Small-area power tube-based low-mismatching multi-channel light-emitting diode (LED) constant current source driving circuit

A driving circuit and constant current source technology, which is applied in the field of low-mismatch multi-channel LED constant current source drive circuit structure, can solve problems such as copy mismatch of different channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

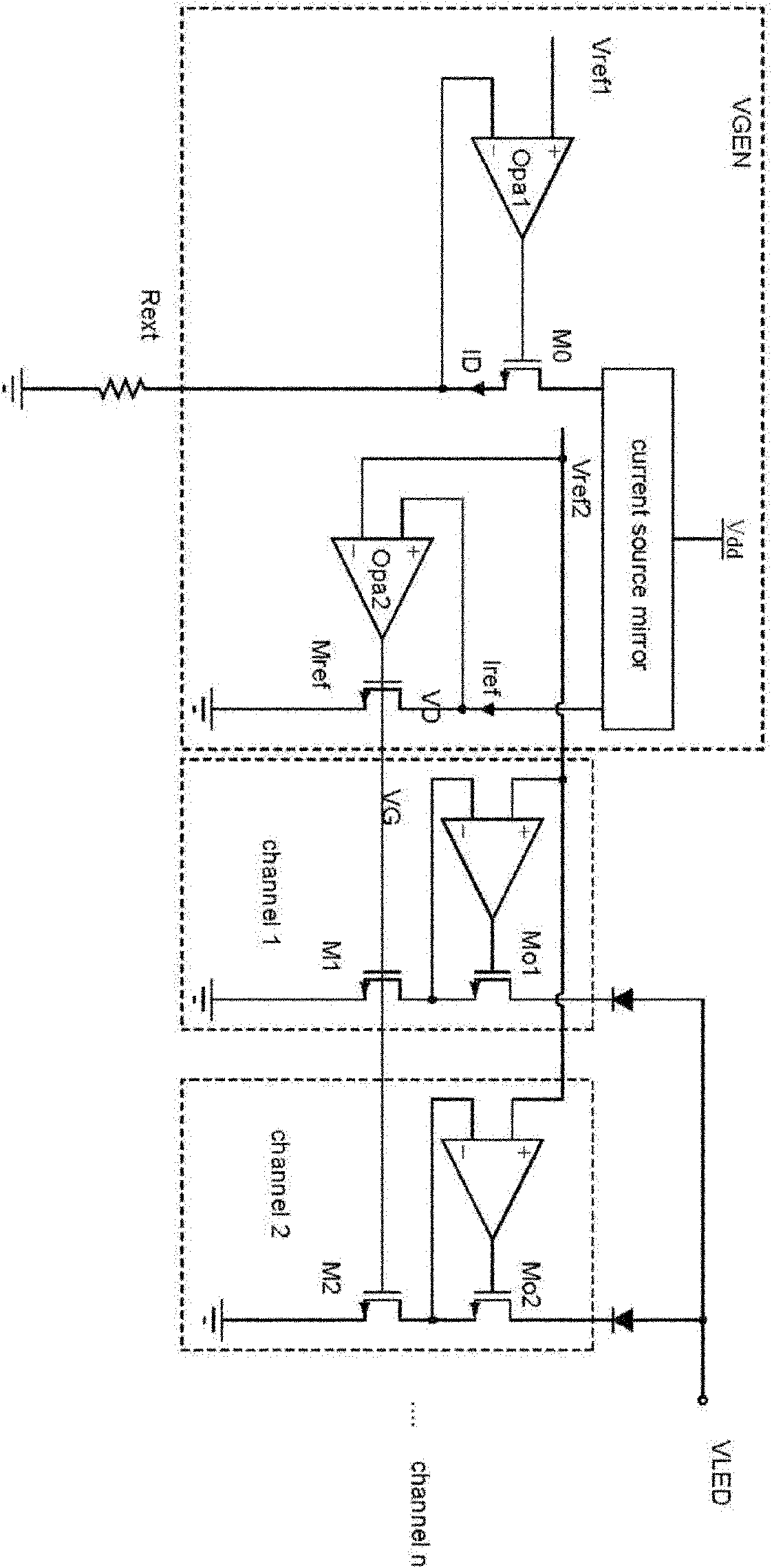

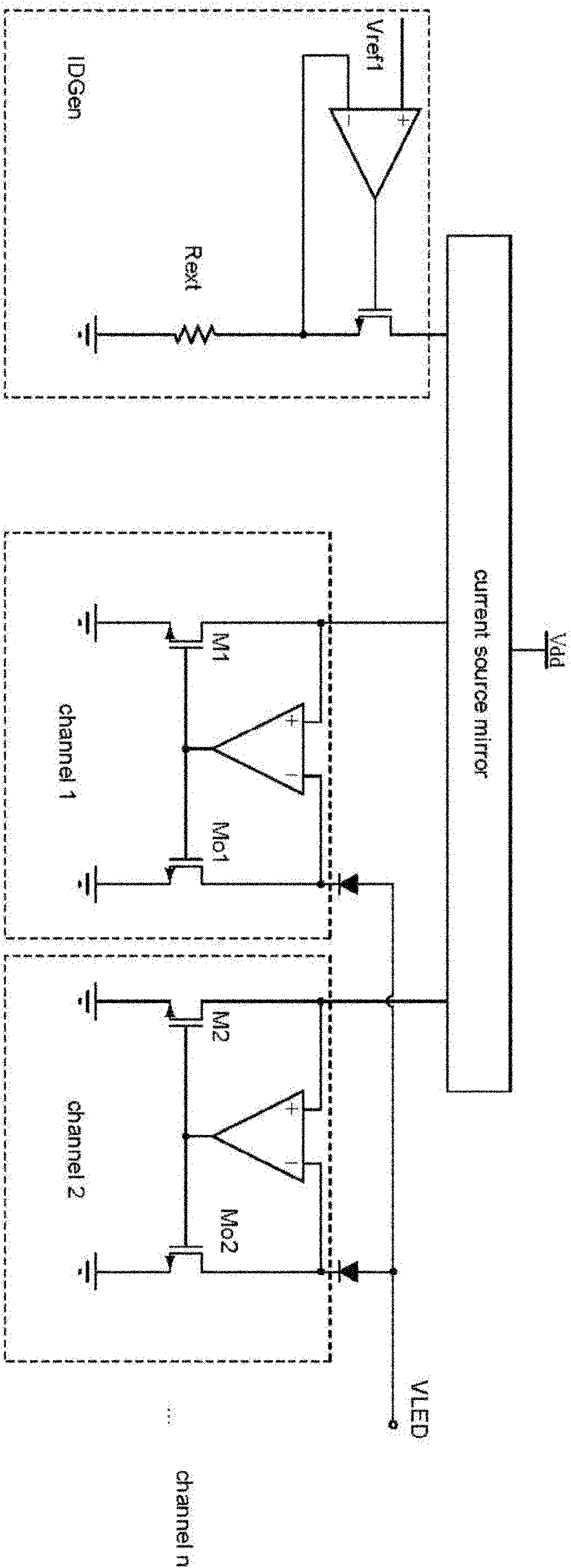

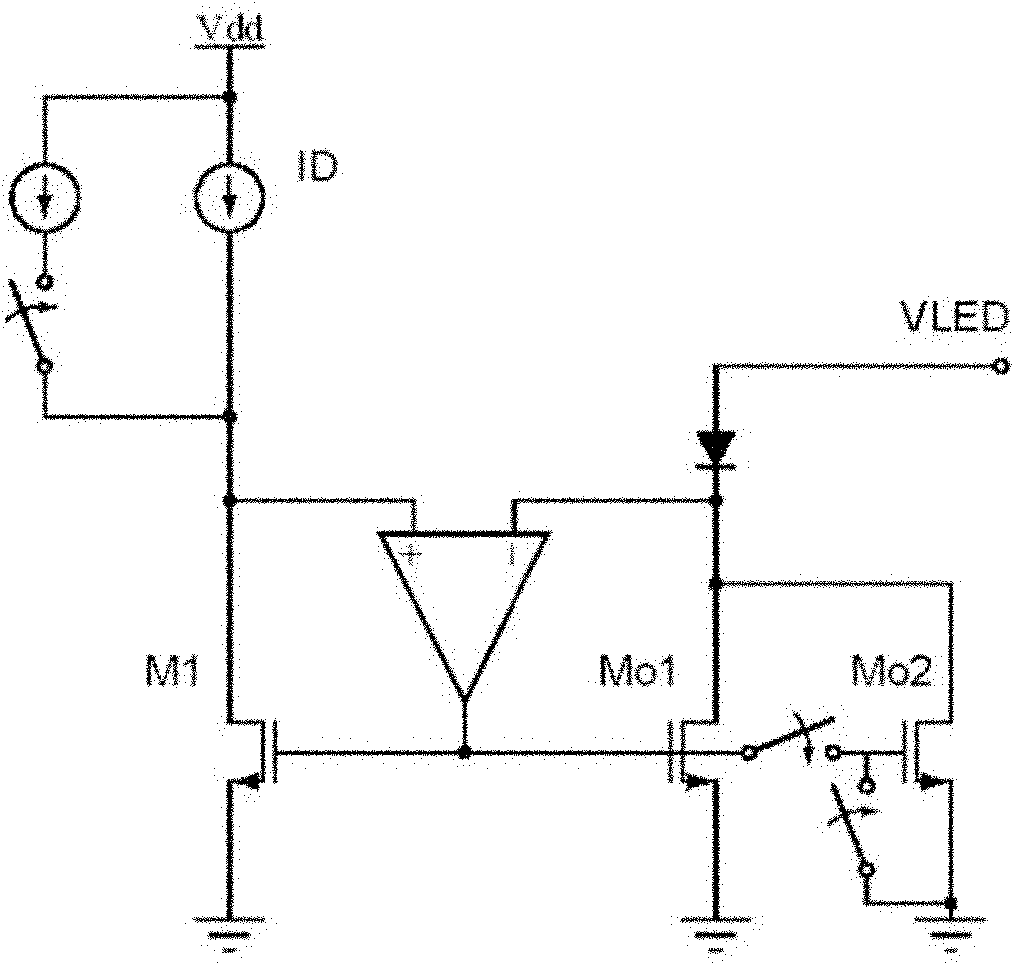

[0017] figure 2 For the concrete circuit diagram of the structural embodiment that the present invention proposes, as figure 2 As shown, the structure gives a schematic diagram of the two channels. IDGen generates ID, and the current mirror generates Iref, which is provided to different channels. In order to make the replication more accurate and make the power tube work in the linear region, its mismatch is given by the following formula:

[0018] ΔIout Iout = Δ ( W L ) ( W L ) + Δ ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com