Diamond / W-C gradient structure composite coating and preparing method thereof

A gradient structure, composite coating technology, applied in the direction of metal material coating process, coating, overlay plating, etc., to achieve the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

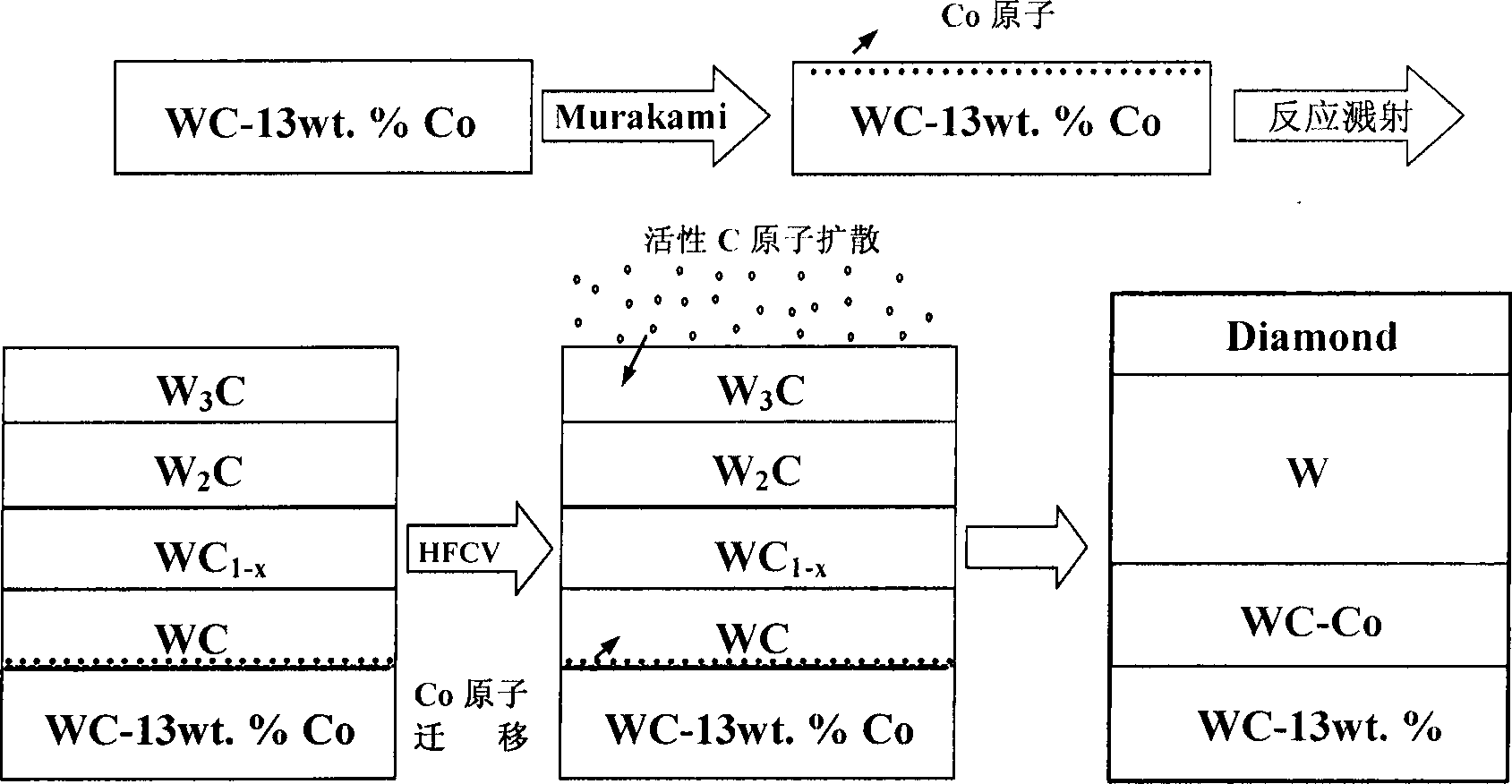

[0035] Embodiment 1: a kind of diamond / W-C gradient structure composite coating, comprise the transition layer of W-C gradient structure and diamond wear-resistant layer, described transition layer is made up of WC layer and WC-Co layer, and described wear-resistant layer is diamond film. The thickness of the transition layer is 0.5-15 μm, and the thickness of the wear-resistant layer is 4 μm; the WC layer includes the following four layers in turn: WC, WC 1-x , W 2 C and W3 C; where the value range of x is 0.34-0.43.

