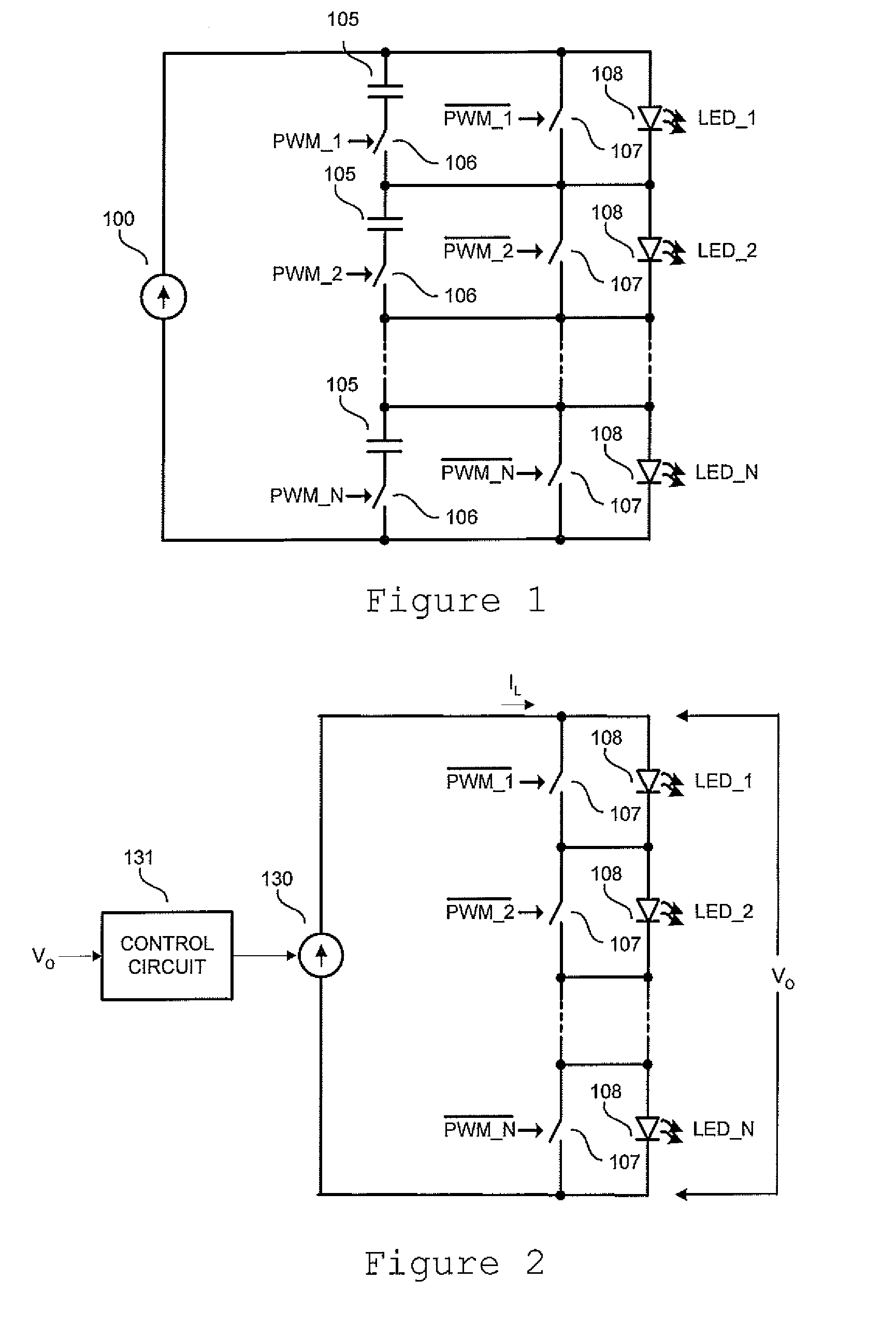

Shunting type pwm dimming circuit for individually controlling brightness of series connected leds operated at constant current and method therefor

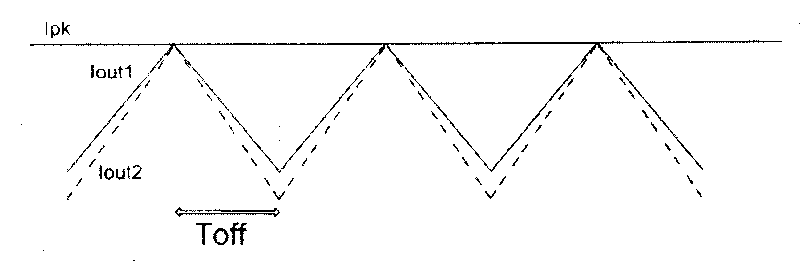

A Pulse Width Modulation (PWM) dimming circuit for individually controlling brightness of series connected Light Emitting Diodes (LEDS) operated at constant current has a first plurality of switching devices, a signal switching device of the first plurality coupled to an individual LED of series connected LEDS to control a brightness of the individual LED by periodically shunting the individual LED. A power converter supplies a constant output current to the series connected LEDs. Control circuitry is coupled to the power converter, wherein the control circuit corrects an internal DC state based on a feedback signal VO so that the output current of the power supply remains unchanged when at least one LEDs is shunted.

Owner:MICROCHIP TECH INC

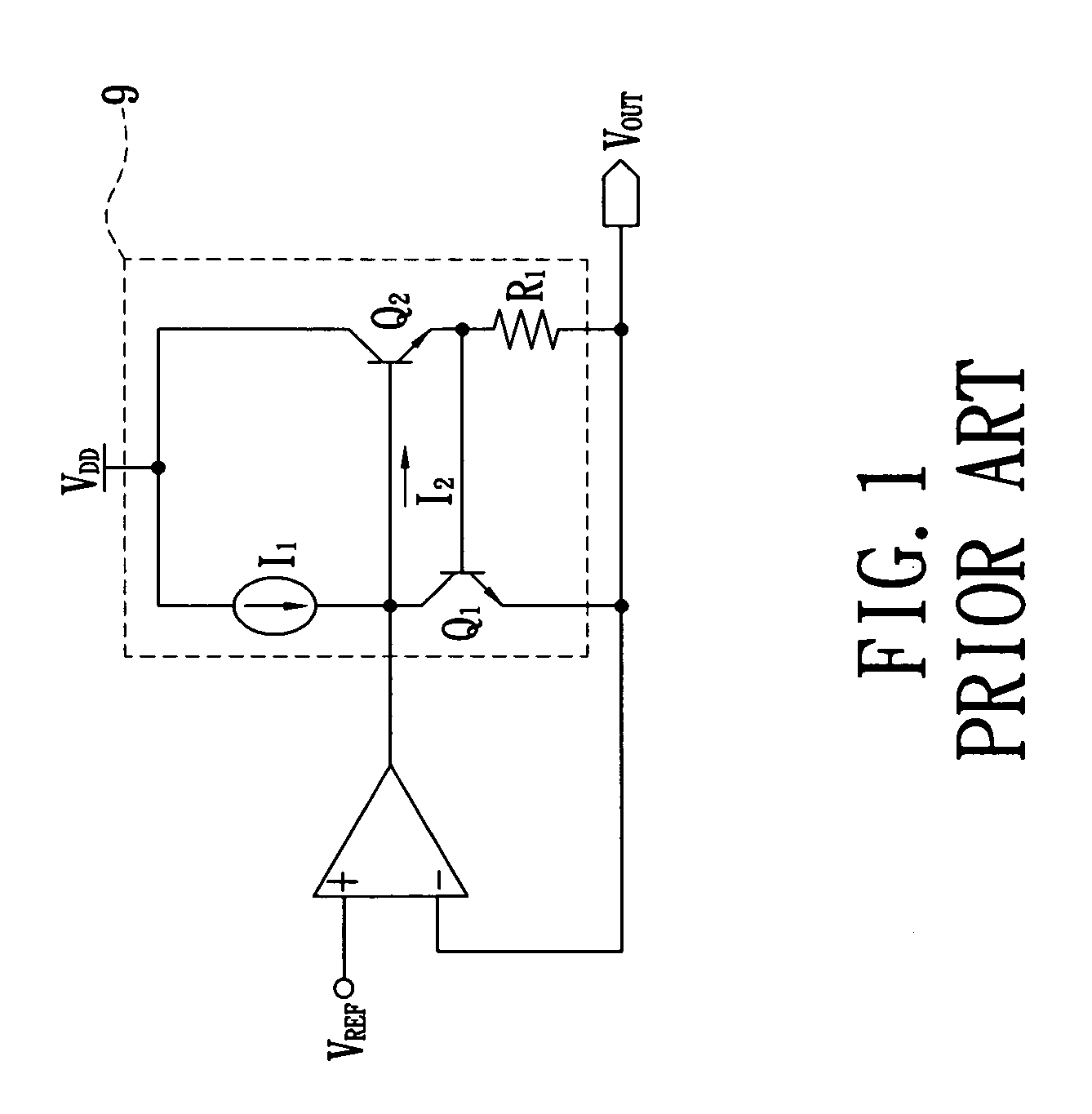

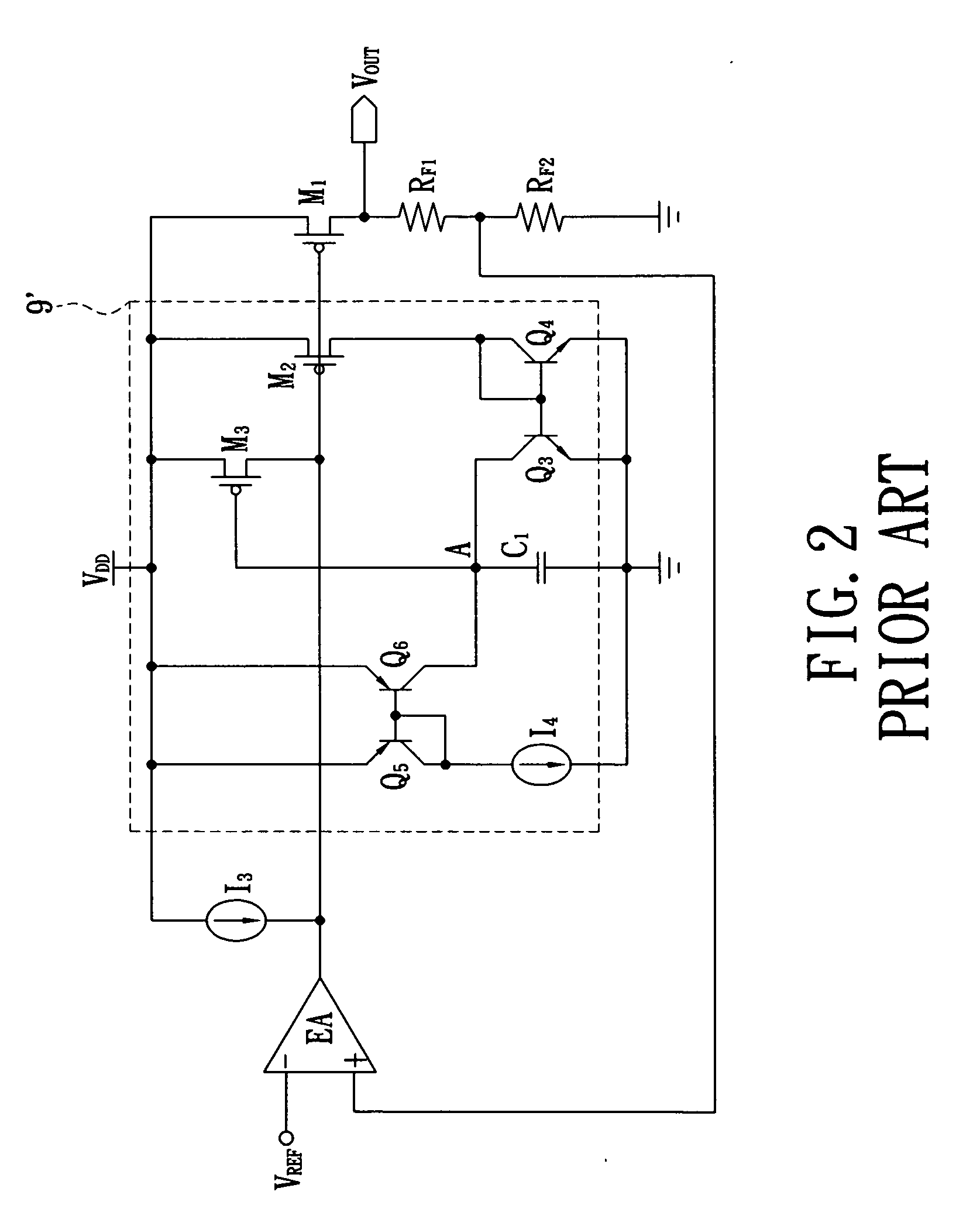

Power IC with an over-current protection circuit and method thereof

ActiveUS20090195953A1Reduce total powerArrangements responsive to excess currentEmergency protective arrangements for limiting excess voltage/currentEngineeringConstant-current diode

A power IC with an over-current protection receives an input voltage and converts the input voltage into an output voltage to a load. The present invention controls a power transistor to provide an output current to the load, and uses the output control unit to control the power transistor. Furthermore, the over-current protection circuit has a constant current limit threshold and a fold-back current limit threshold for controlling the power transistor. When the output current is larger than the constant current limit threshold, the output current is clamped to a constant current value to descend the output voltage to a rated value. When the output current is larger than the fold-back current limit threshold, the output current is limited to a low current value to descend the output voltage to zero. Thereby, the inner circuit of the power IC and the load are protected.

Owner:HOLTEK SEMICON

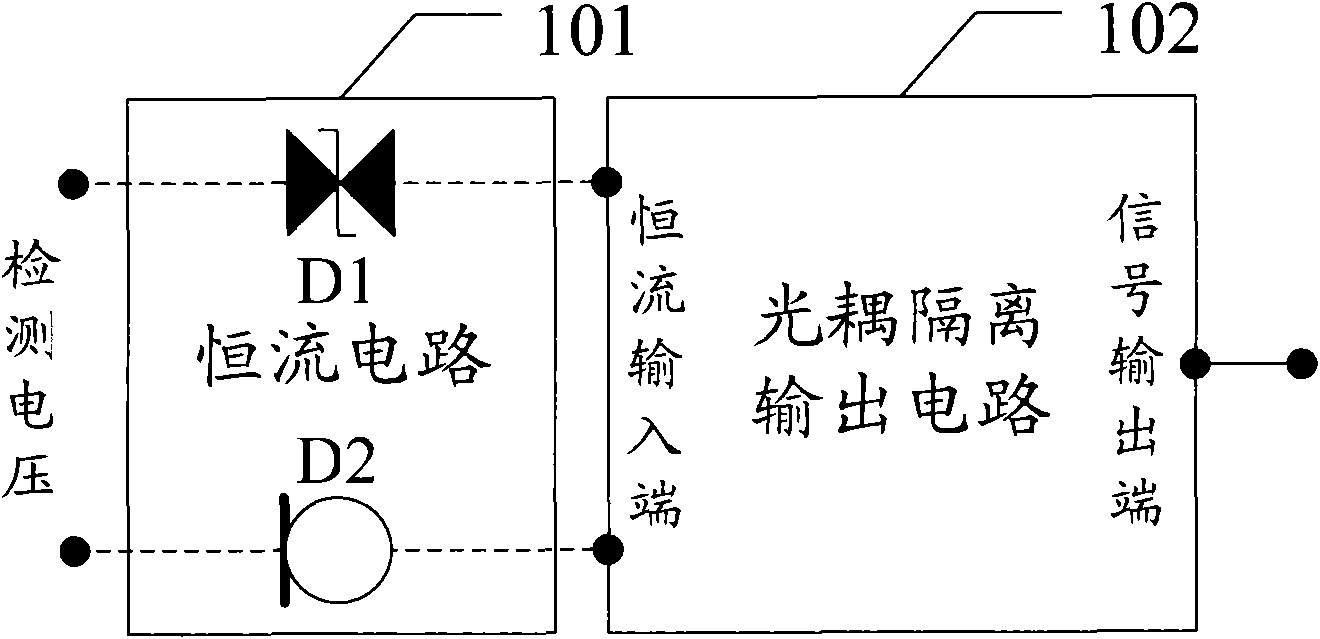

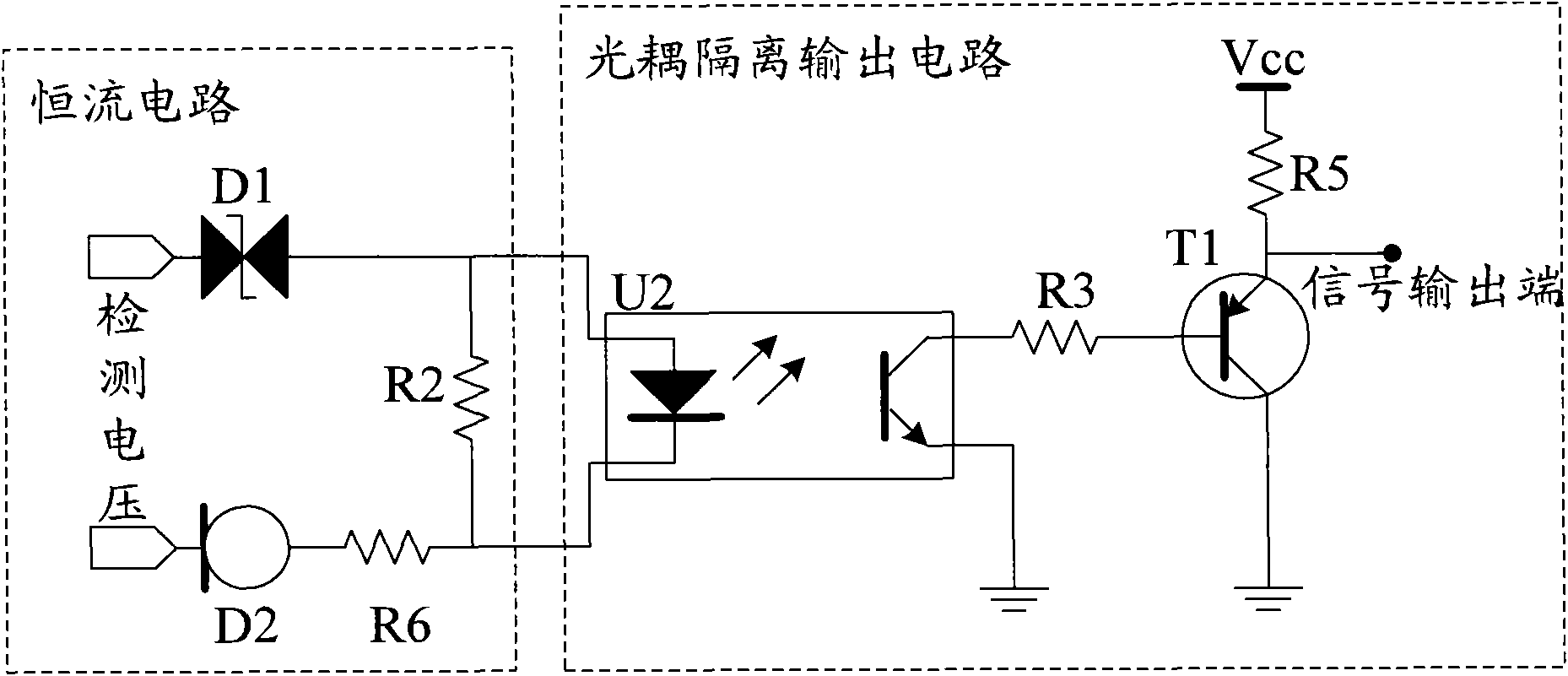

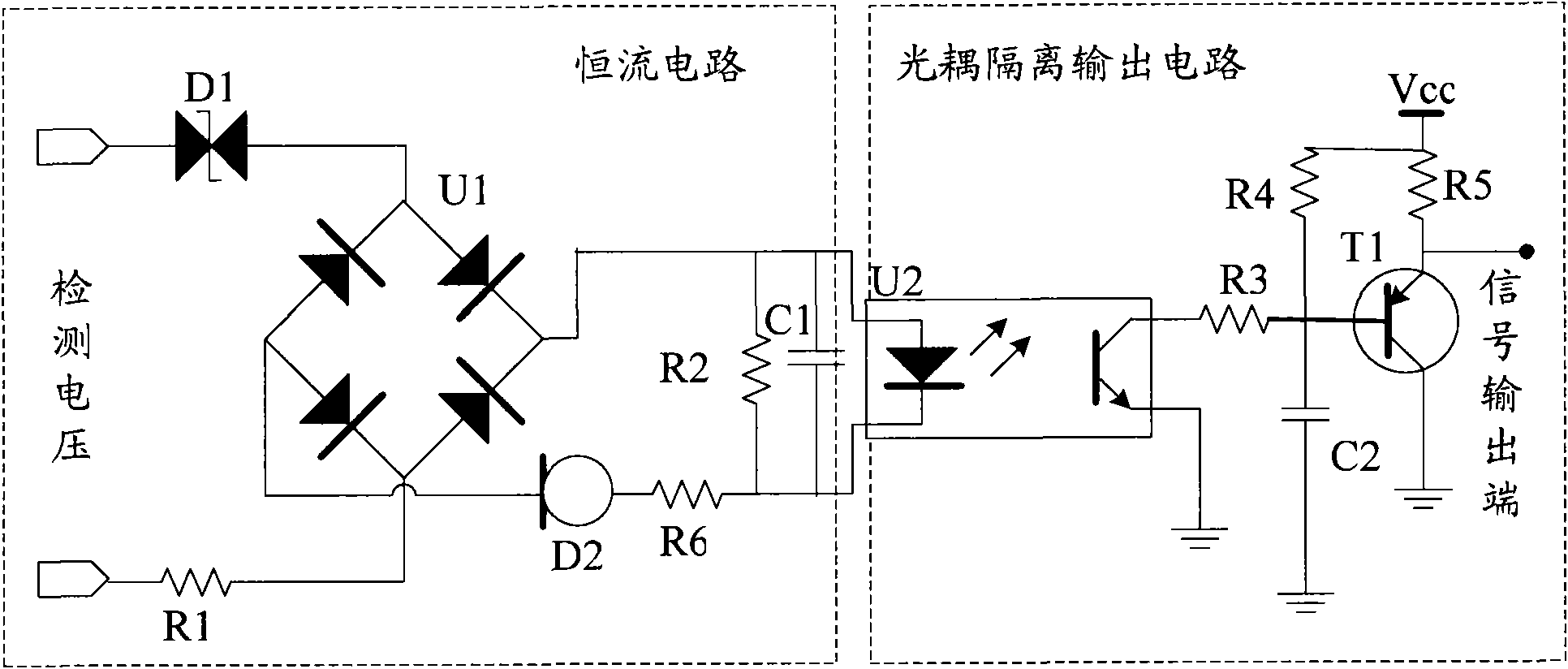

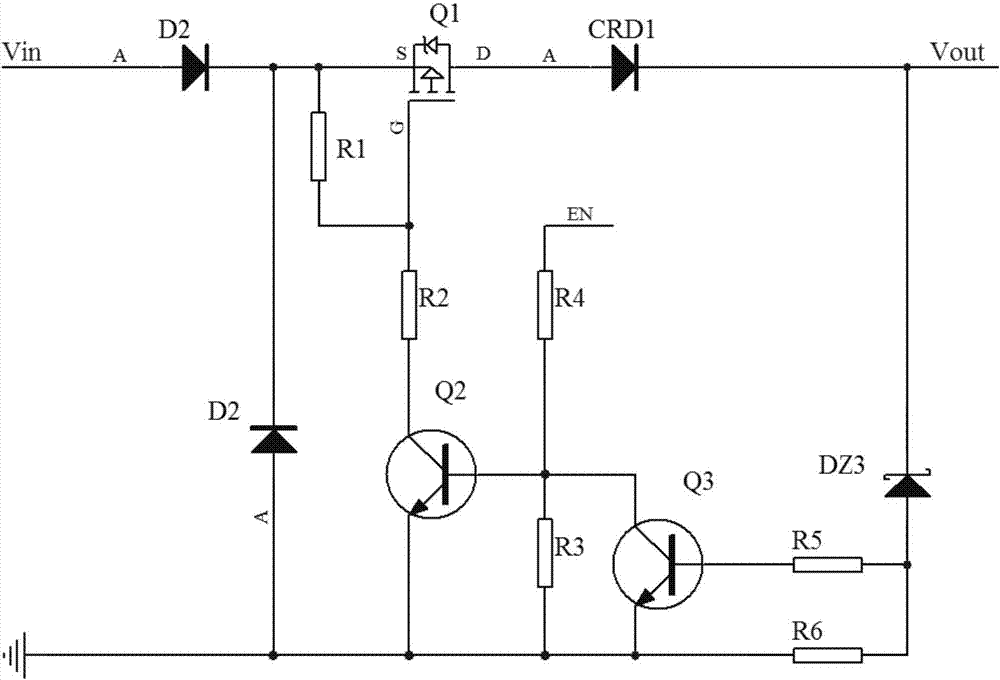

Relay protection device detection circuit

InactiveCN101957413AGuaranteed to workConstant currentOverload protection arrangementsElectrical testingControl signalLow voltage

The embodiment of the invention discloses a relay protection device detection circuit, which is used for ensuring normal work of a circuit element in the detection circuit when voltage boosting is detected. The detection circuit of the embodiment of the invention comprises a constant current circuit and an optical coupler isolating output circuit, wherein an input end of the constant current circuit is connected with detection voltage; the input end of the optical coupler isolating output circuit is connected with the output end of the constant current circuit; the constant current circuit comprises a transient diode (D1) and a constant current diode (D2) which are connected in series; the transient diode (D1) is used for providing threshold voltage and allocating the input detection voltage; the constant current diode (D2) is used for providing stable current for the detection circuit; and the optical coupler isolating output circuit is used for transmitting a low-voltage control signal. In addition, the detection circuit can realize compatibility of input of alternating current detection voltage and direct current detection voltage by improvement.

