Patents

Literature

82results about How to "Low room temperature resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon nanotube-graphene oxide mixed reinforced composite material

ActiveCN106189088AEvenly dispersedGood self-sustainabilityHeat-exchange elementsPorous carbonResin matrix

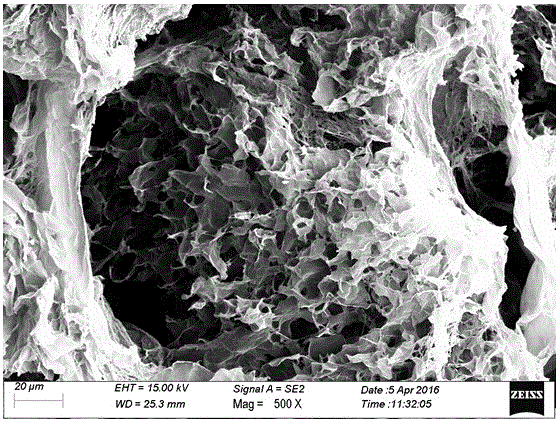

The invention belongs to the field of polymer matrix composite manufacturing, and particularly relates to a preparation method of a carbon nanotube-graphene oxide mixed reinforced composite material. Graphene oxide and carbon naotubes are assembled into a nano-carbon mixed structure reinforcement with the high self-supporting property, and after resin matrix infiltration and polymerization, the carbon nanotube-graphene oxide mixed reinforced composite material is obtained; the porous carbon nanotube-graphene oxide reinforcement with the low density and the high specific surface area is prepared by taking 2-ethyl-4-methylimidazole as a bridge between the nanotubes and graphene oxide, and the reinforcement retains the respective characteristics of graphene oxide and the carbon nanotubes and is composited with multiple resin matrixes by serving as three-dimensional macroscopic continuous reinforcement with the high electricity conductivity and thermal conductivity, and then the multifunctional low-cost carbon nanotube-graphene oxide mixed reinforced composite material is prepared.

Owner:淮安航空产业研究院有限公司

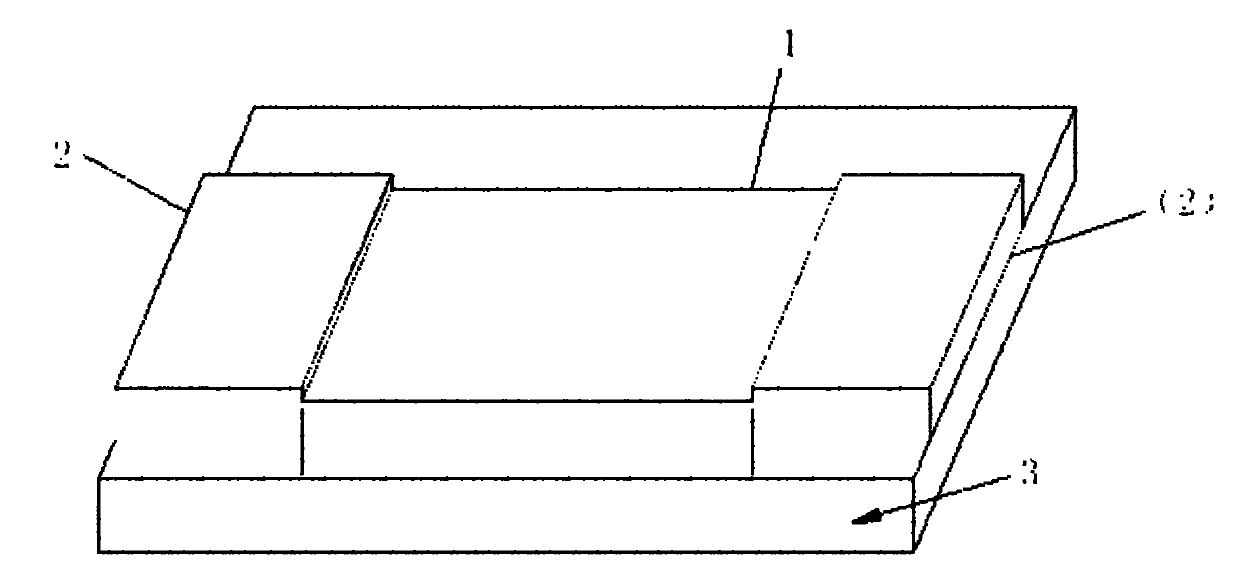

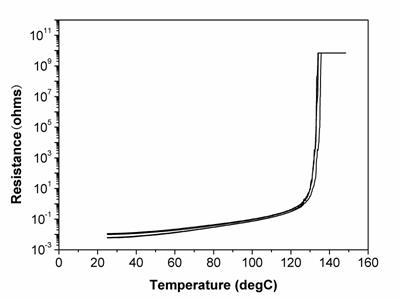

Conductive composite material and PTC (Positive Temperature Coefficient) thermal sensitive element prepared from same

InactiveCN102127287AImprove conductivityLow room temperature resistivityNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsMetal foilPhosphoric acid

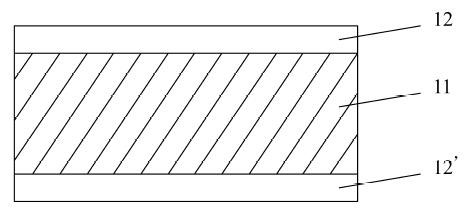

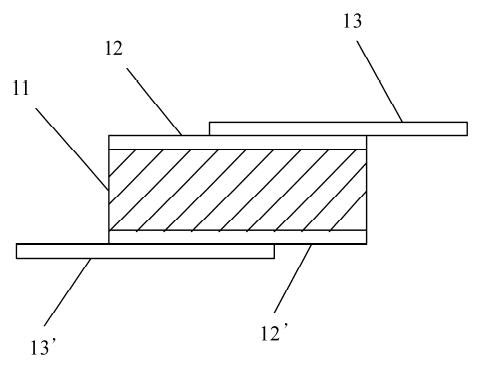

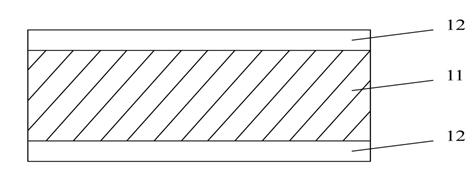

The invention relates to a conductive composite material and a PTC (Positive Temperature Coefficient) thermal sensitive element prepared from the same. The conductive composite material comprises the following components in parts by volume: 15-75 percent of crystalline polymer substrate and 25-85 percent of conductive filler with the particle size between 0.1 mum and 10 mum, wherein the conductive filler is dispersed in the crystalline polymer; and a coupling agent is titanic acid ester which accounts for 0.05-5 percent by volume of the conductive filler. The structural formula of the conductive composite material is (R1O)m-Ti-(OX-R2-Y)n, wherein radical R1 is alkyl, radical X is phosphoric acid easer base, radical R2 is alkyl, radical Y is acyloxy, m is more than or equal to 1 and less than or equal to 4, n is more than or equal to 1 and less than or equal to 3, and m and n are integers. The PTC thermal sensitive element prepared from the conductive composite material is formed by fixedly clamping a conductive composite material layer between two metal foils. The invention has the advantages that: the conductive material has high electric conductivity; and the PTC element prepared from the conductive composite material has very low room temperature resistivity, high PTC intensity and resistance reproducibility.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

