NTC heat-sensitive conductive ceramic material and method of manufacturing the same

A conductive ceramic material and a technology for preparing ceramics, applied in the field of conductive ceramic materials, can solve the problems of high production energy consumption, low B value, high tin price, etc., and achieve the effects of simple preparation process, reduced price and production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] with SnO 2 , Fe 2 o 3 、BaCO 3 Raw materials are mixed in a molar ratio of 0.5:0.25:1, wet-milled with absolute ethanol as a medium, and dried at 950°C for 3 hours to synthesize BaFe 0.5 sn 0.5 o 3 Ceramic blanks.

[0019] BaFe 0.5 sn 0.5 o 3 The ceramic blank is dried by ball milling for the second time, and then a 3% PVA solution is added as a binder, and pressed into a disc with a diameter of 18mm and a thickness of 1-1.4mm under a pressure of 100MPa, and the heating rate is 150℃ / h at 600℃ Keep warm for 2 hours to discharge the binder, then keep warm at 1250°C for 2 hours at a heating rate of 300°C / h, and finally cool to room temperature with the furnace. The ceramic sheet is covered with silver electrodes on both sides.

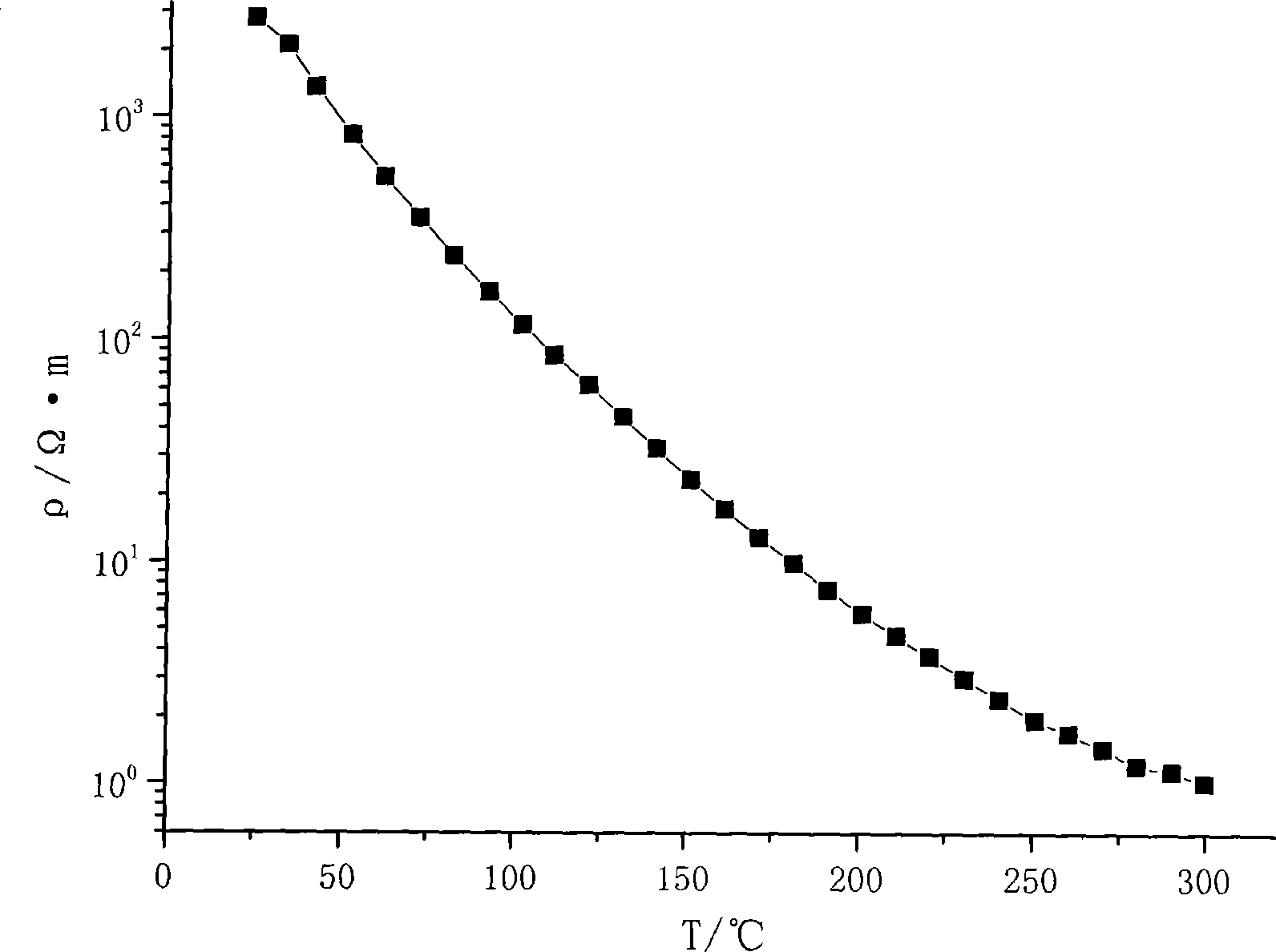

[0020] Performance tests show that the room temperature resistivity ρ 25 2800Ω·m, B 25 / 85 The value is 4500K. Related data such as figure 1 shown.