Owner:深圳市华力特电气有限公司

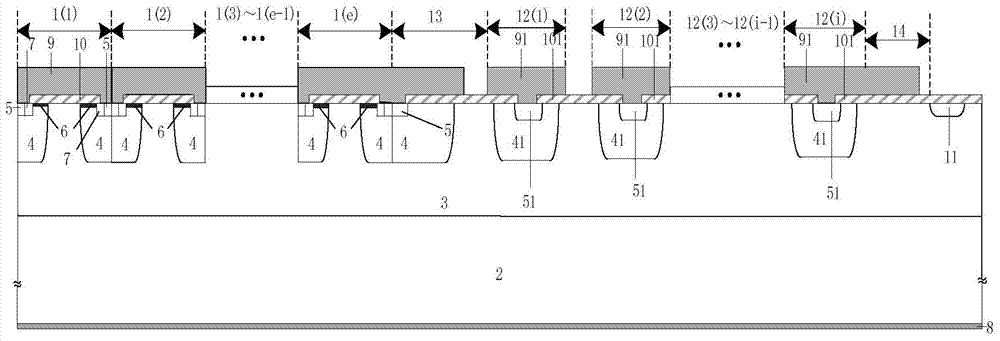

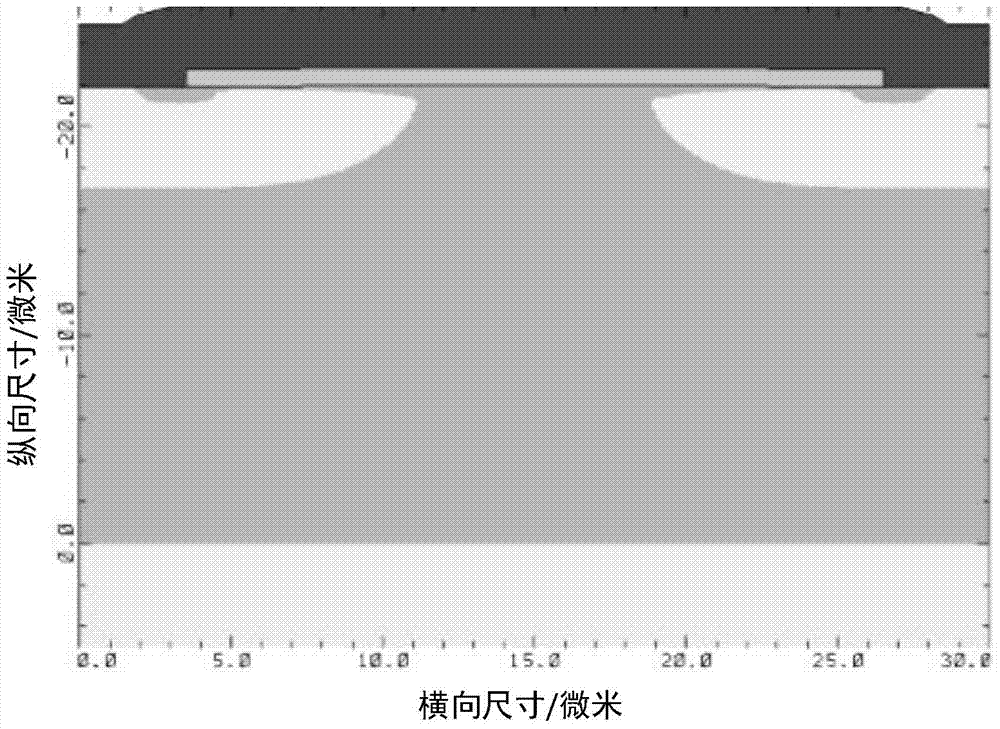

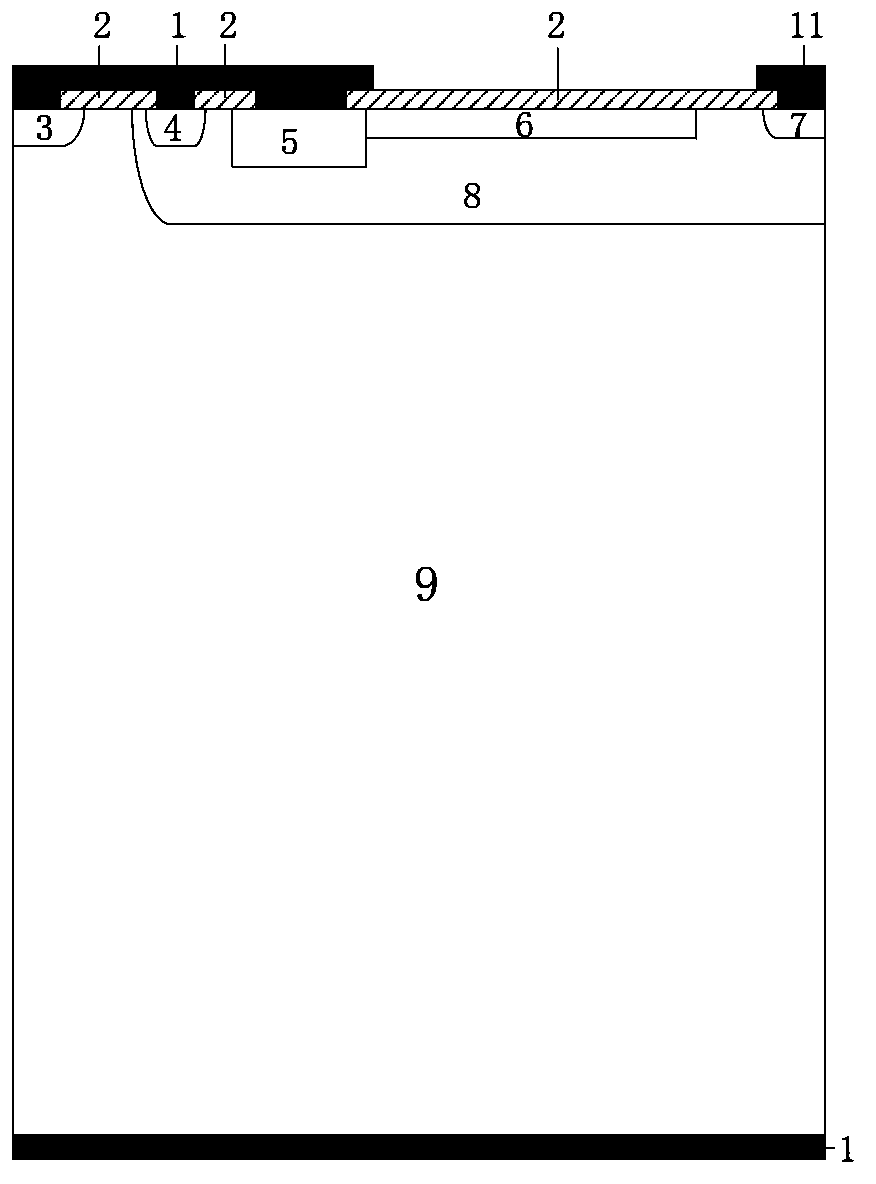

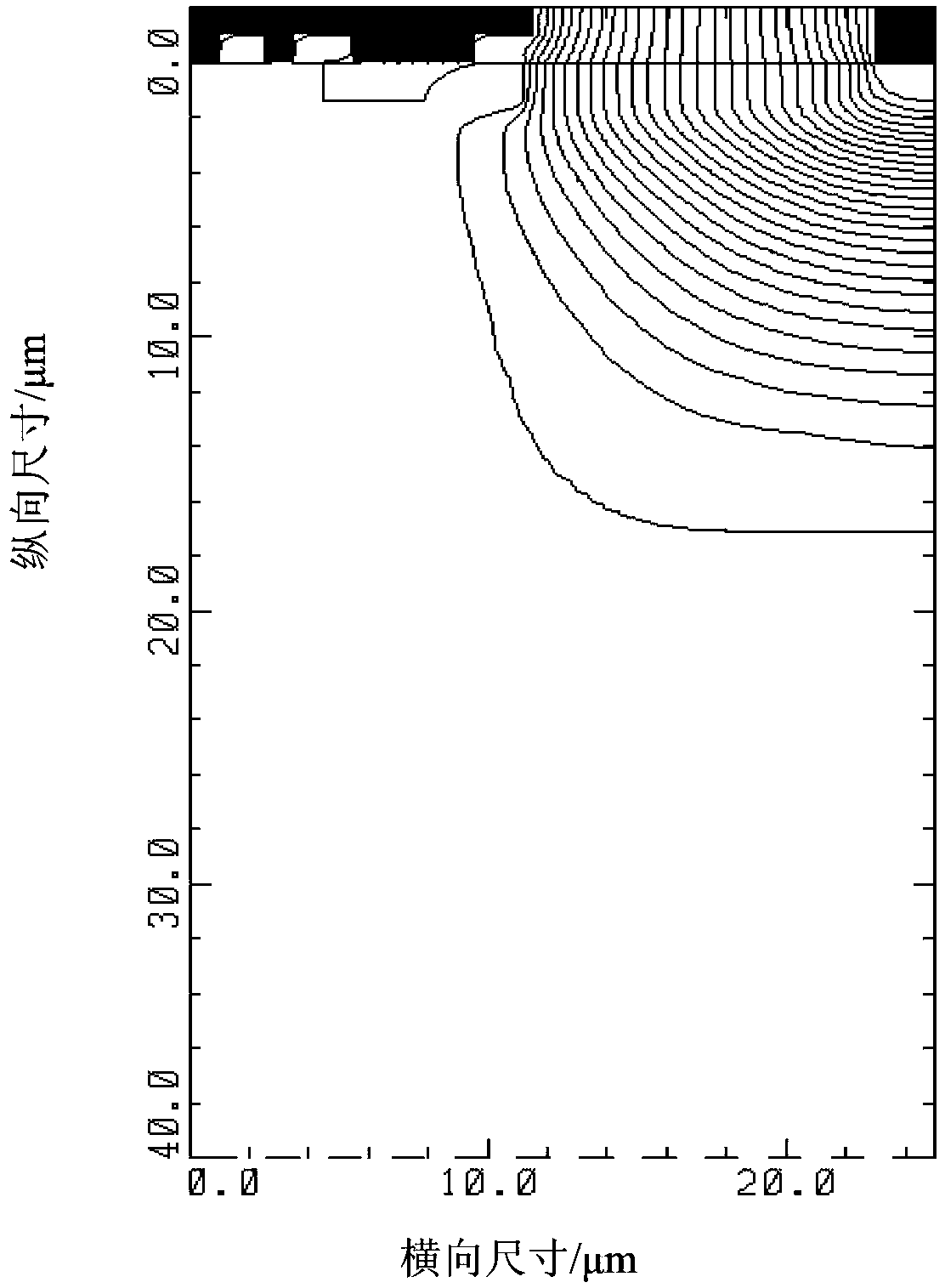

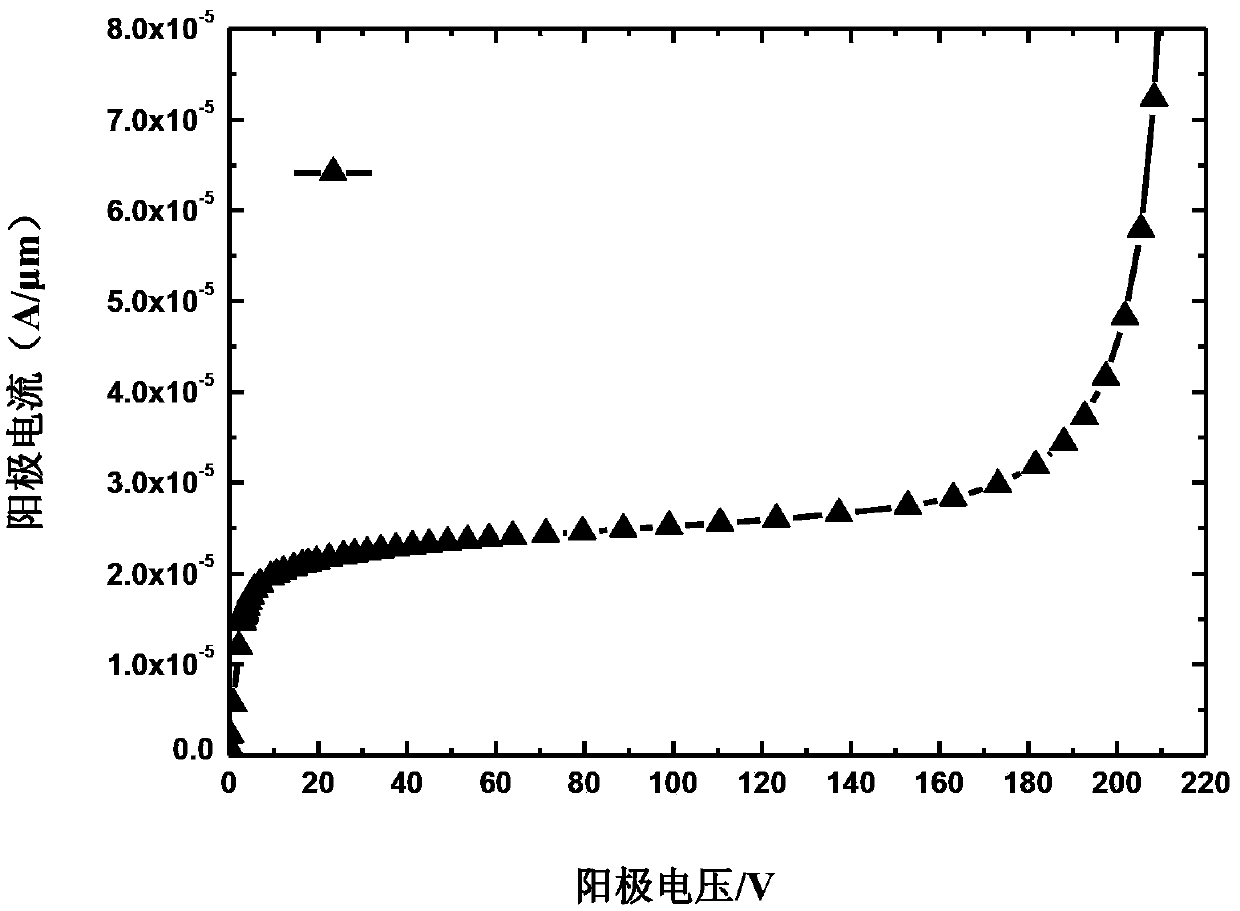

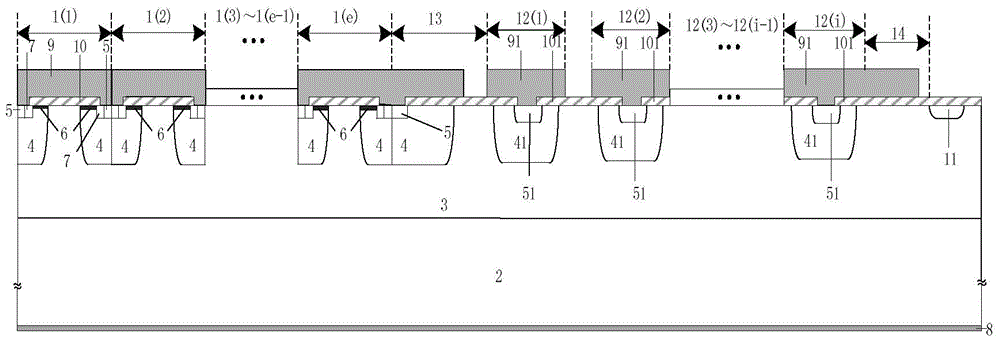

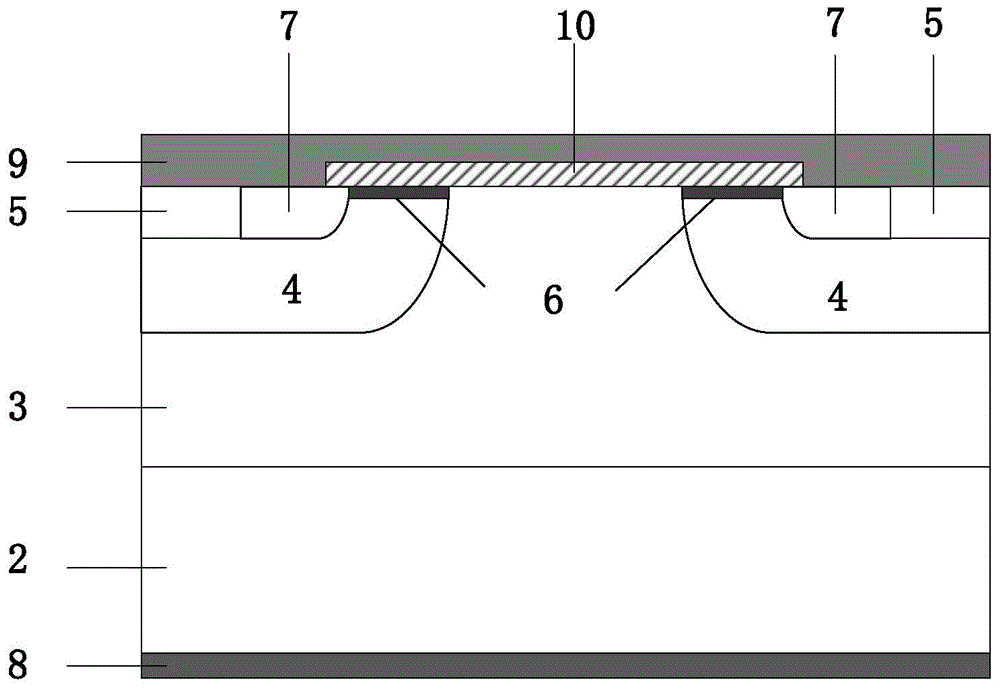

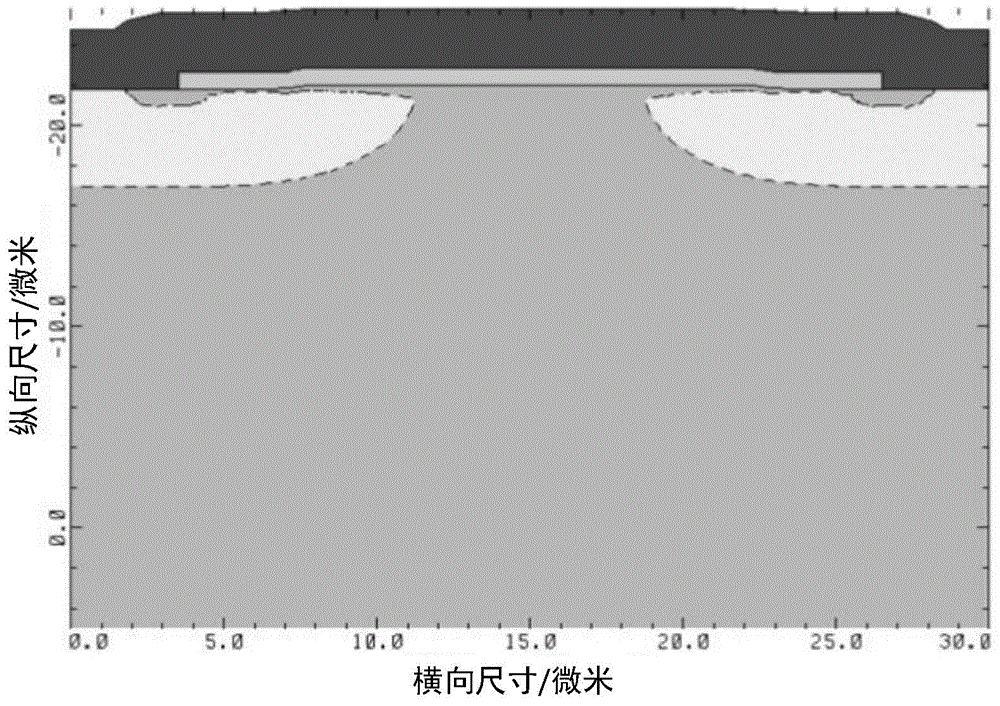

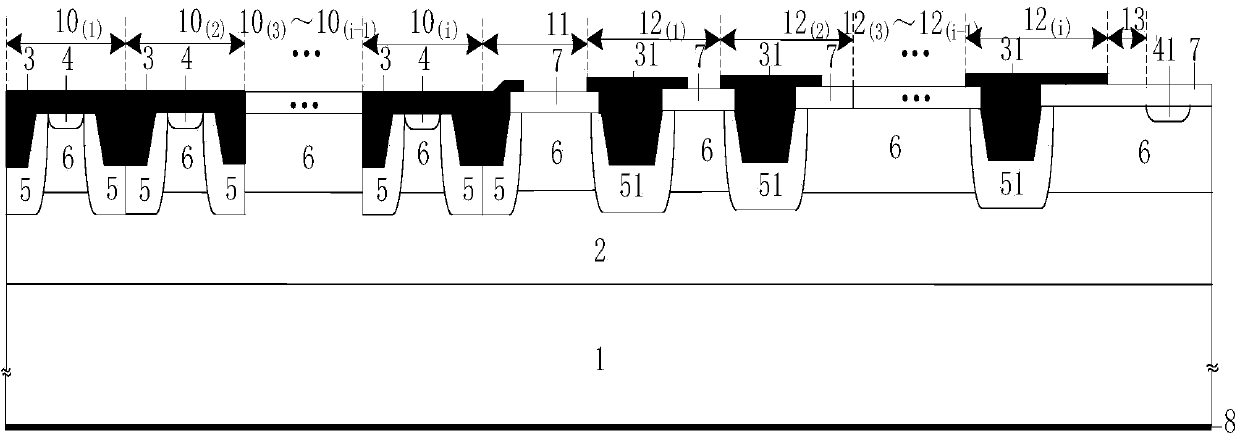

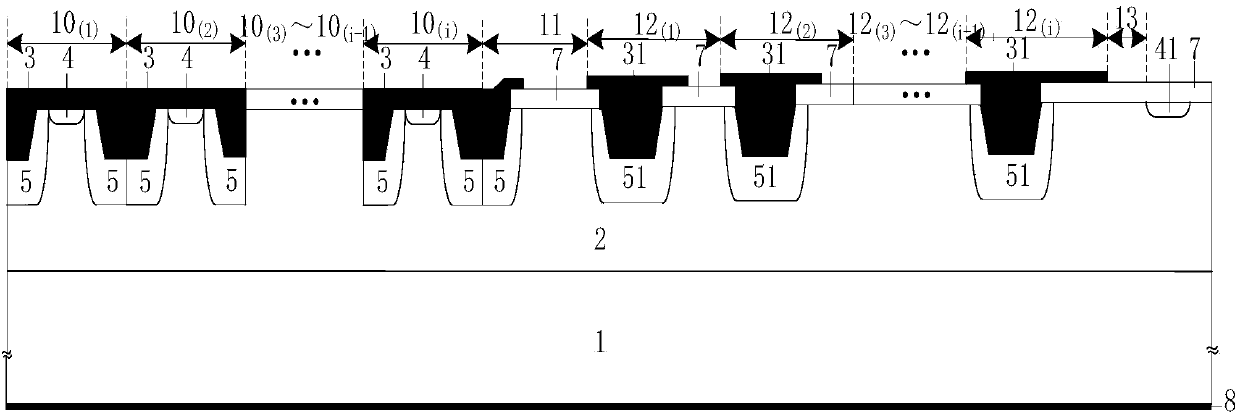

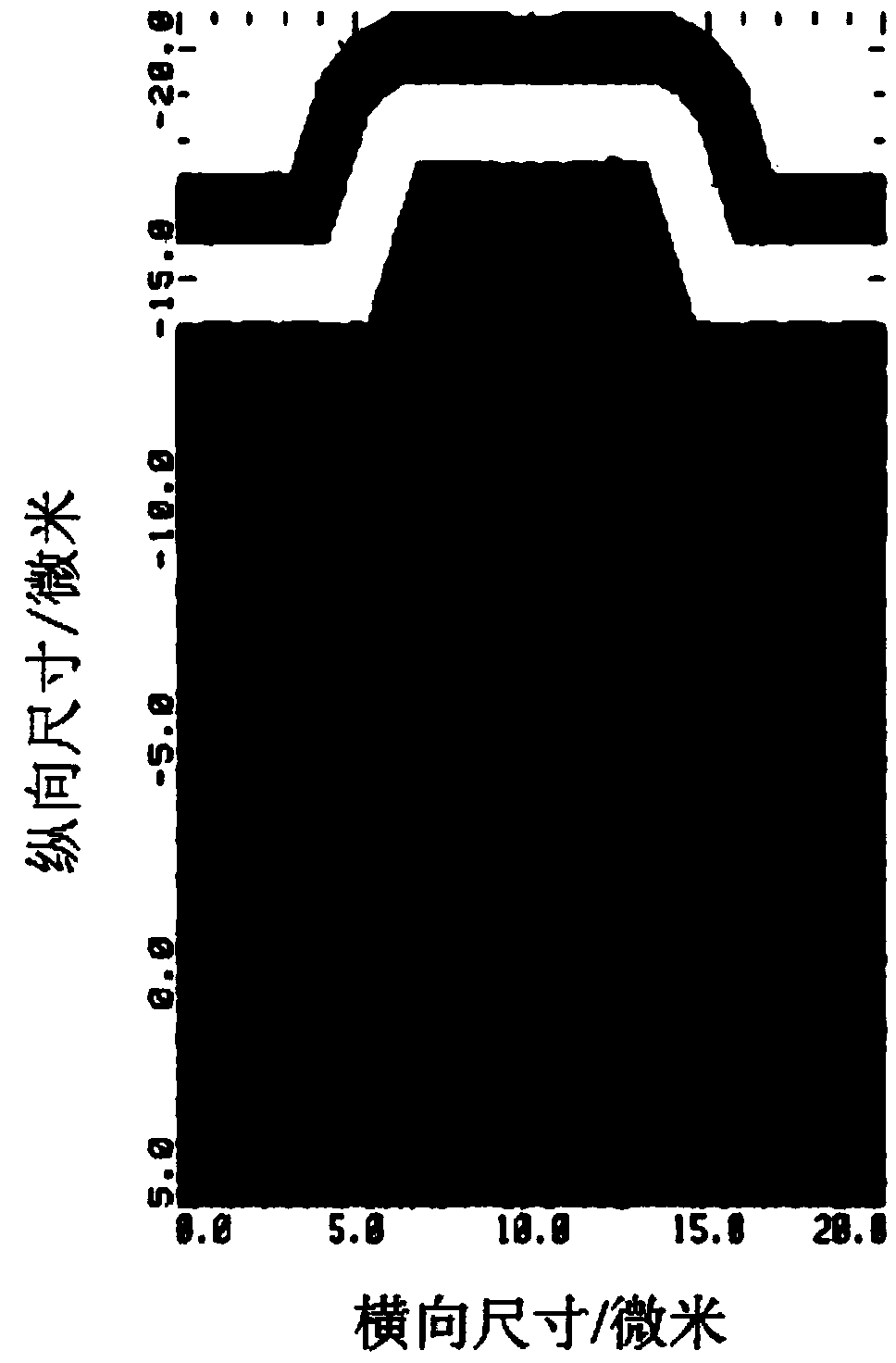

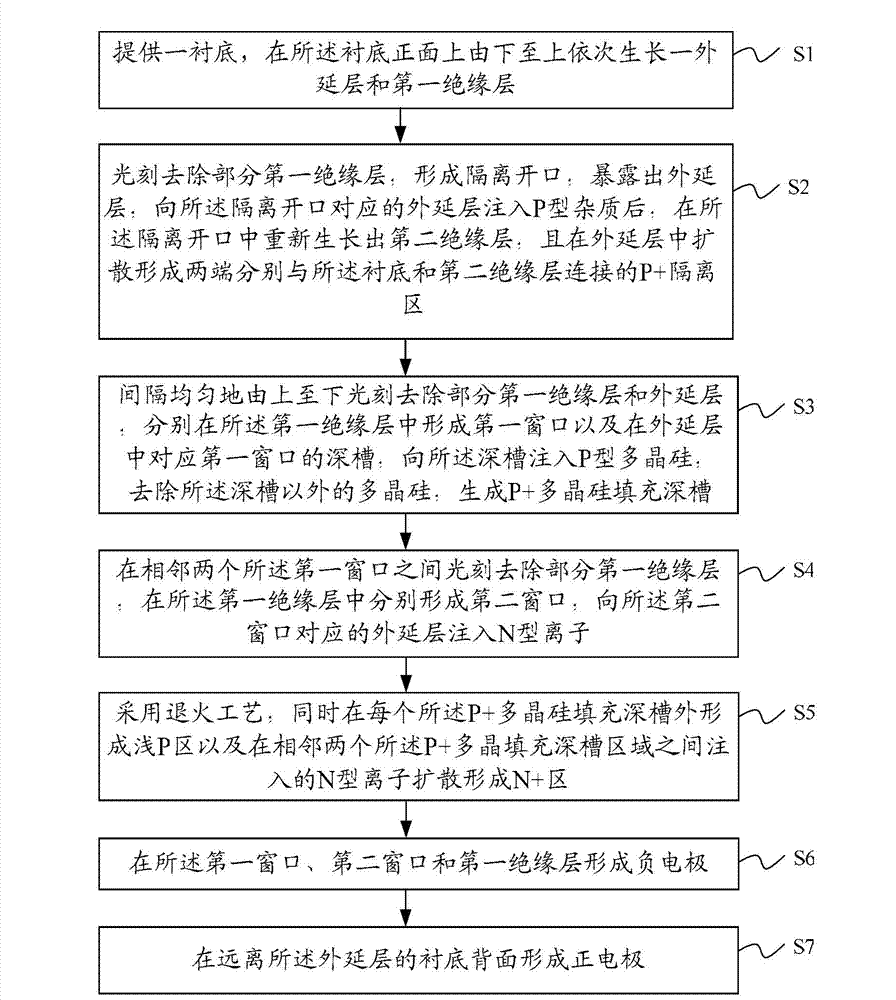

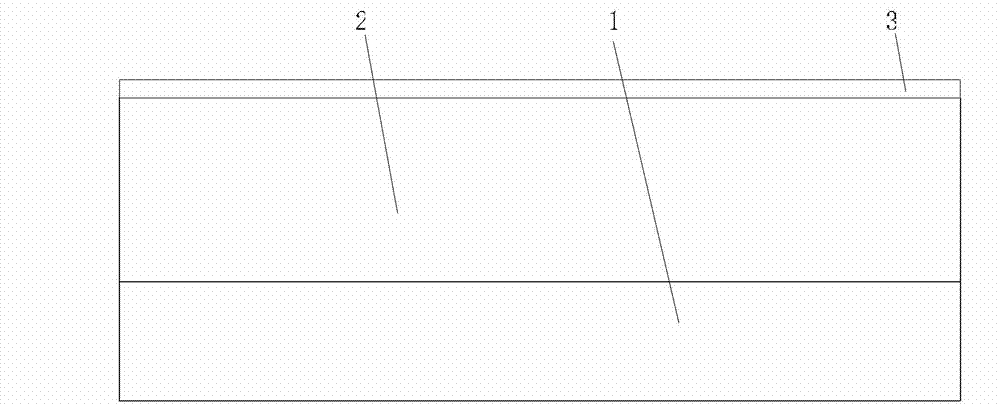

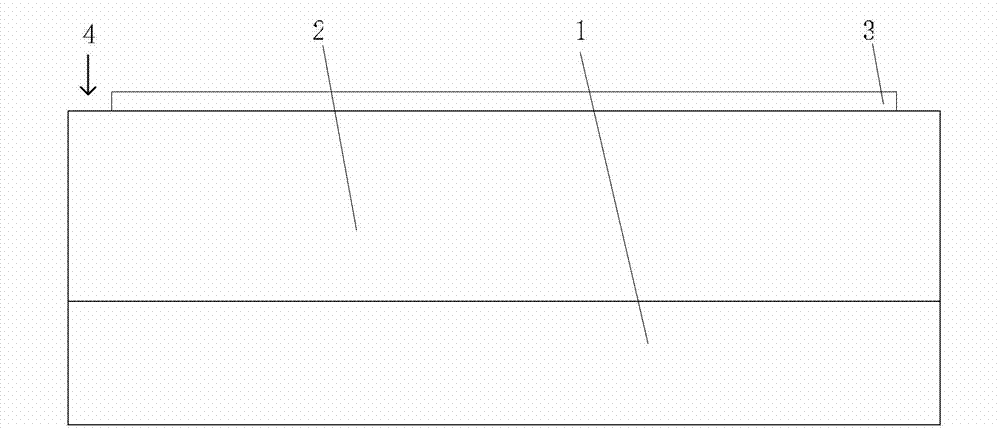

Vertical constant-current diode and manufacturing method thereof

ActiveCN104779303AIncrease current densityFaster pinch offSemiconductor/solid-state device manufacturingSemiconductor devicesElectron currentEngineering

The invention discloses a vertical constant-current diode and a manufacturing method thereof, and belongs to the technical field of semiconductors. The vertical constant-current diode comprises a cellular structure and a terminal structure connected in sequence, wherein the cellular structure comprises a plurality of cells same in structure and connected in sequence; the terminal structure comprises a cut-off ring and a plurality of field limiting rings connected in sequence. The constant-current diode adopts a P-type doped semiconductor material opposite to an epitaxial layer in doping type as a substrate, and a P-type