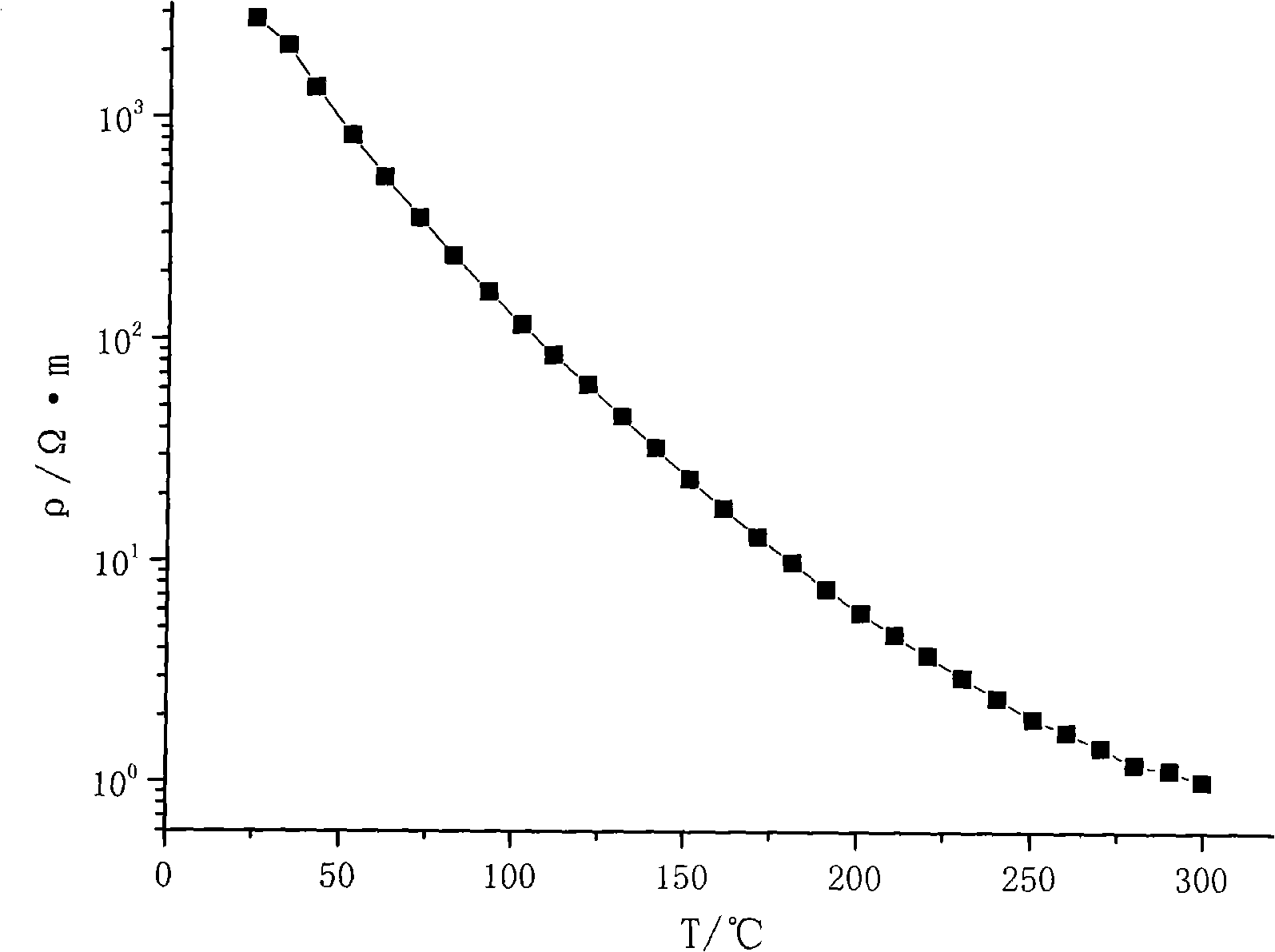

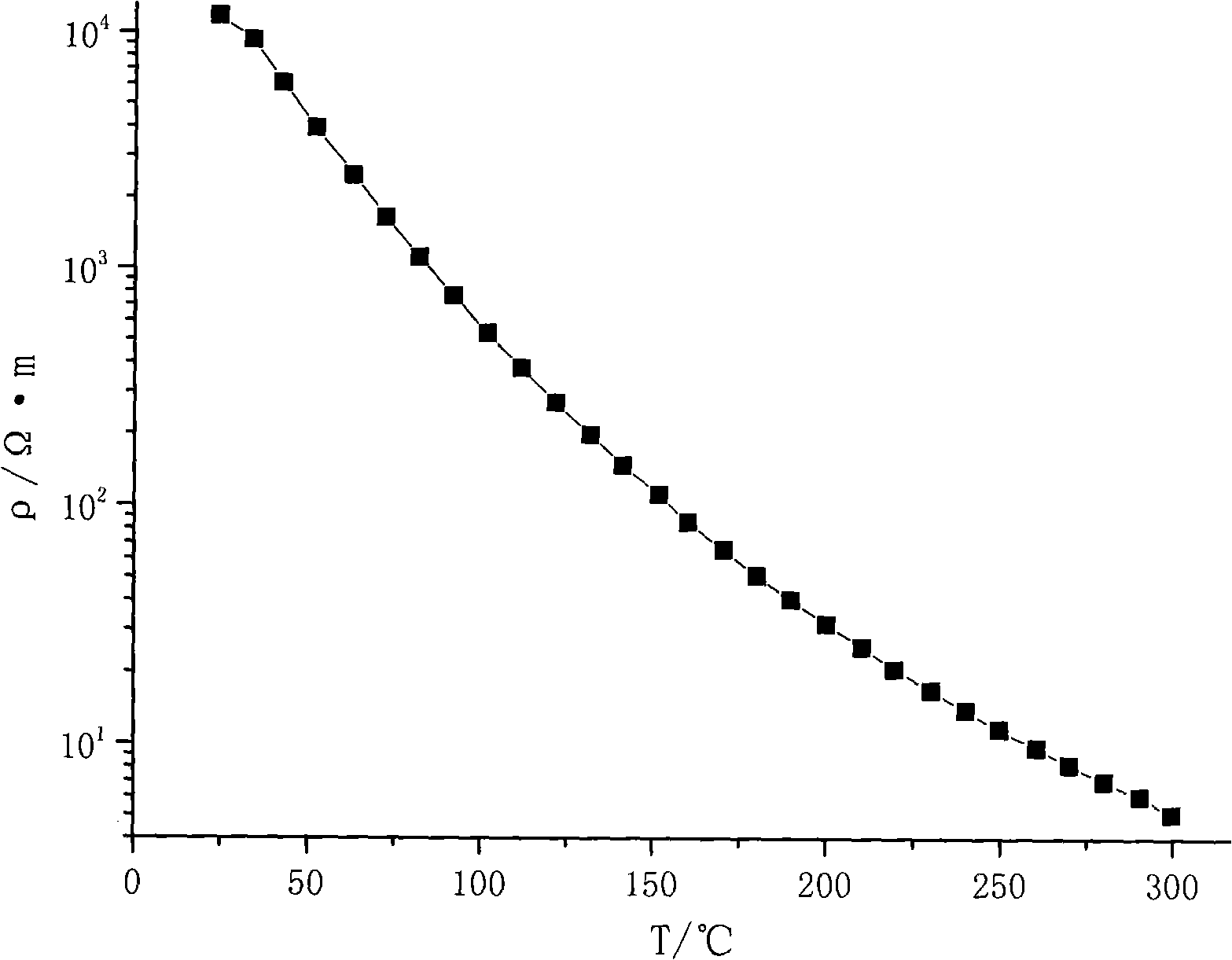

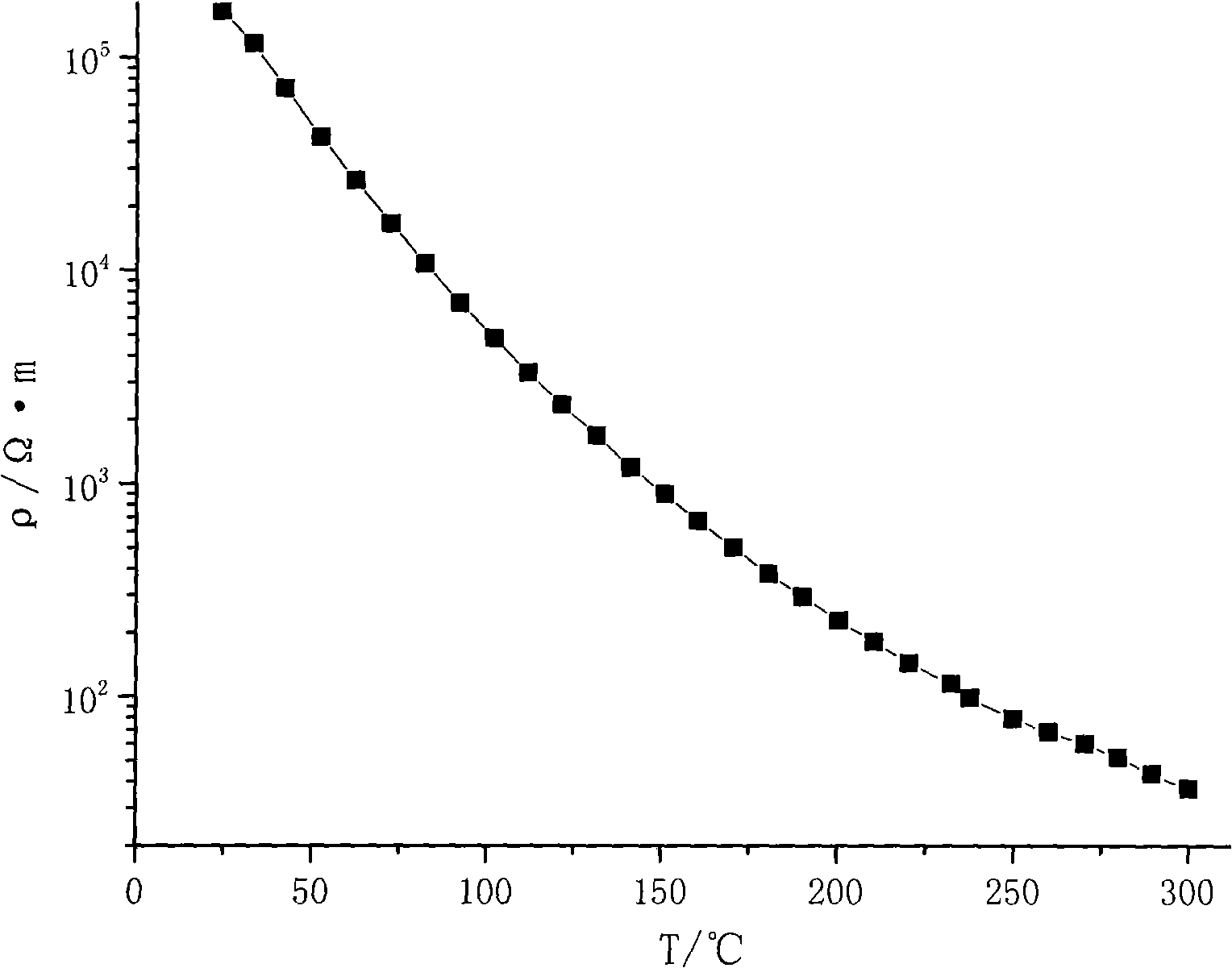

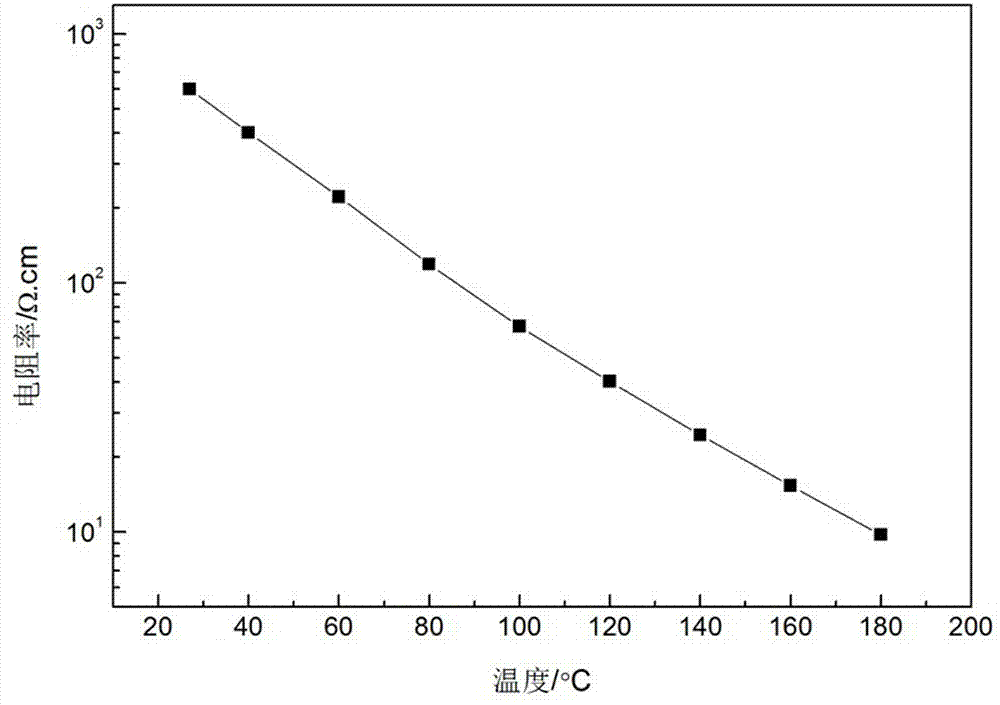

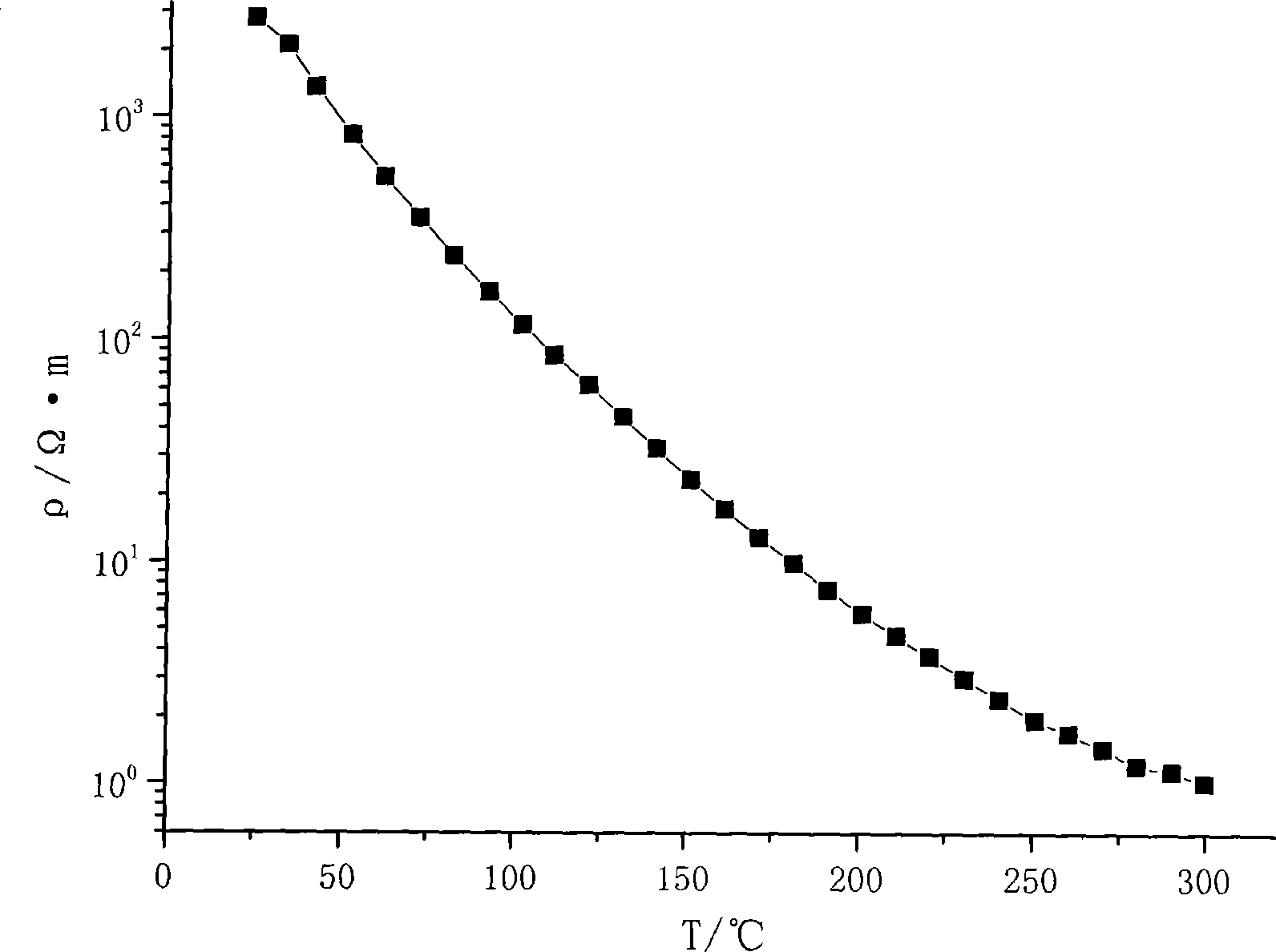

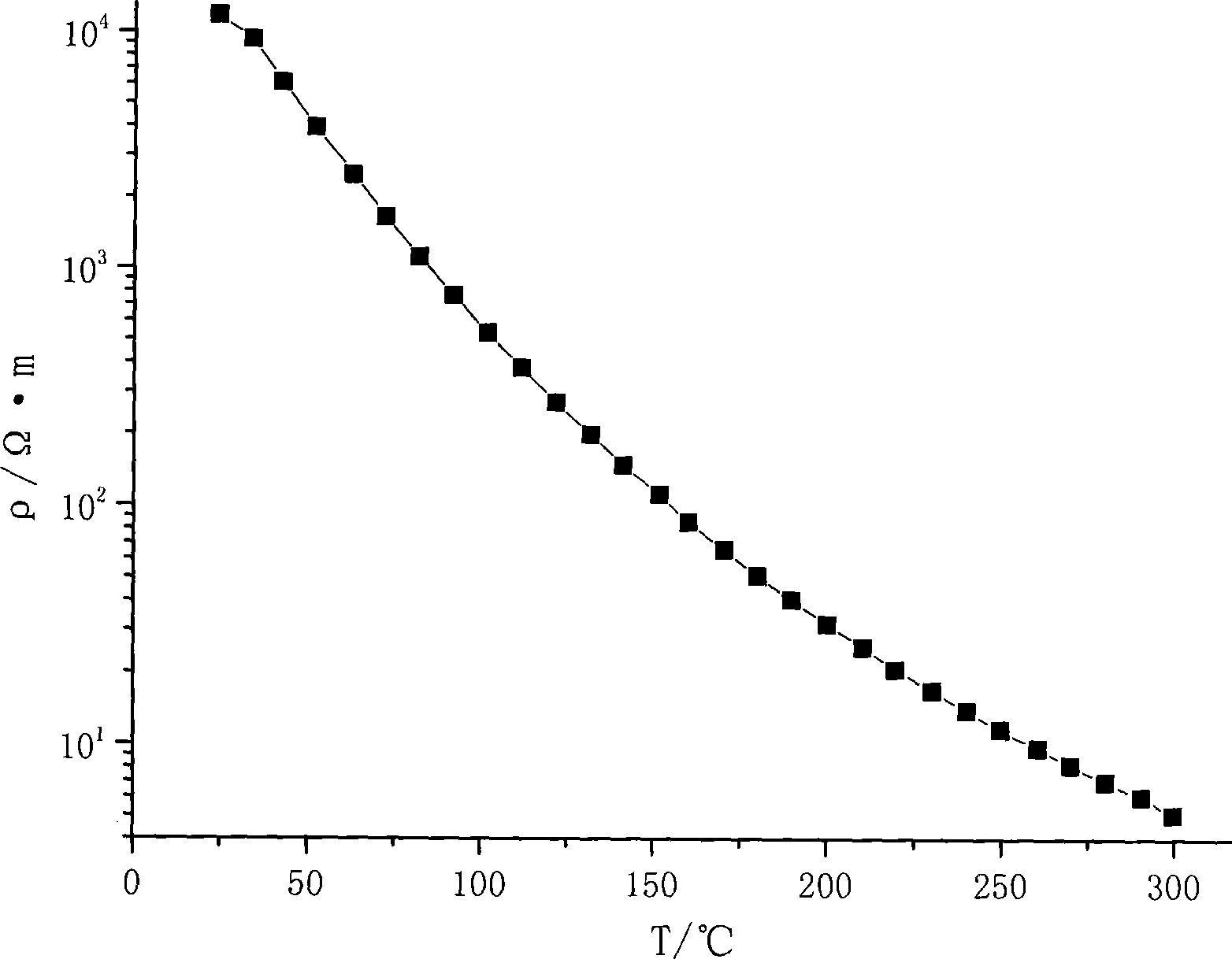

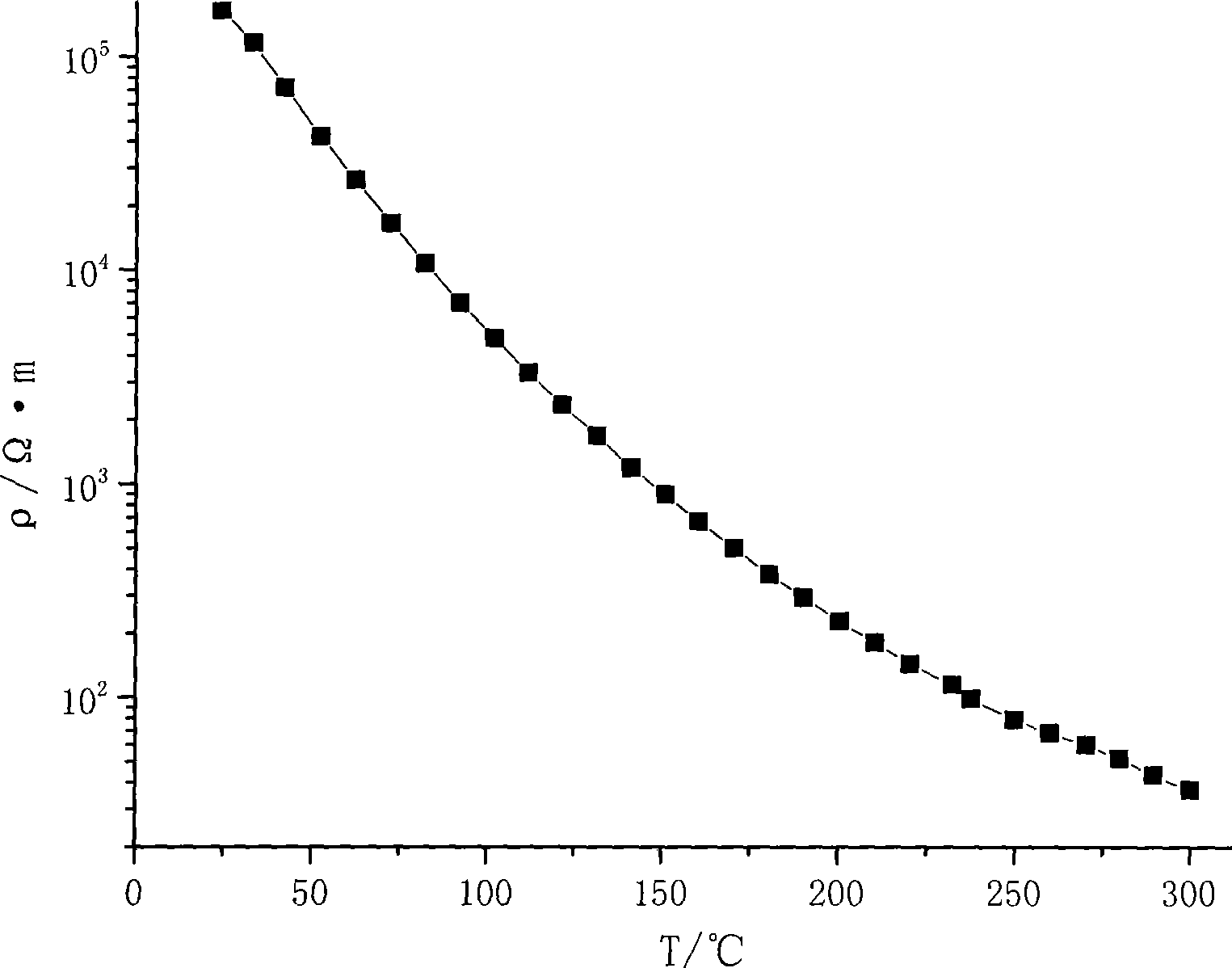

NTC heat-sensitive conductive ceramic material and method of manufacturing the same

