LED fluorescent tube with modified structure

A LED fluorescent lamp, improved structure technology, applied in the direction of light source, electric light source, slender light source, etc., can solve the problems of local high temperature of the lamp tube, difficulty in meeting the requirements of safety regulations and electromagnetic compatibility of the driving power supply, high maintenance cost, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

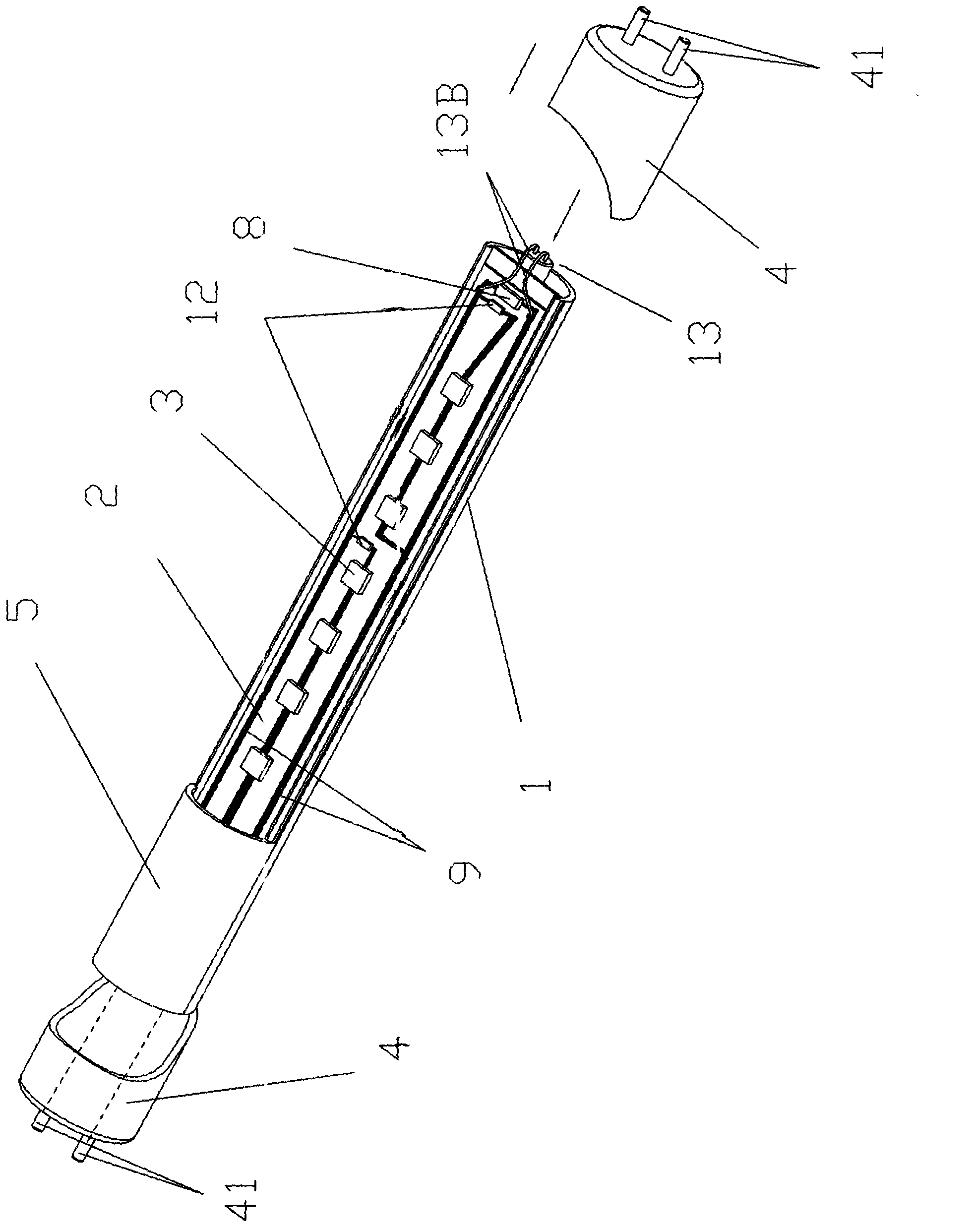