light-doped substrate injects holes to an N-type light-doped epitaxial layer, so that the constant-current diode has two carrier currents, namely hole current and electron current, and the current density of a device is increased; moreover, substrates with different doping types assist in depletion of a channel, accelerate pinching-off of a JFET (junction field-effect transistor) region channel and enable pinch-off voltage to be lower than 4 V.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

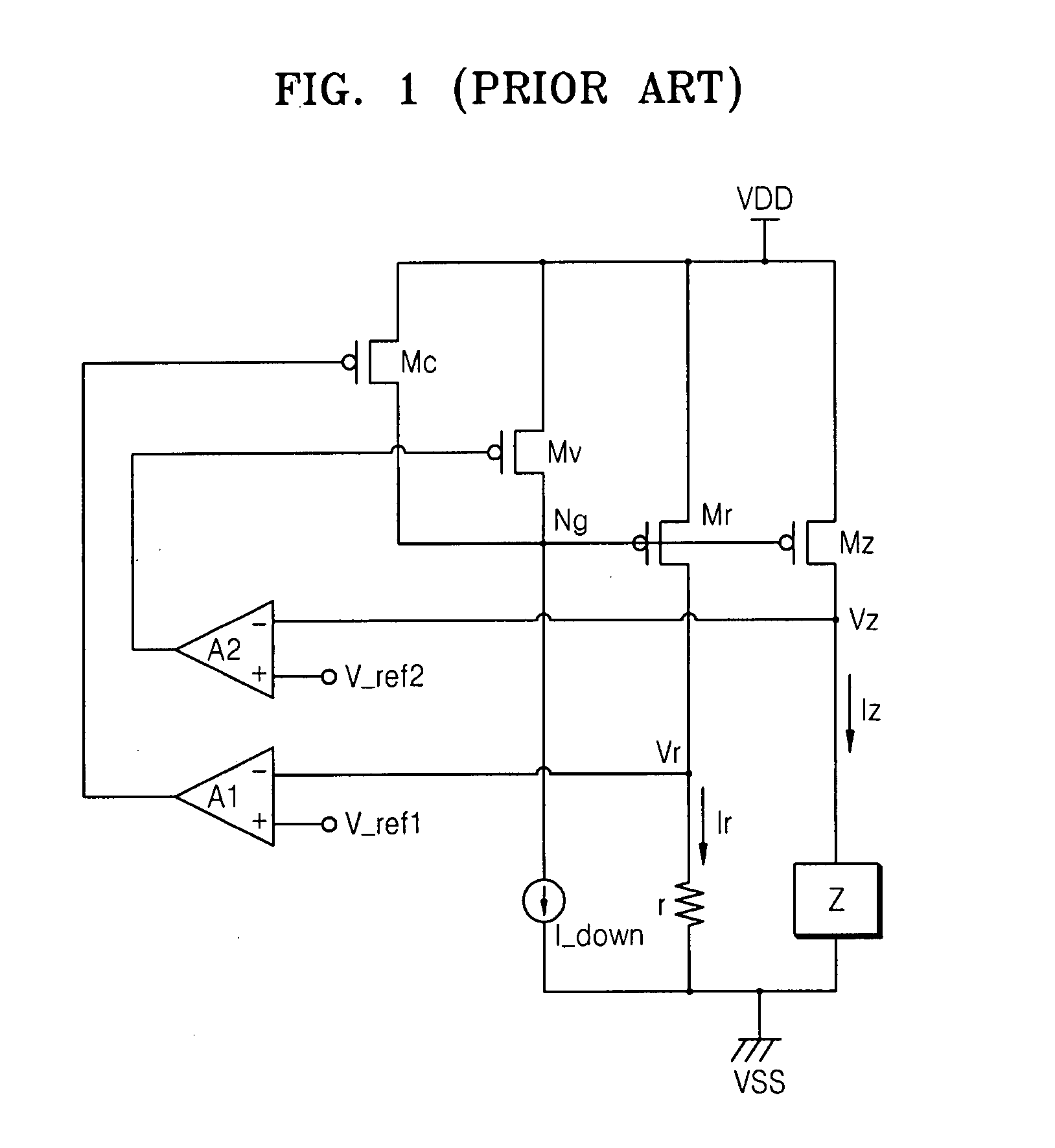

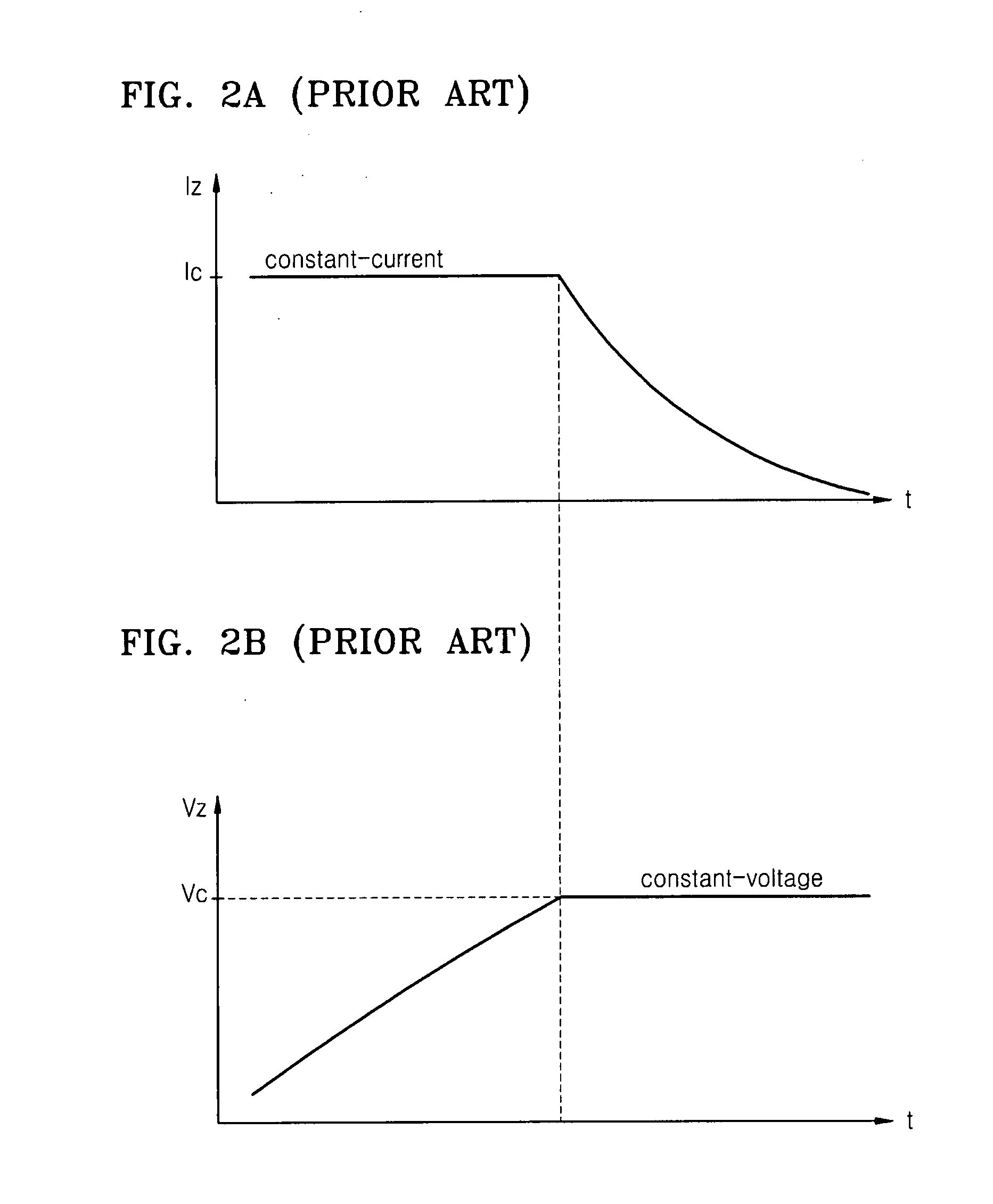

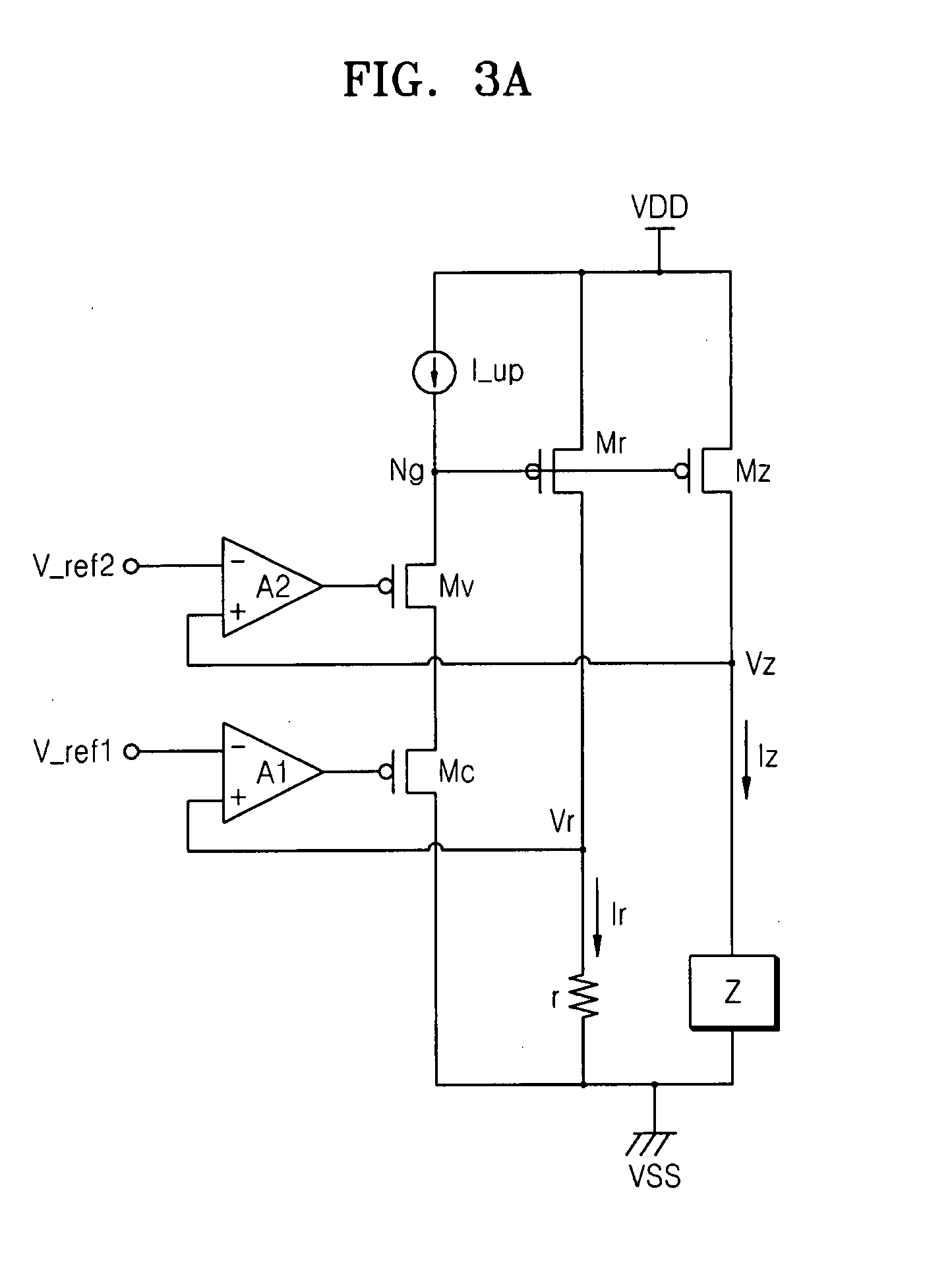

Charging controller for performing constant current and voltage modes

ActiveUS20070210756A1Avoid damageBatteries circuit arrangementsElectric powerAudio power amplifierReference device

A charging controller includes a control node having a control voltage generated thereon for controlling a first current to a charged device and a second current to a reference device. Feedback loops are formed with amplifiers and a pull-up current source and control transistors, or with amplifiers and transfer transistors, for maintaining the second current at a constant current level during a constant current mode and for maintaining a voltage of the charged device at a constant voltage level during a constant voltage mode. Use of a pull-down current source at the control node is avoided for preventing damage to the charged device.

