High-precision multi-channel platinum resistor temperature measurement module and method based on constant current source

A temperature measurement module, platinum resistance technology, which is applied in the direction of navigation through velocity/acceleration measurement, thermometers and thermometers using electrical/magnetic components directly sensitive to heat, and can solve the problems affecting the accuracy of optical fiber strapdown systems and the accuracy of temperature information. It can reduce the power consumption, low hardware cost and simple circuit structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

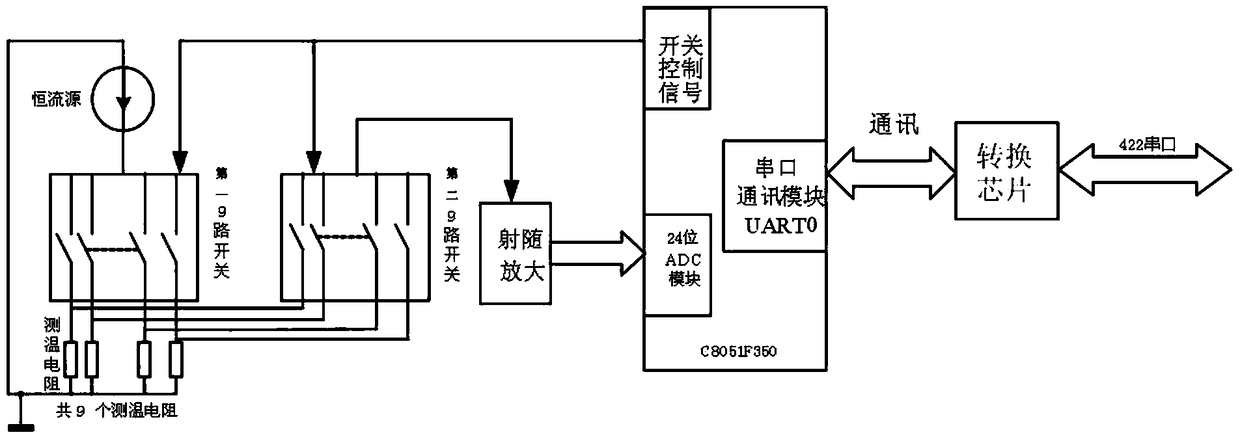

[0023] A high-precision multi-channel platinum resistance temperature measurement module based on a constant current source, such as figure 1 As shown, it includes a high-precision constant current source, a first nine-channel switch circuit, multiple temperature-measuring platinum resistances, a second nine-channel switch circuit, an emitter follower amplifier circuit and a microprocessor signal processing circuit;

[0024] The output ends of the high-precision constant current source are respectively connected with a plurality of temperature-measuring platinum resistors through the first nine-channel switch circuit to generate voltages, and the other ends of the multiple temperature-measuring platinum resistances are all grounded; the second nine-channel The input ends of the switch circuit are respectively connected with a plurality of platinum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com