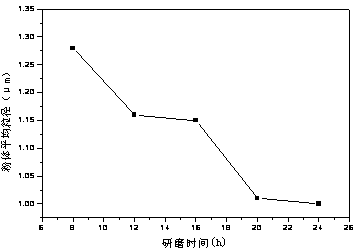

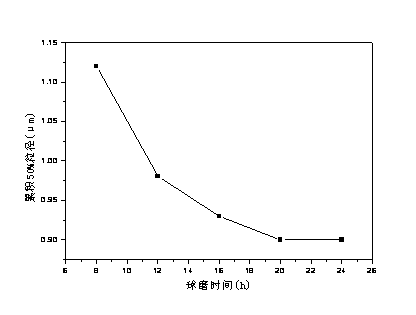

The invention discloses an NTC heat sensitive conducting ceramic material and a method for preparing the same. The method for preparing the NTC heat sensitive conducting ceramic material comprises the following steps: using BaCO3, SrCO3, SnO2 and Fe2O3 as main raw materials, mixing and ball-milling the raw materials, and drying the mixture to obtain a Ba1-ySryFexSn1-xO3 blank which is not doped, or doped singly, or doped compositely for a secondary ball milling; and adopting an ordinary ceramic preparation process. The B value of the NTC heat sensitive conducting ceramic prepared in the invention can reach 5,100K, and the resistivity at room temperature can be reduced to 2,800 omega.m. The NTC heat sensitive conducting ceramic material has simple preparation process and low cost, and the obtained products can be applied to the aspects of temperature measurement, temperature control, automatic gain adjustment, temperature compensation and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

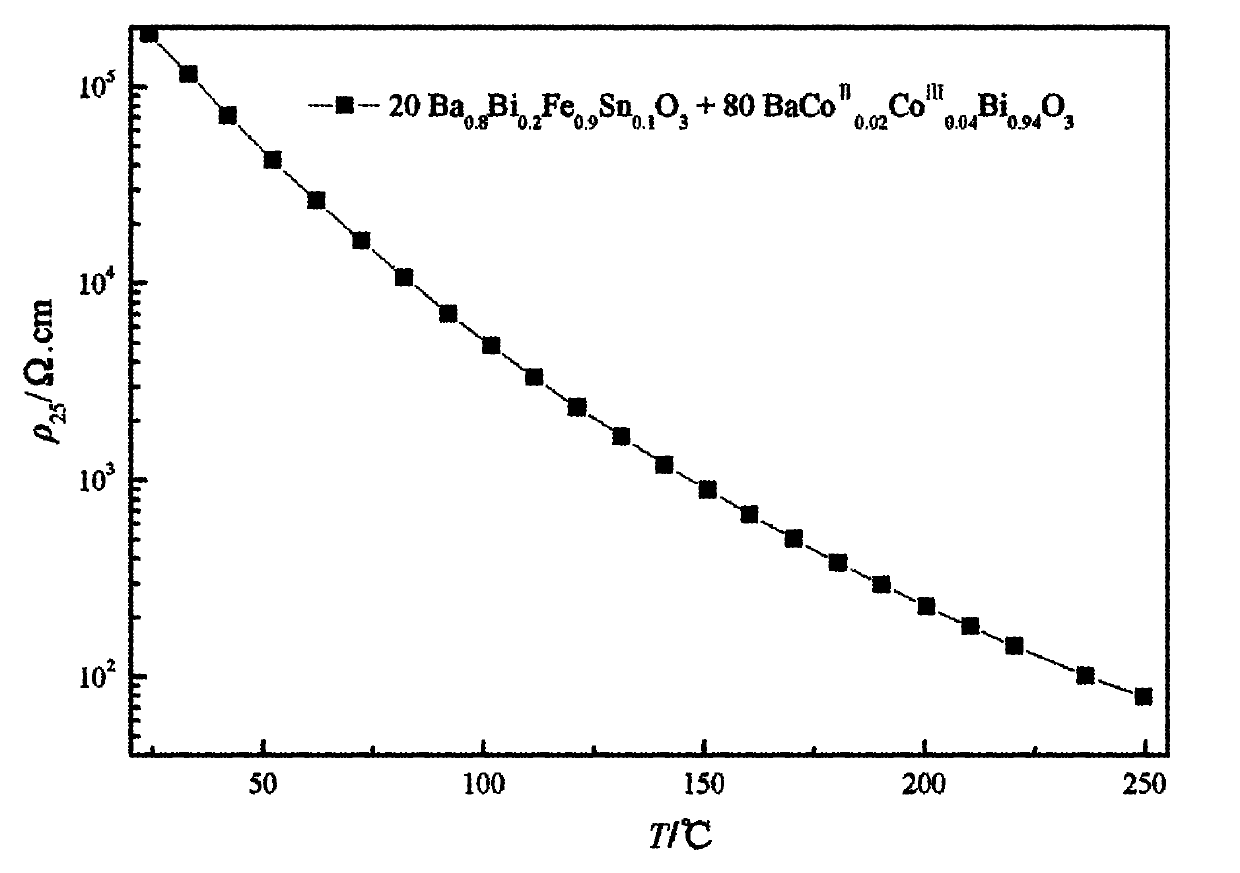

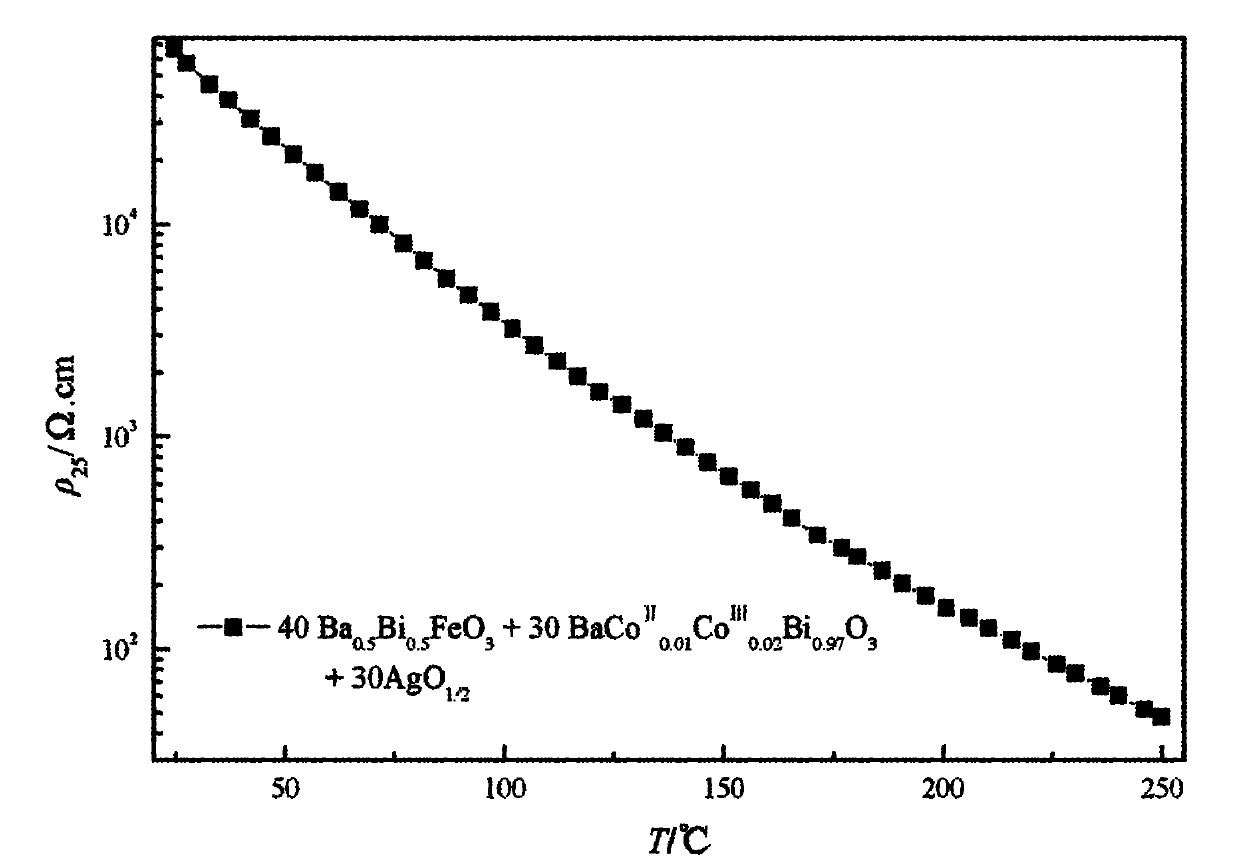

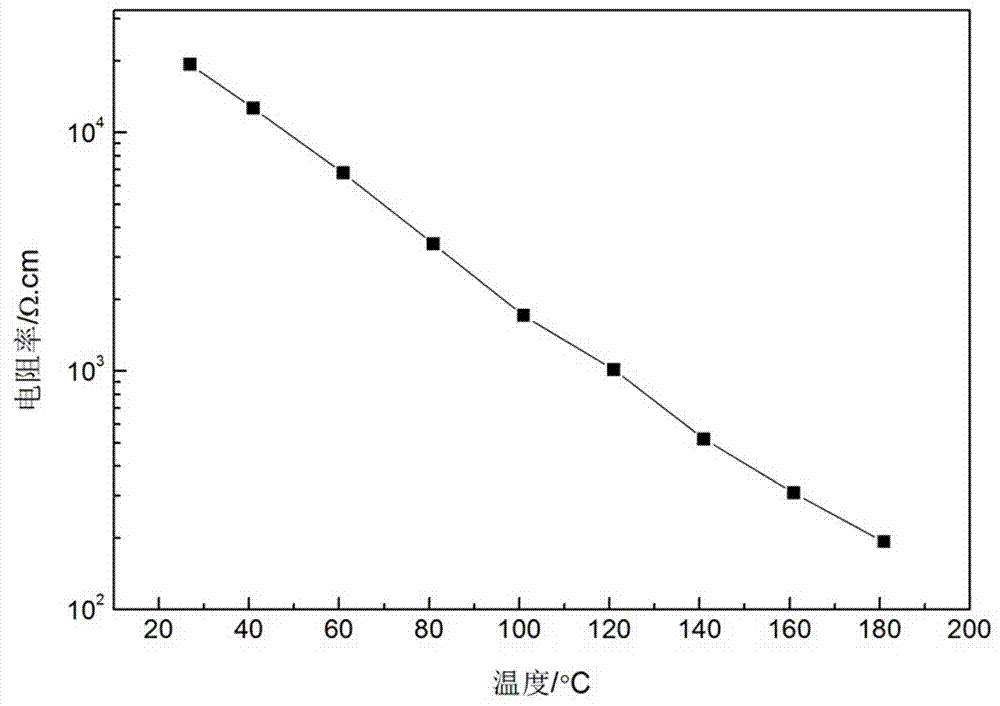

High-performance lead-free negative temperature coefficient temperature-sensitive thick film and preparation method thereof

InactiveCN102005273AImprove thermal performanceIncreased thermal constant valueNegative temperature coefficient thermistorsResistor manufactureNanotechnology

The invention discloses a high-performance lead-free negative temperature coefficient temperature-sensitive thick film and a preparation method thereof. Major composite components are combined in two combination modes. In an inorganic phase I combination mode, (1-t)Ba1-yMyFe1-xSnxO3+tBaCo<II>zCo<III>2zBi1-3zO3, wherein t is more than or equal to 0.4 and less than or equal to 0.95 and is a molar ratio; and in an inorganic phase II combination mode, (1-m-1)Ba1-yMyFe1-xSnxO3+mBaCo<II>zCo<III>2zBi1-3zO3+1 / 2Ag2O, wherein m is more than or equal to 0.3 and less than or equal to 0.65; l is more than or equal to 0.05 and less than or equal to 0.3; m and l are molar ratios; and the composite components are uniformly mixed with an organic carrier in the mass ratio of 75:25 so as to form thick film resistance paste. The preparation method comprises the following steps of: printing the paste on a substrate by a screen printing process; flattening, baking, pre-sintering and repeatedly printing so as to obtain a thick film biscuit with a required thickness; and sintering the biscuit at the temperature of between 750 and 850 DEG C and preserving heat for 40 to 80 minutes so as to obtain the lead-free negative temperature coefficient temperature-sensitive thick film. The thick film has a simple preparation process and a low film forming temperature, the film thickness is between 10 and 100 mu m, the temperature sensitive constant value is between 2,500 and 5,500 K, the room temperature resistivity is between 150 ohm.cm and 10 M ohm.cm and the aging resistant time is over 800 hours.