Owner:SAMSUNG ELECTRONICS CO LTD

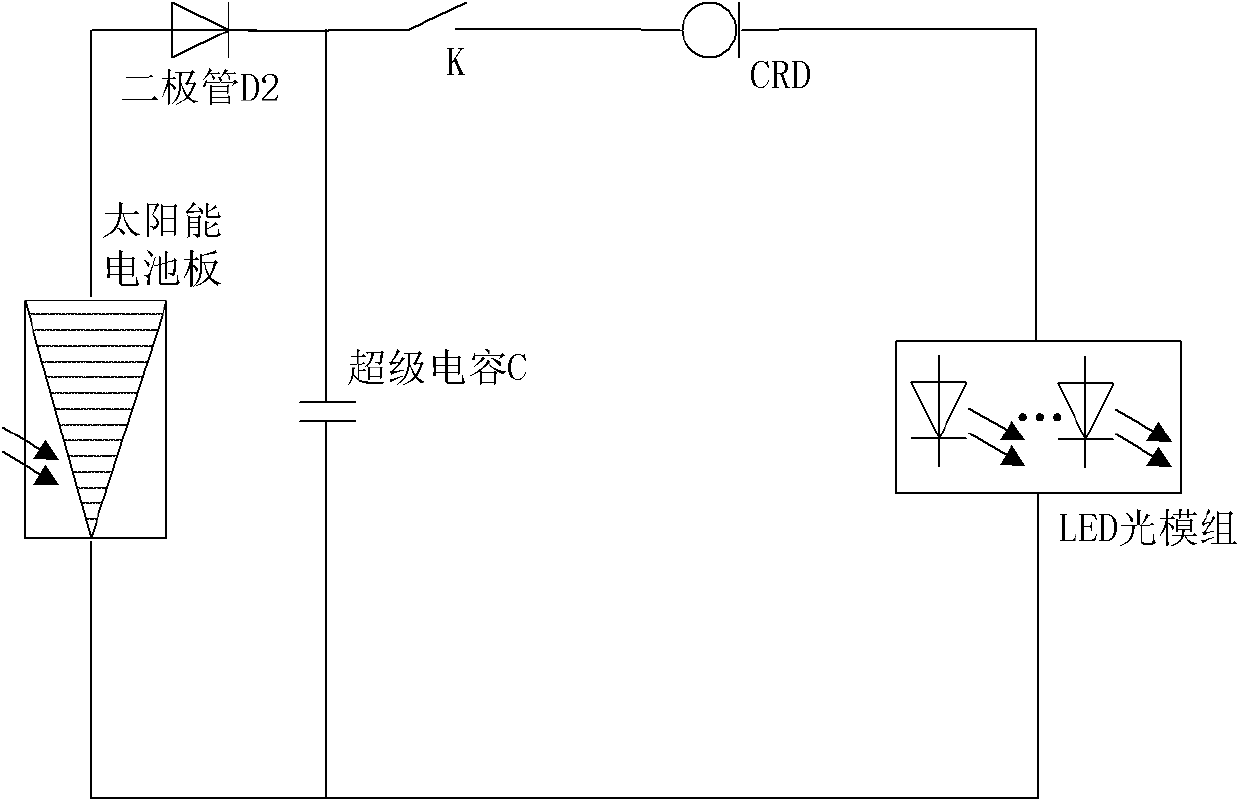

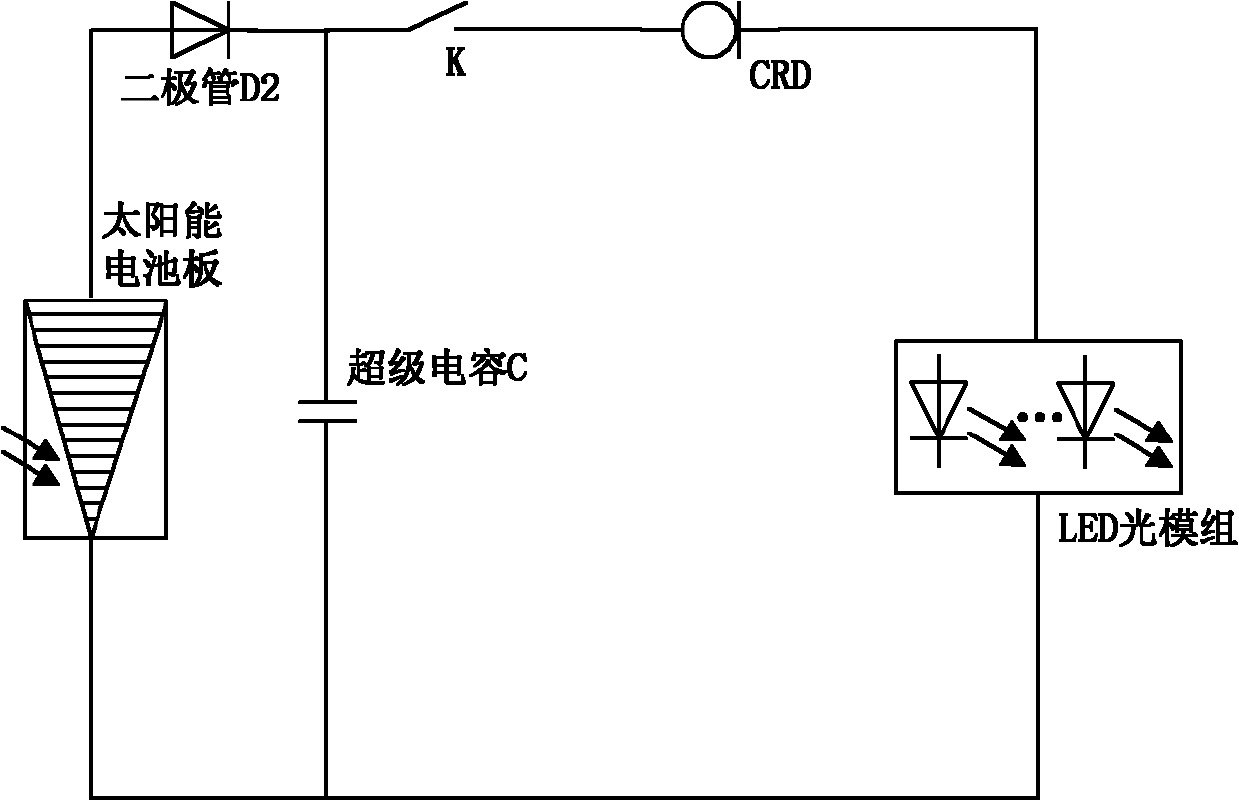

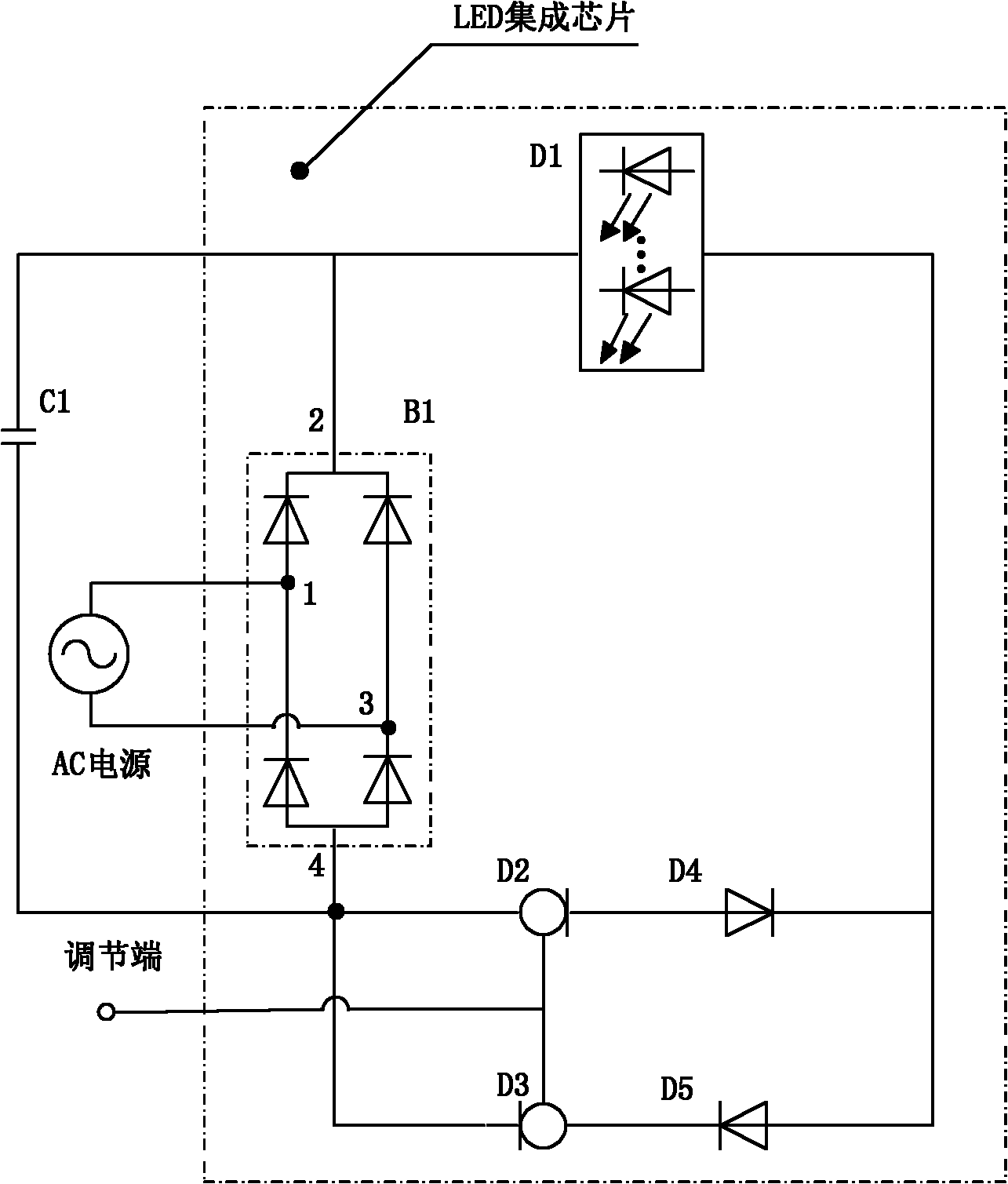

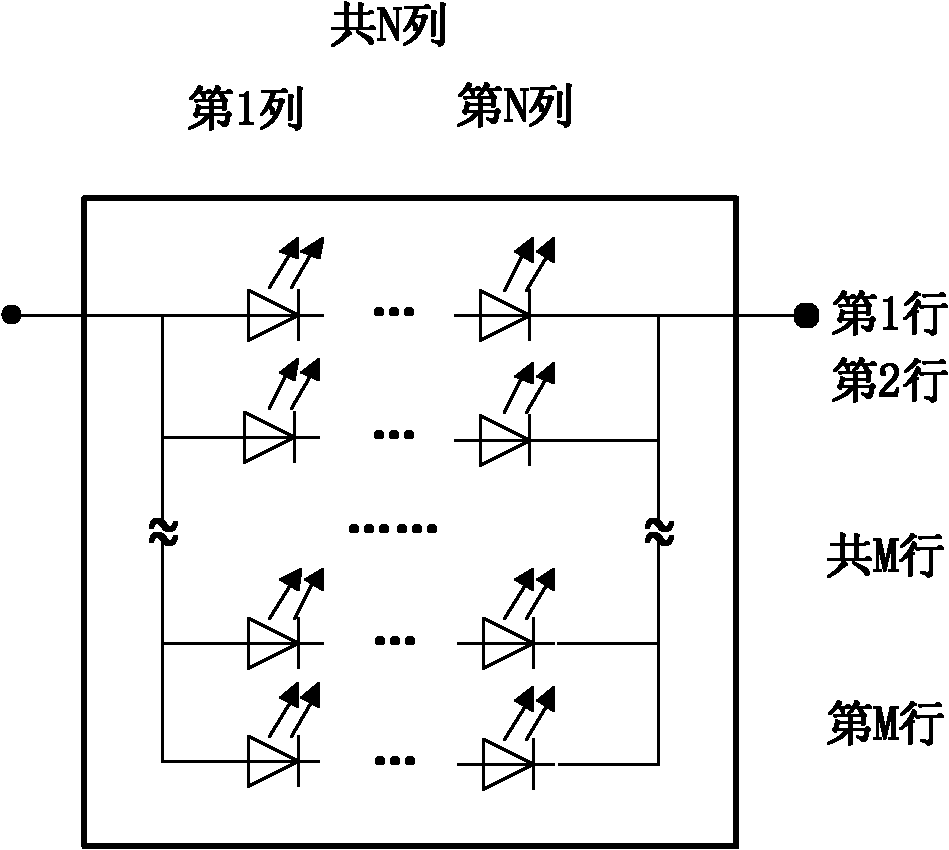

LED lighting method and device

ActiveCN101909393ASimple structureThere will be no phenomenon that the temperature is too high to aggravate the light decayPoint-like light sourceElectric circuit arrangementsNegative powerEffect light

The invention relates to LED lighting method and device, which is characterized in that an electric power supply drives an LED to illuminate after being subject to the constant current action of a constant current diode CRD (Capacitor-Resistor Diode), and the constant current diode CRD and an LED light module are packaged and integrated in a chip to form an LED light module integrated chip. The constant current diode CRD has the characteristic of negative power so that the LED light module integrated chip has the physical characteristic of negative power. When the working temperature of the entire LED integrated chip is too high, the constant current diode CRD can automatically reduce circuit power input so as to lower the temperature of the LED light module integrated chip, so that the LED light module integrated chip can be protected, and the problem of LED light attenuation due to overheating is avoided.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

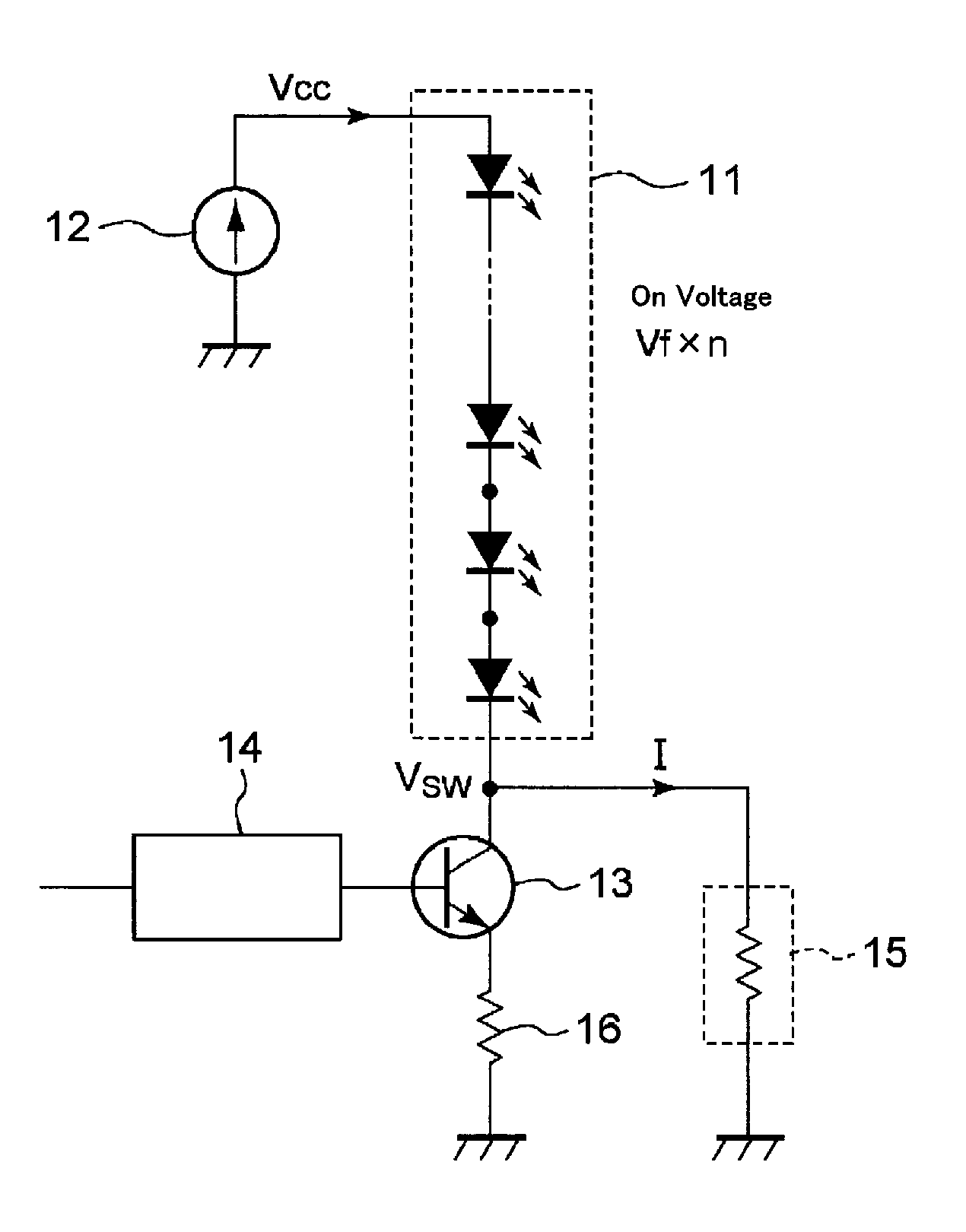

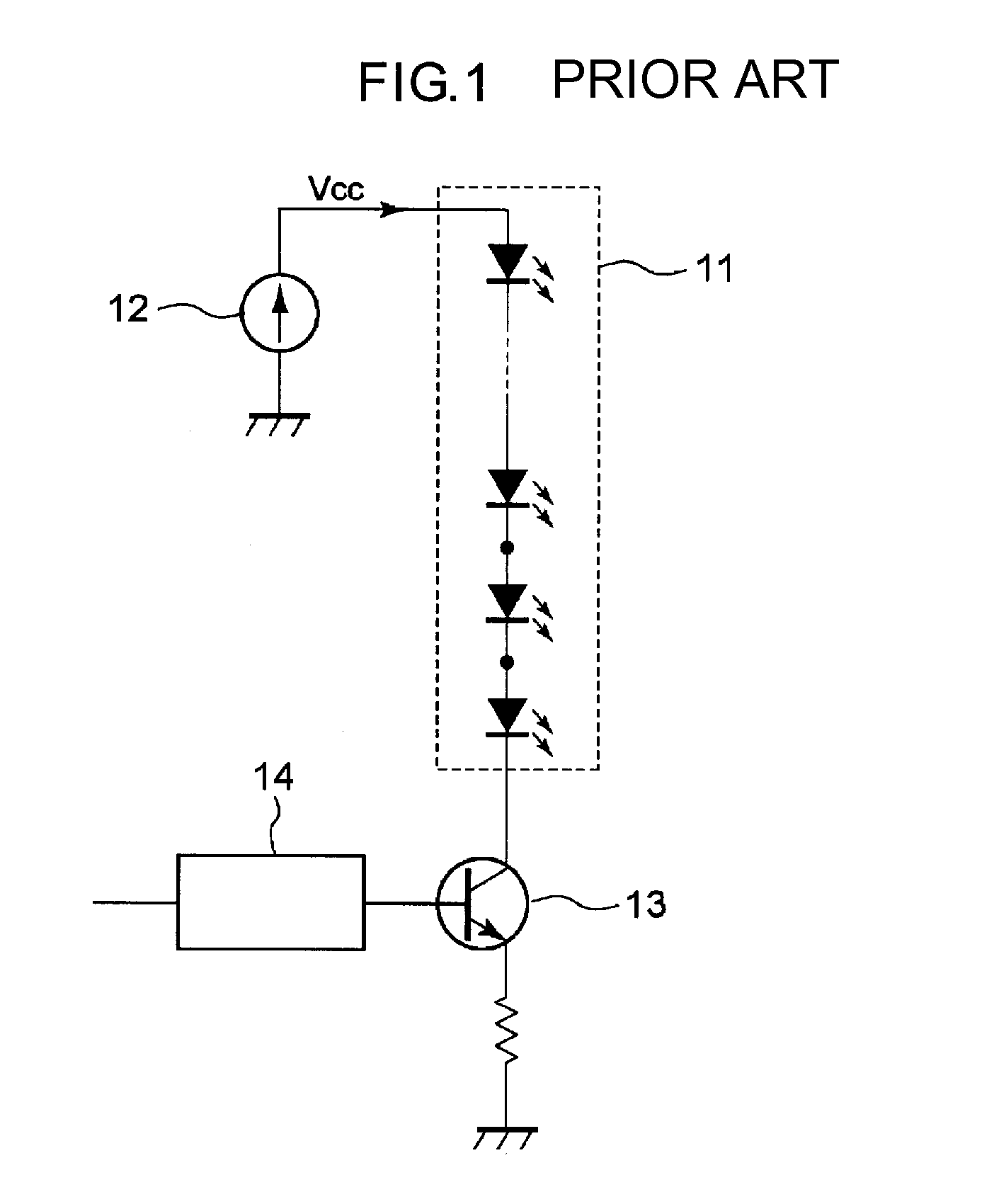

LED driving circuit

InactiveUS8324816B2Increase the number ofChange LED light volume widely and accuratelyElectrical apparatusElectroluminescent light sourcesLED circuitConstant-current diode

An LED driving circuit is provided for making it possible to economically drive a serially connected LED circuit by means of a switching device with a relatively low withstanding voltage even if the number of serially connected LED devices increases. In an LED driving circuit provided with a serially connected LED circuit (11) in which many LED devices are serially connected and a switching device (13) serially connected with the serially connected LED circuit (11) to control that an electrical current flowing through the serially connected LED circuit (11) is turned on or off, wherein a circuit device (15), which comprises a resistor, a constant voltage diode, a constant current diode, or the like, is connected in parallel with the switching device to make a minute current flow through the serially connected LED circuit (11) to the extent that the LED devices are not turned on when the switching device is turned off.