Embodiment 2

[0037] A preparation method of diamond / W-C gradient structure composite coating is as follows:

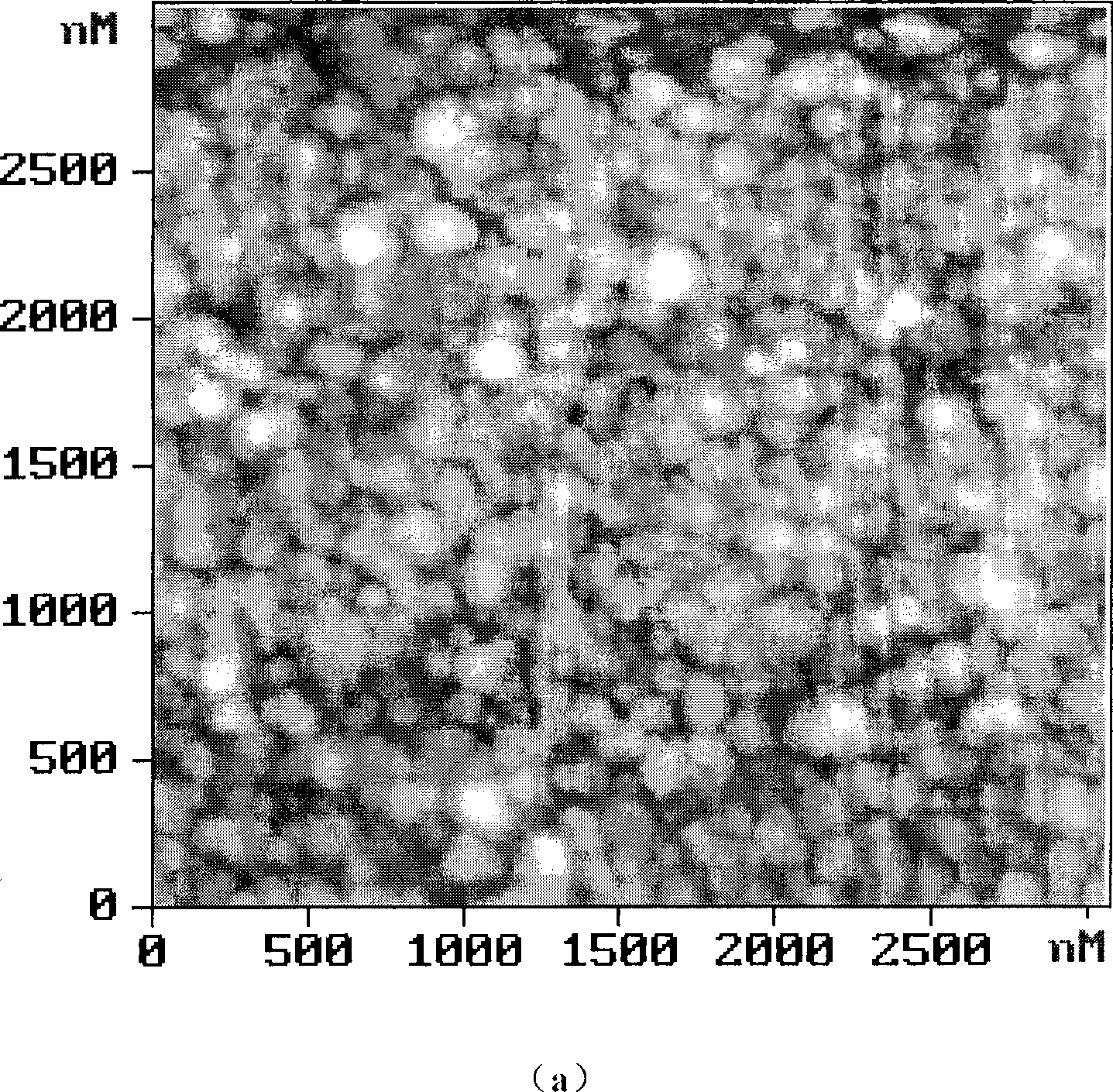

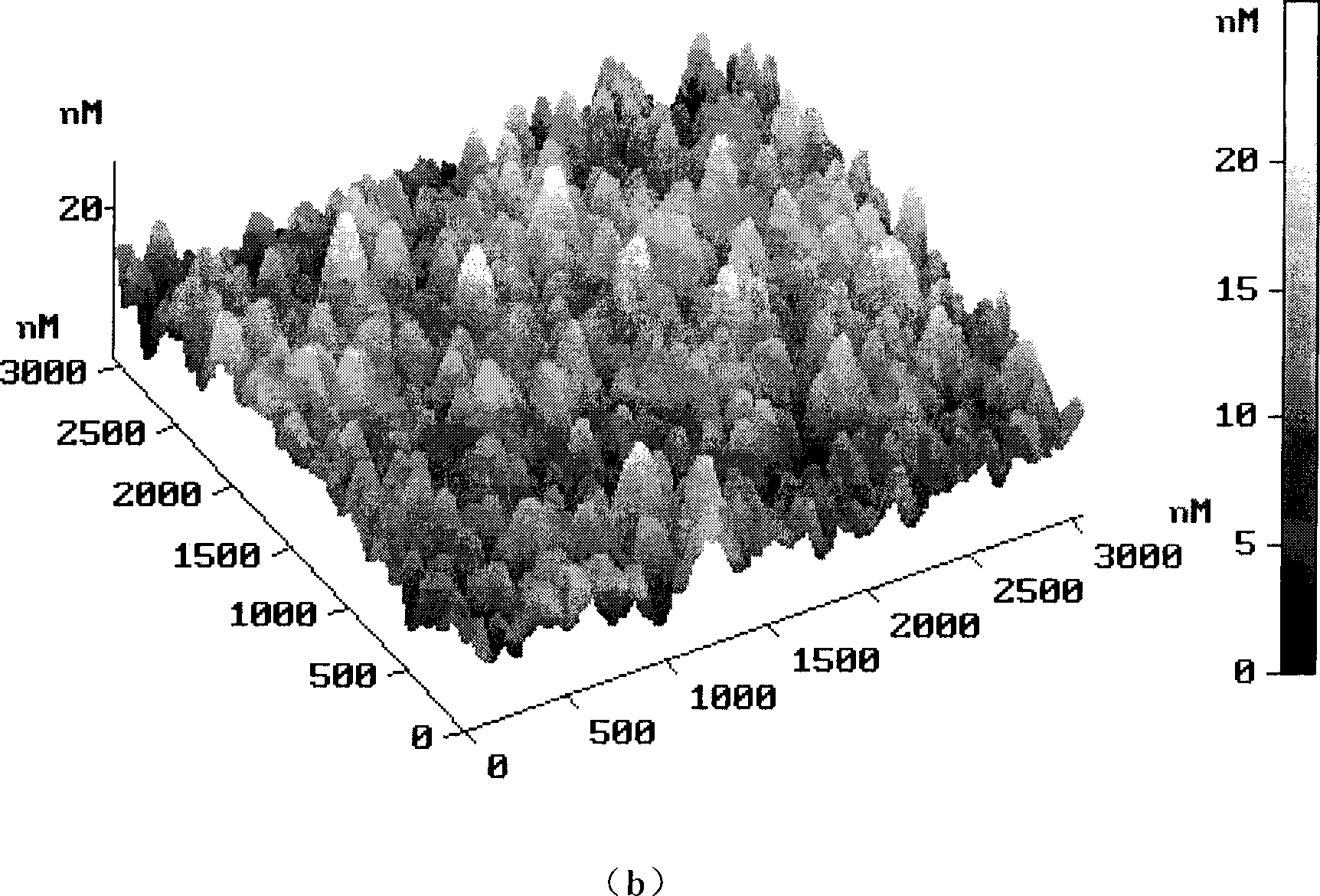

[0038] 1. The sample is WC-13%wt.Co (that is, YG13, containing 13% (mass ratio) of Co, and 87% (mass ratio) of WC). After polishing with diamond powder polishing agent, the atomic force microscope The detected surface roughness is less than 50nm. After treatment, wash with distilled water and dry for later use.

[0039] 2. Prepare a cobalt-rich layer on the surface of the sample: use K 3 [Fe(CN) 6 ]:KOH:H 2 O=1:1:10 (volume ratio) Murakami reagent was ultrasonically etched for 3 minutes, and the ultrasonic power was 100W.

[0040] 3. Gradient transition layer preparation: The sample was washed repeatedly with distilled water and absolute ethanol, and then reactively sputtered to prepare a W-C gradient transition layer. First, a layer of WC is deposited on the surface of the sample by reactive sputtering, and then the volume percentage of carbon-containing gas in the reaction at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com