Owner:GUILIN UNIV OF ELECTRONIC TECH

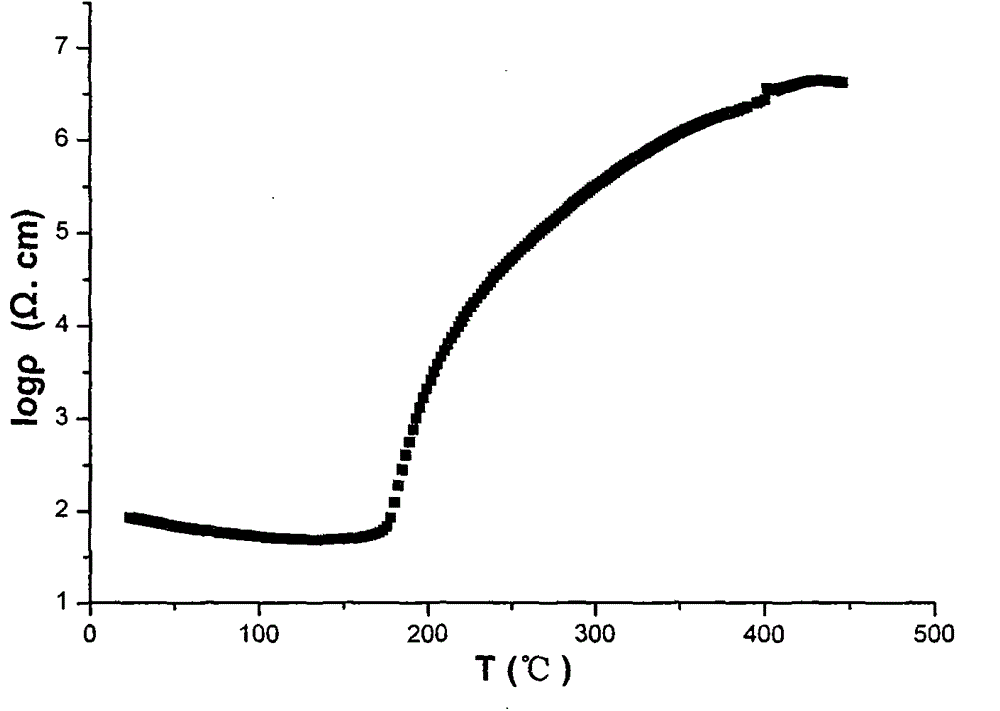

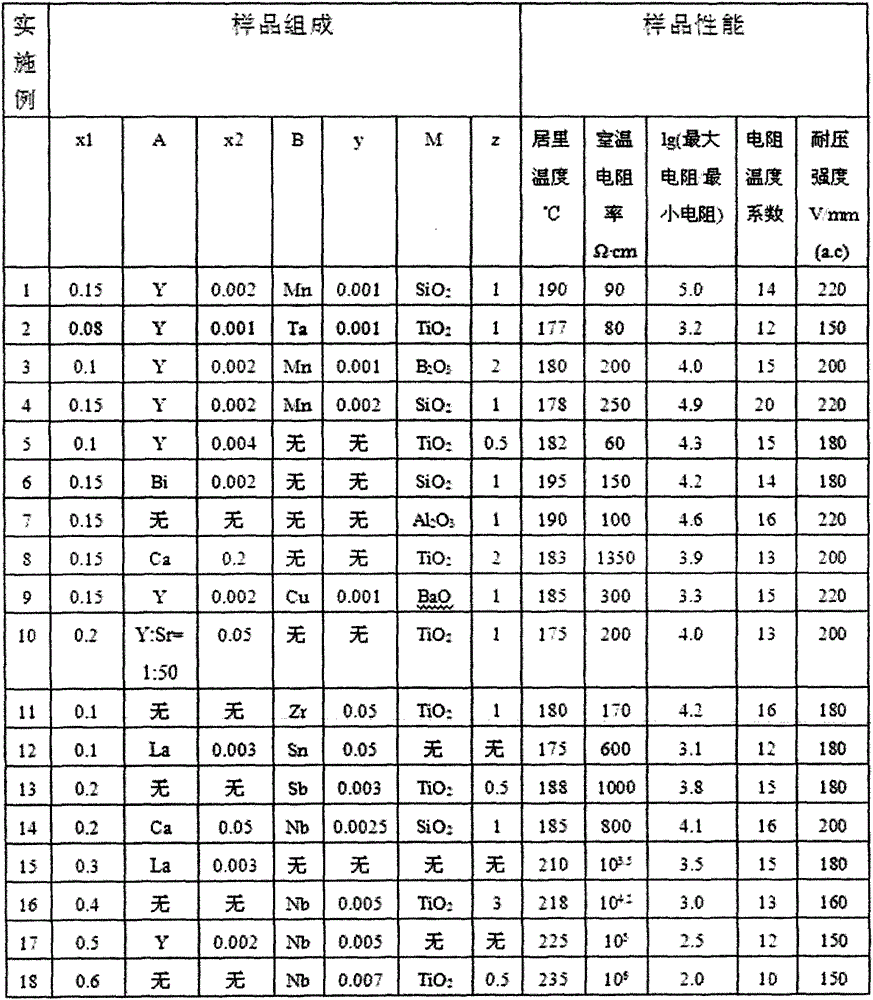

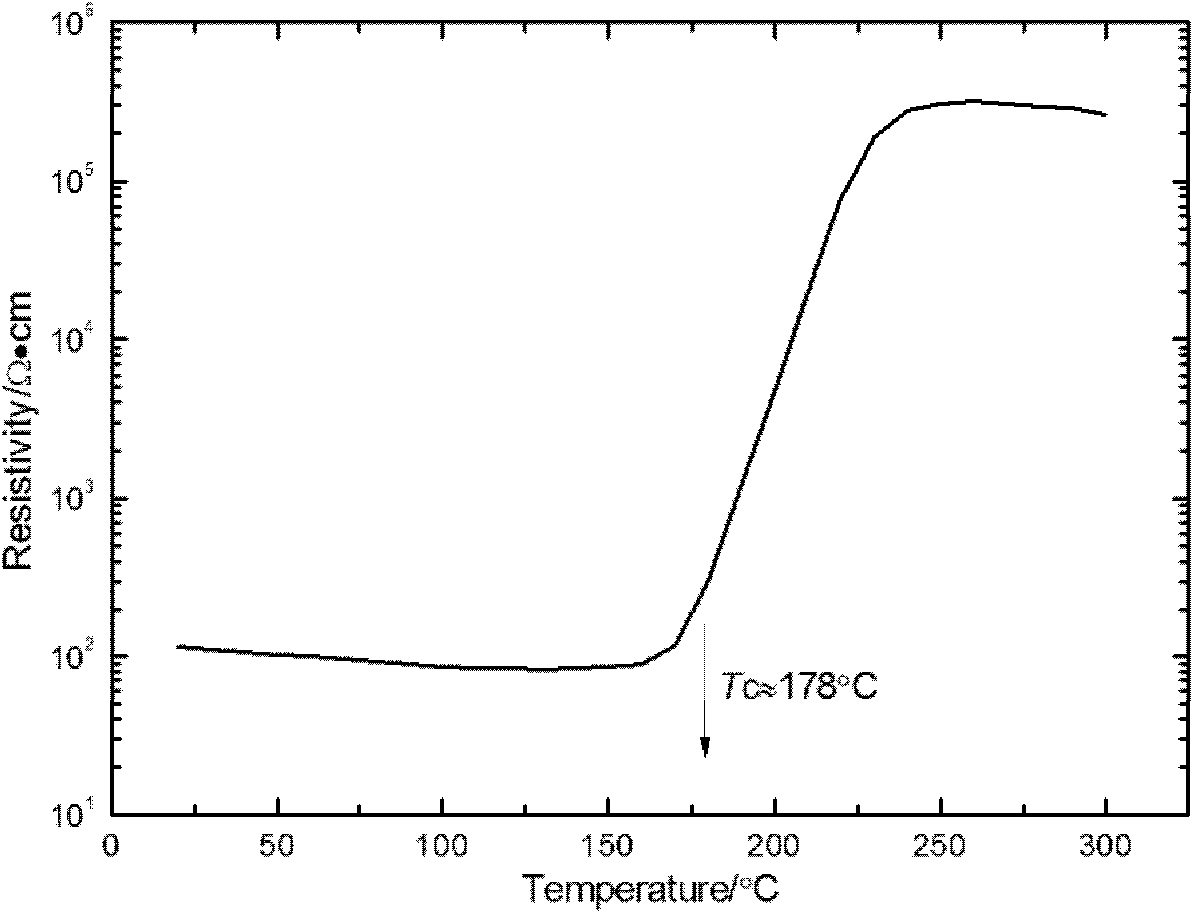

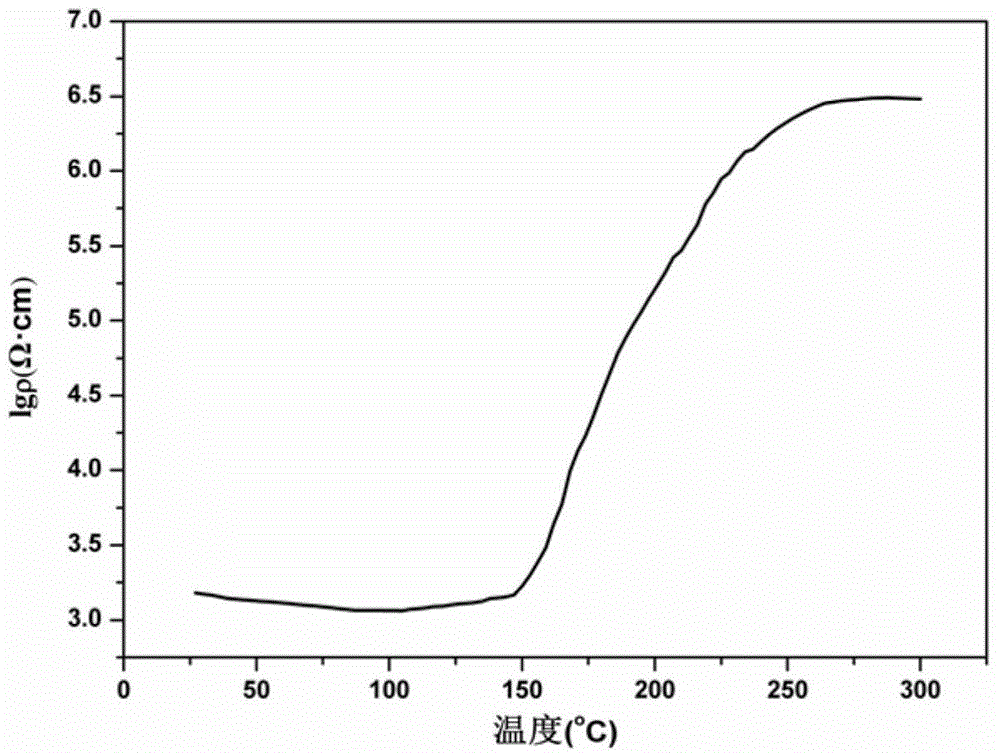

High use temperature lead-free PTCR (positive temperature coefficient resistance) ceramic and preparation method thereof

The invention discloses a high use temperature lead-free PTCR (positive temperature coefficient resistance) ceramic and a preparation method thereof, and belongs to the field of lead-free electronic ceramic materials. A general formula of the material composition is as follows: (Na0.5Bi0.5)x1 (Ba1-x1-x2Ax2) Ti1-yByO3+zmol%M), wherein x1 is greater than or equal to 0.08 and less than or equal to 0.6, x2 is greater than or equal to 0 and less than or equal to 0.2, y is greater than or equal to 0 and less than or equal to 0.05, z is greater than or equal to 0 and less than or equal to 3, A is one or more of Sr, Ca, Bi, Y and La, B is one or more of Zr, Sn, Mn, Cu, Nb, Ta and Sb, and M is one or more of Al2O3, SiO2, TiO2, BaO and B2O3. The high use temperature lead-free PTCR ceramic prepared by method has the following performance indicators: Curie temperature is at 175 to 235 DEG C; resistance jump ratio is 2 to 5 orders of magnitude; room temperature resistivity is 60-106 Omega .cm; temperature coefficient of resistance is 10-20% / DEG C; and withstand voltage strength is 150-220V / mm (a.c.). A ceramic sample is prepared in nitrogen by one-step sintering method, and has the advantages of simple controllable process, stable material performance and good repeatability.

Owner:TONGREN UNIV

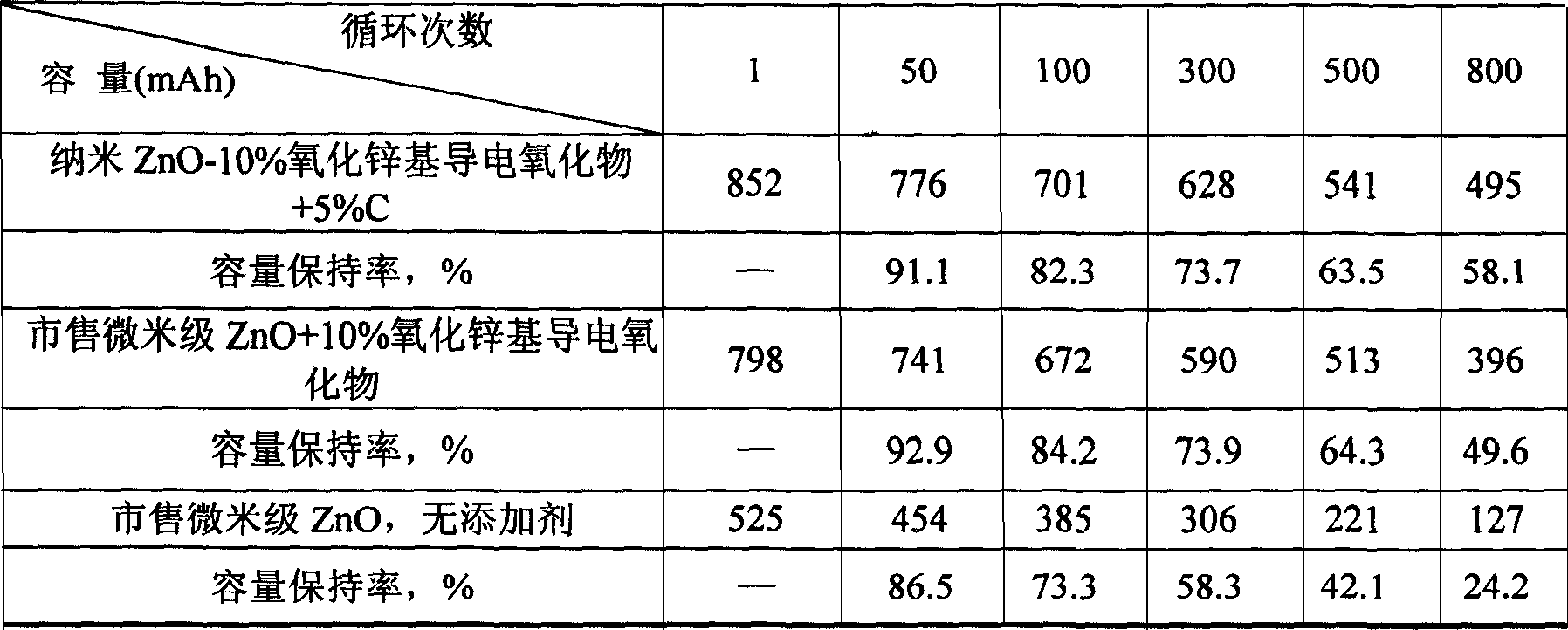

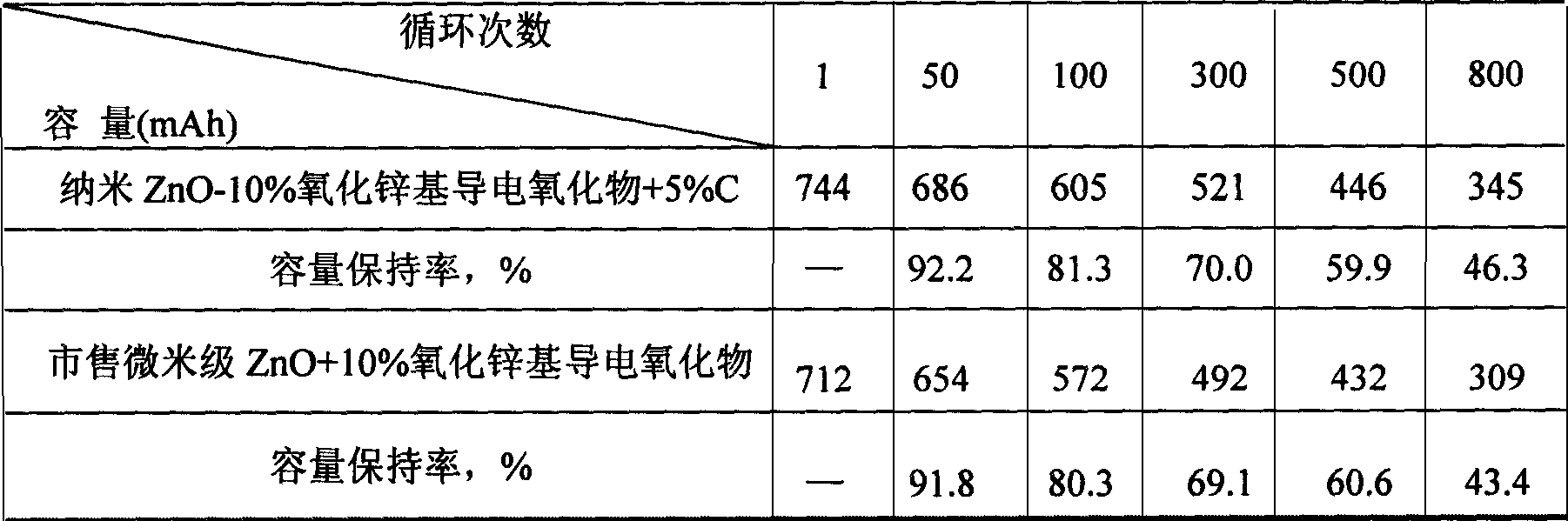

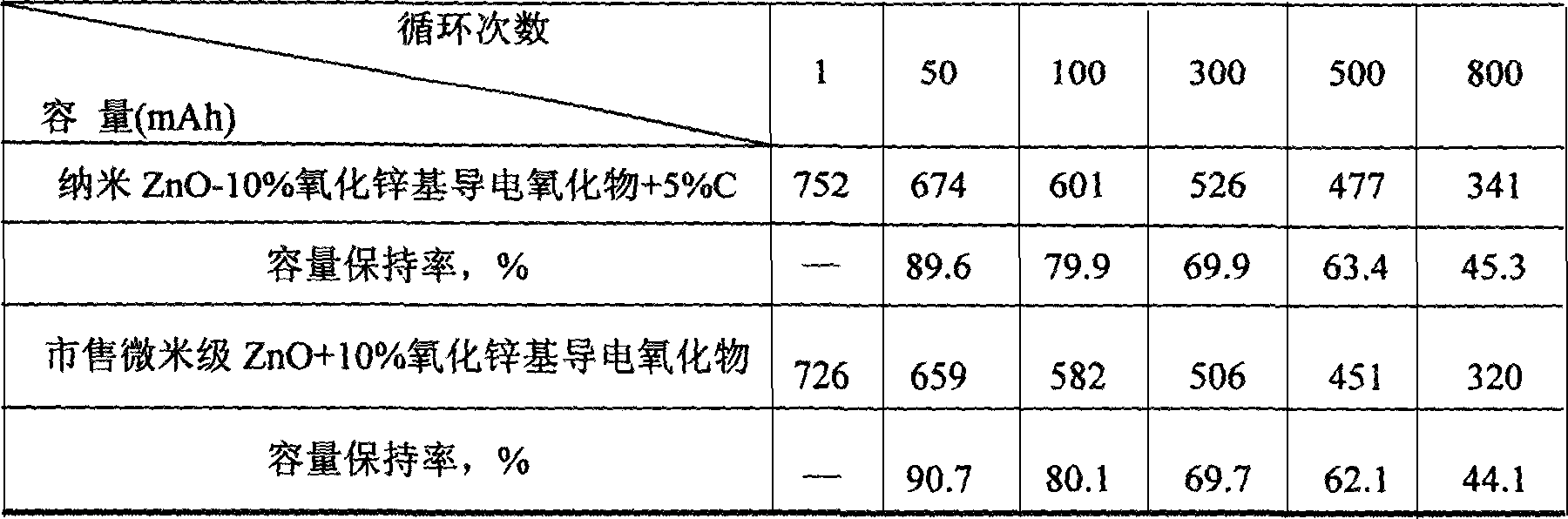

Cathode material for alkaline secondary zinc electrode and its preparing method

InactiveCN1744355AImprove electrochemical performanceReduce and prevent internal resistanceElectrode manufacturing processesAlkaline accumulator electrodesChemical compositionInternal resistance

Conducting oxide based on zinc oxide is as kernel. Nano grains of zinc oxide wrap outside kernel evenly. Primary chemical composition of the zinc oxide based conducting oxide is ZnO and CO2O3. The said zinc oxide based conducting oxide can also be conducting oxides of containing Bi2O3, Co2O3, La2O3 etc. Method of deposition in homogeneous phase is adopted to prepare the disclosed material for cathode. Advantages are: (1) being added to zinc electrode, the zinc oxide based conducting oxide can be as center of crystallization; increasing use ratio of active material and discharge capacity, and reducing and preventing generation of tree like crystal of zinc, and raising cycle life of electrode; (2) reducing internal resistance of electrode. The invention possesses favorable effect for improving synthetical electrochemical performance of secondary zinc electrode.

