Cellular heating ceramic containing rare earth oxide and preparation method thereof

A rare earth oxide and honeycomb technology, which is applied in the field of honeycomb heating ceramics and its preparation, can solve the problems of high room temperature resistivity, low density and hardness of honeycomb heating ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1 of the present invention: a kind of honeycomb heat-generating ceramics containing rare earth oxide, calculated according to molar percentage, it is doped with 0.06% Y by mixed ceramic powder 2 o 3 Prepared from; the mixed ceramic powder, calculated according to molar percentage, consists of 96% MgAl 2 o 4 , 2% SiO2 2 and 2% TiO 2 composition. The MgAl 2 o 4 From Al with a molar ratio of 1:1 2 o 3 It reacts with MgO. The Al 2 o 3 for a-Al 2 o 3 .

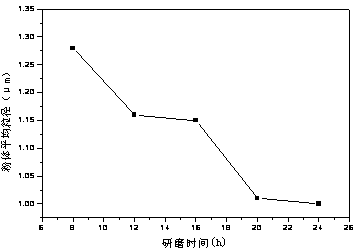

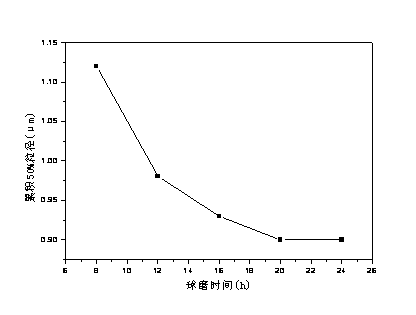

[0085] A preparation method of the above-mentioned honeycomb heating ceramics containing rare earth oxides, comprising: taking Al 2 o 3 After calcination, Al with a molar ratio of 1:1 2 o 3 After mixing with MgO and ball milling, put it into a resistance furnace and raise the temperature to 1200°C for 120 minutes for sintering to obtain MgAl 2 o 4 phase; according to the molar percentage calculation, 96% of MgAl 2 o 4 , 2% SiO2 2 , 2% TiO 2 Mixing and grinding, on this basis, according to th...

Embodiment 2

[0086] Embodiment 2: A kind of honeycomb heat-generating ceramics containing rare earth oxide, calculated according to molar percentage, it is doped 0.10% Y by mixed ceramic powder 2 o 3 Prepared from; the mixed ceramic powder, calculated according to molar percentage, consists of 96% MgAl 2 o 4 , 3% SiO 2 and 1% TiO 2 composition. The MgAl 2 o 4 From Al with a molar ratio of 1:1 2 o 3 It reacts with MgO.

[0087]A preparation method of the above-mentioned honeycomb heating ceramics containing rare earth oxides, comprising: adding Al with a molar ratio of 1:1 2 o 3 After mixing with MgO and ball milling, put it into a resistance furnace and raise the temperature to 1200°C for 120 minutes for sintering to obtain MgAl 2 o 4 phase; according to the molar percentage calculation, 96% of MgAl 2 o 4 , 3% SiO 2 , 1% TiO 2 Mixing and grinding, on this basis, according to the molar percentage calculation, doped with 0.10% Y 2 o 3 , add a dispersant and ball mill for 24...

Embodiment 3

[0088] Embodiment 3: A kind of honeycomb heating ceramics containing rare earth oxide, calculated according to molar percentage, it is doped 0.02% Y by mixed ceramic powder 2 o 3 Prepared from; the mixed ceramic powder, calculated according to molar percentage, consists of 96% MgAl 2 o 4 , 1% SiO 2 and 3% TiO 2 composition. The MgAl 2 o 4 From Al with a molar ratio of 1:1 2 o 3 It reacts with MgO.

[0089] A preparation method of the above-mentioned honeycomb heating ceramics containing rare earth oxides, comprising: adding Al with a molar ratio of 1:1 2 o 3 After mixing with MgO and ball milling, put it into a resistance furnace and raise the temperature to 1200°C for 120 minutes for sintering to obtain MgAl 2 o 4 phase; according to the molar percentage calculation, 96% of MgAl 2 o 4 , 1% SiO 2 , 3% TiO 2 Mixing and grinding, on this basis, according to the molar percentage calculation, doped with 0.02% Y 2 o 3 , adding a dispersant and ball milling for 8 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com