Owner:KOA CORP

Transverse constant current diode

InactiveCN103400863AIncrease the constant currentEasy to pinch offSemiconductor devicesConstant-current diodeSemiconductor

The invention relates to semiconductor technologies, and particularly relates to a transverse constant current diode. The transverse constant current diode provided by the invention forms a P-type well region through introducing a lightly doped P-type region and a heavily doped P-type region into an N-type well region, thereby modulating a surface electric field, and improving breakdown voltage. Meanwhile, the lightly doped P-type region can assist to exhaust the N-type well region, thereby enabling a channel to be pinched off more easily, coming into a constant current region quickly, enabling the constant current diode to have lower pinch-off voltage, shortening the channel length of the deep heavily doped P-type region, and improving the constant current of the constant current diode. The transverse constant current diode has the beneficial effects that the breakdown voltage of the transverse constant current diode is improved effectively, the channel is enabled to be pinched off more easily at the same time, the constant current region can be entered quickly, the transverse constant current diode is enabled to have lower pinch-off voltage, and the constant current of the transverse constant current diode is effectively improved. The transverse constant current diode provided by the invention is especially applied to transverse constant current diodes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

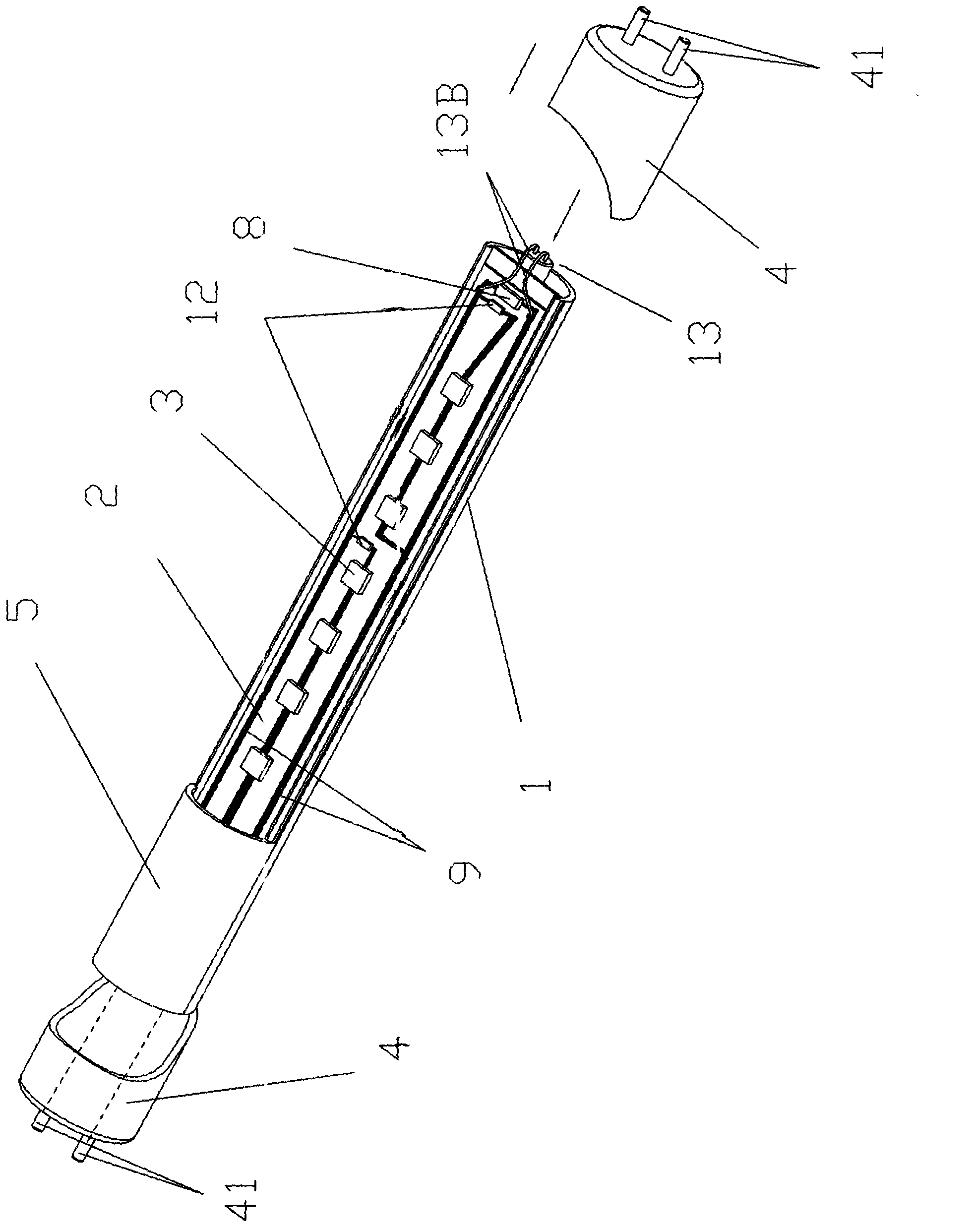

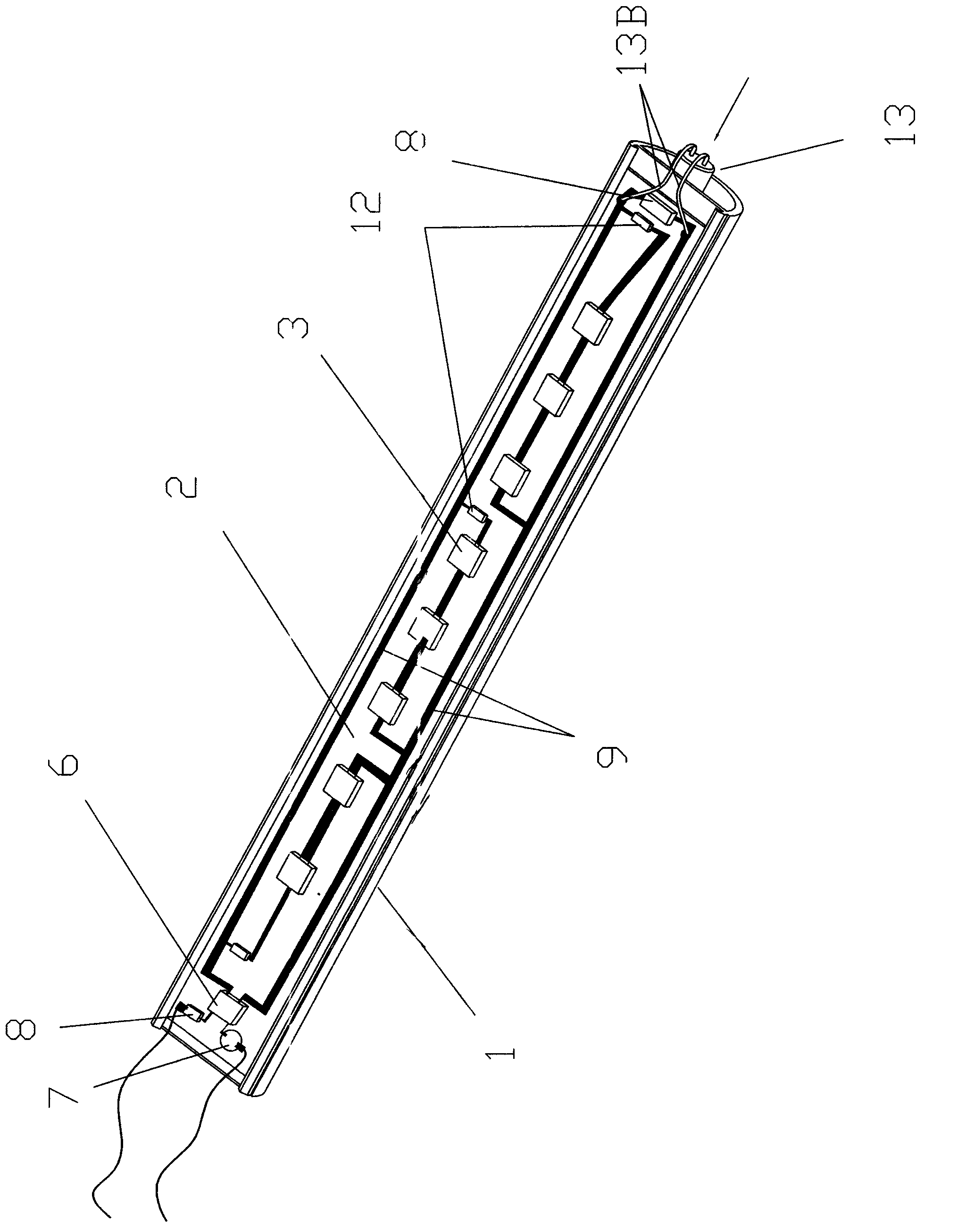

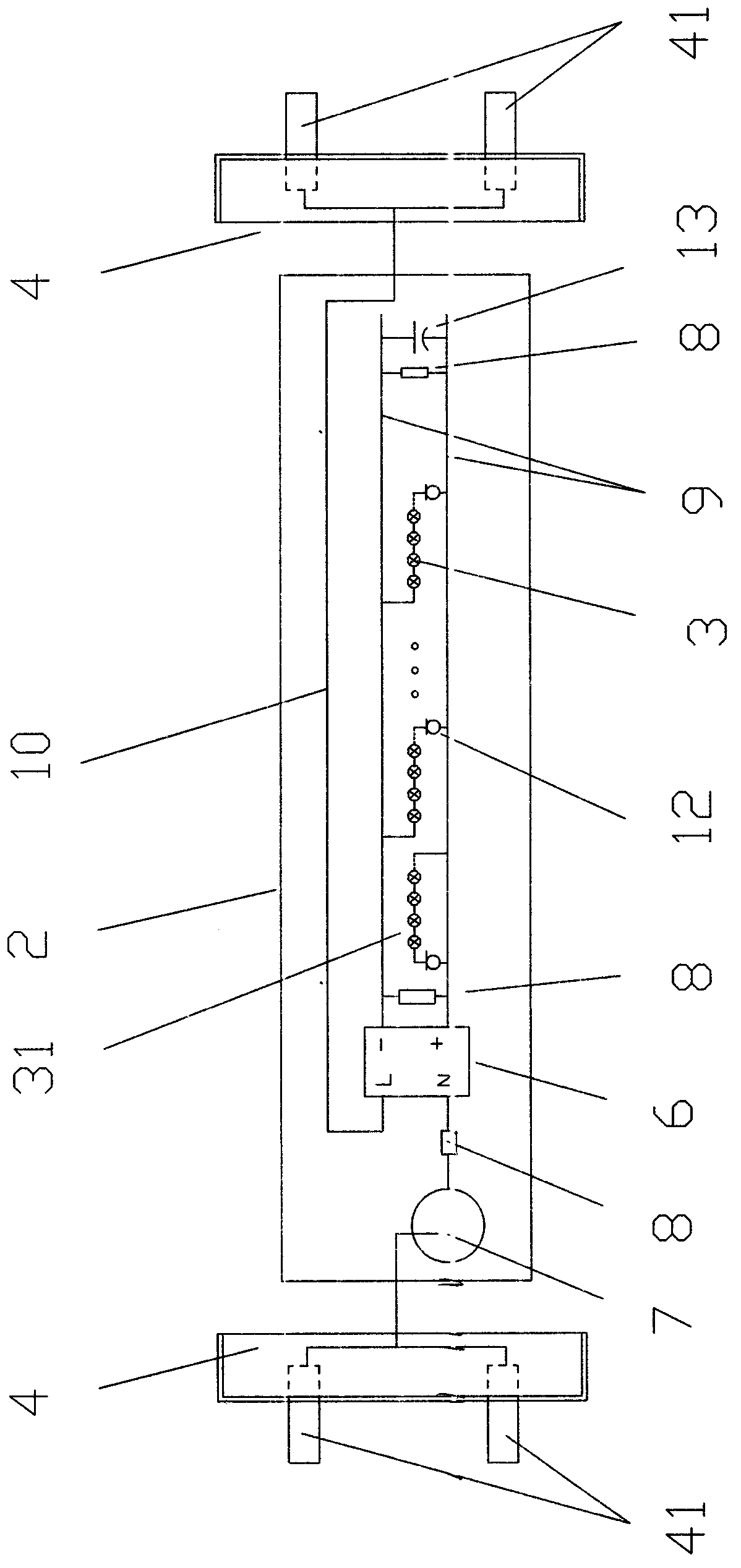

LED fluorescent tube with modified structure

InactiveCN103574331AReasonable distributionReasonable currentPoint-like light sourceElongate light sourcesCapacitanceElectrical resistance and conductance

The invention discloses an LED fluorescent tube with a modified structure. The LED fluorescent tube comprises a lamp tube base, and a plastic housing, a PCB board, an LED illuminant and an end cover which are arranged on the lamp tube base, wherein at least one bridge rectifier and at least one resistor are arranged on the surface of at least one end of the PCB board, at least one capacitor is arranged on the surface of the other end, at least one resistor or constant current diode which is connected with two conductive pins of the capacitor in parallel is arranged between the two conductive pins of the capacitor, the bridge rectifier and the resistor are arranged between an LED on the tail end and the end face of a PCB, the capacitor and the resistor or the constant current diode are arranged between the LED on the other end of the surface of the PCB board and the end face of the PCB, the anodes and the cathodes of the two conductive pins of the capacitor are respectively electrically connected with conductive circuit layers which are arranged on two sides of the LED along a longitudinal direction and are provided with anodes and cathodes, and a plurality of LED lamp string groups are arranged between the conductive circuit layers provided with the anodes and the cathodes. The LED fluorescent tube has the advantages of low cost, high efficiency, safety, long service life, convenience for maintenance and low cost.

Owner:姚志峰

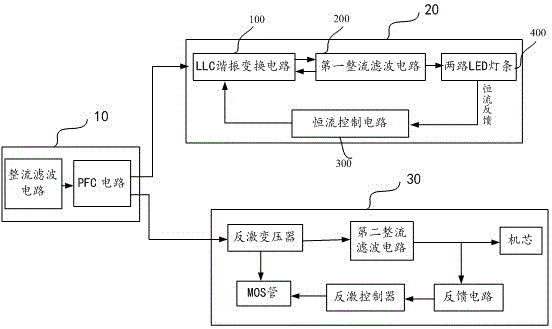

Two-way constant current circuit and power supply device

ActiveCN106304492AAvoid lossLow costElectrical apparatusElectroluminescent light sourcesCapacitanceEngineering

The invention discloses a two-way constant current circuit and a power supply device. The two-way constant current circuit comprises an LLC resonant converter circuit which is used for driving a current to carry out cycle conversion; a first rectifying circuit which is used for balancing voltage difference between LED light bars; and a constant current control circuit which is used for realizing constant current feedback through constant current feedback. The LLC resonant converter circuit inputs power supply currents to two paths of light bars. When voltage difference exists between the two paths of LED light bars, the first rectifying circuit carries out balancing through charge and discharge of a capacitor. The constant current feedback is carried out on the currents passing through the two paths of LED light bars by the constant current control circuit, thereby outputting the constant currents to the two paths of LED light bars. The invention also discloses a power supply device, comprising a current preprocessing circuit, a machine core power supply circuit and the two-way constant current circuit. According to the circuit and the device, voltage boost is not carried out by adoption of Boost in the constant current circuit, and the problems that serious loss occurs in the constant current and the cost is high are solved.

Owner:KONKA GROUP

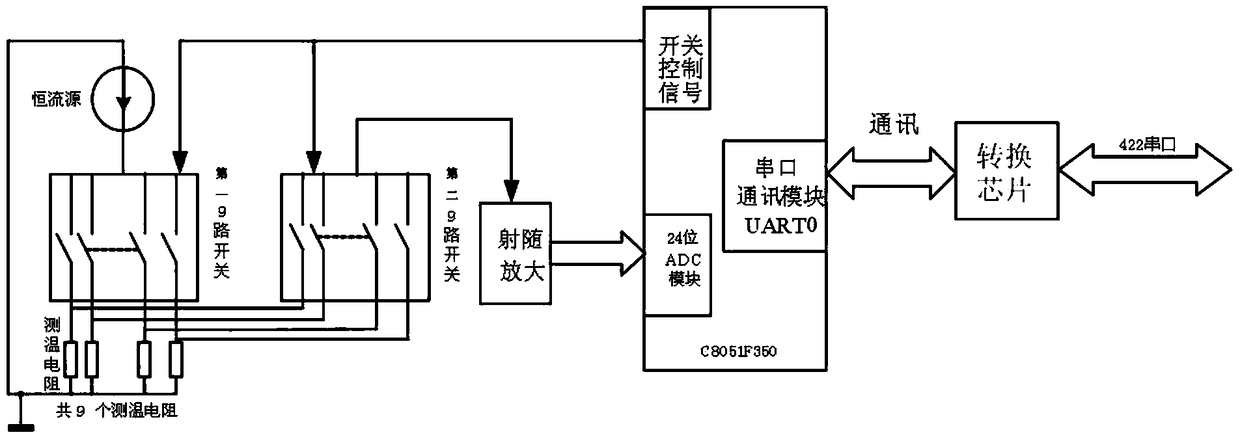

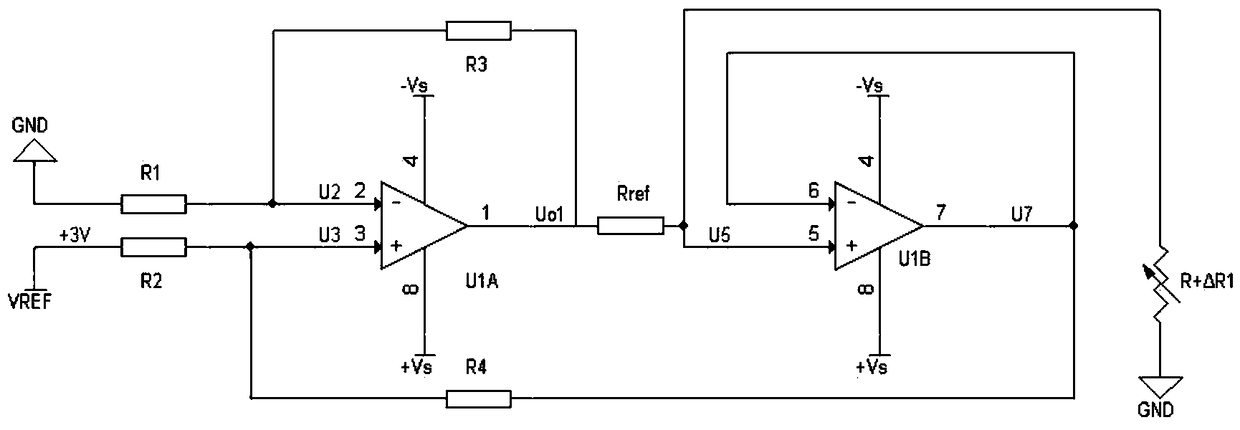

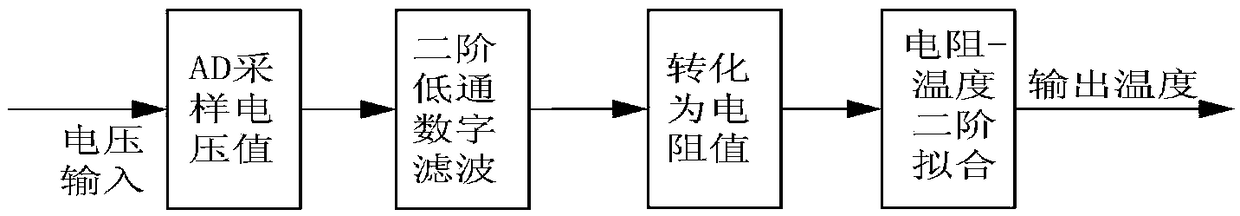

High-precision multi-channel platinum resistor temperature measurement module and method based on constant current source

ActiveCN109489853ASimple structureReduce hardware costsThermometers using electric/magnetic elementsNavigation by speed/acceleration measurementsSignal processing circuitsEngineering

The invention relates to a high-precision multi-channel platinum resistor temperature measurement module and method based on a constant current source. The module is characterized by comprising a high-precision constant current source, a first nine-channel switching circuit, a plurality of temperature measuring platinum resistors, a second nine-channel switching circuit, an emitter following amplifier circuit and a microprocessor signal processing circuit; an output end of the high-precision constant-current source is respectively connected with a plurality of temperature measuring platinum resistors through the first nine-channel switching circuit and generates voltage, and the other ends of the temperature measuring platinum resistors are grounded; the input end of the second nine-channel switching circuit is respectively connected with a plurality of temperature measuring platinum resistors, the output end of the second nine-channel switching circuit is connected with the microprocessor signal processing circuit through the emitter following amplifier circuit used for buffering the generated voltage through the second nine-channel switching circuit and the emitter following amplifier circuit and then inputting the buffered voltage into the microprocessor signal processing circuit to acquire a corresponding voltage value. The module has simple circuit structure, lower hardware cost and high reliability.