Owner:ZHEJIANG UNIV OF TECH

PTC (Positive Temperature Coefficient) protection element capable of maintaining ultralarge current

InactiveCN105139984ALower resistanceImprove conductivityCurrent responsive resistorsPositive temperature coefficient thermistorsElectric carsCrystallinity

The invention discloses a PTC (Positive Temperature Coefficient) protection element capable of maintaining ultralarge current, which comprises a first external conducting metal pin, a second external conducting metal pin and a resistance PTC chip, wherein the resistance PTC chip is arranged between the first external conducting metal pin and the second external conducting metal pin; the resistance PTC chip comprises (1) at least one crystallinity high polymer material; (2) a conductive filler dispersed in the crystallinity high polymer material, wherein the mass resistivity of the conductive filler is lower than 200[mu]omega.cm, heat conductivity is larger than 10W / (m.k), the particle size is between 0.1[mu]m to 30[mu]m and D50 is not larger than 20[mu]m; (3) and at least two metal electrode foils, wherein the first / second external conducting metal pin is respectively connected to the electrode foils at two faces of the PTC chip. The PTC thermal sensitive element has ultralow electrical resistance property, discharging of high voltage and large current is realized by low specific resistance and high thermal conductivity of the material while overtemperature protection under small current is realized, and application in an accumulator of an electric bicycle is realized.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

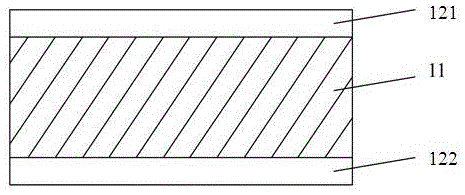

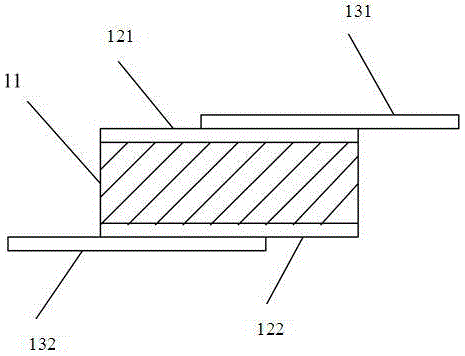

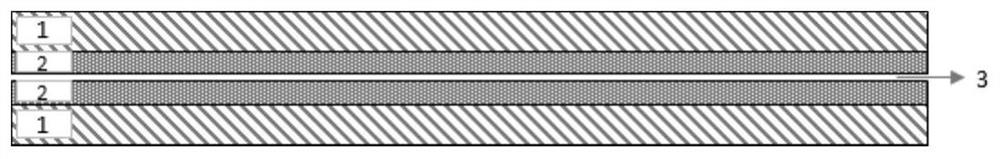

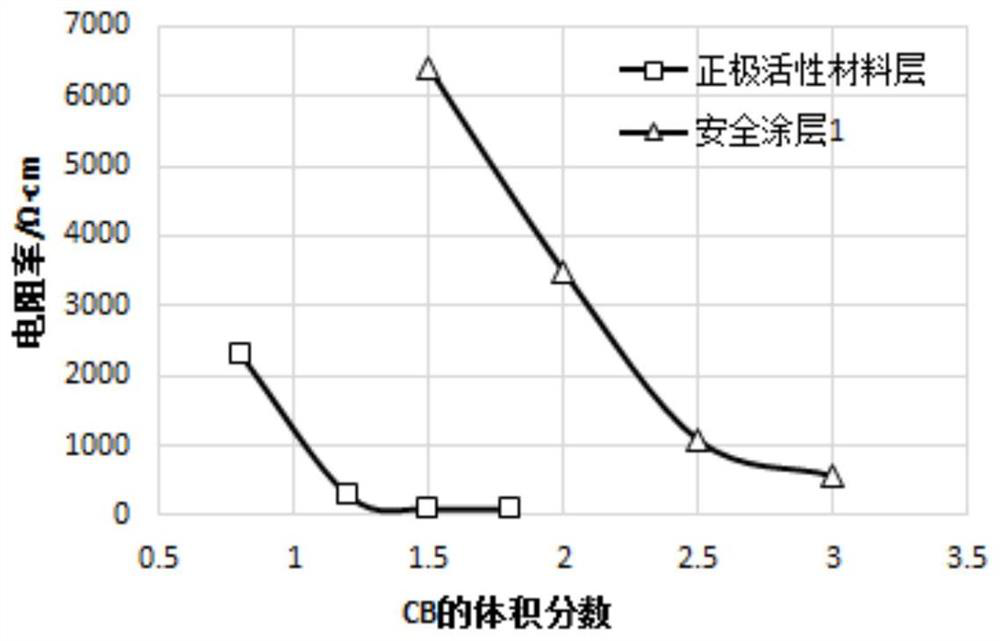

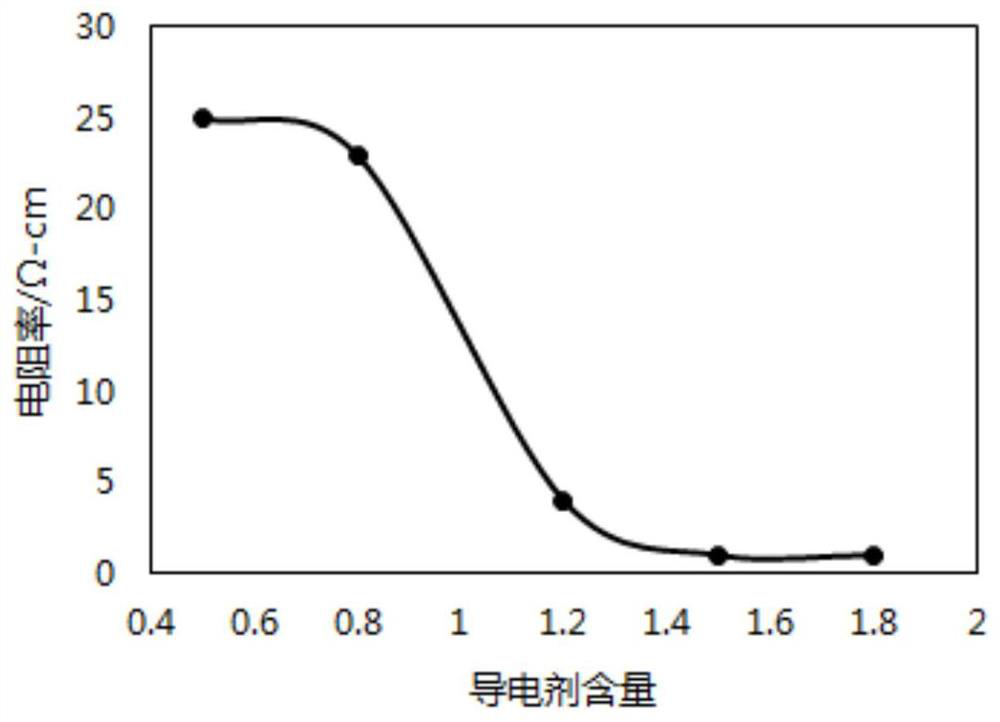

Positive plate and lithium ion battery containing positive plate

ActiveCN111900392AIncrease energy densityIncreased seepage thresholdPositive electrodesSecondary cells servicing/maintenanceHigh energyPhysical chemistry

The invention provides a positive plate and a lithium ion battery containing the positive plate. The safety of the battery cell is improved by controlling the seepage thresholds of the safety coatingcoating the surface of the positive current collector and the positive active material layer, and meanwhile, relatively high energy density and excellent electrical properties are ensured. Particularly, the seepage threshold value of the positive active material layer is small, and the addition amount of the conductive agent is small, so that a good electron path can be ensured, and the energy density of the positive plate can be increased.

Owner:ZHUHAI COSMX BATTERY CO LTD

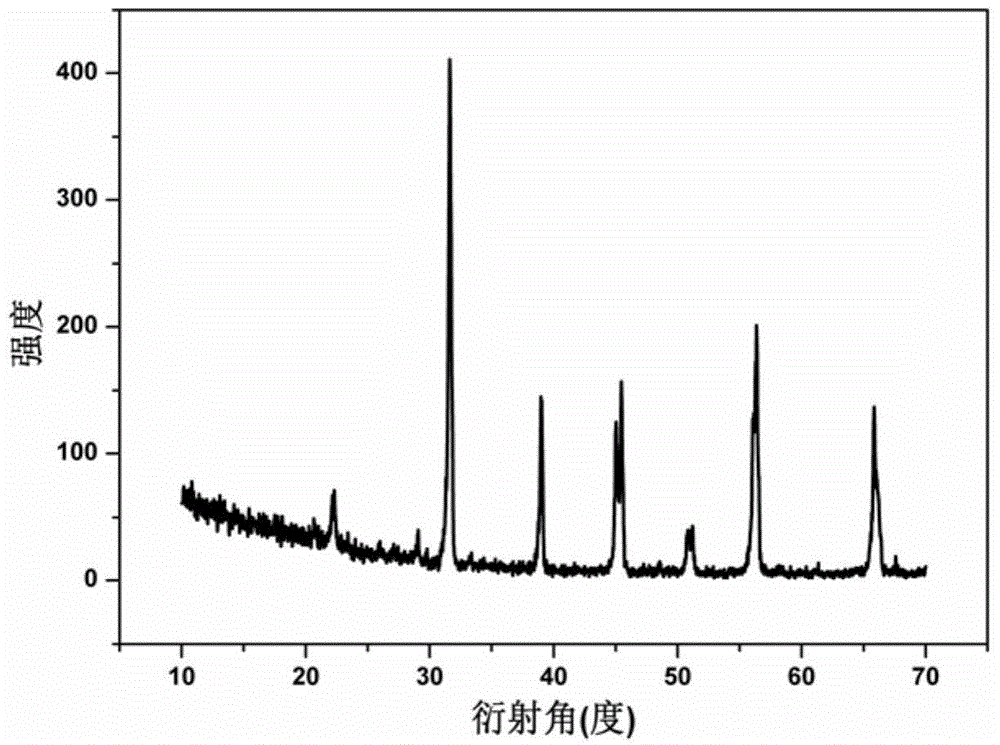

Doped BKT-BT series lead-free PTCR ceramic material and preparation method thereof

InactiveCN101624284AIncrease the slopeRaise resistance kickThermometers using electric/magnetic elementsUsing electrical meansTemperature coefficientPositive temperature

The invention relates to a doped BKT-BT series lead-free positive temperature coefficient resistance ceramic material and a prepration method thereof, the general formula of the composition of the material is (Bi0.5K0.5)*1(Ba1-*1-*2)AX2)Ti1-yMyO3+Zmol%D, wherein, x1 is more than 0 and not more than 0.7, x2 is more than 0 and not more than 0.6%, y is more than 0 and less than 0.2%, Z is not less than 0 and less than 1, A is one or more of Ce, Y, La and Bi, M is one or more of Nb, Sb, Ta and Mo, and D is one or more of MnO2, TiO2, SiO2 and B2O3. For a series of the lead-free ceramic materials, TC, alpha, betaRT and resistance sudden jump Rmax / Rmin are respectively changed between 140 and 250 DEG C, between 10 and 45% / DEG C, between 20 and 60 omega.Cm and between 10<2> and 10<5> along with the change of x1, x2, y and Z.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

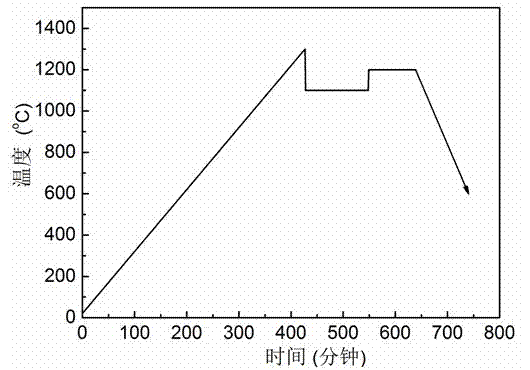

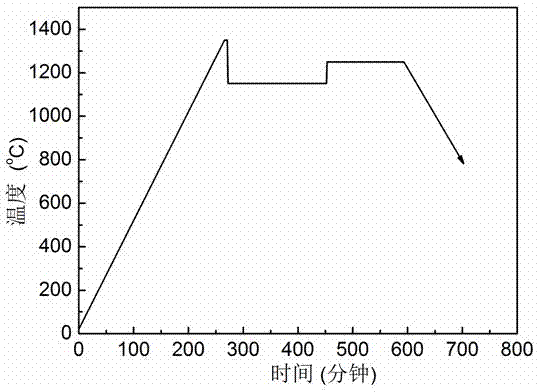

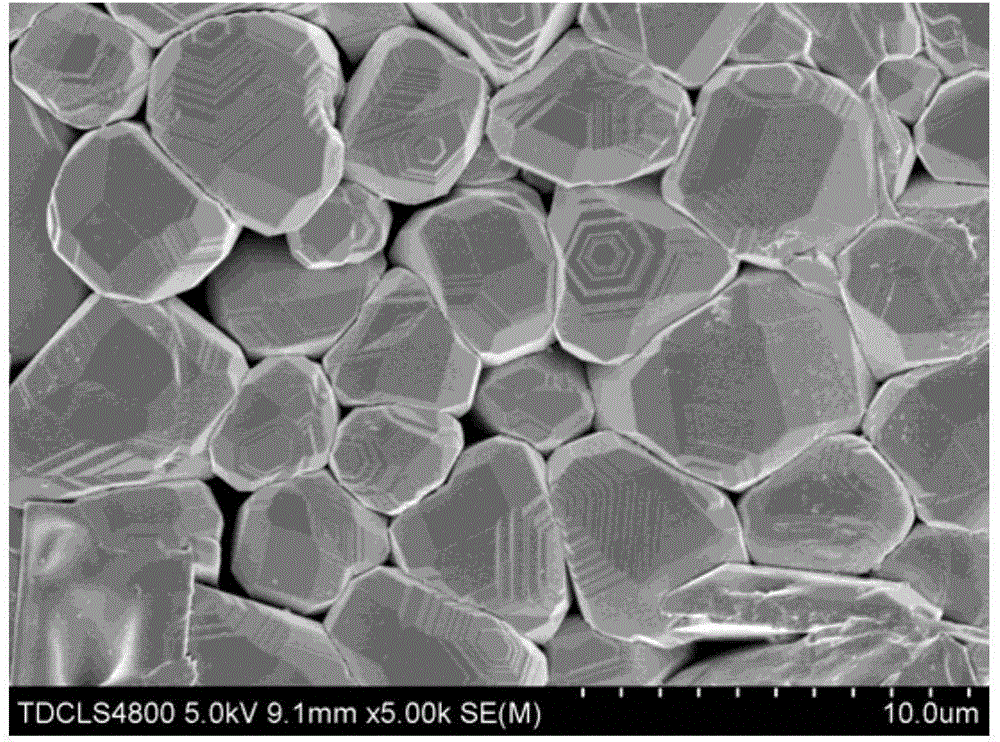

PTC ceramic sintering method

The invention discloses a PTC (positive temperature coefficient) ceramic sintering method. The method comprises the steps that a PTC ceramic biscuit is put into a crucible, and subjected to quick temperature rise-heat preservation, quick cooling-heat preservation, and further quick temperature rise to slightly high temperature-heat preservation; after the three-step sintering technology, a sintering block body is compacted quickly, and then subjected to furnace cooling; and the density of ceramic reaches the theoretical density. The sintering block body experiences higher sintering temperature, and then is subjected to the heat preservation at a lower temperature by changing the ceramic sintering technology; quick moving of a crystal boundary is inhibited; the sintering block body with fine and uniform crystal grains can be obtained, and further treated at the slightly high temperature; the sintering time can be shortened greatly; and the ceramic which is compact in structure and uniform in grain size, and has lower room temperature resistivity and a higher PTC effect is obtained finally. The characteristics are beneficial for meeting various functional requirements, such as high sensitivity, high reliability, imoact resistance and high safety, of a PTC ceramic sensor.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

PTC thermal sensitive ceramic material and method for preparing the same

InactiveCN101357844APromote sinteringLow room temperature resistivityElectrical resistance and conductanceAdhesive

The invention provides a PTC heat sensitive ceramic material which consists of the following components according to molecular fraction: 45 to 87 parts of BaCO3, 8 to 40 parts of PbO, 1 to 5 parts of CaCO3, TiO2, the molecular fraction of which is the sum of the parts of the BaCO3, PbO and CaCO3, 0.1 to 0.5 part of Nb2O5, 0.02 to 0.08 part of MnCO3 and o.1 to 0.6 part of BN. The preparation method of the ceramic material comprises the following steps: a. wet mixing; b. after dehydrating, drying and sintering, then adding an adhesive for granulating; c. sheet pressing, sintering in the air and natural cooling. The PTC heat sensitive ceramic material can obtain higher static bearable voltage and larger temperature coefficient of resistance and greatly reduce the room temperature resistivity.

