Polymer complex substance with resistance nonlinear positive temperature coefficient effect

A composite and polymer technology, applied in the field of polymer composites, can solve the problems of increasing the room temperature resistance of components, unable to effectively suppress the NTC effect of polymer composites, and low bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

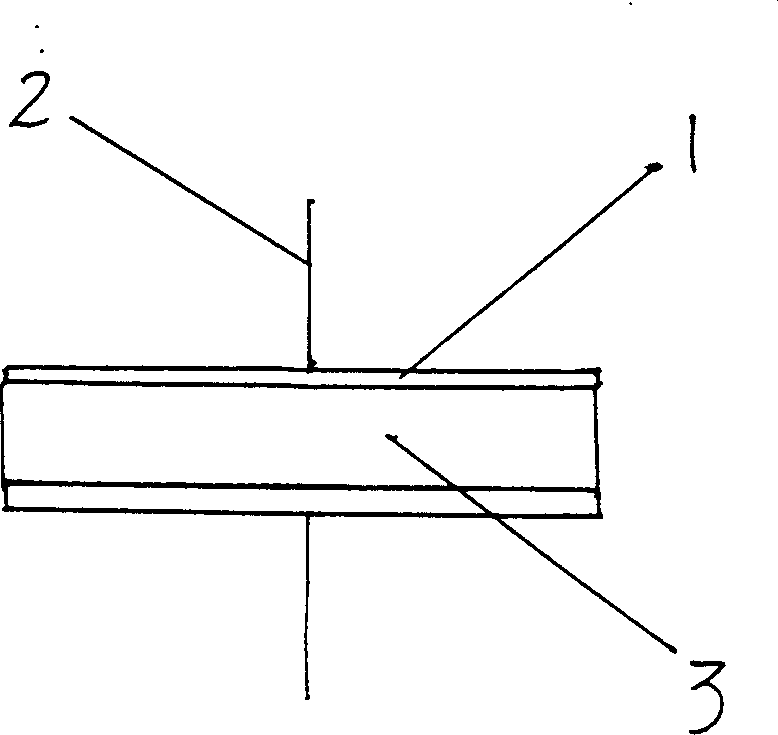

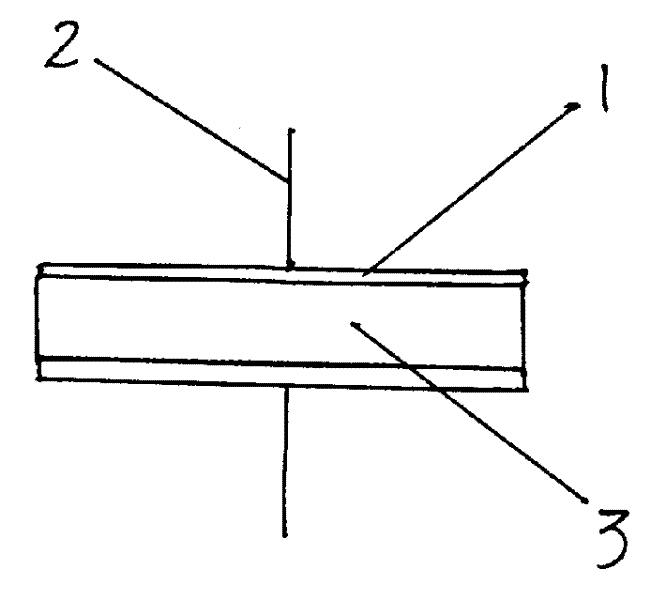

Image

Examples

Embodiment 1

[0014] 44 kg of high-density polyethylene with different MFR values, 39 kg of carbon black, 13 kg of magnesium oxide, 3 kg of crosslinking agent triallyl isocyanurate (TAIC), and 1 kg of antioxidant 1010 were mixed in a mixer Pre-mixed, then melted and kneaded by an internal mixer, out of the sheet, cooled, hot-pressed on both sides of the metal foil and cut into small pieces, welded electrodes, using Co 60 γ-rays were irradiated for cross-linking with a dose of 200kGy. An overcurrent protection element is produced. The resistance of the test sample changes with time at the melting point temperature of the polymer. Taking the resistance R after 2 hours 2 Instead of the maximum resistance R achieved during the test max The ratio of is used to characterize the size of the NTC phenomenon that is inhibited. The larger the ratio, the less obvious the NTC phenomenon and the better the effect of inhibiting the NTC effect.

[0015] Example one

[0016] It can be seen ...

Embodiment 2

[0018] 13 kg of different inorganic fillers, 44 kg of high-density polyethylene, 39 kg of carbon black, 3 kg of cross-linking aid triallyl isocyanurate (TAIC), 1 kg of antioxidant 1010, etc. in the mixer Pre-mixed in the internal mixer, then melted and kneaded by an internal mixer, out of the sheet, cooled, hot-pressed on both sides of the metal foil and cut into small pieces, welded electrodes, using Co 60 γ-rays were irradiated for cross-linking with a dose of 200kGy. An overcurrent protection element is produced. Test the resistivity of the sample at room temperature, and measure its PTC strength, the results are shown in Table 2. The surface of the polymer composite sheet was analyzed by electron spectroscopy, and the results are shown in Table 3.

[0019] Example one

[0020]

[0021] It can be seen from Table 2 and Table 3 that adding polar oxygen-containing inorganic fillers to the polymer composite increases the number of oxygen-containing gro...

Embodiment 3

[0023] 44 kg of polyethylene with different crystallinity values (characterized by density), 39 kg of carbon black, 13 kg of magnesium oxide, 3 kg of crosslinking agent triallyl isocyanurate (TAIC), 1 kg of antioxidant 1010 Pre-mixed in a mixer, then melted and kneaded by an internal mixer, discharged, cooled, hot-pressed on both sides of the metal foil and cut into small pieces, welded electrodes, using Co 60 γ-rays were irradiated for cross-linking with a dose of 200kGy. An overcurrent protection element is produced. Test the resistivity of the sample at room temperature, and measure its PTC strength.

[0024] Example one

[0025] It can be seen from Table 4 that by optimizing the density value of polyethylene, the polymer composite can have both lower resistivity and higher PTC strength, and the comparative example is the existing conventional value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com