Embodiment 2

[0022] with SnO 2 , Fe 2 o 3 , SrCO 3 The raw materials are mixed according to the molar ratio of 0.7:0.15:1, wet-milled with absolute ethanol as the medium, dried and kept at 950°C for 3 hours to synthesize SrFe 0.3 sn 0.7 o 3 Ceramic blanks.

[0023] SrFe 0.3 sn 0.7 o 3 The ceramic blank is dried by ball milling for the second time, and then a 3% PVA solution is added as a binder, and pressed into a disc with a diameter of 18mm and a thickness of 1-1.4mm under a pressure of 100MPa, and the heating rate is 150℃ / h at 600℃ Keep warm for 2 hours to discharge the binder, then keep warm at 1300°C for 2 hours at a heating rate of 300°C / h, and finally cool to room temperature with the furnace. The ceramic sheet is covered with silver electrodes on both sides.

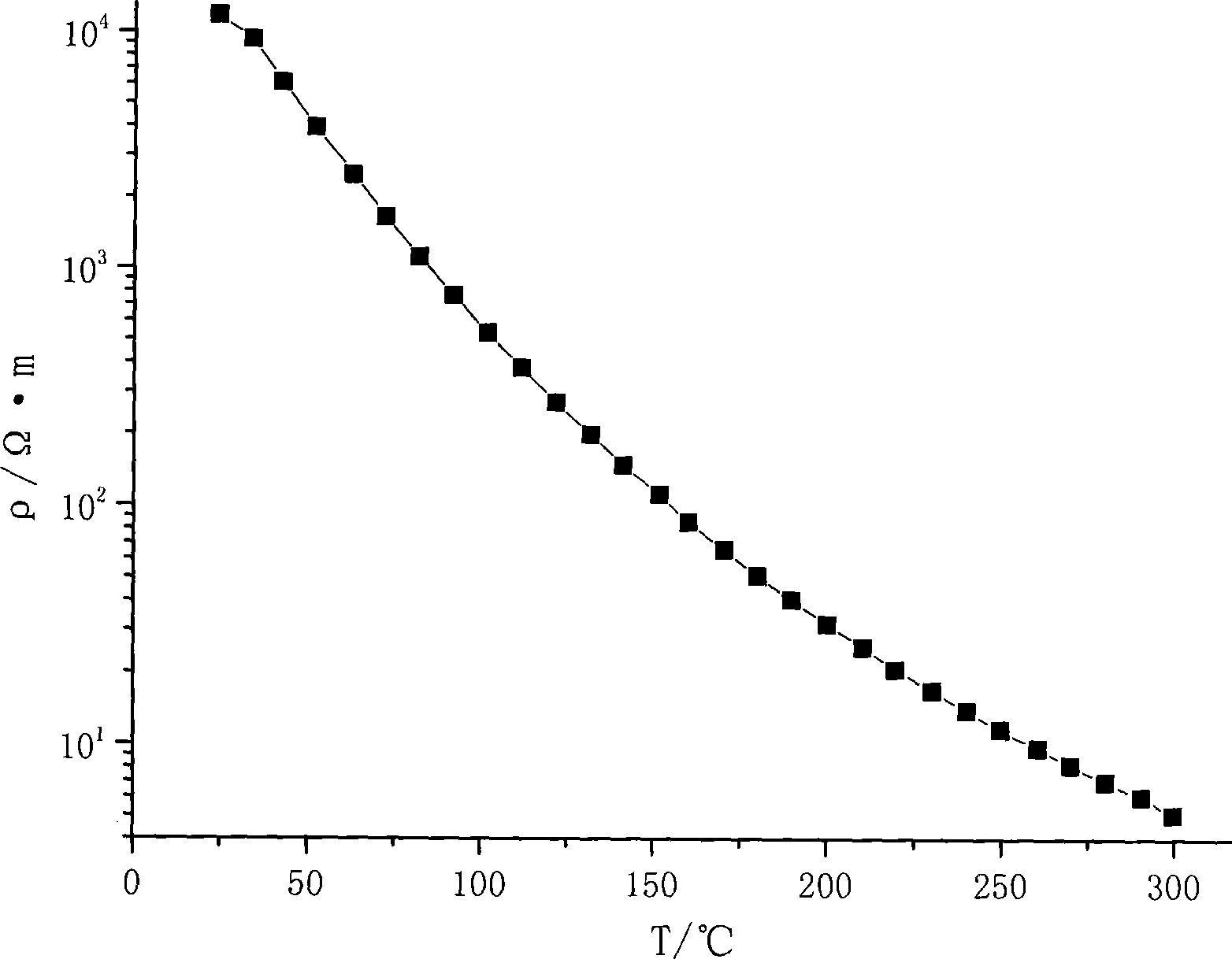

[0024] Performance tests show that the room temperature resistivity ρ 25 1.2×10 4 Ω·m, B 25 / 85 The value is 4400K. Related data such as figure 2 shown.