Owner:周金平

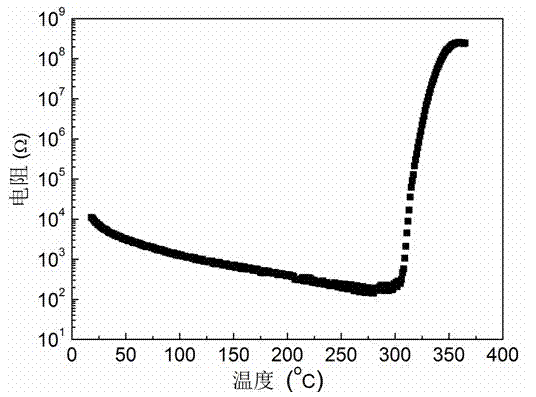

BaTiO3-based PTC thermal sensitive ceramic material and preparation method thereof

InactiveCN101838144AGood repeatabilityLow room temperature resistivityAir atmosphereNitrogen atmosphere

The invention provides a BaTiO3-based PTC thermal sensitive ceramic material and a preparation method thereof. The thermal sensitive ceramic material comprises the primary materials of TiO2, BaCO3, Bi2O3 and K2CO3 and the auxiliary materials of Nb2O5, Y2O3, Mn(NO3)2 and Sb2O3. The preparation method comprises the following steps of: mixing the primary materials and mixing the primary materials with zirconium ballstones and deionized water and roasting into pre-combined materials, mixing with the auxiliary materials, zirconium ballstones and deionized water to form complete dosing, then after mixing the complete dosing with zirconium ballstones and deionized water, ball-milling, drying, prilling and screening to press as samples, then transferring to the high temperature electric furnace in nitrogen atmosphere to raise the temperature and reduce the temperature, changing the in-furnace atmosphere to air with nitrogen when the temperature is reduced to 1100-900 DEG C and maintaining the temperature, then cooling along with the furnace and finally coating the electrode slurry to obtain the PTC thermal sensitive ceramic material. The ceramic material prepared by the method has higher room temperature which achieves 185 DEG C maximally, is non-poisonous and has low room temperature resistivity.

Owner:SHAANXI UNIV OF SCI & TECH

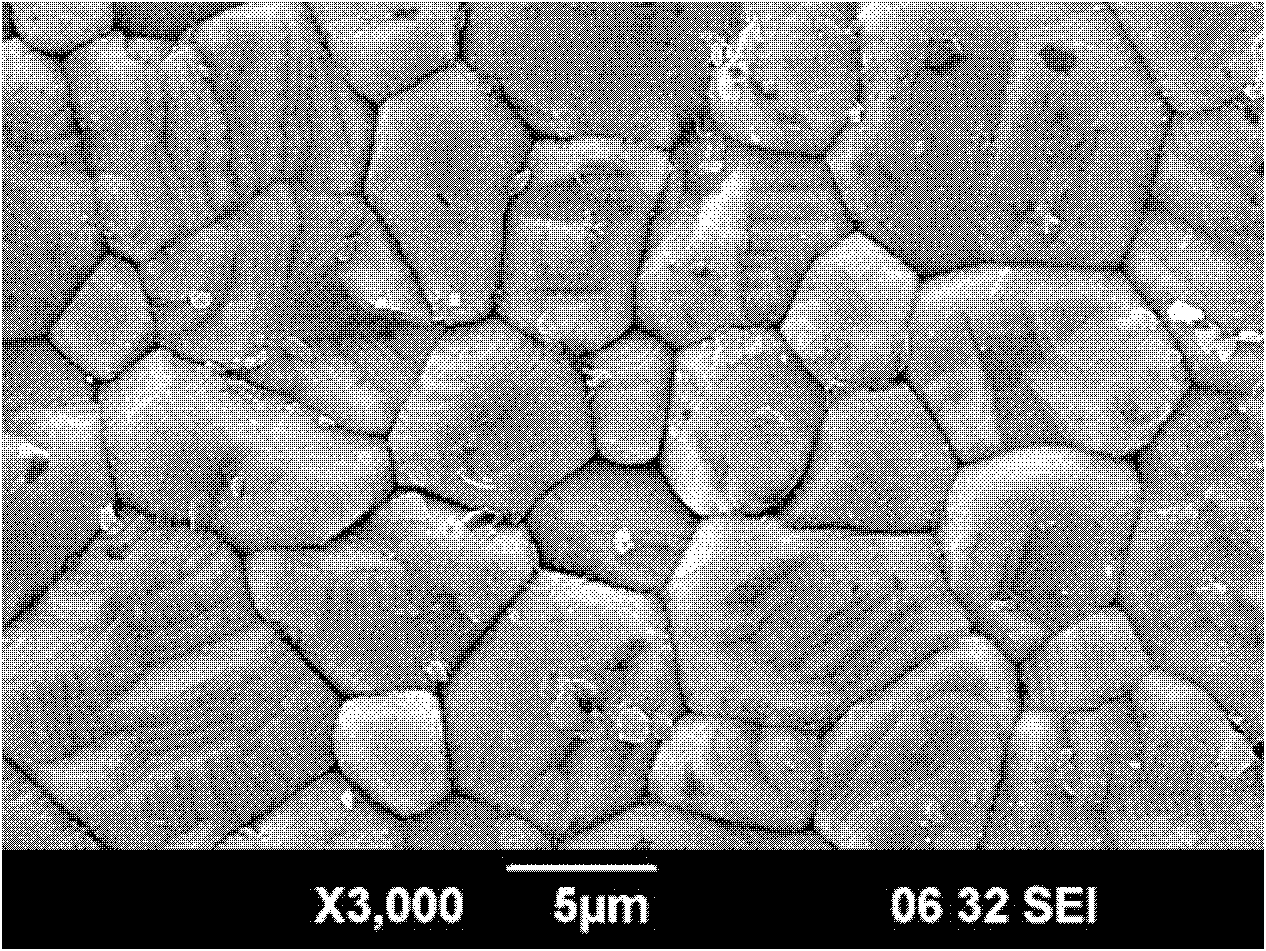

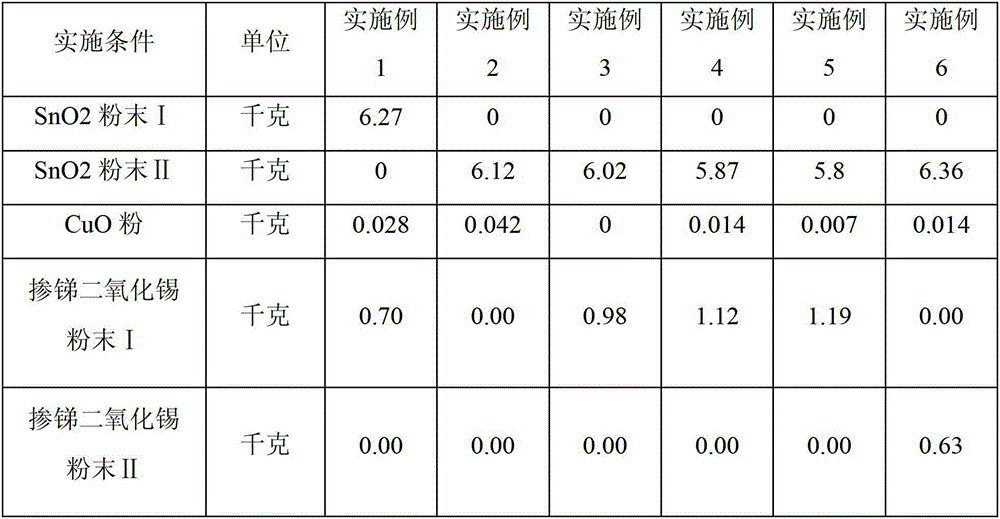

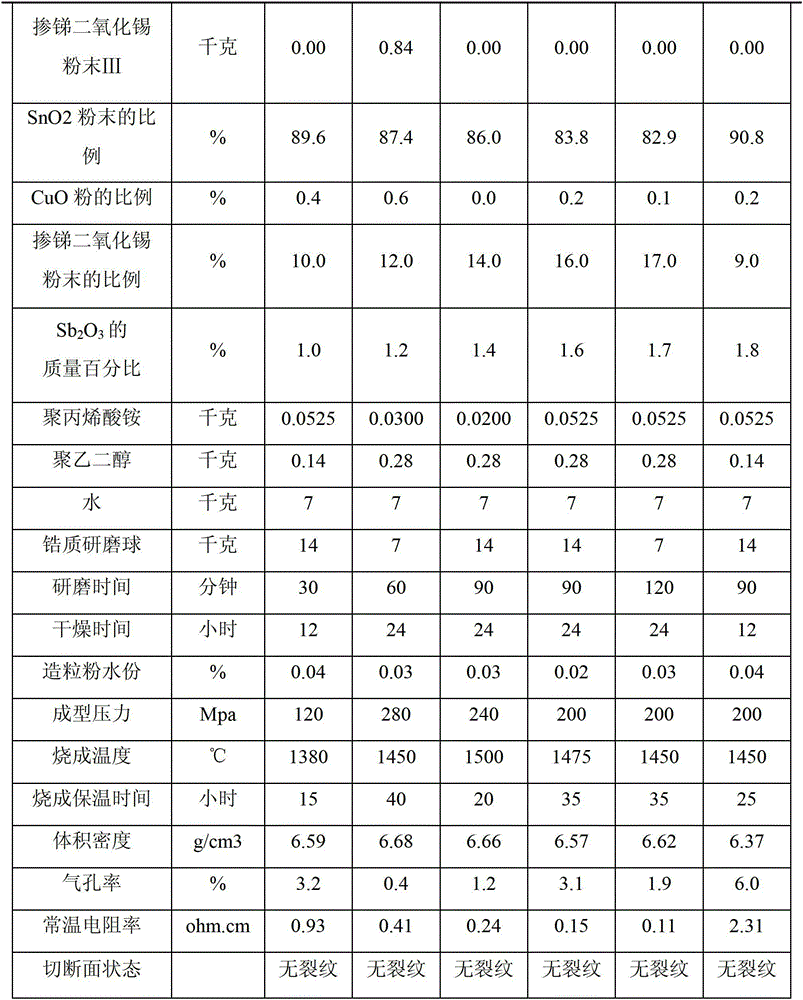

Preparation method of stannic oxide ceramic electrode

The invention discloses a preparation method of a stannic oxide ceramic electrode, belonging to the field of a ceramic technology. The method comprises the steps of: by taking nano antimony-doped stannic oxide powder and CuO powder as sintering aids, blending SnO2 powder with the sintering aids; then, adding a dispersing agent and a bonding agent into the mixture obtained from the former step; and carrying out wet grinding, drying, crushing granulation and isostatic compaction and then firing to prepare the stannic oxide ceramic electrode, wherein the mass percent of the SnO2 powder is 83-91% of the ingredients, the mass percent of the nano antimony-doped stannic oxide powder in the sintering aids is 9-17% of the ingredients, and the mass percent of the CuO powder is 0-0.6% of the ingredients. The preparation method is simple in technology and high in product pass rate, and the obtained stannic oxide ceramic electrode is high in density and low in resistivity at the room temperature and the high temperature.

Owner:ZIBO GT INDAL CERAMICS

Method for preparing conductive titanate powder by rare earth gas-phase diffusive permeation

A process for preparing the electrically conductive titanate powder by gas-phase RE diffusion method includes such steps as thermally dissolving RE oxide in concentrated nitric acid, cooling using amide reagent to regulate its concentration to obtain RE contained panetrant, preheating carburizing furnace, dropping amide reagent into it, quickly loading titanate powder in the furnace dripping said penetrant in the furnace, and diffusing at 860-950deg.C for 3-6 hr.

Owner:HARBIN INST OF TECH

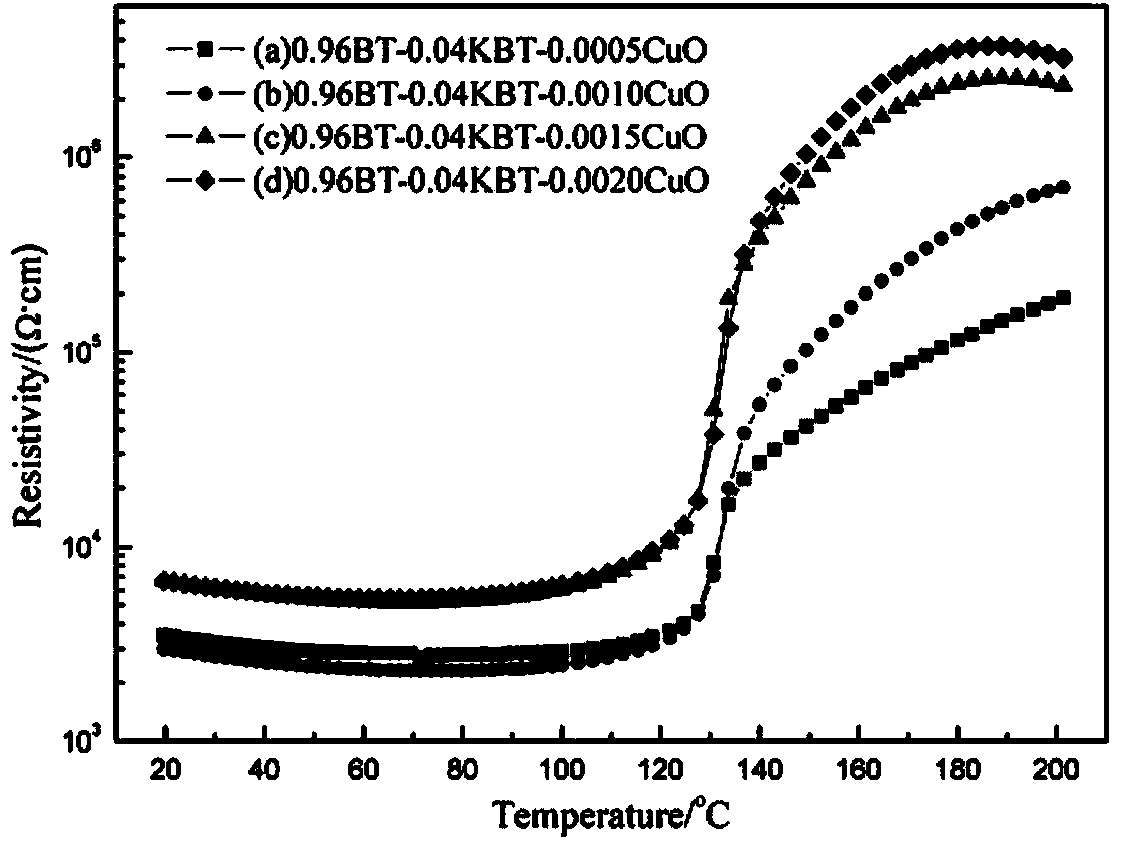

BaTiO3-based lead-free PTC (positive temperature coefficient) thermistor ceramic material sintered in reducing atmosphere and preparation method thereof

The invention discloses a BaTiO3-based lead-free PTC (positive temperature coefficient) thermistor ceramic material sintered in a reducing atmosphere and a preparation method thereof. The method comprises the following steps: weighing BaCO3 and TiO2, and mixing to form a mixture A; weighing Bi2O3, K2CO3 and TiO2 to form a mixture B; respectively performing ball-milling, drying and briquetting the mixture A and the mixture B, preserving the heat in a box type furnace to obtain pure phase BaTiO3 powder and Bi0.5K0.5TiO3 powder; mixing the two pure phase powder and an auxiliary material CuO to form a mixture; performing ball-milling, drying and granulating to form granules; pressing the granules into a sample, and sintering in the reducing atmosphere. According to the BaTiO3-based lead-free PTC thermistor ceramic material prepared by the preparation method disclosed by the invention, treatment of the oxidation process is not needed, the preparation process is simple, the material cost is low, and the ceramic material has low room temperature electrical resistivity and high resistance kick.

