BaTiO3-based lead-free PTC (positive temperature coefficient) thermistor ceramic material sintered in reducing atmosphere and preparation method thereof

A thermistor and ceramic material technology, applied in the field of lead-free PTC thermistor ceramic materials, can solve the problems of complex preparation method, no PTC performance, etc., and achieve the effect of simple preparation method, low cost and increasing Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of BaTiO sintered in reducing atmosphere 3 The preparation method of lead-free PTC thermistor ceramic material comprises the steps:

[0023] Step 1: Preparation of BaTiO 3 and Bi 0.5 K 0.5 TiO 3 Standby: Weigh BaCO according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 , K 2 CO 3 and TiO 2 Mix to form Mixture B.

[0024] Step 2: Mix the mixture A with zirconium balls and deionized water according to the mass ratio of 1:2:(2-2.5), then ball mill in a star ball mill for 3-4 hours, then dry and briquetting, Place in a box furnace at 1150-1250°C for 2-3 hours to obtain pure phase BaTiO 3 Powder: mix mixture B with zirconium balls and deionized water according to the mass ratio of 1:2:(2~2.5), then ball mill in star ball mill for 3~4 hours, then dry and briquetting, Place in a box furnace at 900-950°C for 3-4 hours to obtain a pure phase of Bi 0.5 K 0.5 TiO 3 Powder, spare;

[0025] Ste...

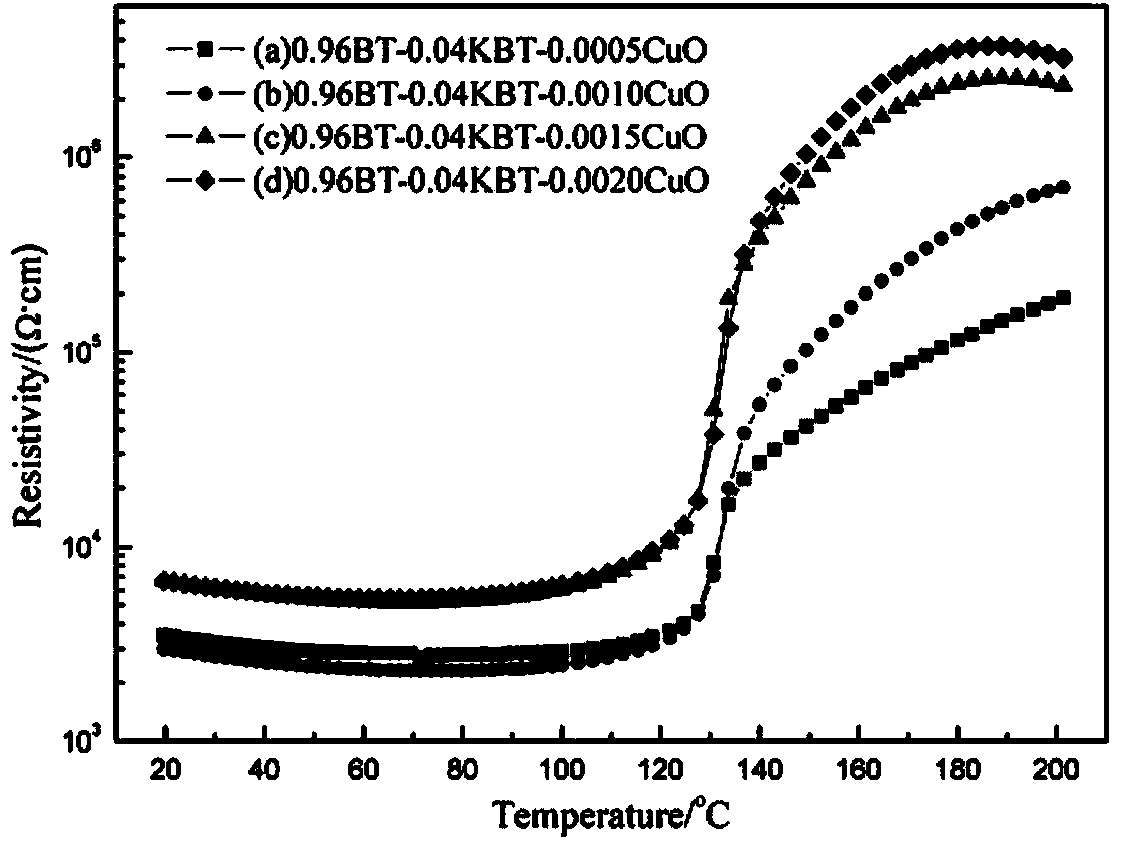

Embodiment 1

[0031] A kind of BaTiO sintered in reducing atmosphere of the present invention 3 Lead-free PTC thermistor ceramic materials, including the main material BaTiO 3 and Bi 0.5 K 0.5 TiO 3 , the molar ratio is 0.96:0.04, the auxiliary material is CuO, and CuO and BaTiO 3 The molar ratio is 0.0005:0.96.

[0032] The aforementioned BaTiO 3 The preparation method of lead-free PTC thermistor ceramic material comprises the following steps:

[0033] Step 1: Preparation of BaTiO 3 Powder and Bi 0.5 K 0.5 TiO 3 Powder standby: weigh BaCO according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 、K 2 CO 3 and TiO 2 Mix to form Mixture B.

[0034] Step 2: Take mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:2:2, and then perform ball milling in a star-type ball mill for 3 hours, then dry and briquette, and place in a box-type furnace Insulated at 1150 °C for 3 hours to ...

Embodiment 2

[0041] A kind of BaTiO sintered in reducing atmosphere of the present invention 3 Lead-free PTC thermistor ceramic materials, including the main material BaTiO 3 and Bi 0.5 K 0.5 TiO 3 , the molar ratio is 0.96:0.04, the auxiliary material is CuO, and CuO and BaTiO 3 The molar ratio is 0.0010:0.96.

[0042] The aforementioned BaTiO 3 The preparation method of lead-free PTC thermistor ceramic material comprises the following steps:

[0043] Step 1: Preparation of BaTiO 3 Powder and Bi 0.5 K 0.5 TiO 3 Powder standby: weigh BaCO according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 、K 2 CO 3 and TiO 2 Mix to form Mixture B.

[0044] Step 2: Take the mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:2:2.5, and then perform ball milling in a star-type ball mill for 4 hours, dry, and briquette, and then place them in a box furnace. 1250℃ for 2 hours to synthes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com