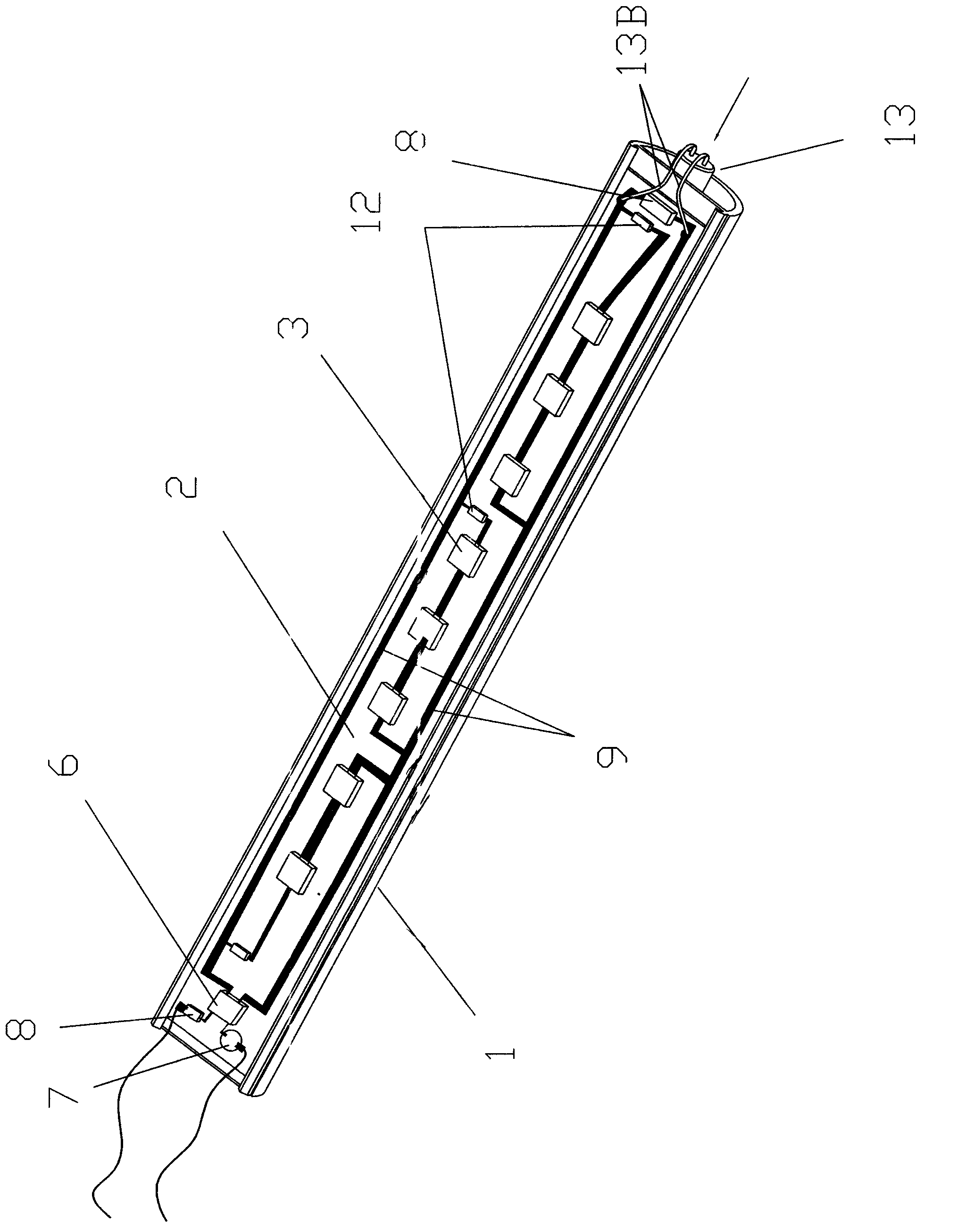

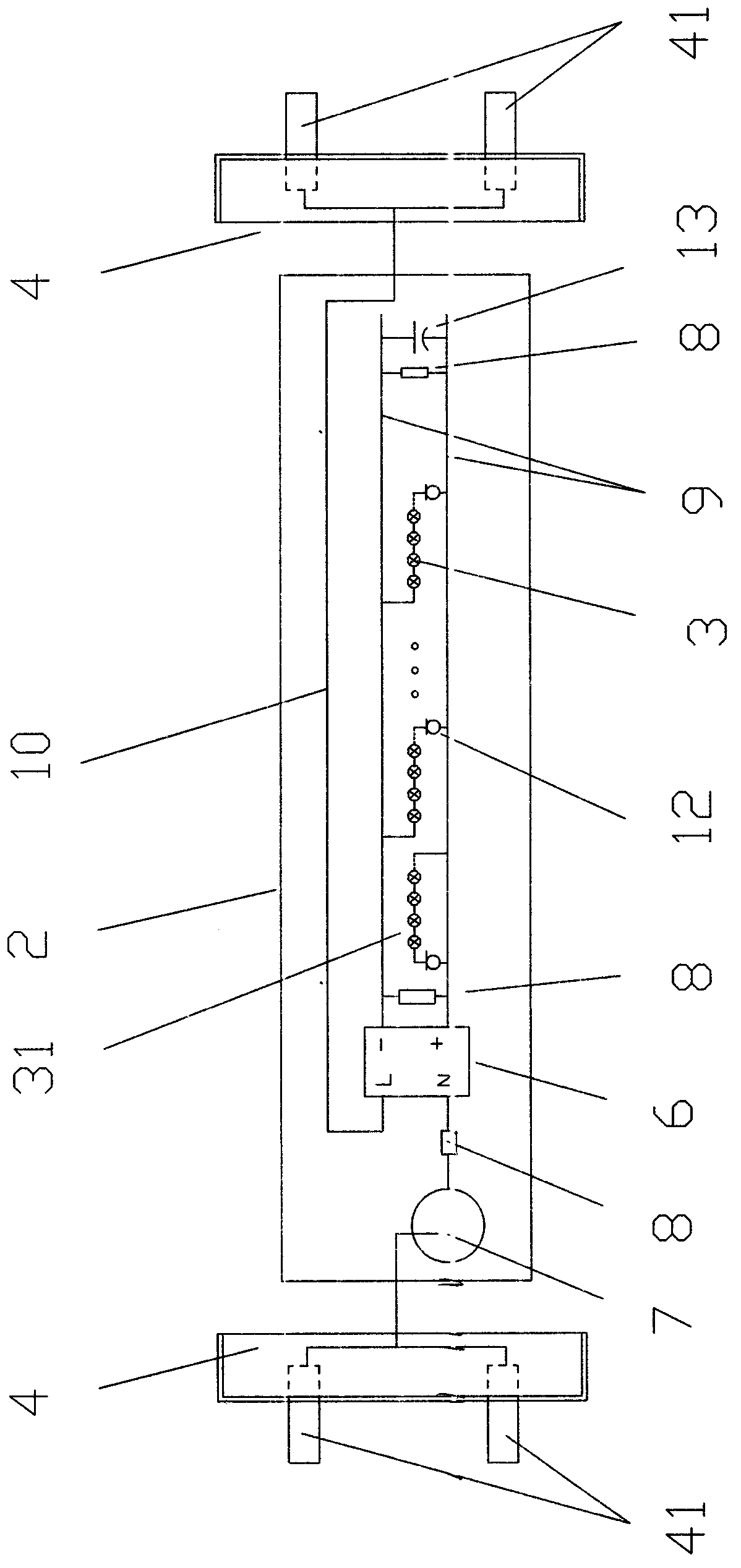

[0029] refer to Figure 1 to Figure 41. An improved structure of the LED fluorescent tube structure of the present invention comprises: a light tube base 1, a plastic cover 5 arranged on the lamp base, a strip-shaped PCB board 2, and the width of the strip-shaped PCB board 2 is 5 to 30 mm, the strip-shaped PCB board 2 can be a PCB board with a single-sided cloth conductive circuit layer, because the light pipe base 1 can be made of aluminum alloy material, the bottom surface of the PCB board 2 is close to the top surface of the light pipe base 1, and is arranged on The end caps 4 at both ends of the base and the casing, at least one end cap at the two ends is provided with a conductive column 41 connected to the power supply and the conductive circuit layer of the PCB board, and at least one rectifier bridge stack 6 is provided on at least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com