Owner:盐城青墩津邦水务有限公司

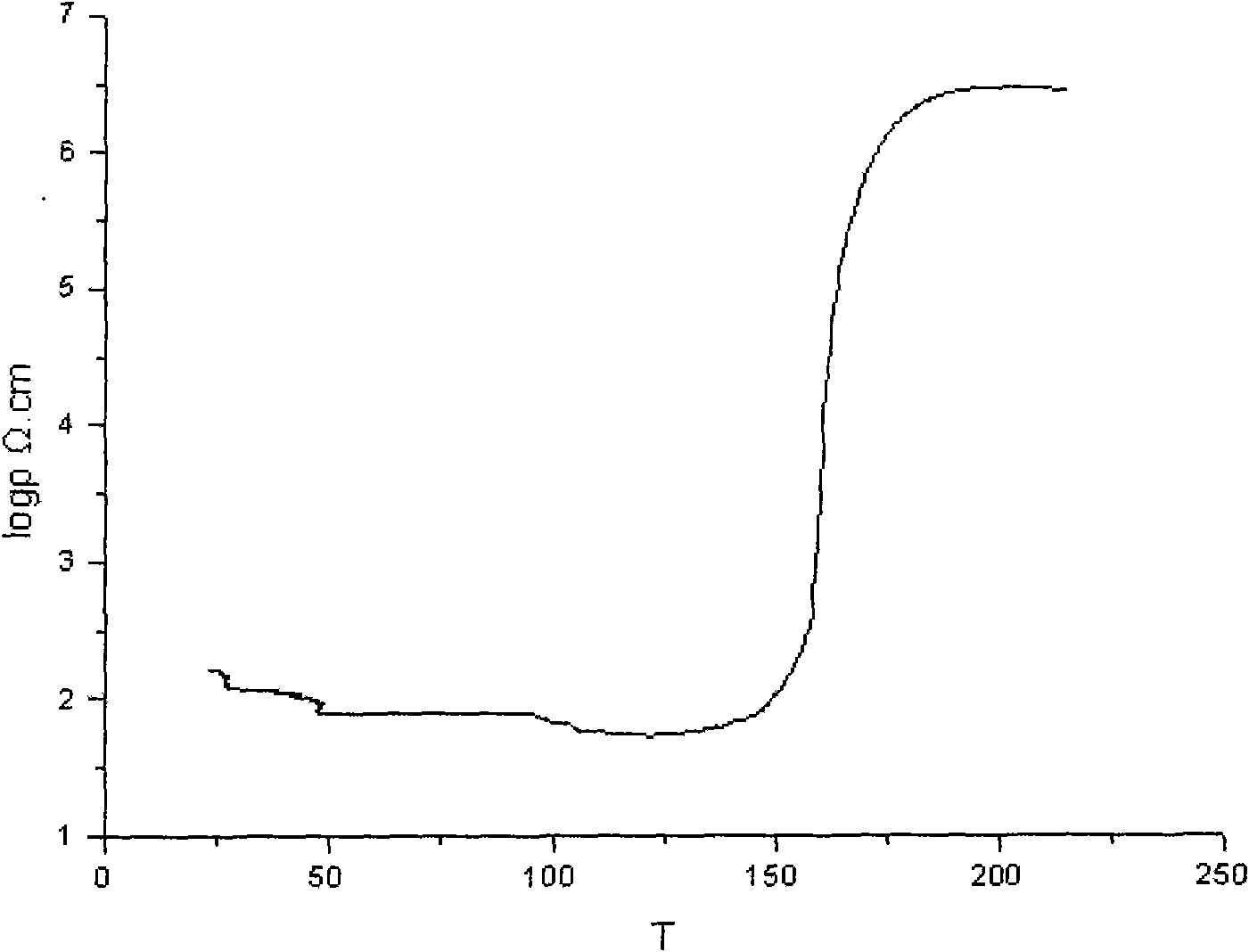

Conducting composite material with resistance positive-temperature effect and overcurrent-protecting element

ActiveCN102522173ALower resistanceLow resistivityCurrent responsive resistorsPositive temperature coefficient thermistorsWeather resistancePolymer substrate

The invention relates to a conducting composite material with a resistance positive-temperature effect and an overcurrent-protecting element. The conducting composite material with the resistance positive-temperature effect comprises a polymeric base material and a conducting filler, wherein the polymeric base material counts for 20 to 75 percent of the volume fraction of the conducting composite material; and the conducting filler has a core-shell type granular structure which is formed by an inner core and an outer shell, the conducting filler counts for 25 to 80 percent of the volume fraction of the conducting composite material, the grain diameter is 0.1 to 20 mu m, the volume resistivity is not greater than 100mu omega. cm, and the conducting filler is dispersed in the polymeric base material. The conducting composite material with the resistance positive-temperature effect disclosed by the invention has low resistivity and excellent weather resistance, the overcurrent-protecting element prepared from the conducting composite material with the resistance positive-temperature effect has extremely-low room-temperature resistivity and simultaneously still has good weather-resisting performance and excellent resistance reproducibility and PTC (Positive Temperature Coefficient) strength.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

High-Curie-temperature lead-free barium-titanate-base PTCR (positive temperature coefficient of resistance) ceramic material, and preparation and application thereof

InactiveCN104557024ALow room temperature resistivityHigh Curie temperatureElectrical resistance and conductanceBarium titanate

The invention discloses a high-Curie-temperature lead-free barium-titanate-base PTCR (positive temperature coefficient of resistance) ceramic material which is composed of BaTiO3, BaBiO3, (Bi0.5Na0.5)TiO3, MnO2 and Si3N4. The chemical formula of the material is (1-x-y)BaTiO[3-x]BaBiO[3-y](Bi0.5Na0.5)TiO3, wherein x=0.001-0.003, and y=0-0.01. 0.00034-0.00038mol of MnO2 and 0.008-0.012mol of Si3N4 are added to prepare every 1mol of (1-x-y)BaTiO[3-x]BaBiO[3-y](Bi0.5Na0.5)TiO3. The preparation method comprises the following steps: weighing and mixing the raw materials according to the mole formula, adding water, carrying out ball milling on the mixture, drying, keeping the temperature, drying, granulating, pelleting, and sintering to obtain the PTCR thermistor. The doping of the proper amount of BaBiO3 can lower the room temperature resistivity of the BaTiO3 system, and can enhance the Curie temperature of the system. The BT-BaBiO3-BNT system can be adopted to obtain the high-Curie-temperature lead-free PTCR material with low room temperature resistivity.

Owner:TIANJIN UNIV

Preparation method of conductive composite material

InactiveCN104650438ALower percolation thresholdLow room temperature resistivityCompression moldingManufactured material

The invention provides a preparation method of a conductive composite material and belongs to the field of material preparation. The preparation method is characterized by comprising the following steps: soaking graphene micro-flakes and an ultrahigh-molecular weight polyethylene powder in ethanol and performing ultrasonic dispersion by use of an ultrasonic cell smasher to form a uniformly distributed suspension; performing suction filtration and vacuum drying to remove the ethanol solvent, so that the graphene micro-flakes are evenly attached on the surface of the ultrahigh-molecular weight polyethylene particles; finally, performing compression molding on the obtained material, and then cooling to a room temperature under a constant pressure, thereby obtaining a raw material. The preparation process is improved, so that a more complete and stable effective conductive network structure can be formed inside the conductive composite material, and therefore, the percolation threshold of the material is greatly reduced, and the material has the maximum peak resistivity and relatively low room temperature resistivity. The preparation method of the conductive composite material is simple to operate, simple and convenient in process, and suitable for popularization and utilization in the related fields.

Owner:王兴

Graphite, phenolic resin, (Ba1-x-y, Srx, Pby) TiO3 based PTC thermistor and method for preparing the same

InactiveCN1546425ALow room temperature resistivityPrevent oxidationPositive temperature coefficient thermistorsGraphiteThermistor

The invention discloses a graphite / phenol resin / (Ba-[1-x-y], Sr-[x], Pb-[y]TiO3 based PTC thermo-sensitive resistor and its making process, wherein its raw material and ingredients are (percentage by weight), Ba[1-x-y], Sr-[x], Pb[y]TiO3 based ceramic powder 62-78%, where x=0.005-0.35, y=0.002-0.56, graphite 14-28%, 5% phenolic resins containing PVA curing agent 8-18.6%. The invention also discloses the process for preparing the thermo-sensitive resistor.

Owner:TIANJIN UNIV

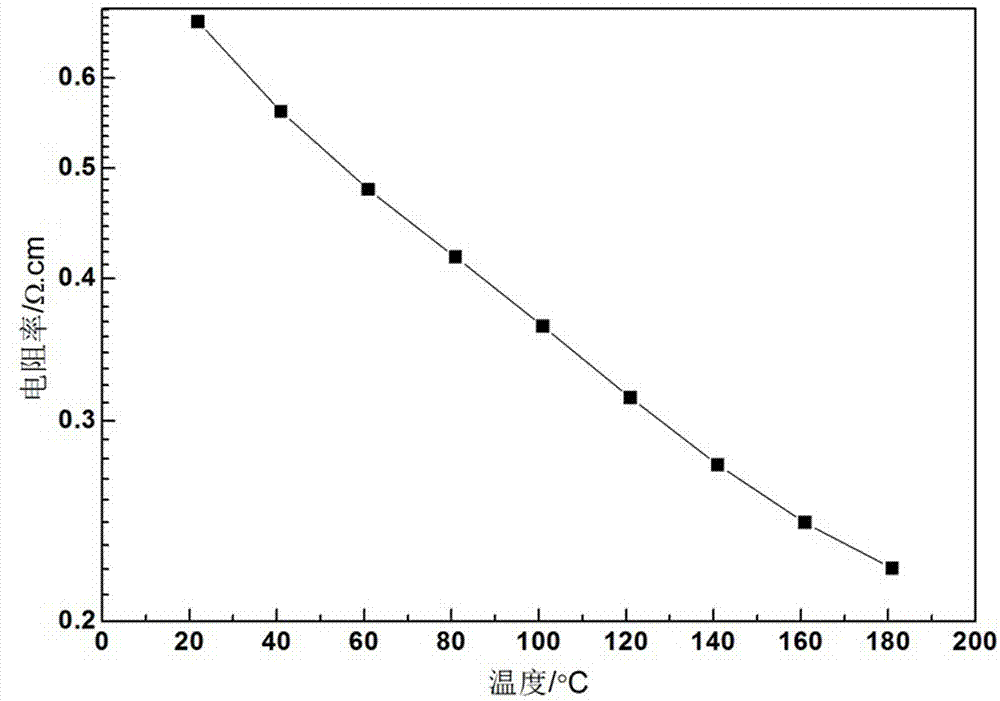

Low-resistance BaM<II><x>Bi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material and preparation method thereof

InactiveCN103864412ALow room temperature resistivityModerate thermal constantFilm resistanceScreen printing

The invention discloses a low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material and a preparation method thereof. The main active ingredient of the low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material is BaMBi<1-x>O3 thermosensitive phase powder, wherein x is more than or equal to 0.01 and less than or equal to 0.05, the M is one of plus 2 oxides of Co, Mn, Ni, Cu and Zn. The preparation method comprises the steps: evenly mixing BaMBi<1-x>O3 thermosensitive phase powder with an organic carrier in the mass ratio of 74:26 to form thick-film resistance paste; printing the resistance paste on a substrate through a silk-screen printing technique, laying flat, drying, pre-roasting and repeatedly printing to obtain the thick-film biscuit with needed thickness; sintering the biscuit at 700-900DEG C, and insulating for 120 minutes to obtain the low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material. The low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material is simple in preparation technique, low in film forming temperature, the thickness of the film is within 20-80mu m, the thermosensitive constant value ranges from 1000-4000K, the room-temperature resistivity is within the range of 0.7ohm.cm to 20kohm.cm, and the aging rate under the condition of insulating for 650hours at150DEG C is lower than 2%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