Owner:TIANJIN NAVIGATION INSTR RES INST

Vertical current regulative diode and manufacturing method thereof

ActiveCN104638023AHigh dynamic impedanceGood constant current effectSemiconductor/solid-state device manufacturingSemiconductor devicesElectricityDynamic impedance

The invention provides a vertical current regulative diode and a manufacturing method thereof, and belongs to the technical field of semiconductors. The vertical current regulative diode provided by the invention comprises a cell structure and a terminal structure which are connected in sequence; the cell structure consists of a plurality of cells which are identical in structure and are connected in sequence; the terminal structure consists of a cut-off ring and a plurality of field limiting rings connected in sequence; the cells are located between a first N-type heavily doped region and an N-type lightly doped epitaxial layer and are respectively embedded into the upper surfaces of first P-type diffusion well regions to form depletion channel regions. According to the vertical current regulative diode provided by the invention, electricity is conducted by the depletion channel regions, so that the depletion channel regions are pinched off earlier than a JFET (junction field-effect transistor) region, and the pinching-off voltage is as low as 5V or less; moreover, after the depletion channel regions are pinched off, current is not increased with the increase of the voltage, so the dynamic impedance is high, and the current regulation capacity is good.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

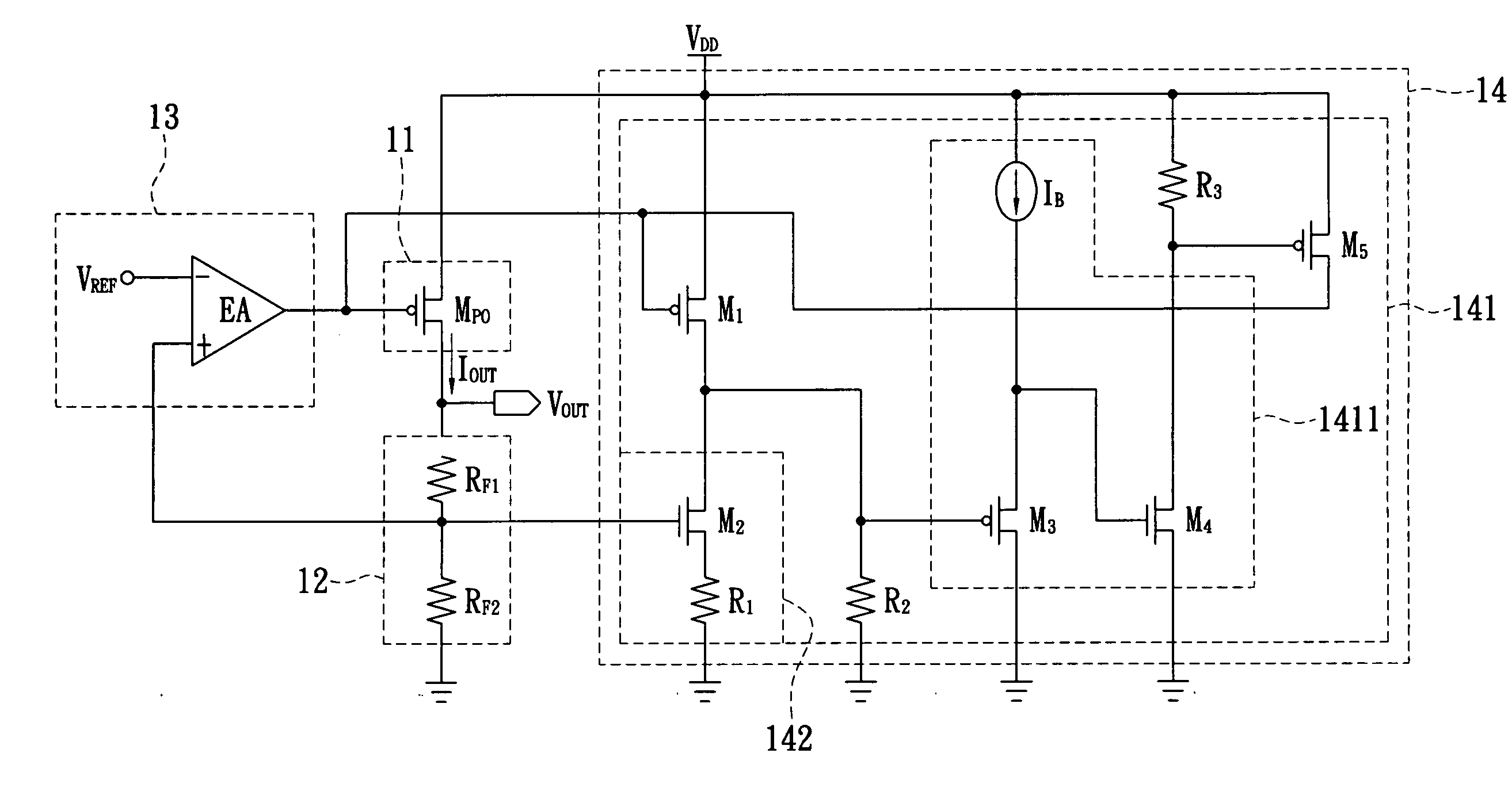

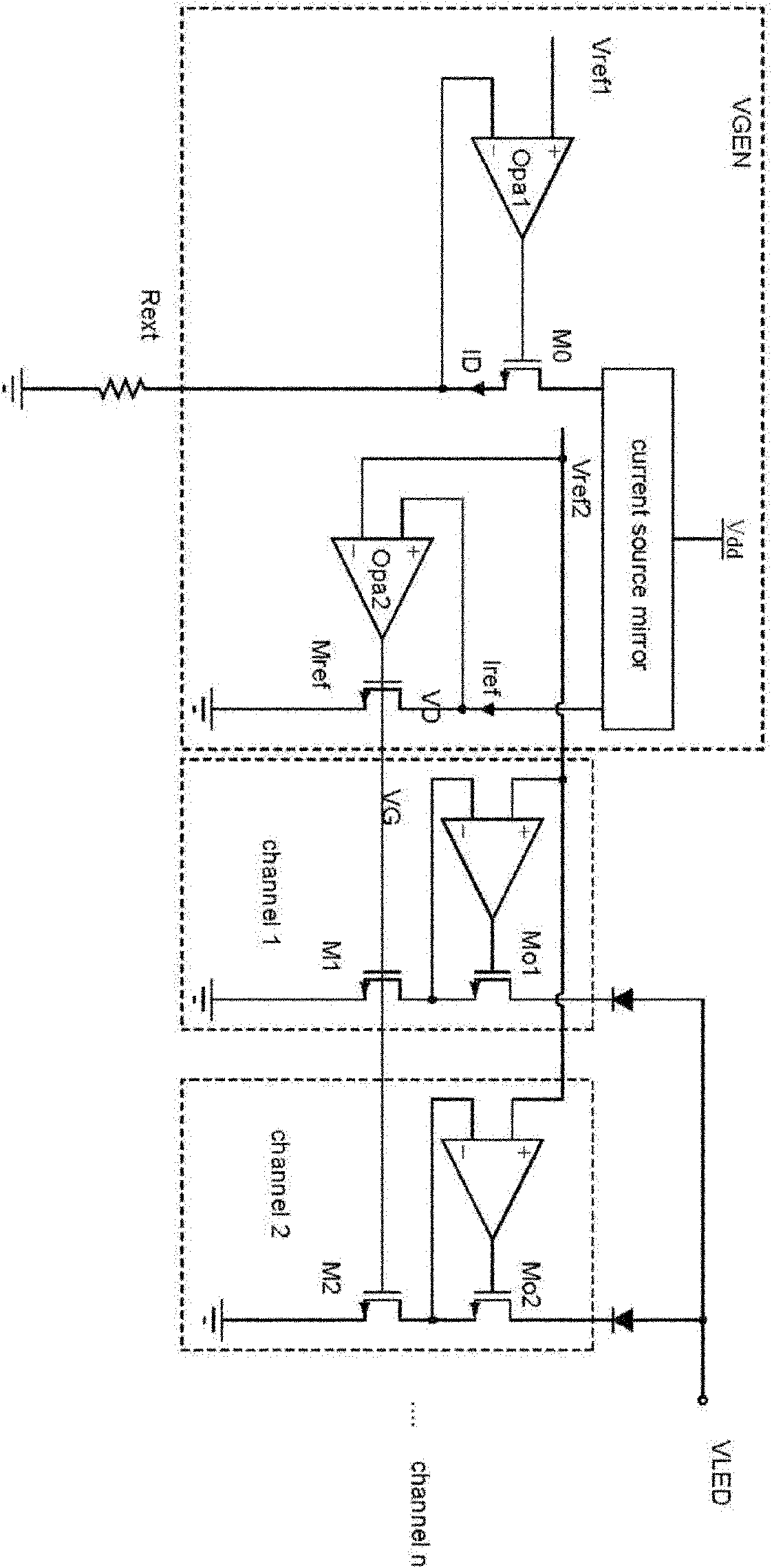

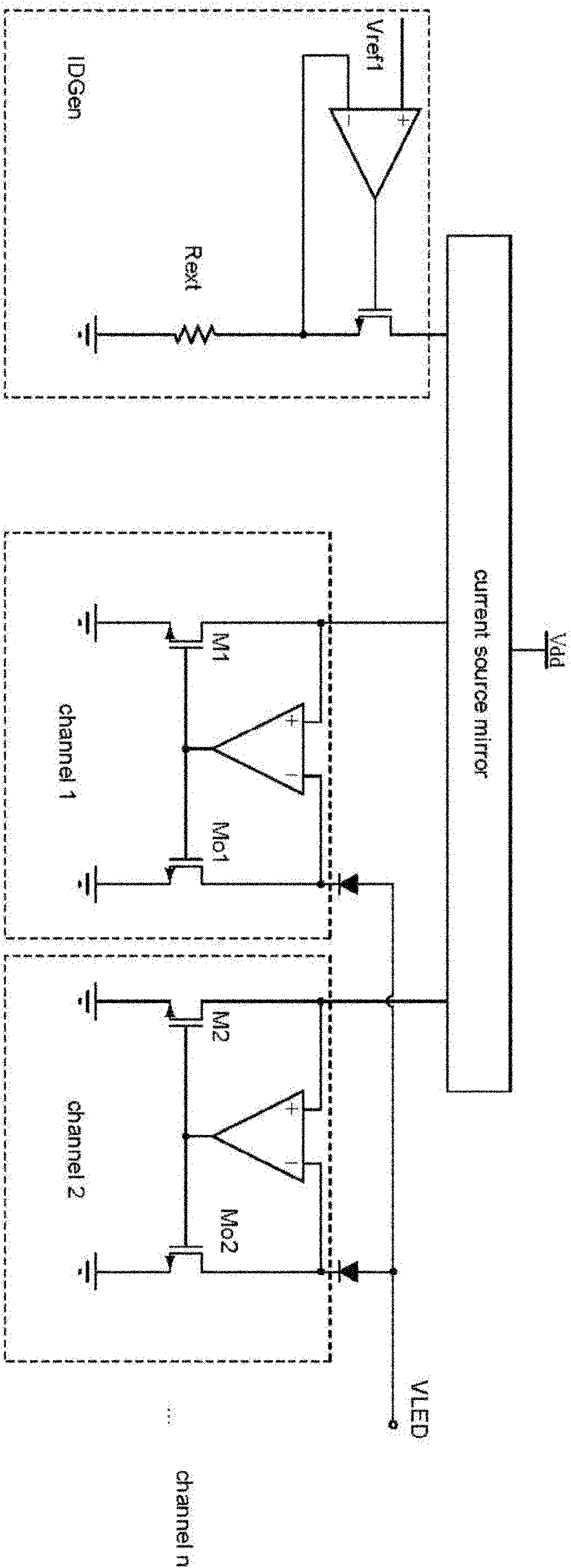

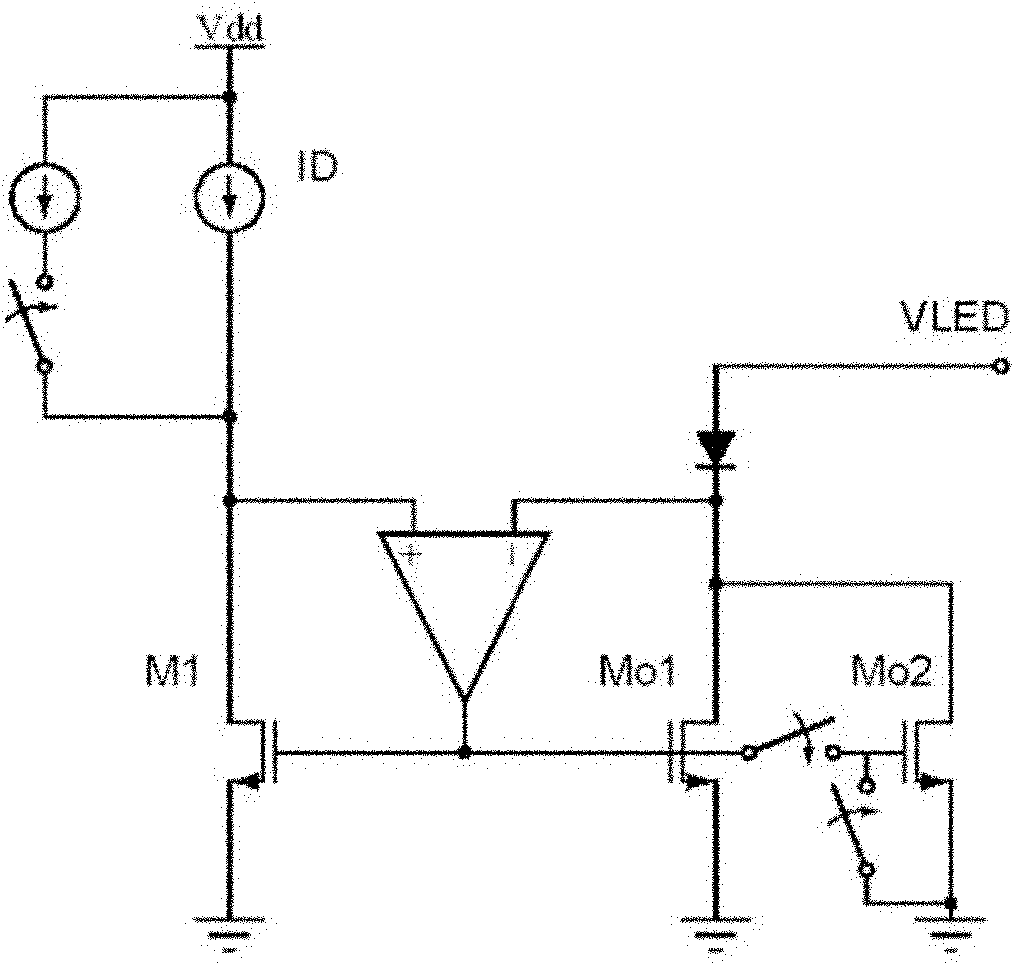

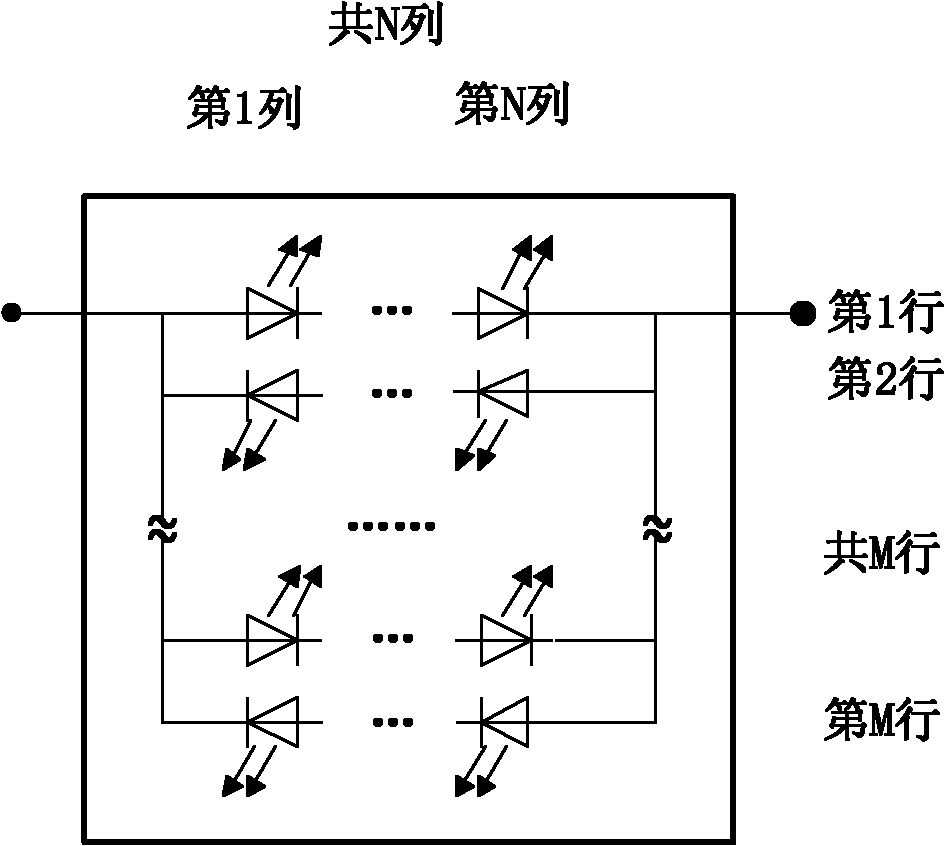

Small-area power tube-based low-mismatching multi-channel light-emitting diode (LED) constant current source driving circuit

The invention provides a small-area power tube-based low-mismatching multi-channel light-emitting diode (LED) constant current source driving circuit structure, and belongs to the technical field of microelectronics and LED driving. The LED constant current source driving circuit comprises an identity (ID) generation module IDGen, a current mirror and n channels, wherein the ID generation module comprises an operational amplifier and a metal oxide semiconductor (MOS) tube; the current ID of the current mirror generates n equal currents Iref1, Iref2, ..., and Irefn; the n channels have a uniform structure and comprise an operational amplifier and two MOS tubes; and one MOS tube is a power tube, and the width to length ratio of the power tube is m times that of the other MOS tube. The matching design can be performed on the layout so as to reduce mismatching to the minimum extent.

