A Method of Controlling Pn Junction Defect Energy Level Based on Electron Irradiation

A technology of defect energy level and electron irradiation, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

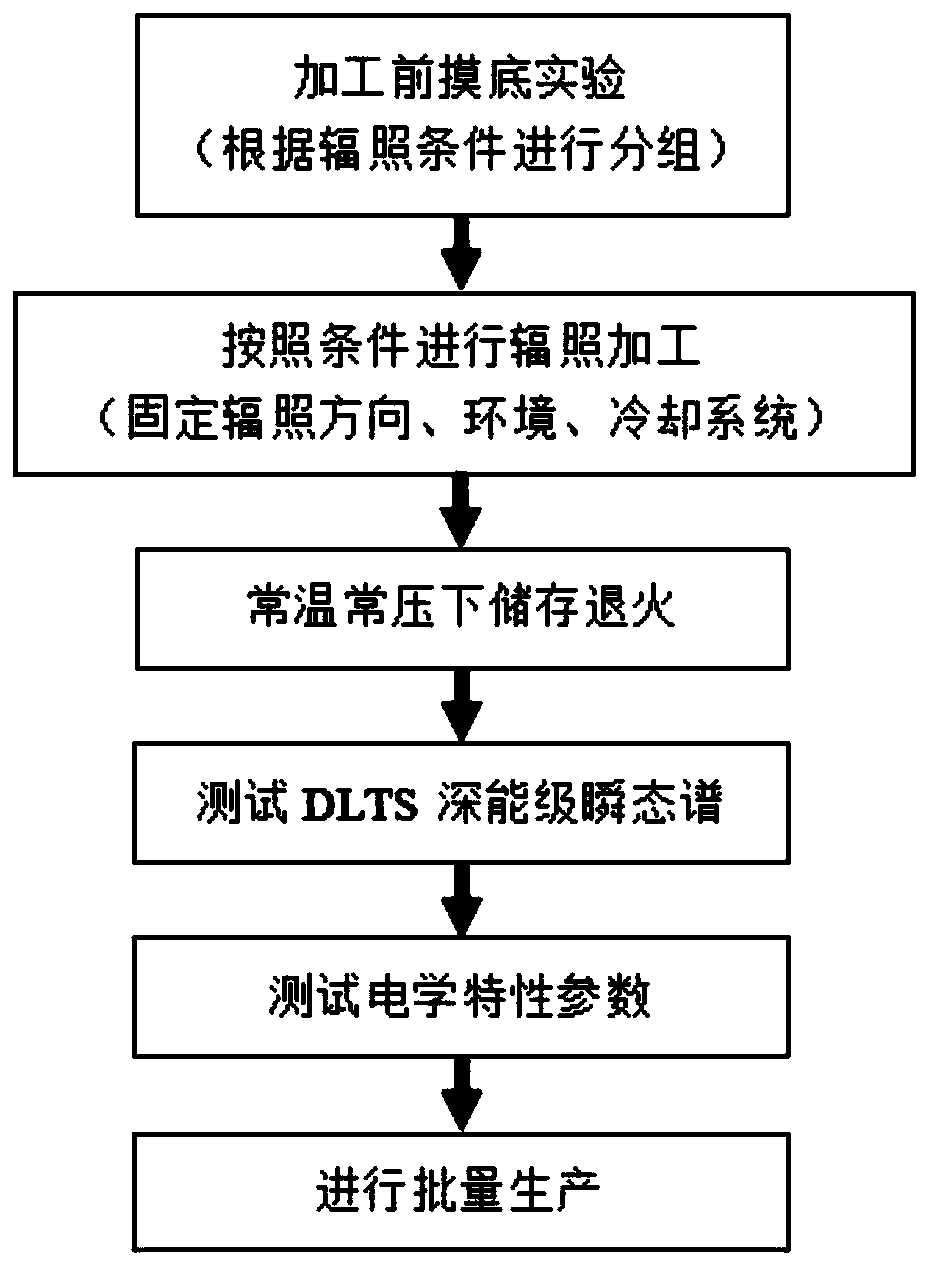

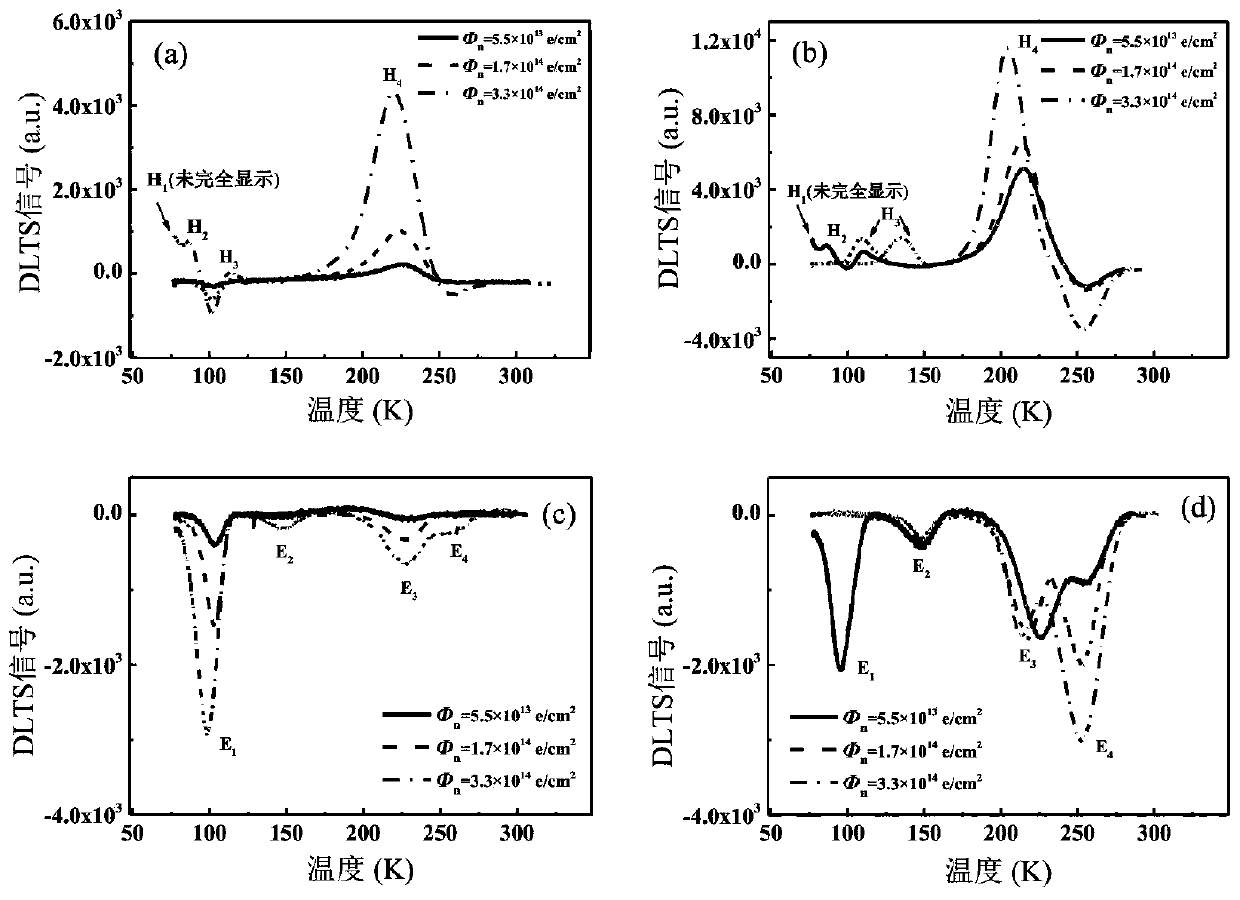

[0020] Embodiment 1 The method of the present invention for controlling the energy level of PN junction defects based on electron irradiation includes the following steps:

[0021] (1) Group the 1N4007 n-Si rectifier diodes that require performance optimization before irradiation. According to two kinds of irradiation energy 2.0, 5.0MeV and three kinds of irradiation fluence 5.5×10 13 , 1.7×10 14 , 3.3×10 14 e / cm -2 (I.e. irradiation time 30, 90, 180s) The conditions are divided into 6 groups, and there is a non-irradiated comparison group, a total of 7 groups, each group contains 3 devices.

[0022] (2) Use 2.0 and 5.0MeV linear electron accelerators to irradiate the device under test, respectively, the irradiation fluence is 5.5×10 13 , 1.7×10 14 , 3.3×10 14 e / cm -2 , That is, the irradiation time is 30, 90, 180s.

[0023] (3) The electron beam intensity of the electron accelerator used is 0.1mA, and the current is unstable <±2%, unevenness <±5%.

[0024] (4) The irradiation environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com