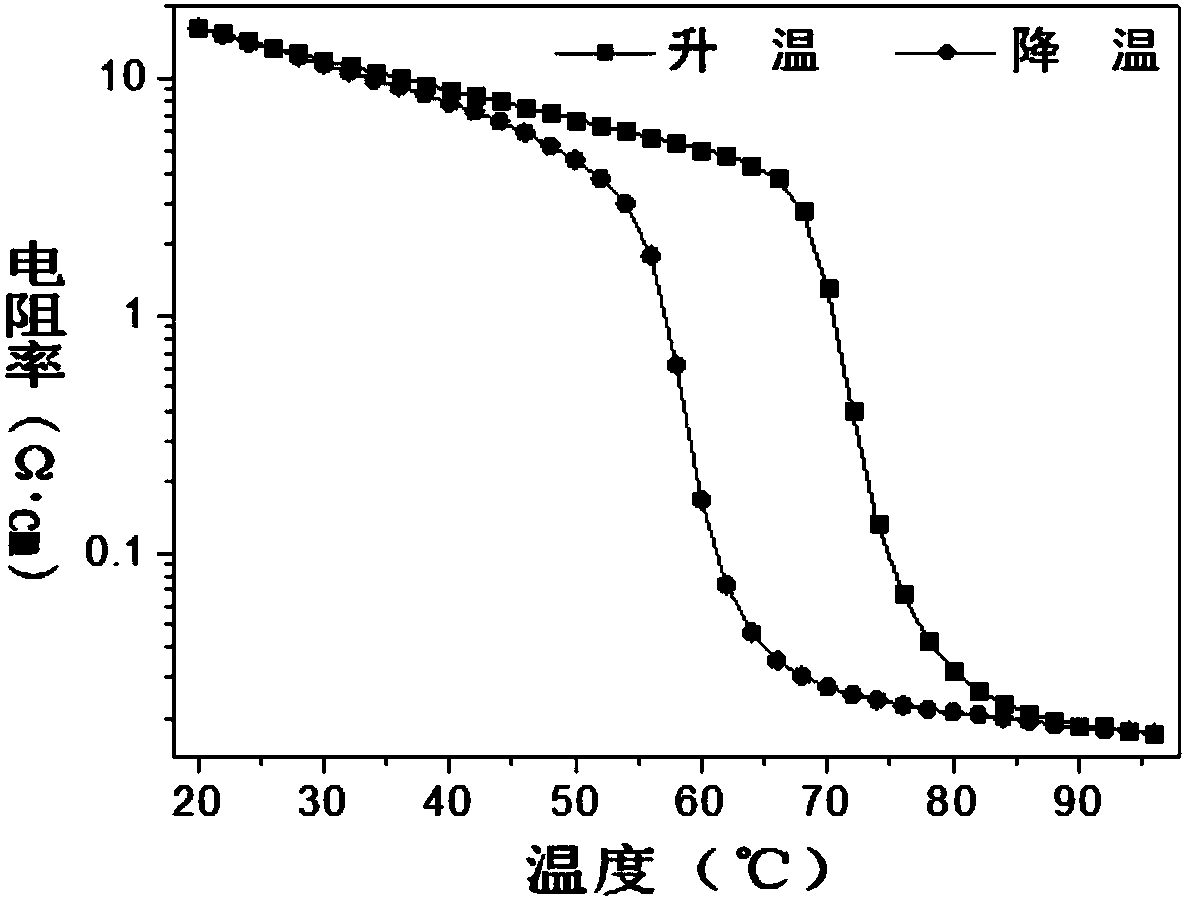

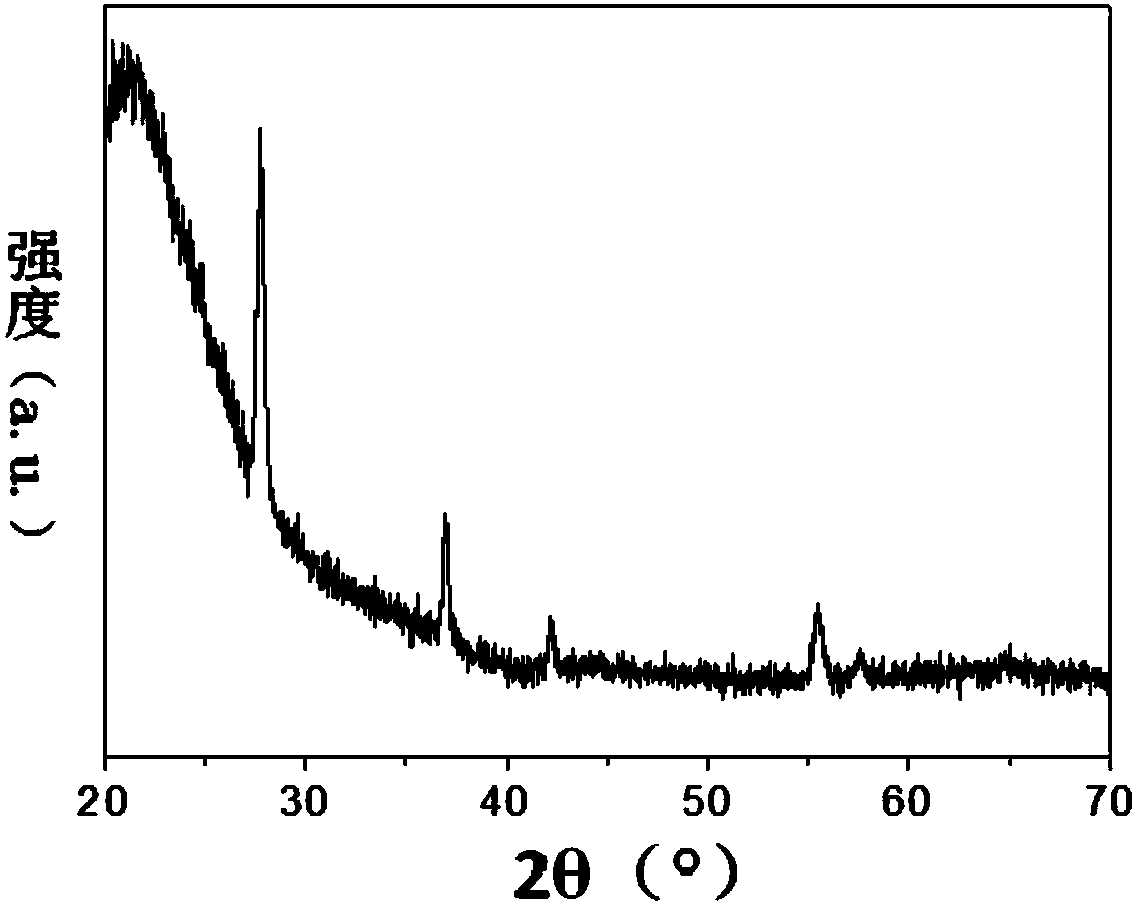

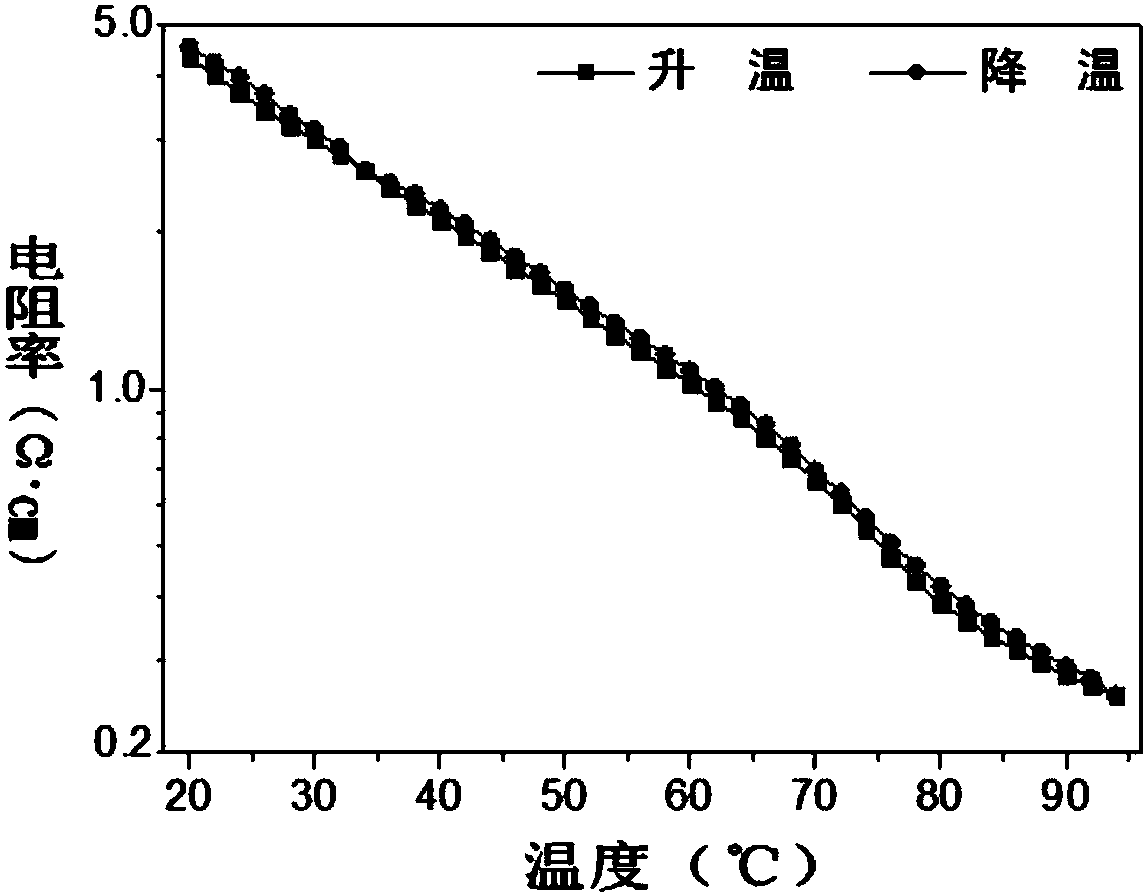

Titanium-ruthenium co-doped vanadium dioxide thermo-sensitive thin film material and preparation method thereof

ActiveCN107686973AAvoid Process LimitationsReduce adverse effectsVacuum evaporation coatingSputtering coatingVanadium dioxideSource material

The invention discloses a titanium-ruthenium co-doped vanadium dioxide thermo-sensitive thin film material and a preparation method thereof which can be applied to the technical field of uncooled infrared detectors and electronic thin films. The vanadium dioxide thermo-sensitive thin film material is prepared with titanium and ruthenium as a dopant and comprises a substrate layer and a titanium-ruthenium co-doped vanadium dioxide thin film layer; the titanium-ruthenium co-doped vanadium dioxide thin film layer comprises, by atomic percent, 4.0-7.0% of titanium, 0.5-1.5% of ruthenium, 25.0-30.0% of vanadium and the balance oxygen. The invention further provides a method for preparing the vanadium dioxide thermo-sensitive thin film material by means of the method of reactive sputtering witha titanium-ruthenium-vanadium alloy target as a source material or the method of reactive co-sputtering with a titanium target, a ruthenium target and a vanadium target as sputtering sources. A prepared vanadium dioxide thin film is of a monoclinic poly-crystal structure, the non-phase-change characteristic is shown, the low room temperature specific resistance is achieved, and the resistance temperature coefficient higher than those of a vanadium dioxide and common VOX non-doped thermo-sensitive thin film is achieved; and a preparation technology of the titanium-ruthenium co-doped vanadium dioxide thermo-sensitive thin film material is easy to achieve through an existing sputtering device or improvement of the existing device and is compatible with a device MEMS technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of stannic oxide electrode

The invention belongs to the technical field of ceramics, relating to a preparation method of a stannic oxide electrode. The preparation method of the stannic oxide electrode comprises the following steps: placing stannic oxide powder, copper hydroxide or copper carbonate powder and metal stibium powder in a polyurethane tank for ball milling and wet mixing evenly according to a mass ratio of 100:0.2-1.5:0.05-1.0; drying and screening the evenly mixed slurry and then putting in a rubber sleeve die for molding by using cold isostatic pressing; placing the molded green body in a molybdenum disilicide resistor furnace; vacuumizing, and introducing oxygen with the purity of over 98% until the pressure therein reaches 0.1-0.2 MPa; and electrifying and heating to 1450-1500 DEG C and keeping heat for 3-10h. The invention has simple preparation process and less doping, and the obtained stannic oxide electrode has high density and low normal temperature resistivity.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Polymer complex substance with resistance nonlinear positive temperature coefficient effect

This invention refers to a kind of polymer complex of non-linear positive temperature coefficient effect of resistance and the overflow protection organ of electrocircuit made from this polymer complex and is featured by the following components: polyethylene whose fusion index changes between 0.2g / 10min and 10.0g / 10min and whose density varies from 0.90g / cm3 to 0.99g / cm3, charcoal black, inorganic filler, crosslinking auxiliary agent and antioxidant. The inorganic filler is polar compound with oxygen, and the crosslinking agent is polyfunctional group compound with double bond. This invention makes use of the polymer complex to produce the overflow protection organ of electrocircuit and includes double-decked tinsel and electrode and its feature lies in there is sheet material of polymer complex between the two tinsels and that the tinsels connect with sheet material of polymer complex through hot pressing. The invention has positive temperature coefficient effect of resistance, restrains the NTC effect and has relatively low resistivity at room temperature and high PTC intensity.

Owner:沈守兵

Polyvinyl PTC thermo-sensitive conductive composite material and manufacturing method thereof

InactiveCN101870783AImprove conductivityImprove thermal conductivityNon-conductive material with dispersed conductive materialRoom temperatureStearic acid

The invention relates to a polyvinyl PTC thermo-sensitive conductive composite material, which comprises a base material and an additive, wherein the base material comprises 10-25% of LDPE, 20-40% of TiB2, 0-8% of CB and the balance of HDPE, and the additive comprises 0.1-0.3% of antioxidant1010, 1-3% of stearic acid, 1-2% vinyl trimethoxysilane, 3-5% of Sb2O3 and 8-12% of decabromodiphenyl ethane; and the adding amount of the additive is measured by the mass of organic matter components in the base material. The material has room temperature resistivity of 23.5omega . cm, long-term current capacity flow of greater than 100A and PTC intensity of 7.8, and resistance keeps stable after 100 thermal cycles.

Owner:合肥上雅电子科技有限公司

Composite material for thermistor and preparing method thereof

The invention discloses a composite material for a thermistor and a preparing method thereof. The composite material is prepared from, by weight, 80-90 parts of high-density polyethylene, 25-35 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polytetrafluoroethylene, 5-15 parts of polyvinylpyrrolidone, 25-35 parts of conductive filler, 6-8 parts of coupling agent, 3-5 parts of crosslinking agent, 1-3 parts of antioxidant and 2-4 parts of lubricant. The conductive filler is a mixture of titanium diboride and carbon fiber by the weight ratio of (6-10):1; the coupling agent is isobutyl triethoxy silane; the crosslinking agent is trimethylolpropane triacrylate. A positive-temperature-coefficient thermistor made of the composite material for the thermistor is low in room temperature electrical resistivity and high in PTC strength, after circulation for 100 times, the change rate of room temperature electrical resistivity and PTC strength is small, and the composite material has low room temperature, high PTC electrical resistivity and stability.

Owner:东莞市天纵企业管理咨询有限公司

Polyethylene/titanium diboride PTC (Positive Temperature Coefficient) composite material and preparation method thereof

InactiveCN102702603AImprove conductivityImprove thermal conductivityNon-conductive material with dispersed conductive materialLow-density polyethyleneVolumetric Mass Density

The invention discloses a polyethylene / titanium diboride PTC (Positive Temperature Coefficient) composite material and a preparation method thereof. The polyethylene / titanium diboride PTC composite material is prepared from the raw materials consisting of main materials and processing auxiliary agents, wherein the main materials comprise the following components in percentage by mass: 10-25 percent of low density polyethylene, 40.1-50 percent of TiB2, 0-6 percent of CB and the balance of high density polyethylene; and the processing auxiliary materials comprise antioxidant 1010, stearic acid, a coupling agent of vinyl trimethoxy silane, antimony trioxide and a fire retardant of decabromodiphenylethane. The polyethylene / titanium diboride PTC composite material has low room temperature resistivity, high voltage resistance, heavy current resistance, long-term flow stability performance, high PTC strength and high PTC stability.

Owner:HEFEI UNIV OF TECH

Cellular heating ceramic containing rare earth oxide and preparation method thereof

The invention discloses a cellular heating ceramic containing rare earth oxide and a preparation method of the cellular heating ceramic. The cellular heating ceramic is prepared by mixing hybrid ceramic powder with 0.02 to 0.1 percent of Y2O3 according to the molar percentage ratio; and the hybrid ceramic powder comprises according to the molar percentage ratio: 96 percent MgAl2O4, 1 to 3 percent of SiO2 and 3 to 1 percent of TiO2 according to the molar percentage ratio. Through the adding of the rare earth oxide Y2O3 in the hybrid ceramic powder, the room temperature resistance rate of the cellular heating ceramic can be reduced effectively, and the density and the hardness of the cellular heating ceramic are improved; according to the molar percentage ratio, when the 0.06 percent of Y2O3 is added in the hybrid ceramic powder, the density and the hardness of the cellular heating ceramic are maximal, and are respectively 93.01% and 349.5HV; and meanwhile, the room temperature resistance rate of the cellular heating ceramic reaches the minimum 5.5*101 omega.m.

Owner:GUIZHOU UNIV

Material with positive temperature coefficients

ActiveCN101638521AImprove PTC StrengthLow room temperature resistivityNon-conductive material with dispersed conductive materialTemperature coefficientPositive temperature

The invention provides a material with positive temperature coefficients, which is a product obtained by mixing a mixture containing conductive particles and polymers, wherein the conductive particlesare metal conductive particles with partially oxidized surfaces, and the oxygen content in the conductive particles is between 0.001 and 0.05 percent by weight. According to the material with positive temperature coefficients, the conductive particles are the metal conductive particles with partially oxidized surfaces so that the compatibility between the conductive particles and the polymers andthe dispersity of the conductive particles in the polymers can be improved; moreover, the material with positive temperature coefficients has high PTC intensity reaching as high as 10.4, and can still maintain low room-temperature resistivity at the same time.

Owner:BYD CO LTD

NTC heat-sensitive conductive ceramic material and method of manufacturing the same

InactiveCN101402521BControl electrical propertiesAchieve low resistanceTemperature controlRoom temperature

The invention discloses an NTC heat sensitive conducting ceramic material and a method for preparing the same. The method for preparing the NTC heat sensitive conducting ceramic material comprises the following steps: using BaCO3, SrCO3, SnO2 and Fe2O3 as main raw materials, mixing and ball-milling the raw materials, and drying the mixture to obtain a Ba1-ySryFexSn1-xO3 blank which is not doped, or doped singly, or doped compositely for a secondary ball milling; and adopting an ordinary ceramic preparation process. The B value of the NTC heat sensitive conducting ceramic prepared in the invention can reach 5,100K, and the resistivity at room temperature can be reduced to 2,800 omega.m. The NTC heat sensitive conducting ceramic material has simple preparation process and low cost, and the obtained products can be applied to the aspects of temperature measurement, temperature control, automatic gain adjustment, temperature compensation and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

PTC thermistor base material and preparation method thereof

The invention belongs to the field of a high-molecular material, and more specifically relates to a PTC thermistor base material and a preparation method thereof. The PTC thermistor base material comprises the following raw materials in parts by weight: 60-70 parts of HDPE, 15-20 parts of PET, 3-5 parts of EEA, 25-30 parts of silver-plated copper powder, 4-8 parts of carbon fiber, 0.8-1 part of graphene, 5-6 parts of palygorskite powder, 3-5 parts of basalt fiber, 3-4 parts of wollastonite, 2-3 parts of mica powder, 2-3 parts of dicumyl peroxide, 5-8 parts of a nano filling material, 3-5 parts of a coupling agent, 2-3 parts of an anti-oxidant, and 2-4 parts of an organosilicon fire retardant. The preparation method comprises the steps of weighing, premixing and mixing. The PCT thermistor has low room-temperature resistivity, high heat resistance, high stability and high intensity, and excellent comprehensive property.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com