Owner:PEKING UNIV

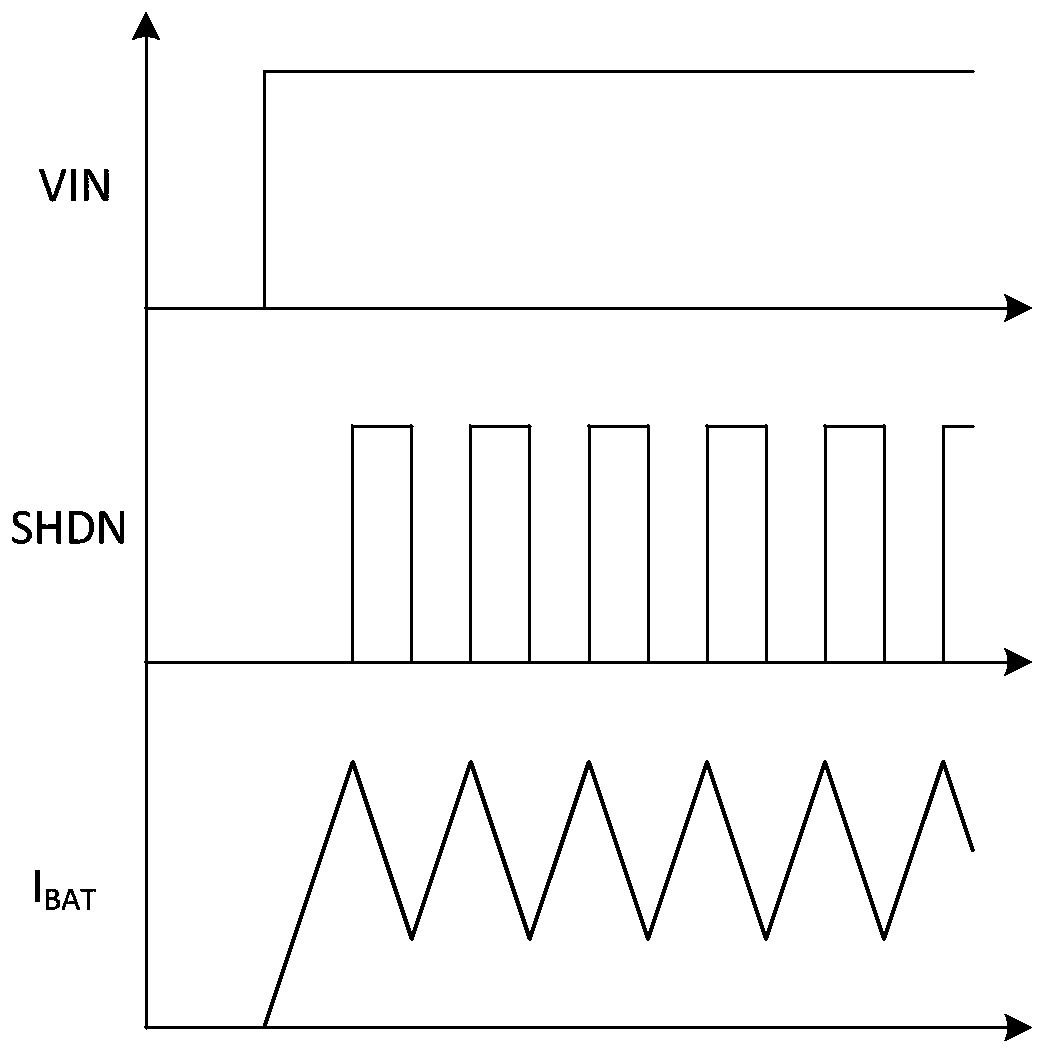

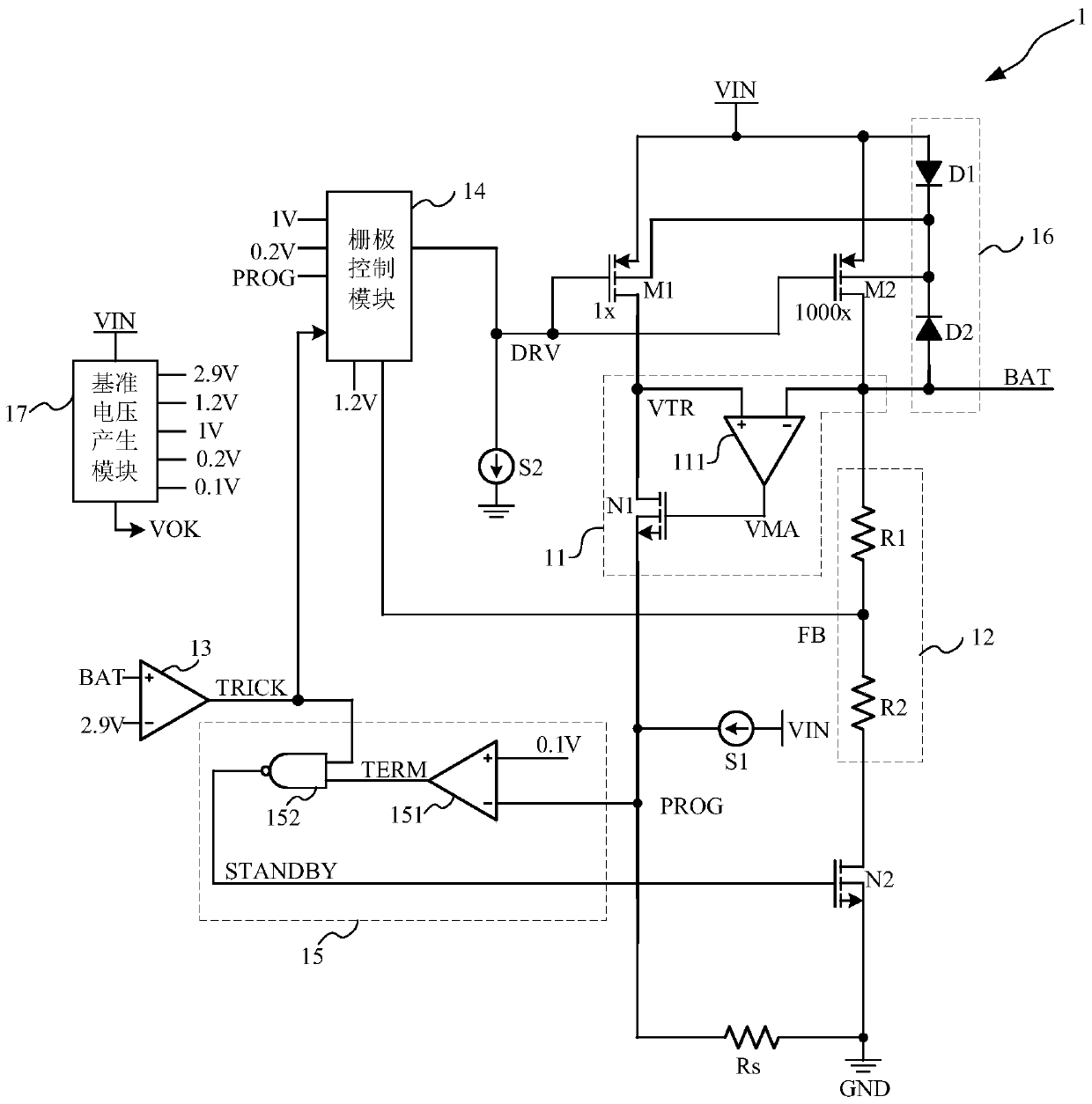

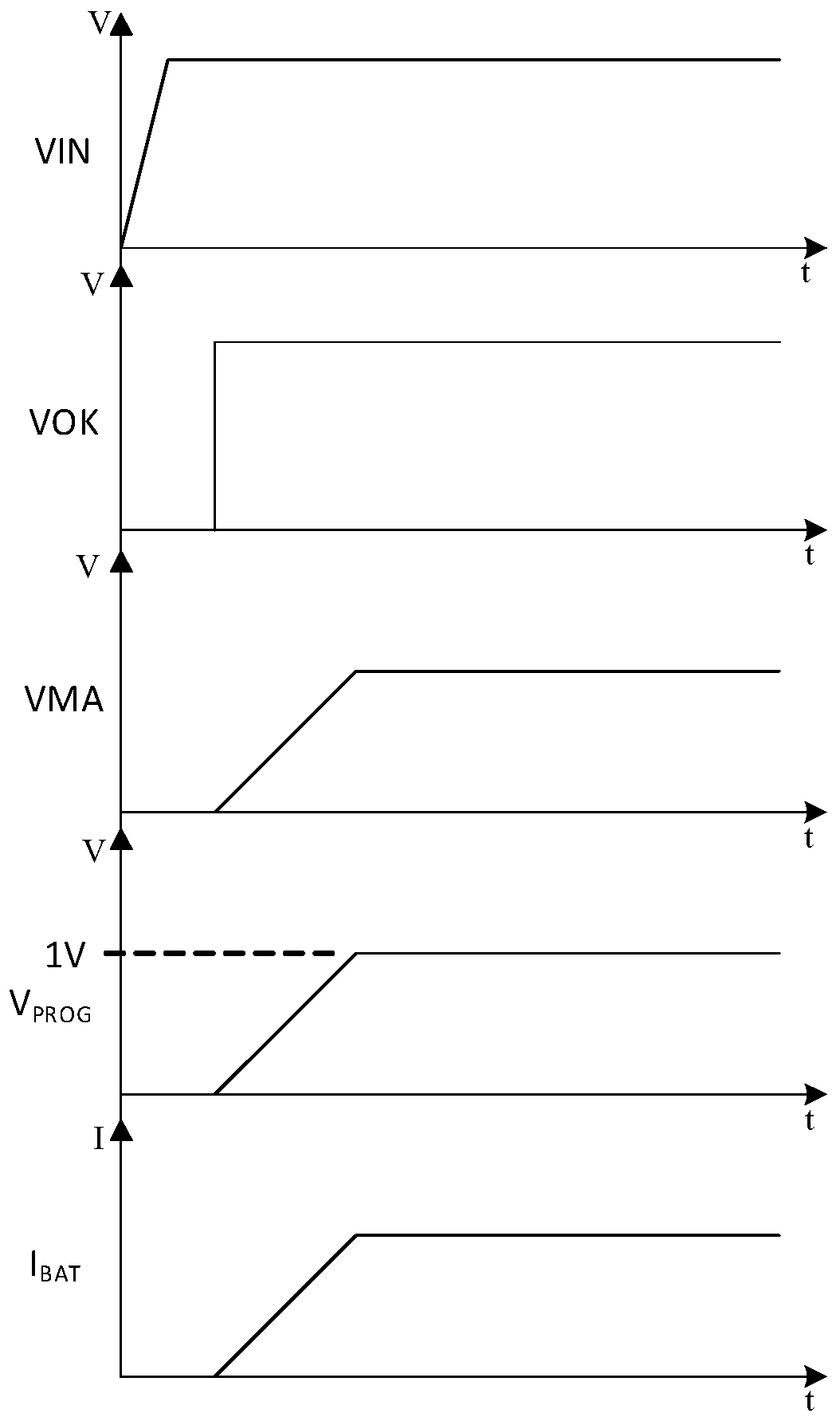

Linear charging system, and constant current and constant voltage control circuit and voltage following control method thereof

PendingCN109861329AHigh precisionHigh Current AmplificationBatteries circuit arrangementsElectric powerLinear controlMagnification

The present invention provides a linear charging system, and a constant current and constant voltage control circuit and a voltage following control method thereof. The linear charging system comprises a constant current and constant voltage control circuit, a power supply input circuit for power supply and a battery module for energy storage. The constant current and constant voltage control circuit comprises a current sampling tube, an output power tube, a control current sampling tube, a voltage following control module having the same drain voltage as the output power tube, and a gate control module configured to regulate the gate voltage of the current sampling tube and the output power tube based on the voltage sampling feedback signals and the current sampling feedback signals. Thelinear charging system, and the constant current and constant voltage control circuit and the voltage following control method thereof perform linear control of impedance of an N-type regulate transistor connected in series with a current sampling branch without starting current overshooting so as to solve the problem of current overshooting when the linear charging management is started and evencontinuous restart caused by the current overshooting and simplify part of the circuit; and moreover, the output current can still maintain the high-precision current magnification times when the output voltage is low.

Owner:SHANGHAI NATLINEAR ELECTRONICS CO LTD

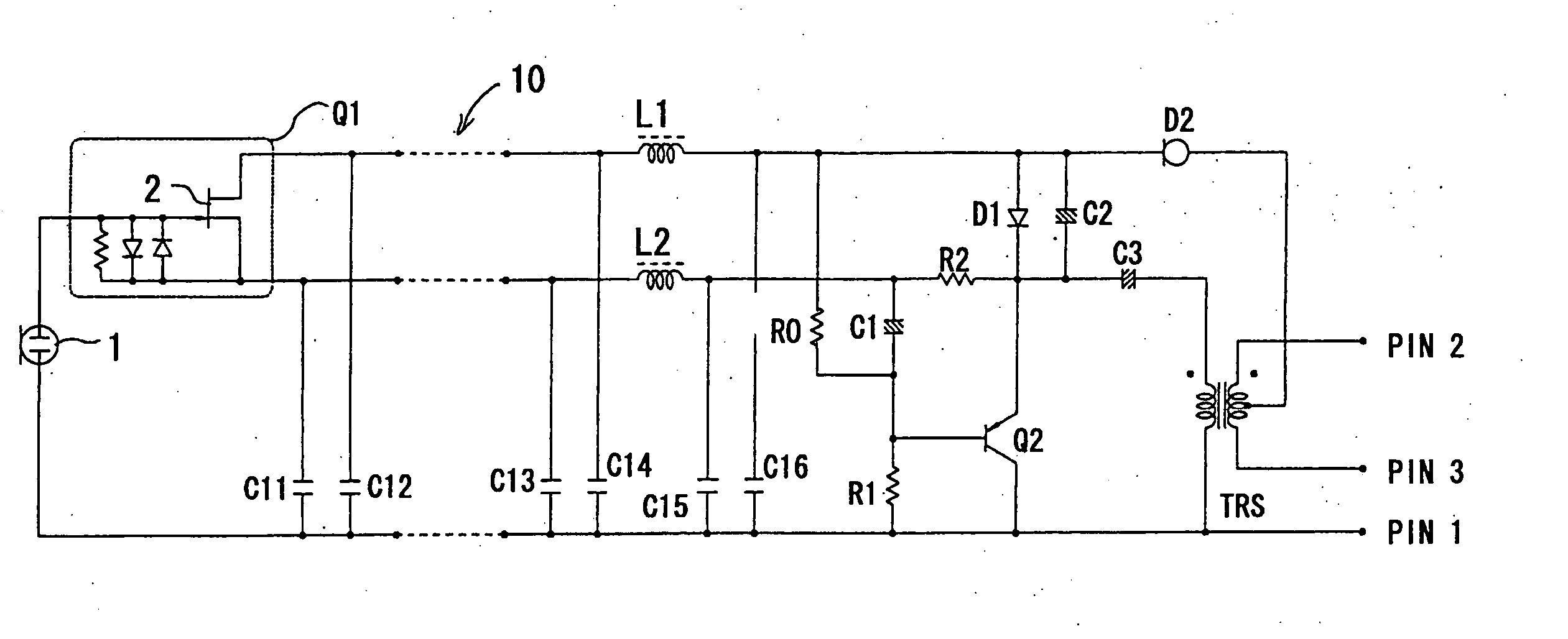

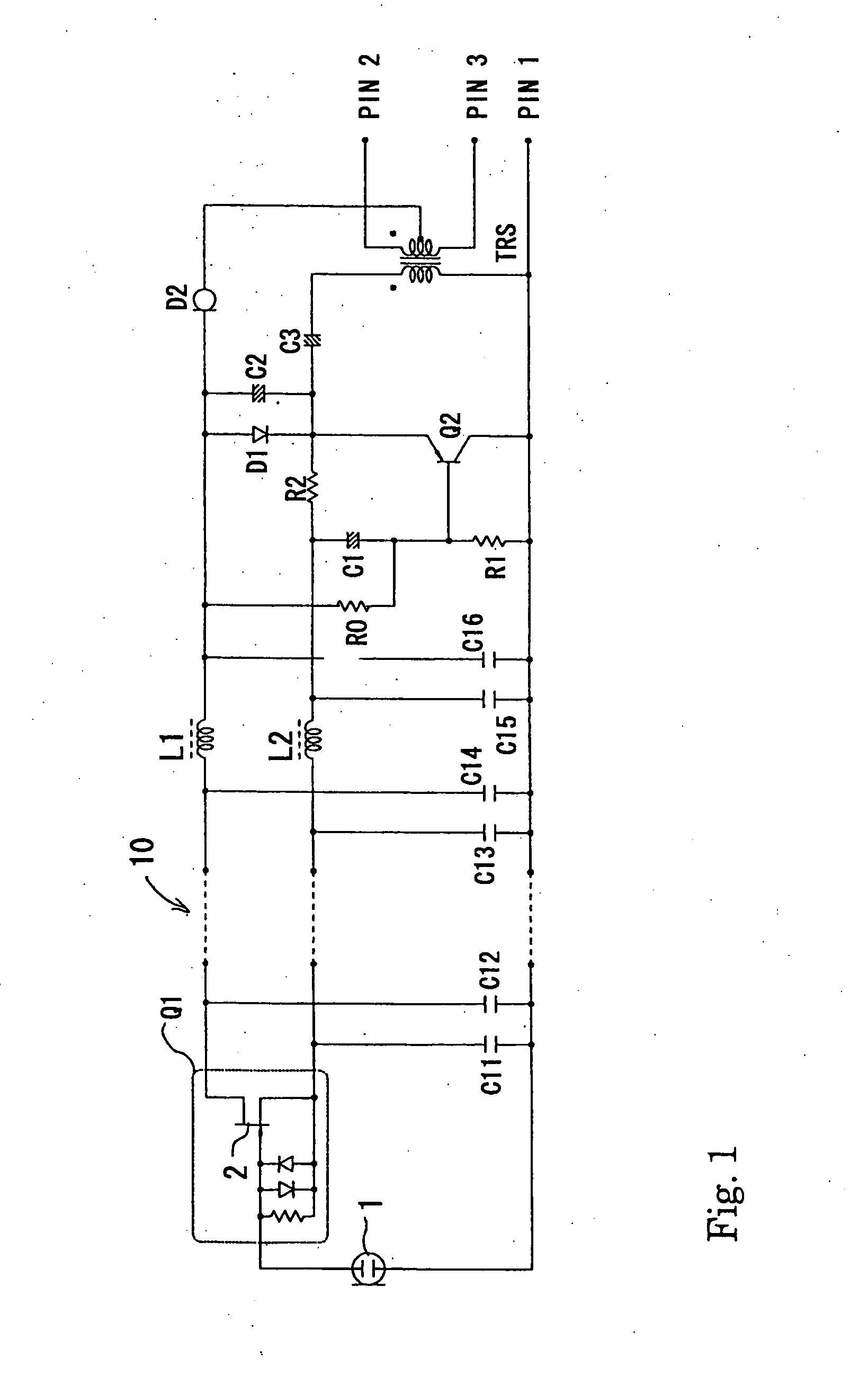

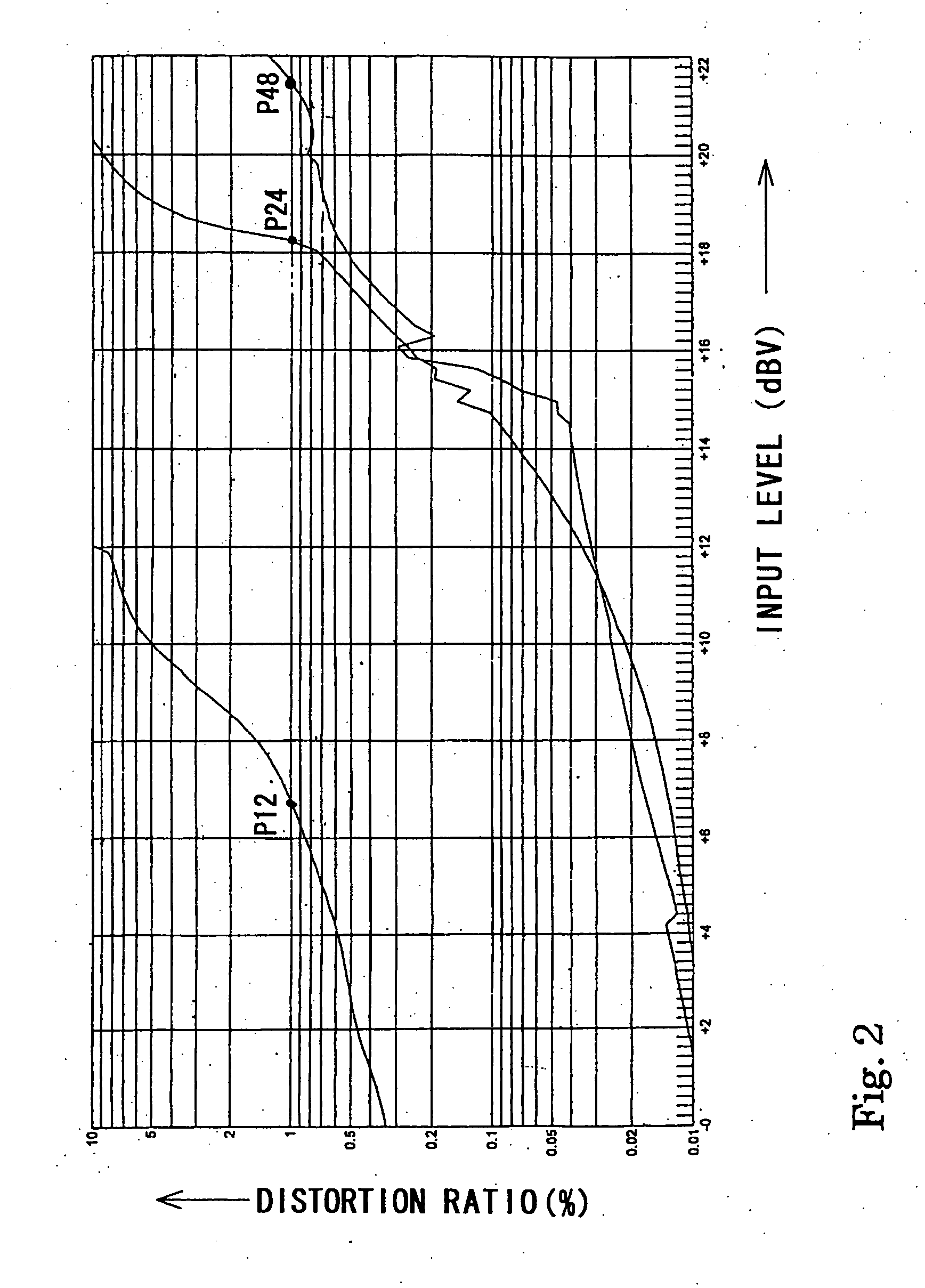

Condenser microphone

ActiveUS20060291672A1Suitable for operationElectrostatic transducer microphonesTransducer casings/cabinets/supportsCapacitanceOutput transformer

A condenser microphone is obtained, in which the bias of a current amplifier circuit in emitter-follower connection immediately after an impedance converter automatically changes in accordance with the switching of phantom power supply voltages and the maximum output level and the maximum permissible input sound pressure level are increased at any power supply voltage. The condenser microphone comprising a transistor Q2 in emitter-follower connection immediately after an FET 2 that constitutes an impedance converter Q1 has a constant current diode D2 connected to an output transformer TRS that also serves as a transformer for phantom power source supply and resistors R0 and R1 that divide the voltage on the cathode side of the constant current diode D2 into a bias voltage that causes the transistor Q2 to operate.

Owner:AUDIO-TECHNICA

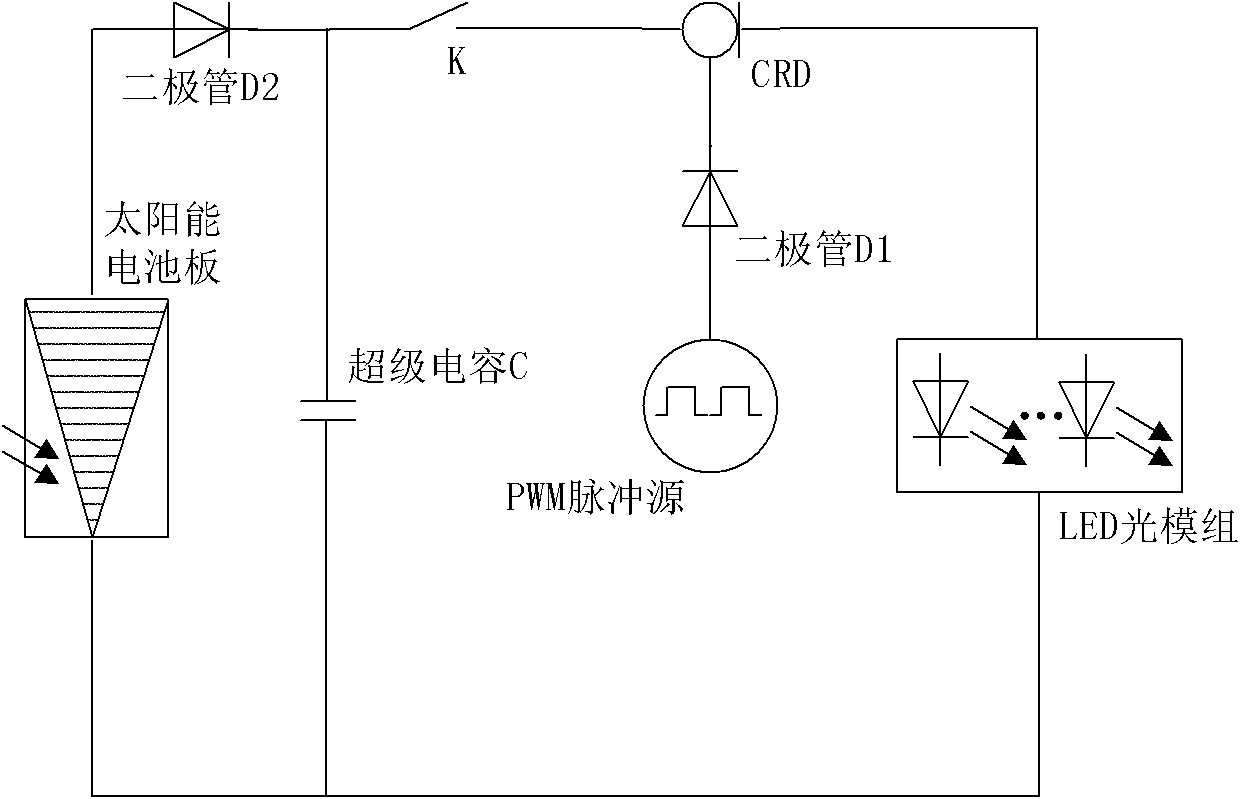

Super capacitor charging control circuit

ActiveCN103501031ACharge controlAvoid damageBatteries circuit arrangementsElectric powerCapacitanceMicrocontroller

The invention provides a super capacitor charging control circuit which comprises an input reverse connection prevention circuit, a switch control circuit, a charging constant current circuit and a charging voltage detection circuit, wherein the input reverse connection prevention circuit is connected with the switch control circuit in series; the switch control circuit is connected with the charging voltage detection circuit in series; one end of the charging constant current circuit is connected with the switch control circuit, and the other end of the charging constant current circuit is connected with an output end of the charging voltage detection circuit. The constant current action mechanism and the voltage limiting action mechanism of the super capacitor charging control circuit are decided by the inherent physical characteristics of a constant current diode and a voltage stabilizing diode and are independent of the normal operation of a single-chip microcomputer or the program thereof; the super capacitor charging control circuit does not adopt a linear direct current (DC) voltage stabilizing circuit of the common charging control circuit, thus being free from electric energy loss caused by a linear adjusting component, and realizing higher power supply efficiency.