Embodiment 3

[0026] with SnO 2 , Fe 2 o 3 、BaCO 3 Raw materials are mixed in a molar ratio of 0.8:0.1:1, wet-milled with anhydrous ethanol as a medium, and dried at 1000°C for 6 hours to synthesize BaFe 0.2 sn 0.8 o 3 Ceramic blanks.

[0027] BaFe 0.2 sn 0.8 o 3 Ceramic blank with Sb 2 o 3 The powder is mixed according to a molar ratio of 100:0.1, then ball-milled and dried for the second time, and then a 3% PVA solution is added as a binder, and pressed into a disc with a diameter of 18mm and a thickness of 1-1.4mm under a pressure of 100MPa. Heat at 600°C for 2 hours at a heating rate of 300°C / h to discharge the binder, then hold at 1350°C for 2 hours at a heating rate of 300°C / h, and finally cool to room temperature with the furnace. The ceramic sheet is covered with silver electrodes on both sides.

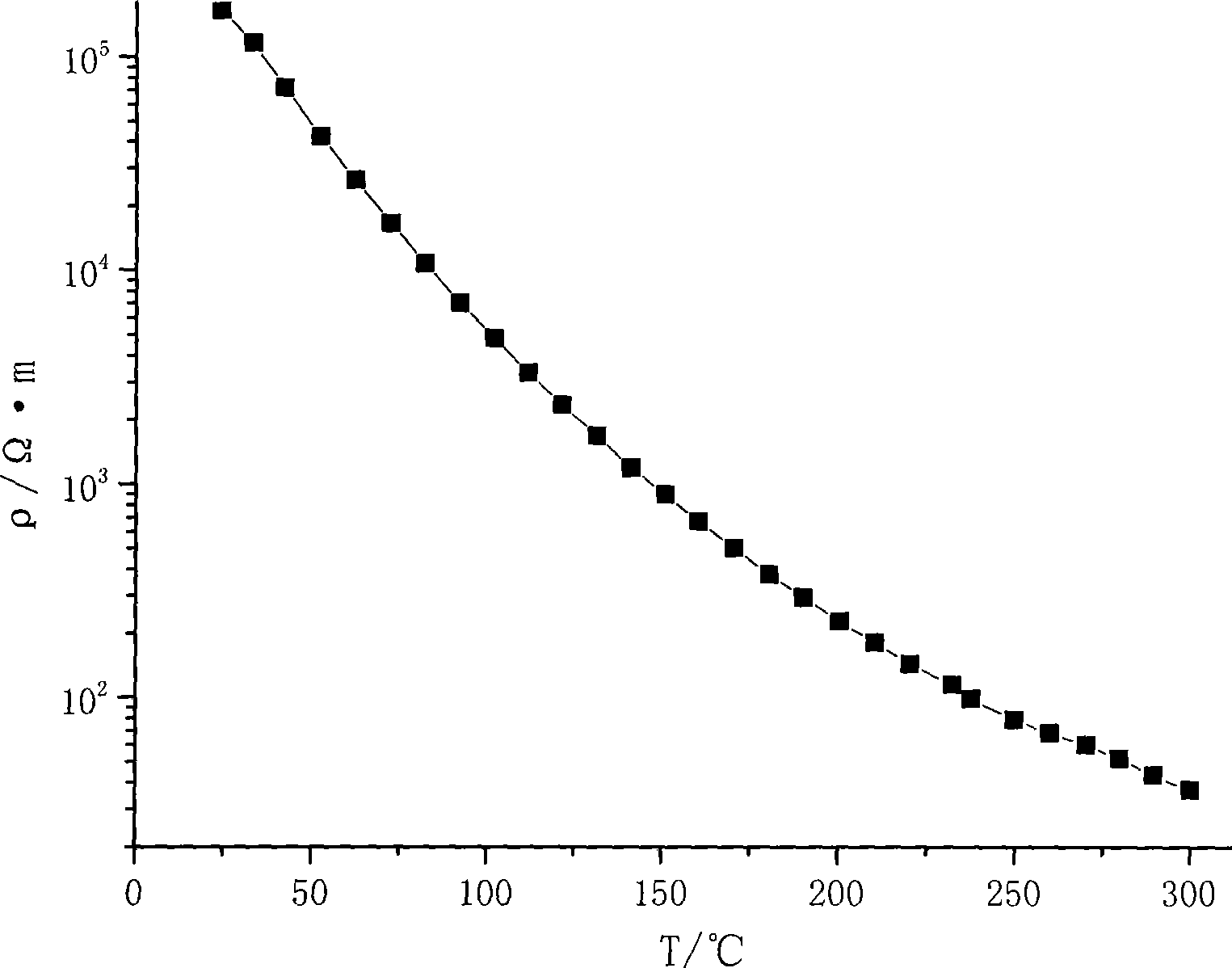

[0028] Performance tests show that the room temperature resistivity ρ 25 1.65×10 5 Ω·m, B 25 / 85 The value is 5000K. Relevant data such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com