Owner:康威通信技术股份有限公司

Vertical current regulative diode and manufacturing method thereof

InactiveCN103426936ALower pinch-off voltageGood constant current effectSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringConstant-current diode

The invention relates to semiconductor technology, in particular to a vertical current regulative diode and a manufacturing method thereof. The vertical current regulative diode comprises an oxide layer, a highly doped N-type epitaxial layer, a lightly doped N-type epitaxial layer, a heavily doped N+ substrate and a metal anode which are sequentially stacked. The vertical current regulative diode is characterized by further comprising a cellular structure, a terminal structure and a cut-off ring which are sequentially connected, the cellular structure comprises a plurality of cells which are the same in structure and are sequentially connected, and the terminal structure comprises a plurality of terminals which are the same in structure and are sequentially connected. The vertical current regulative diode has the advantages that the diode is easily pinched off, pinch-off voltage can be below 5V, a pinch-off point more slowly changes along with increase of the voltage, constant current is more stable, the diode is more flexible in design and more reasonable in structure, an additional photo-etching plate can be omitted, and manufacturing cost is saved. The manufacturing method is particularly applicable to the current regulative diode.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Current mirror circuit and current source circuit

InactiveUS6388508B1Amplifier with semiconductor-devices/discharge-tubesElectric variable regulationDrain currentConstant-current diode

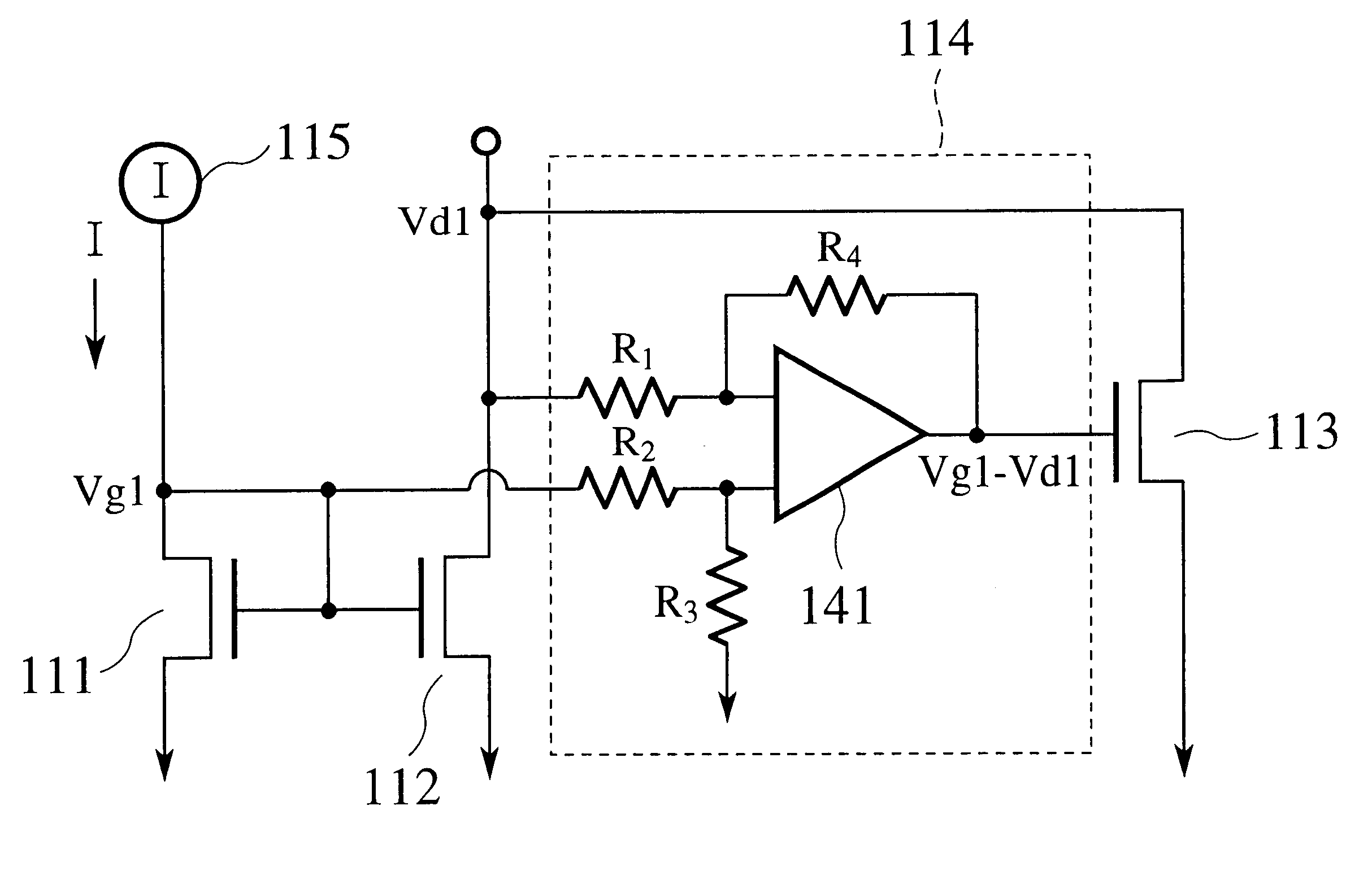

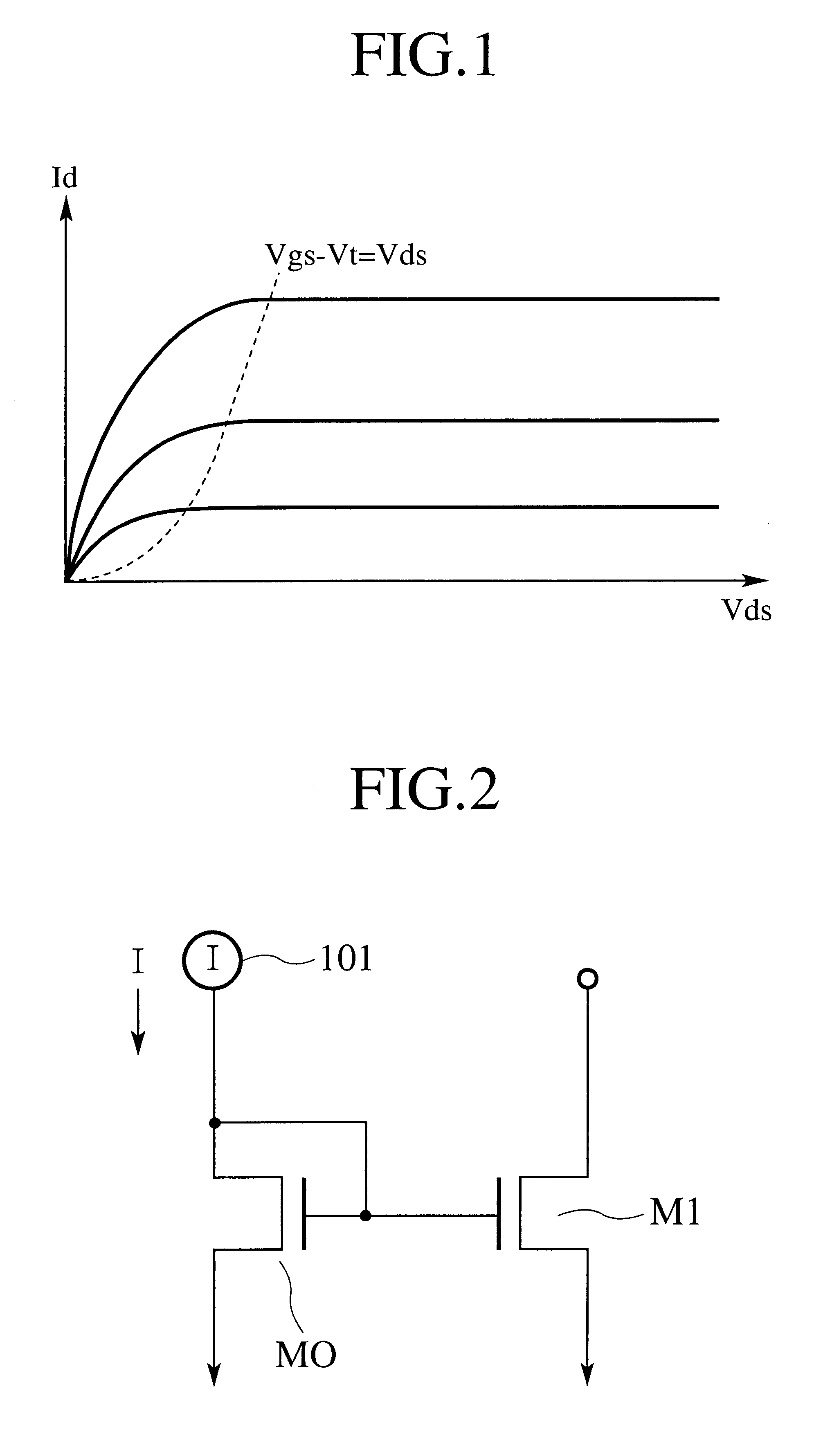

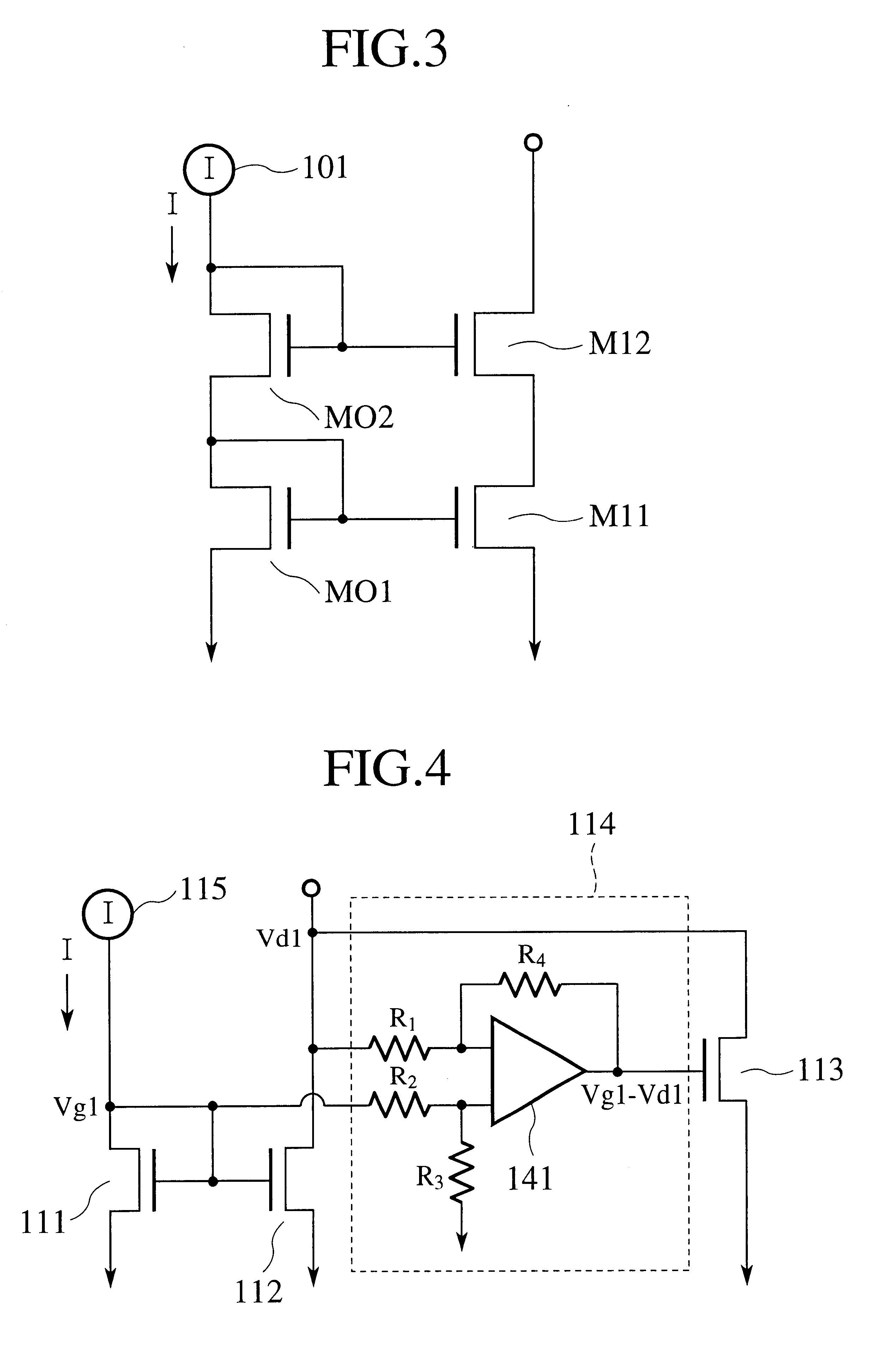

A current mirror circuit that provides an excellent current that does not deteriorate, even when the power source is lower supply voltage. A mirror current flows in a first MOS transistor when a constant current flows in the MOS transistor from a current source. A subtracter outputs the difference between voltage Vg1 of the gate of the MOS transistor and Voltage Vd1 of the drain, and applies this difference to the gate of a second MOS transistor. When the power-supply voltage of this circuit becomes lower supply voltage and the absolute value of Vd1 decreases, the MOS transistors enter the triode region, and the mirror current decreases when the absolute value of Vd1 decreases, because the difference between Vg1 and Vd1 becomes larger, the drain current of the second MOS transistor increases, and the amount by which the mirror current decreases is counterbalanced.

Owner:KK TOSHIBA

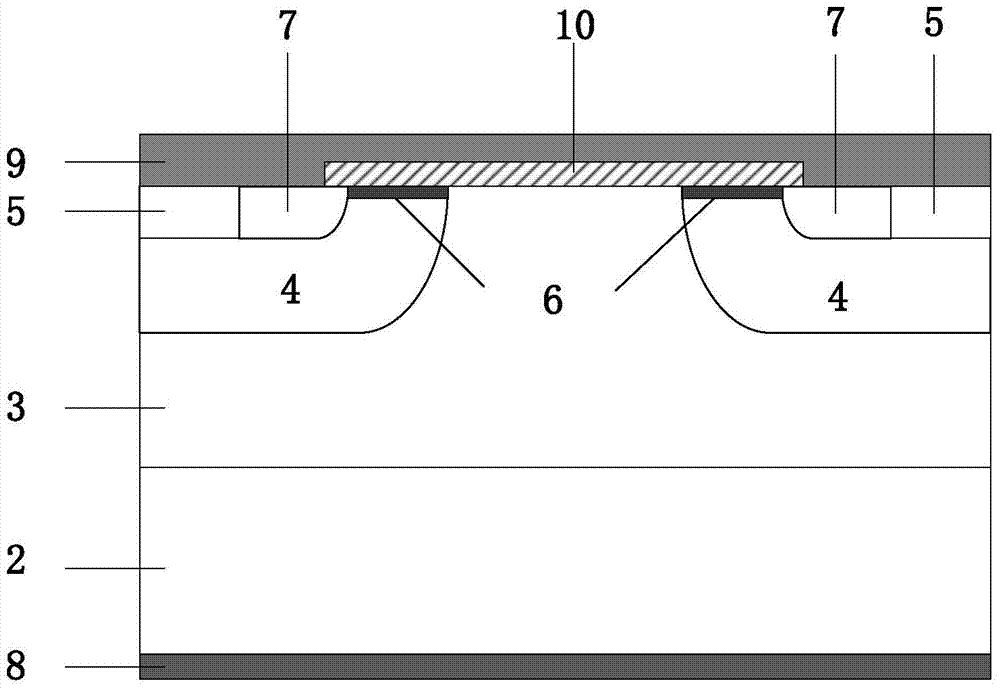

Constant current diode formed by grooving process and manufacturing method thereof

ActiveCN103035745ASmall constant current performanceGood constant current effectSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringConstant-current diode

The invention provides a constant current diode formed by a grooving process. The constant current diode comprises a substrate, an epitaxial layer, a first insulating layer, a second insulating layer, a P+ isolation region, P+ polycrystalline silicon filled deep grooves, shallow P regions, a cathode and an anode, wherein the epitaxial layer is positioned on the front face of the substrate; the first insulating layer is provided with a first window and a second window and covers the surface of the epitaxial layer; the second insulating layer is adjacent to the first insulating layer and positioned on the surface of the epitaxial layer; the P+ isolation region is formed in the epitaxial layer and the two ends of the P+ isolation region are respectively connected with the substrate and the second insulating layer; the P+ polycrystalline silicon filled deep grooves are formed in the epitaxial layer corresponding to the first window; the shallow P region is formed outside each P+ polycrystalline silicon filled deep groove; the N+ region is positioned on the epitaxial layer corresponding to the second window and positioned between the two adjacent P+ polycrystalline silicon filled deep grooves; the cathode is positioned on the first window, the second window and the first insulating layer; and the anode is positioned on the back face of the substrate away from the epitaxial layer. The invention further provides a manufacturing method for the constant current diode formed by the grooving process, so as to solve the problem that current intensity per unit area and constant current characteristic cannot be simultaneously taken into account in the prior art.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT +1

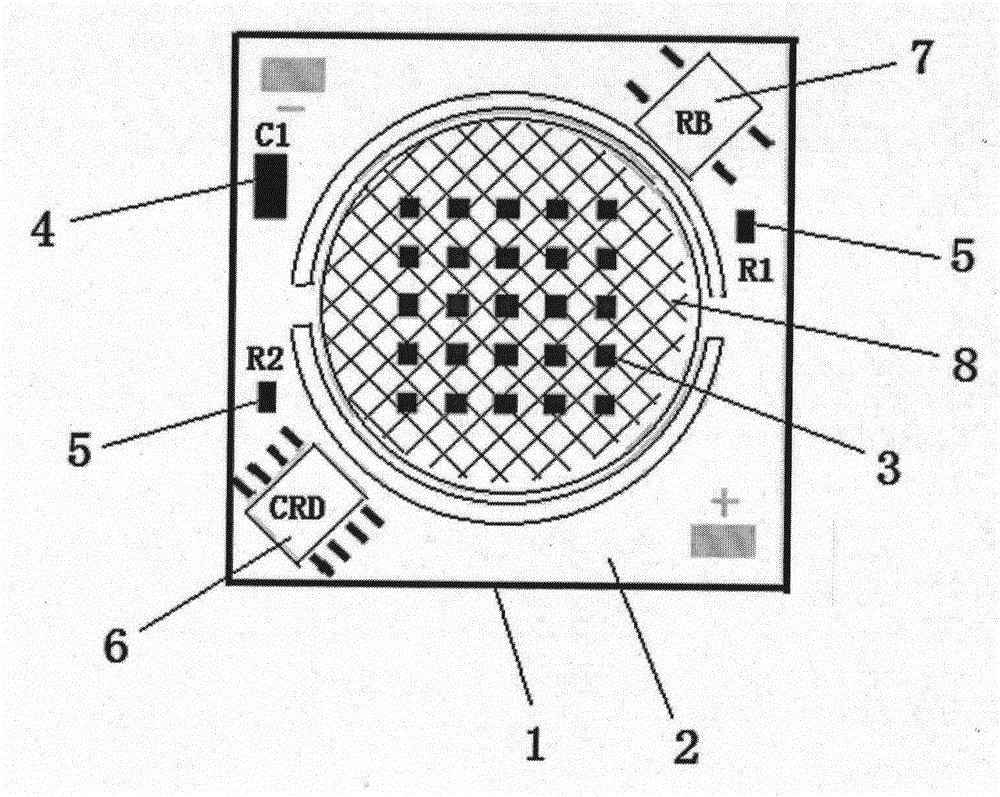

Integrated LED packaging structure

InactiveCN104465956AIncrease heat dissipation channelAvoid reliability impactSolid-state devicesElectric light circuit arrangementCapacitanceWorking temperature

The invention discloses an integrated LED packaging structure. The integrated LED packaging structure is characterized by comprising a ceramic substrate, an insulating layer covering the ceramic substrate, an inverted LED chip arranged on the ceramic substrate, a chip capacitor, a chip resistor, a current regulative diode, a rectifier and packaging glue covering the inverted LED chip, wherein the ceramic substrate is provided with a positive electrode and a negative electrode, and the chip capacitor, the chip resistor, the current regulative diode and the rectifier are arranged on the ceramic substrate. The chip capacitor, the chip resistor, the current regulative diode and the rectifier are collectively known as driving ICs. According to the integrated LED packaging structure, the inverted LED chip and the ceramic substrate with matched coefficients of expansion are adopted, the design of gold wires does not exist, the phenomenon that the packaging glue influences the product reliability when the packaging glue is expanded due to cold and heat changes is avoided, meanwhile, the driving ICs and the inverted LED chip share the ceramic substrate, a radiating channel of a power driving module is added, the product size is reduced, large space and the higher degree of freedom are provided for the design of the radiating module, the product working temperature is lowered, and the product service life is prolonged.

Owner:SHENZHEN JINGTAI

Three-pin package constant current and voltage controller in critical conduction mode

ActiveCN101656484AEfficient power electronics conversionAc-dc conversionSelf-oscillationControl signal

This invention discloses a three-pin package constant current and voltage controller in critical conduction mode, which has less exterior elements, can work in critical conduction mode, can accuratelycontrol constant output current and voltage and can be applied to a self-oscillation inverse converter. The constant current and voltage controller comprises a switch control terminal which is coupled to an inductor switch. The inductor switch is switched off by an inductor switch signal having a connecting time. A controller integrated circuit arranged in an integrated circuit encapsulation adjusts the connecting time in a constant current mode to keep the constant output current of the inverse converter and adjusts the connecting time in a constant voltage mode to keep the constant output voltage of the inverse converter. The constant current and voltage controller further comprises a feedback terminal through which the controller integrated circuit receives electric power and a grounding terminal through which the controller integrated circuit is grounded.

Owner:ACTIVE SEMI SHANGHAI +1

Integration method of LED lighting circuit and LED lighting integrated chip

InactiveCN102006695AEasy to industrializeReduce production linksElectric light circuit arrangementEnergy saving control techniquesEffect lightEngineering

The invention discloses an integration method of an LED lighting circuit and an LED lighting integrated chip, the integration method is characterized in that a rectification circuit, a constant-current diode and an LED in the LED lighting circuit are packaged together to form the LED lighting integrated chip, and a lamp enterprise can obtain LED lamp products only by welding the LED lighting integrated chips on lamp housings. With the integration method and the LED lighting integrated chip, production processes and cost of the LED lighting lamps can be greatly reduced, and industrialization of LED energy-saving lighting products is benefited.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com